Active control system for dynamic behaviors of high-speed train

An active control system and technology for high-speed trains, applied in vibration suppression adjustment, non-rotational vibration suppression, locomotives, etc., can solve the problems of amplification, random vibration of the carriage, and failure to form control force, so as to ensure the control effect and realize vibration control , a wide range of effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] The present invention will be further described below in conjunction with accompanying drawing.

[0029] The high-speed train dynamic behavior active control system of the present invention includes sensors, controllers and control devices installed on the controlled train;

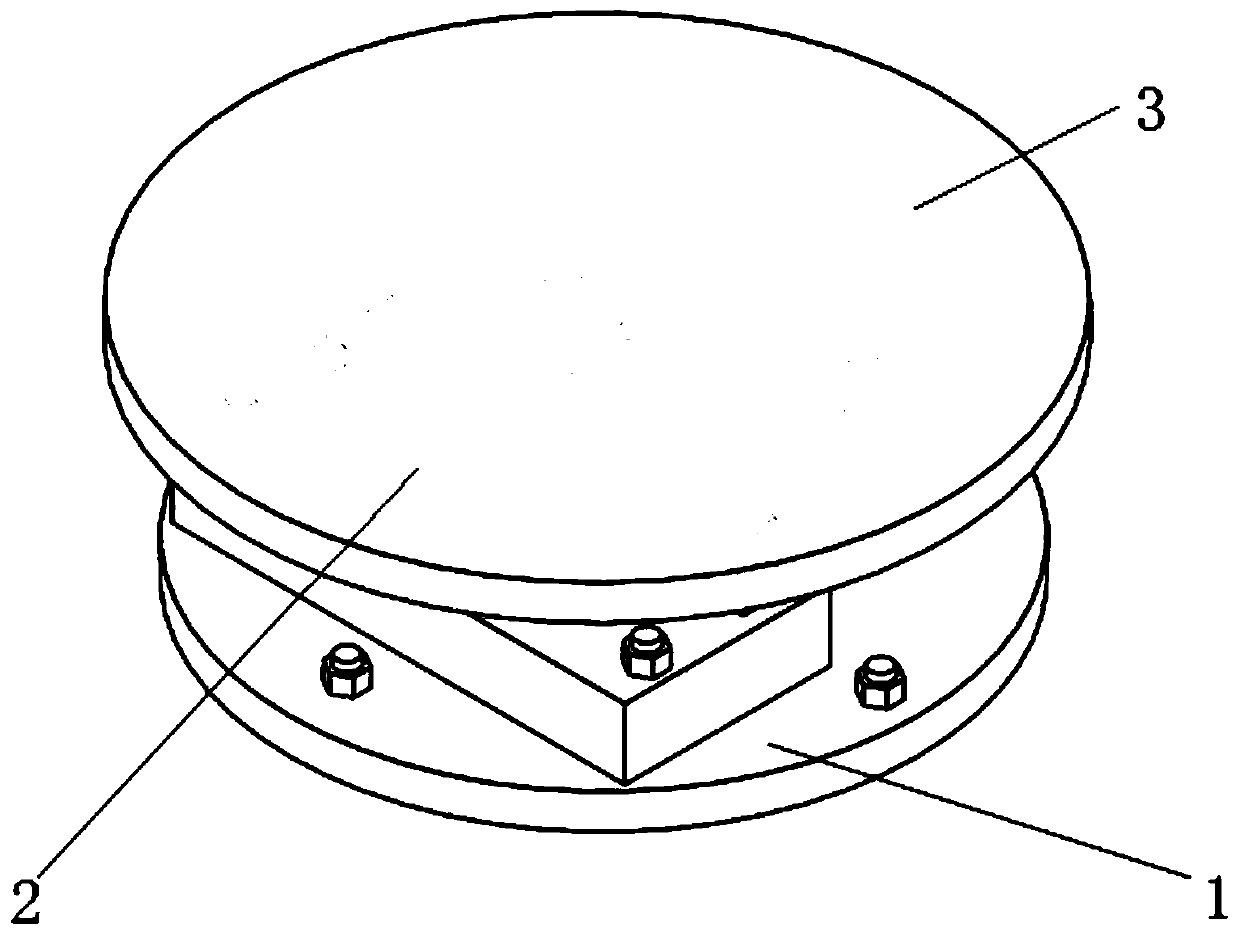

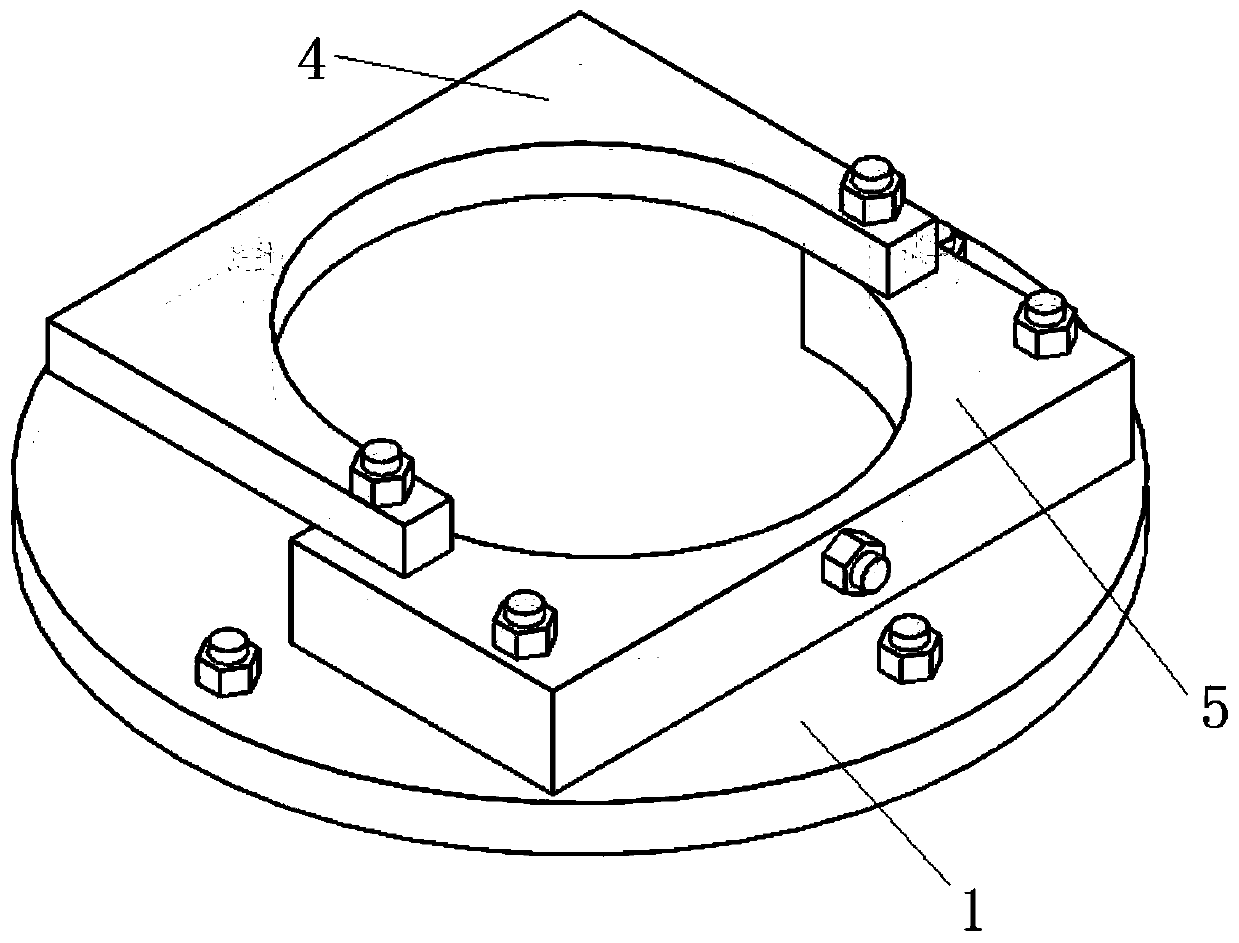

[0030] Such as figure 1 As shown, the control device includes a base 1, a drive motor 2 and a quality disc 3, the base is fixed on the controlled train, and the drive motor is fixed on the base through a clamp assembly; as figure 2 As shown, the pallet assembly includes a left pallet 4 and a right pallet 5, both of the left pallet and the right pallet are U-shaped, the right pallet is fixed on the base, and the two ends of the left pallet are connected with the two ends of the right pallet. Through bolt connection, the driving motor is clamped between the U-shaped sides of the left clamping plate and the right clamping plate.

