Two-stage distributed combined dynamic vibration absorber vibration reduction method aiming at thin-wall part multi-mode time-varying cutting vibration control

A technology of dynamic vibration absorbers and thin-walled parts, applied in the field of damping and vibration reduction, can solve problems such as mechanical or structural material fatigue, troubles or even hazards, bridge collapse, etc., and achieve good robustness, good vibration reduction effect, and wide frequency band Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

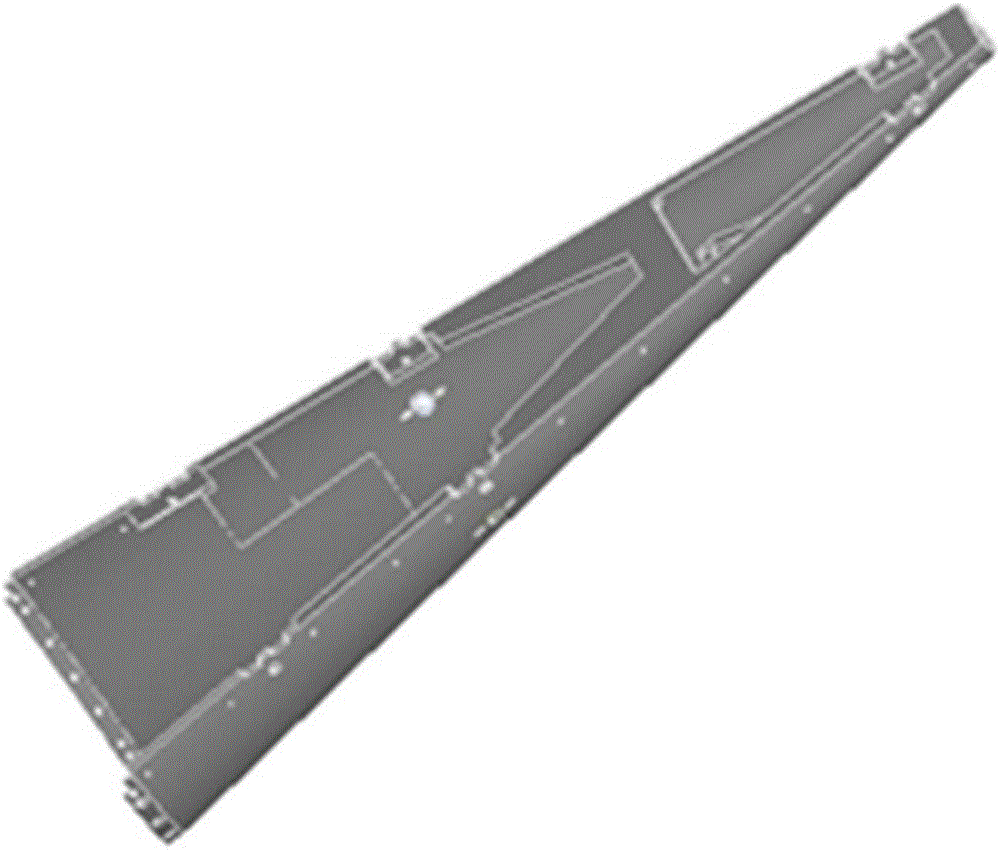

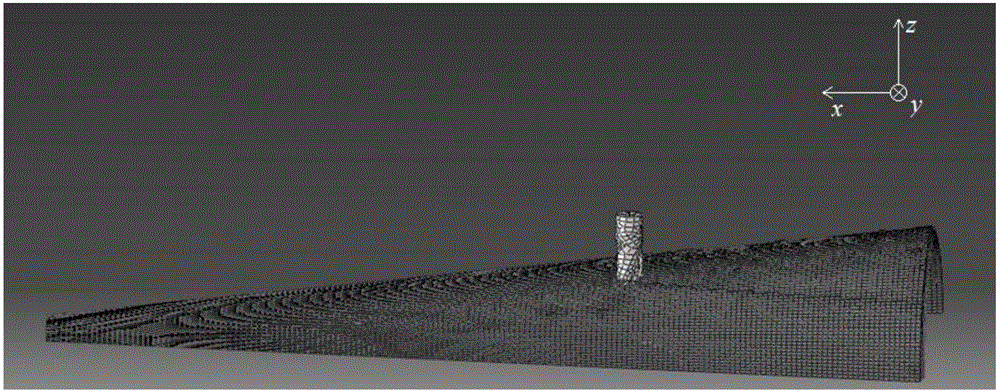

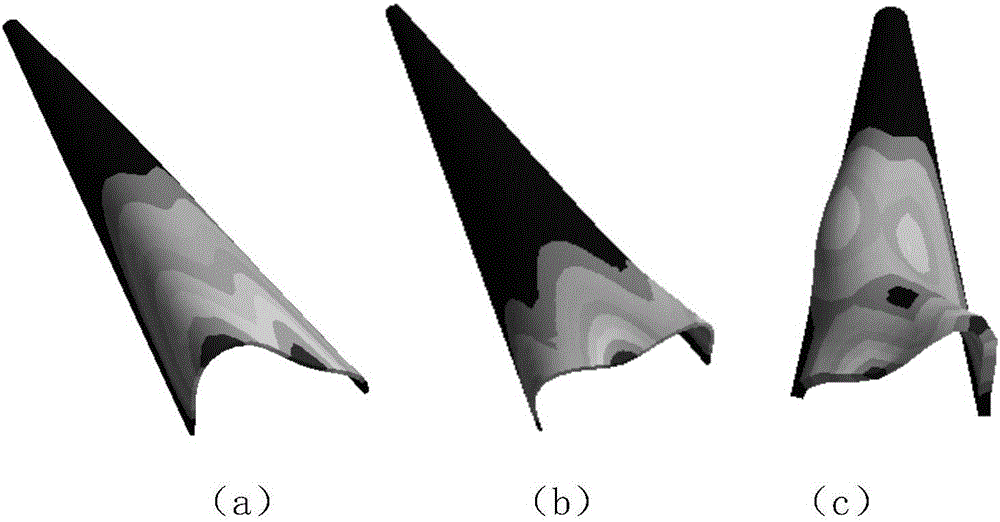

[0027] Such as figure 1 As shown, the small end diameter is 50mm, the large end diameter is 300mm, the length is 850mm, and the semi-conical part with a wall thickness of 16mm is a typical thin-walled structural part. exist figure 2 In the middle, both sides of the bottom surface are fixed and the outer surface is milled. The initial thickness of the part is 16mm, and the thickness of the final processed part is 12mm. When the thickness changes from 16mm to 12mm, its natural frequency and other modal parameters will change, resulting in the migration of machining vibration frequency, which has obvious time-varying vibration characteristics. As the thickness of the part decreases, if the number and parameters of the vibration absorber remain unchanged, the vibration reduction effect of the vibration absorber will become weaker and weaker, which deviates from the optimal vibration reduction effect. Therefore, using this new type of two-stage distributed combined dynamic vibra...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com