Arrayed transverse negative stiffness vibration damper

A vibration damping device, negative stiffness technology, applied in springs/shock absorbers, vibration suppression adjustment, non-rotational vibration suppression, etc. The effect of lateral vibration

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

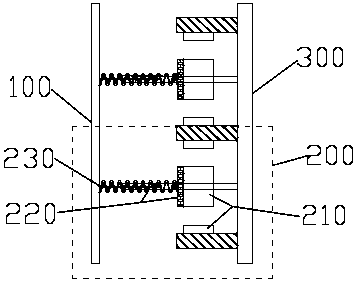

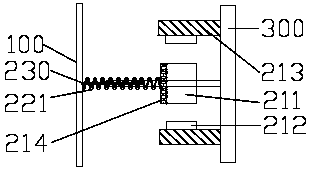

[0022] Such as Figure 1-3 As shown, the present invention provides an array type lateral negative stiffness vibration damping device, which comprises a left movable plate 100 , a vibration damping substructure 200 and a right fixed plate 300 . The left movable plate 100 is installed on the machine body; the vibration damping substructure 200 is arranged between the left movable plate 100 and the right fixed plate 300, including negative stiffness unit 210, positive stiffness unit 220 and hydraulic damping The rod 230 and the damping substructure 200 are vertically arranged in a linear array at intervals; the right fixing plate 300 is fixedly connected to the ground.

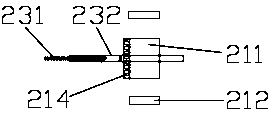

[0023] Such as Figure 2-3 As shown, the vibration damping substructure 200 of the present invention is arranged between the left movable plate 100 and the right fixed plate 300, the sliding magnetic block 211 inside the vibration damping substructure 200 is composed of a ring magnet, and the sliding magnetic b...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com