Fresh air system driven by external equipment

A technology of fresh air system and external equipment, applied in ventilation system, installation of electrical equipment, cleaning equipment, etc., can solve the problems of waste of financial and material resources, non-existence of connection, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

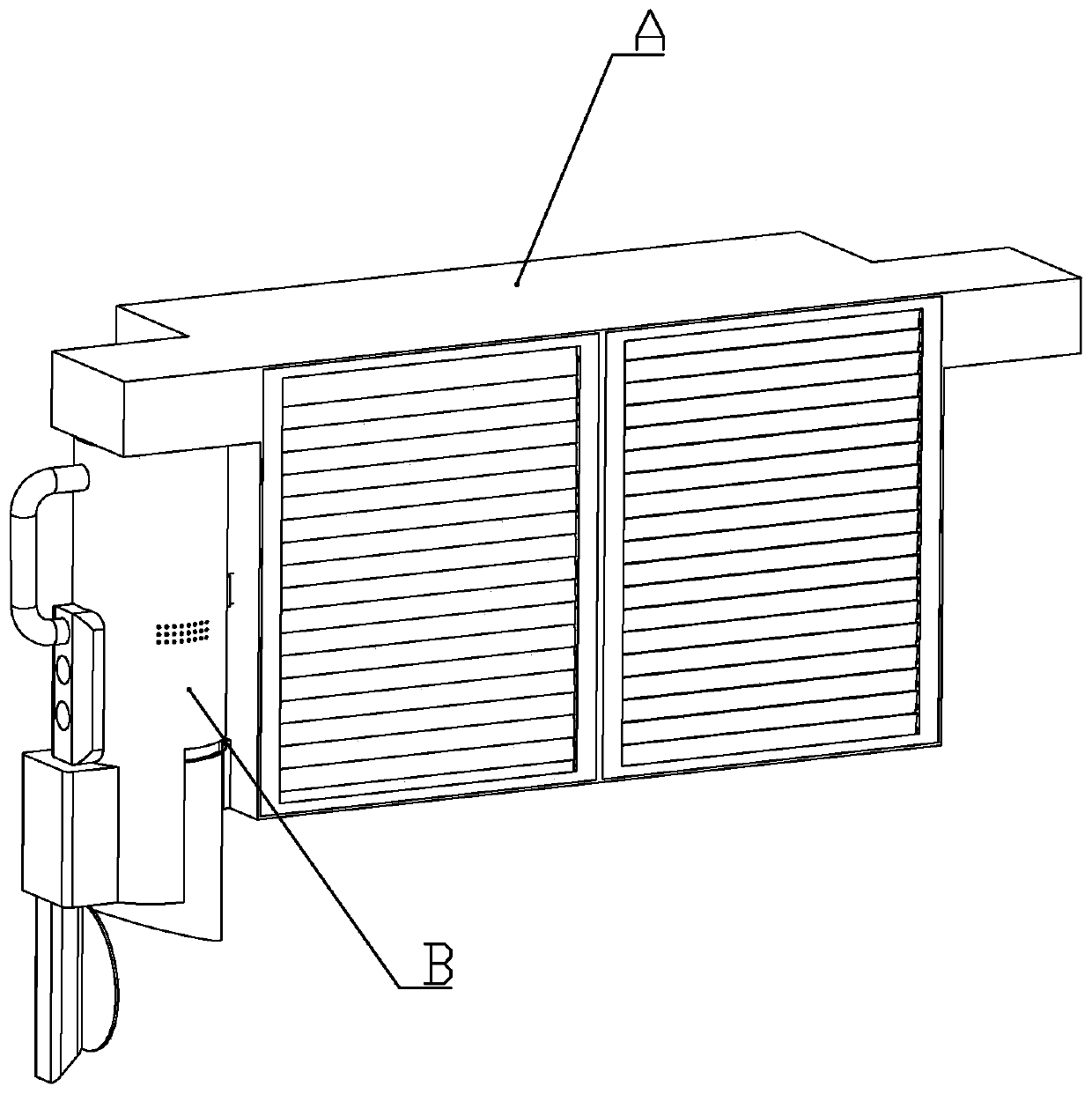

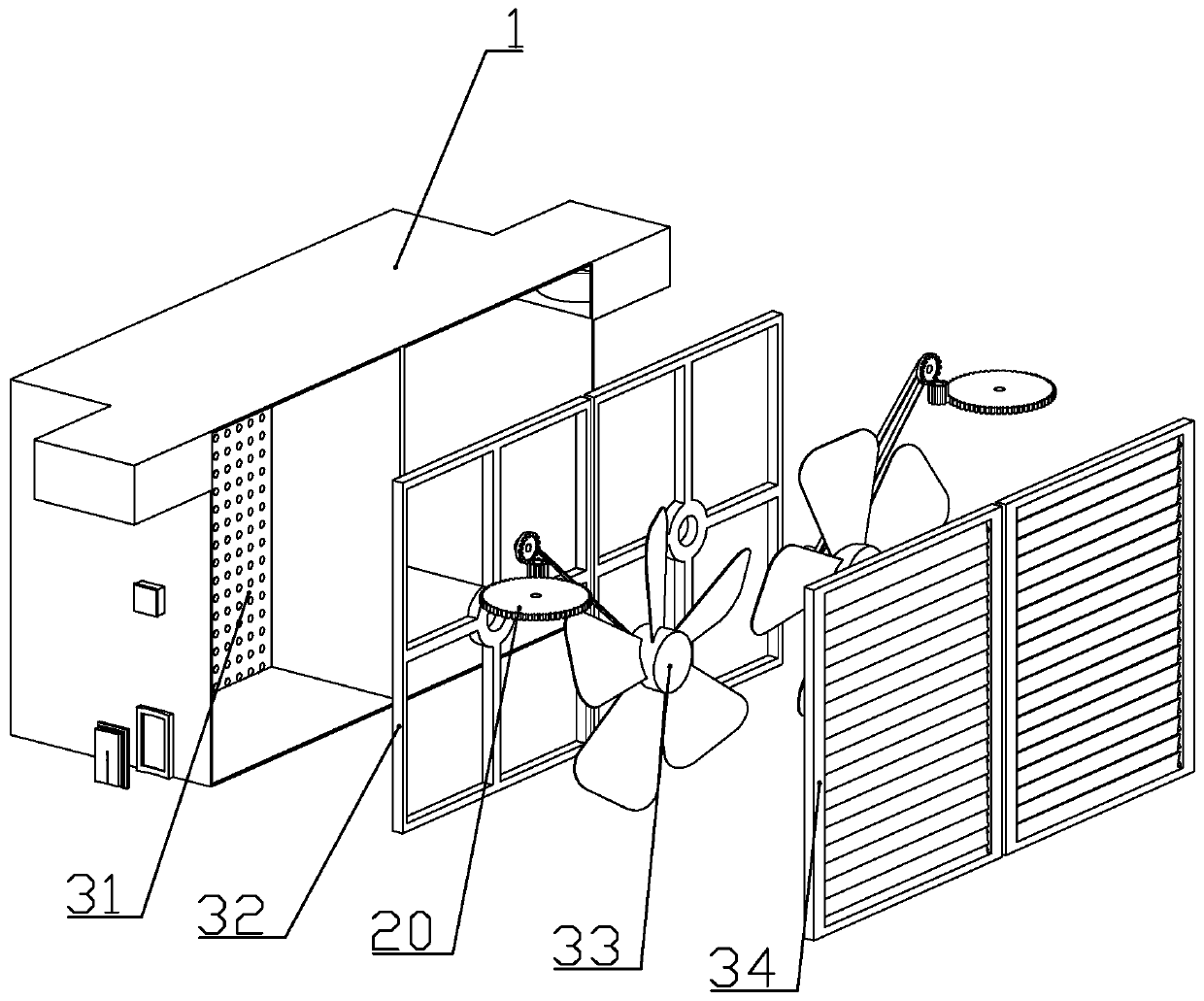

[0061] according to Figure 1 to Figure 15 As shown, a fresh air system driven by external equipment described in this embodiment includes a host A installed on the indoor wall; Ventilation fan 33 with the opposite air direction.

