Tri-axial and six-degree-of-freedom vibration test device

A technology of vibration test and degree of freedom, which is applied in the direction of vibration test, measuring device, machine/structural component test, etc. It can solve the problems of no device, large thrust, and inability to use three-axis six-degree-of-freedom vibration test, etc., to achieve technical Advanced, convenient real-time operation, and wide operating frequency range

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] The present invention will be further described in detail below in conjunction with the accompanying drawings.

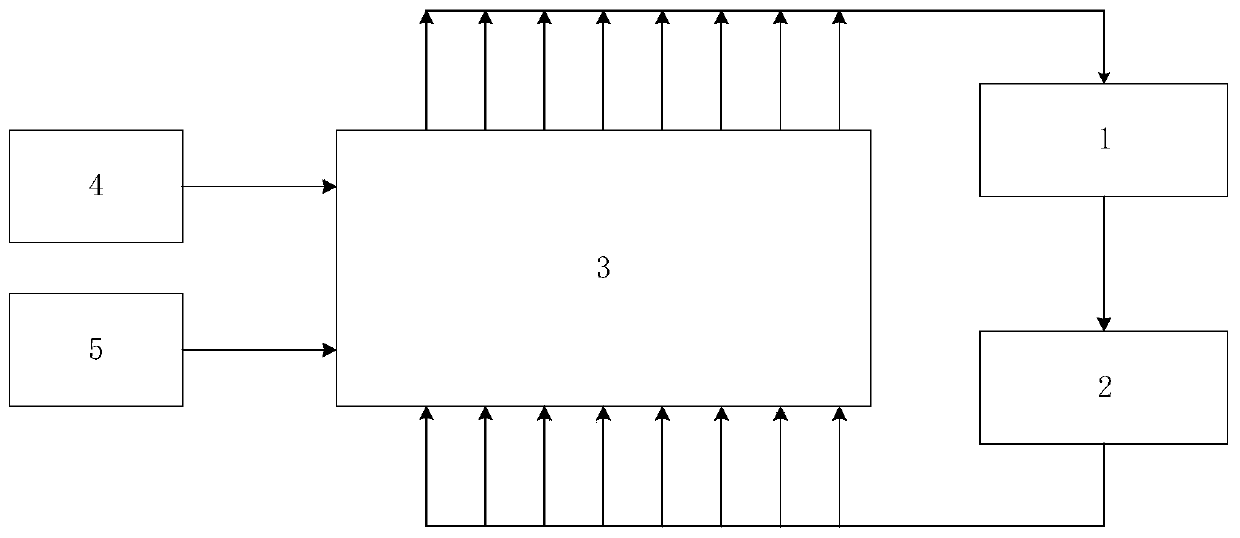

[0031] like figure 1 Shown is a three-axis six-degree-of-freedom vibration test device according to an embodiment of the present invention, which includes a MIMO controller 1, a power amplifier system 2, a vibration platform 3, a water-air system 4 and a hydraulic system 5;

[0032] The drive voltage signal generated by MIMO controller 1 is input to the vibration platform 3 through the power amplifier system 2, so that the vibration platform 3 vibrates, and the response on the vibration plane 3 is fed back to the MIMO controller 1, thereby realizing vibration control;

[0033] The water-air system 4 is connected with the vibrating platform 3 to provide cooling water and compressed air for it;

[0034] The hydraulic system 5 is connected with the vibration platform 3 to supply oil to it.