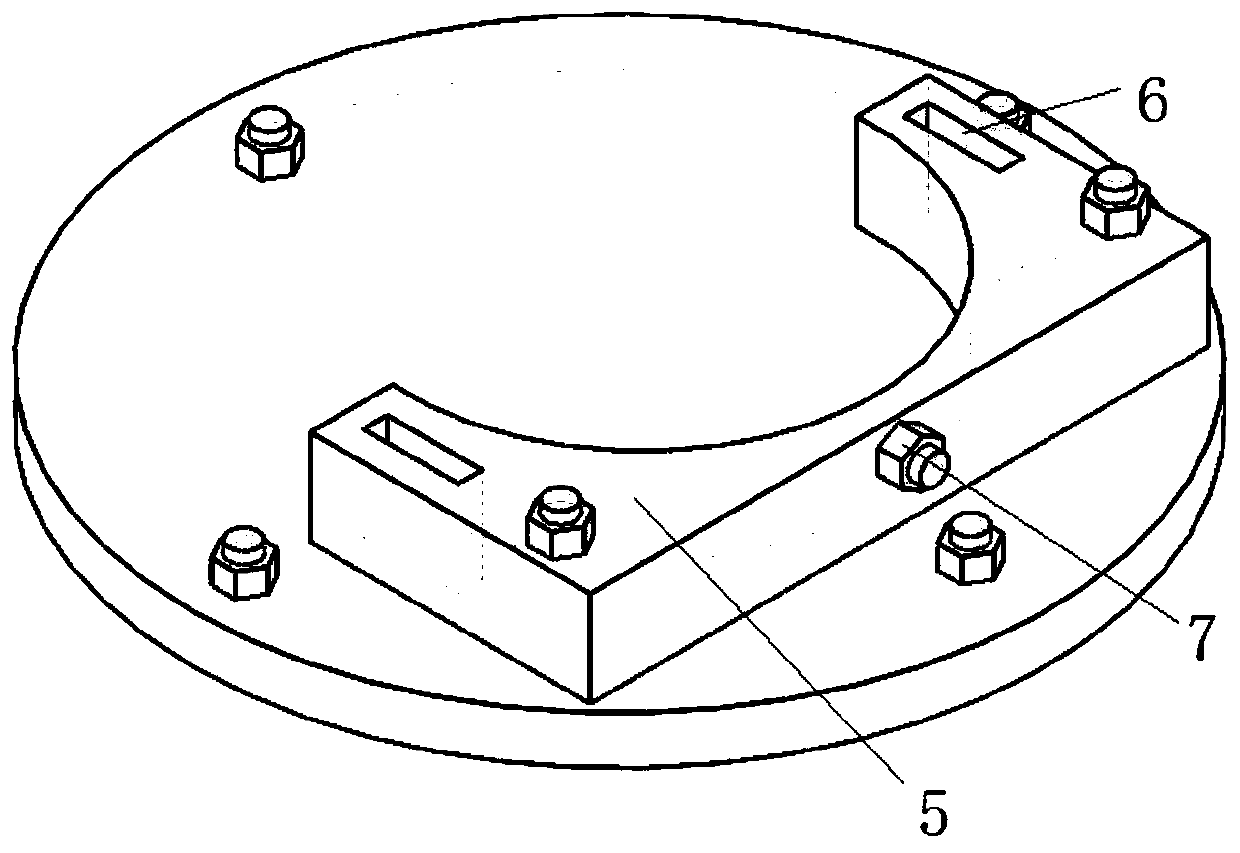

[0031] Such as image 3 As shown, in order to adapt the clamp assem...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com