Wide frequency inertia type active vibration absorber

An inertial vibration absorber technology, which is applied in the field of active vibration absorbers, can solve the problems that semi-active vibration absorbers cannot achieve the vibration reduction effect, and achieve the effects of easy layout and installation, widening the application range, and realizing vibration control

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

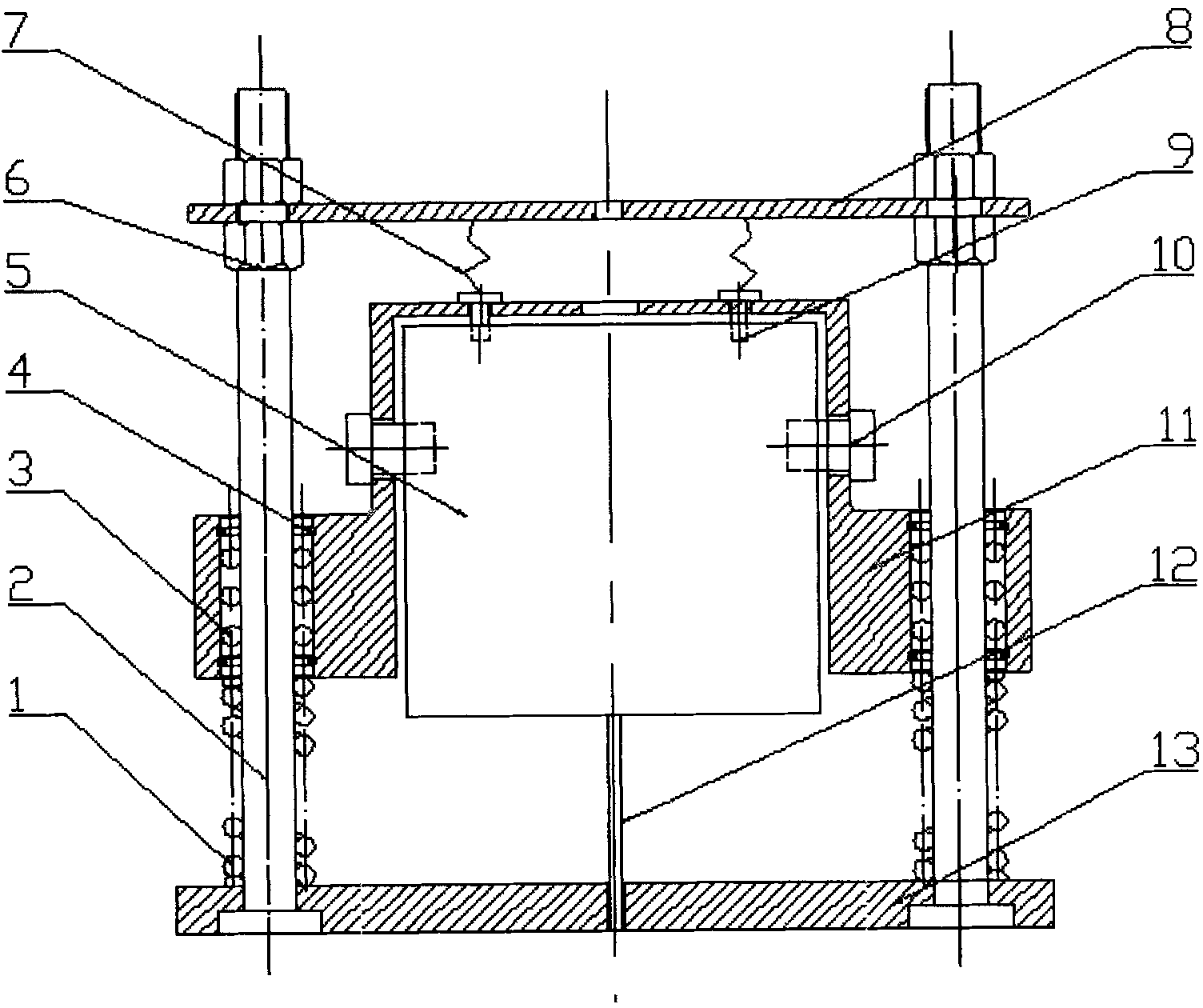

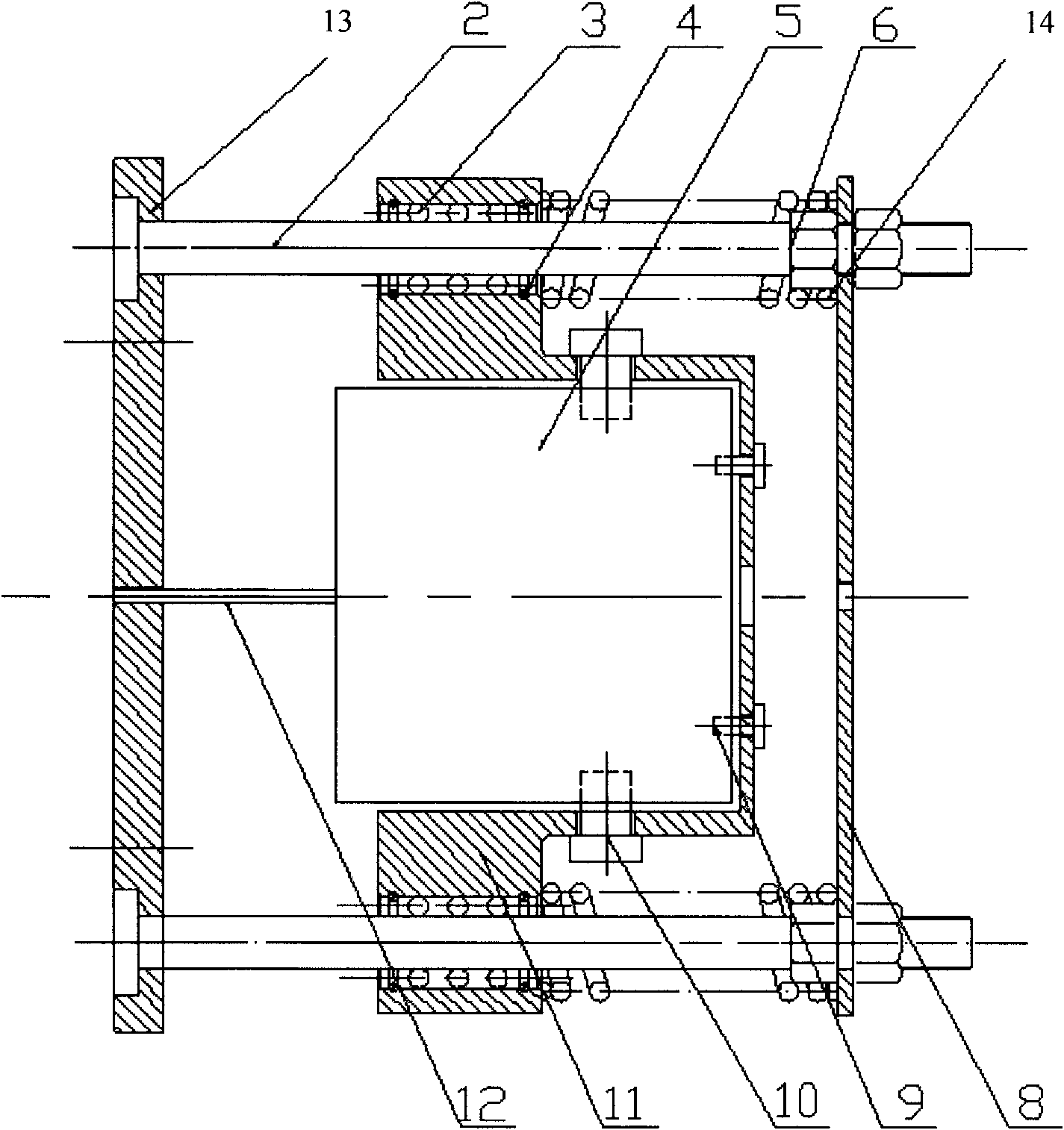