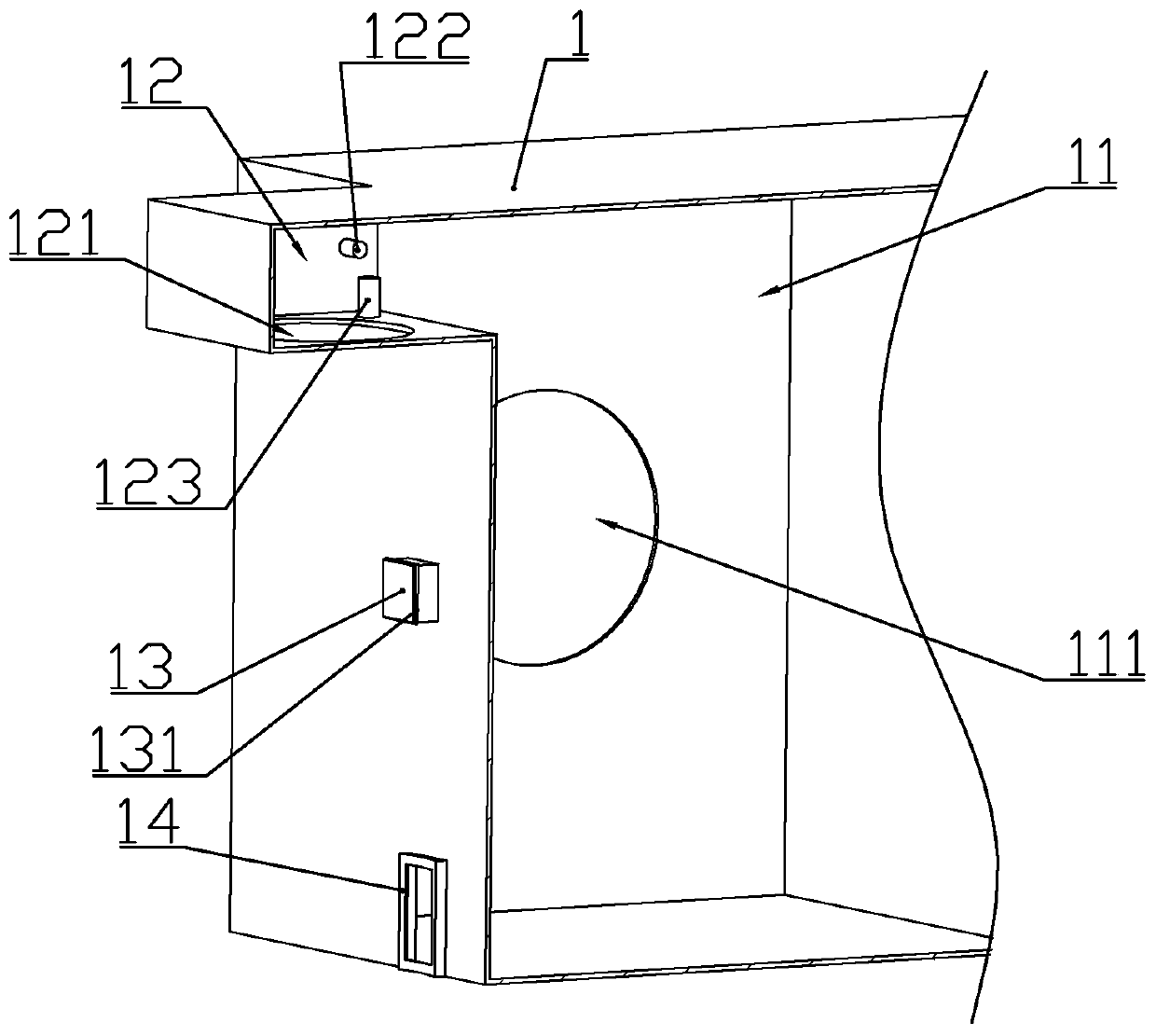

[0062] The front end of the housing is provided with two ventilation cavities 11; each of the ventilation cavities is respectively rotatably connected with a ventilation fan.

[0063] A ventilation fan frame 32 is fixedly connected in the ventilation cavity; a ventilation fan rotating sleeve is formed in the center of the ventilation fan frame; a ventilation fan connecting column 331 is formed in the center of the ventilation fan and connected to the ventilation fan rotating sleeve; Louvers 34 are fixedly connected to the front end of the cavity; ventilation holes 111 are formed on the side wall of the rear end of the ventilation cavity.

[0064] The louvers include a window frame fixedly connected to the ventilation chamber, and louvers connected...

Embodiment 2

[0131] according to Figure 16 to Figure 19 As shown, the difference between this embodiment and Embodiment 1 is that: the main machine includes a second casing 91, and two cross-flow fans 92 arranged longitudinally in the second casing; the second casing is formed with two The second ventilation cavity 911 arranged side by side; a perfusion fan is installed in each second ventilation cavity;

[0132] Shutters are installed on one side of the opening of the second ventilation cavity.

[0133] The front end of the second shell is formed with a second drive installation cavity 912 communicating with each second ventilation cavity; the bottom of the second drive installation cavity is formed with a gear plate socket; the transmission assembly C is installed in the second drive installation cavity .

[0134] The transmission assembly includes a transmission sleeve 22 slidably connected to the gear plate socket, a driven turntable 21 rotatably connected to the lower part of the t...

Embodiment 3

[0146] In this embodiment, the following improvements are made on the basis of Embodiment 1: a controller installation cavity is formed on the side wall of the vacuum cleaner housing; the controller is installed in the controller installation cavity.

[0147] A handle is formed on the side wall of the vacuum cleaner shell; a storage battery for powering the motor is arranged inside the vacuum cleaner; the storage battery is installed in the controller installation cavity or in the handle.

[0148] The side wall of the housing is located below the drive installation cavity and is fixedly connected with an electric socket; the electric socket is electrically connected with a power supply.

[0149] The side wall of the vacuum cleaner housing is fixedly connected with an electric plug that can be plugged into the electric socket; the electric plug is electrically connected to the controller; when the vacuum cleaner is suspended on the main machine, the electric plug is inserted int...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com