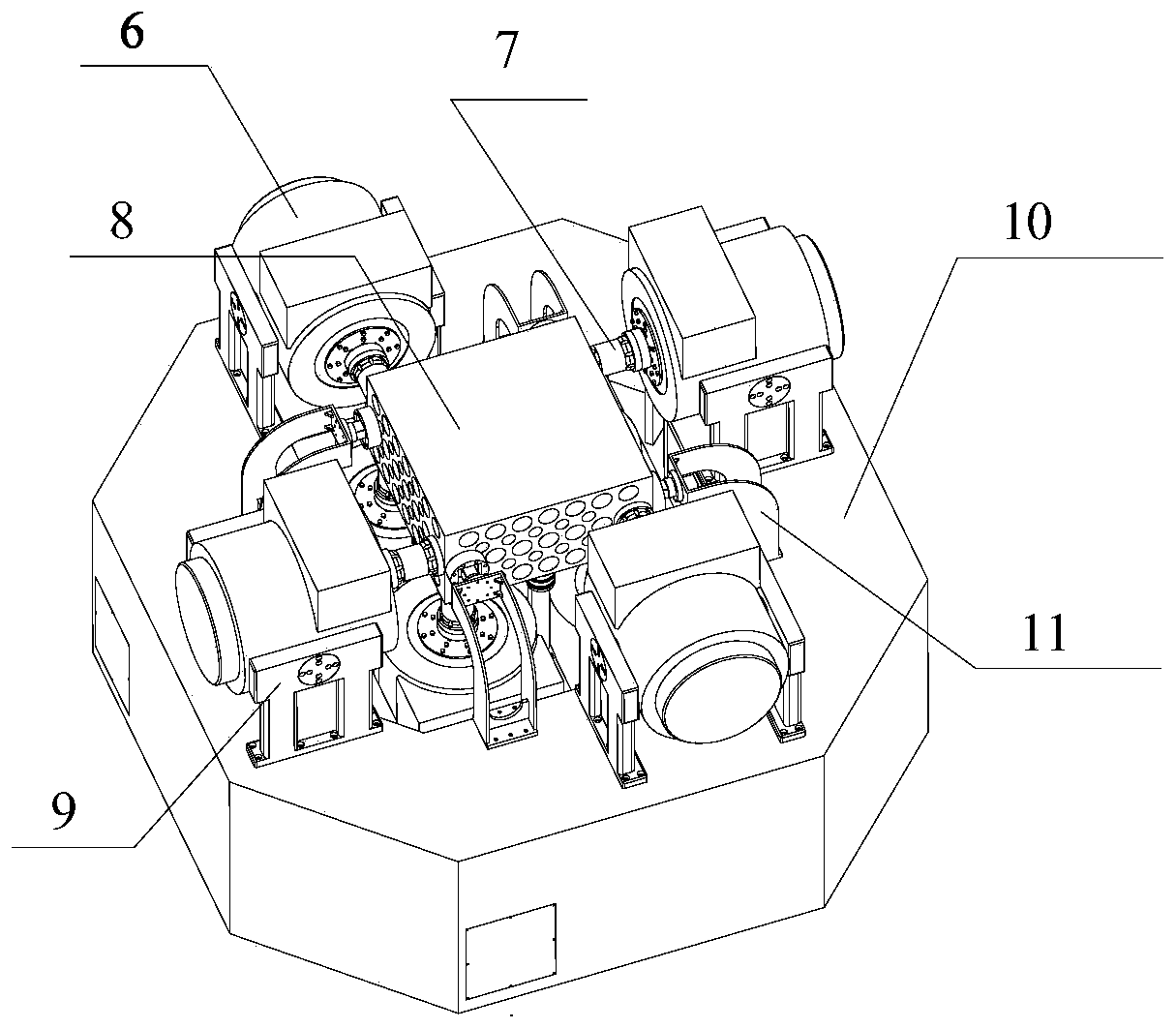

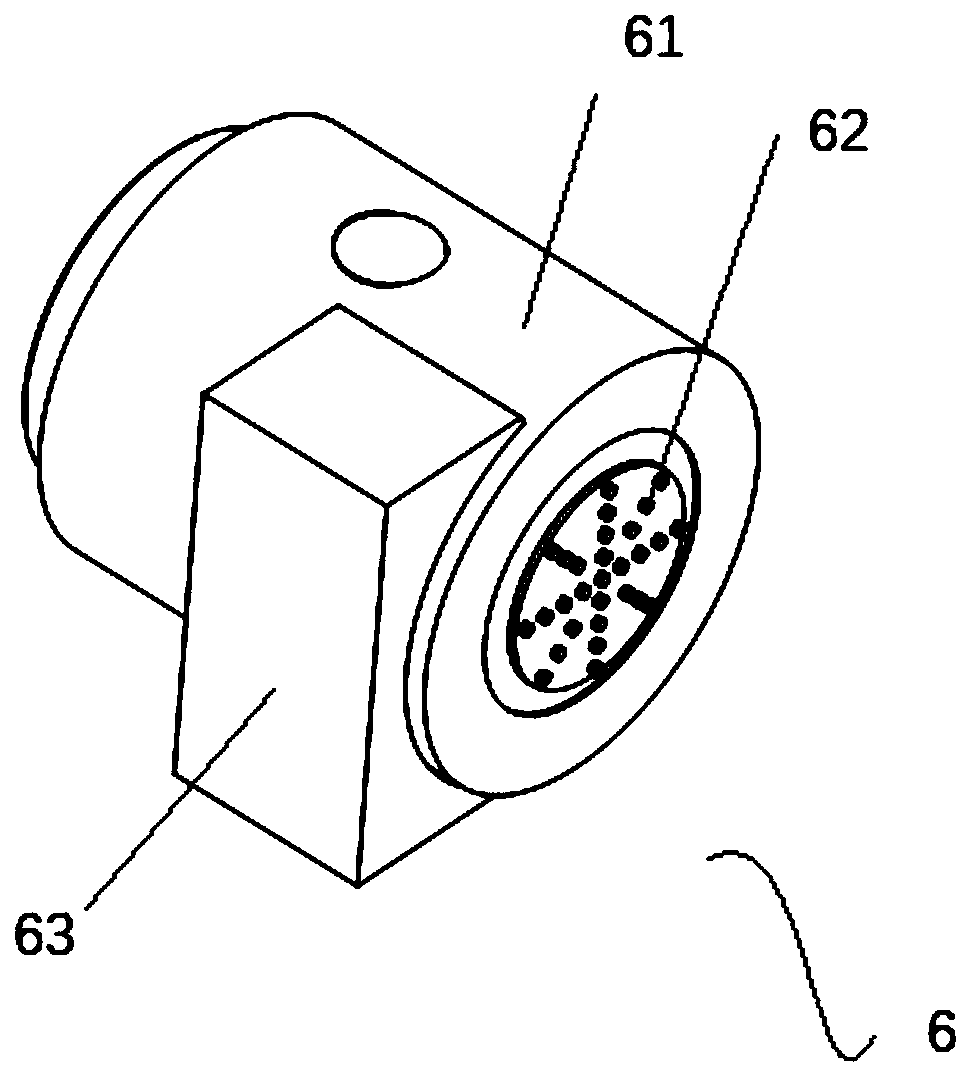

[0035] Preferably, as figure 2 As shown, the vibration platform 3 i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com