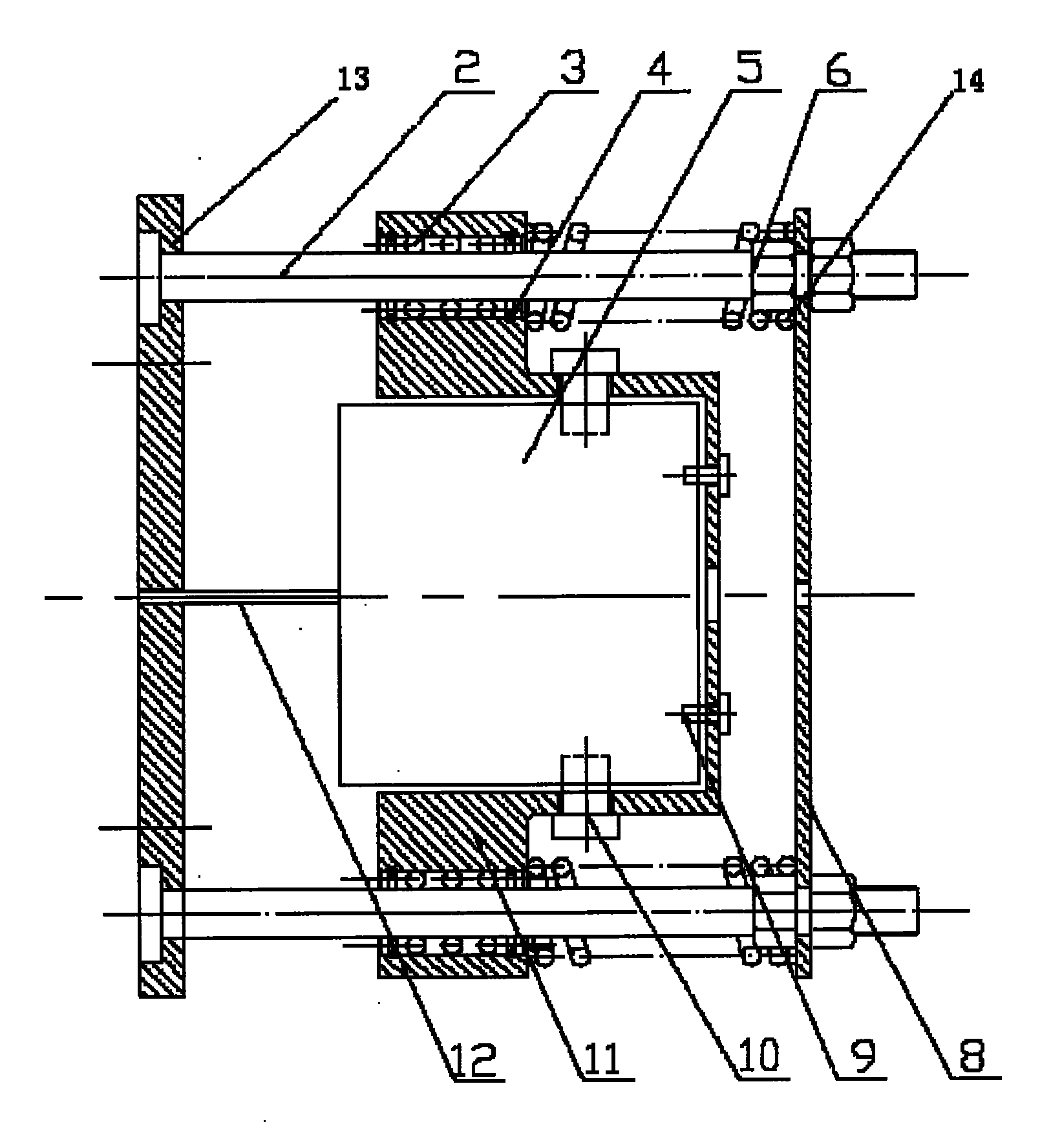

[0018] The present invention is described in more detail below in conjunction with accompanying drawing example:

[0019] combine figure 1 , is a new type of wide-band inertial active vibration absorber for vertical application composed of electrodynamic exciters. It includes a vibrator 5, a metal return spring, a vibrator fixing bracket 11, a guide shaft 2, a base 13 and an adjustment pressure plate 8; two guide shafts are installed on the base, and the adjustment pressure plate is connected between the two guide shafts. , the guide shaft and the adjustment plate form a frame structure; the exciter is fixed on the exciter through the fixing screw 10 and the stop screw 9, and the fixing bracket of the vibrator is installed on the guide shaft and can slide on the guide shaft to excite the vibration. A linear bearing 3 and a snap ring 4 for the positioning of the linear bearing are arranged between the fixed bracket of the vibrator and the guide shaft; the metal return spring i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com