Electric toothbrush eccentric rod sound wave machine and working method thereof

An electric toothbrush and sonic technology, which is applied in the field of electric toothbrush partial rod sonic machines, can solve the problems that the brush head handle is easy to touch the teeth, the vibration swing is small, the brushing force is not in place, etc., and the hand vibration is small and the bristles swing greatly , the effect of reasonable structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

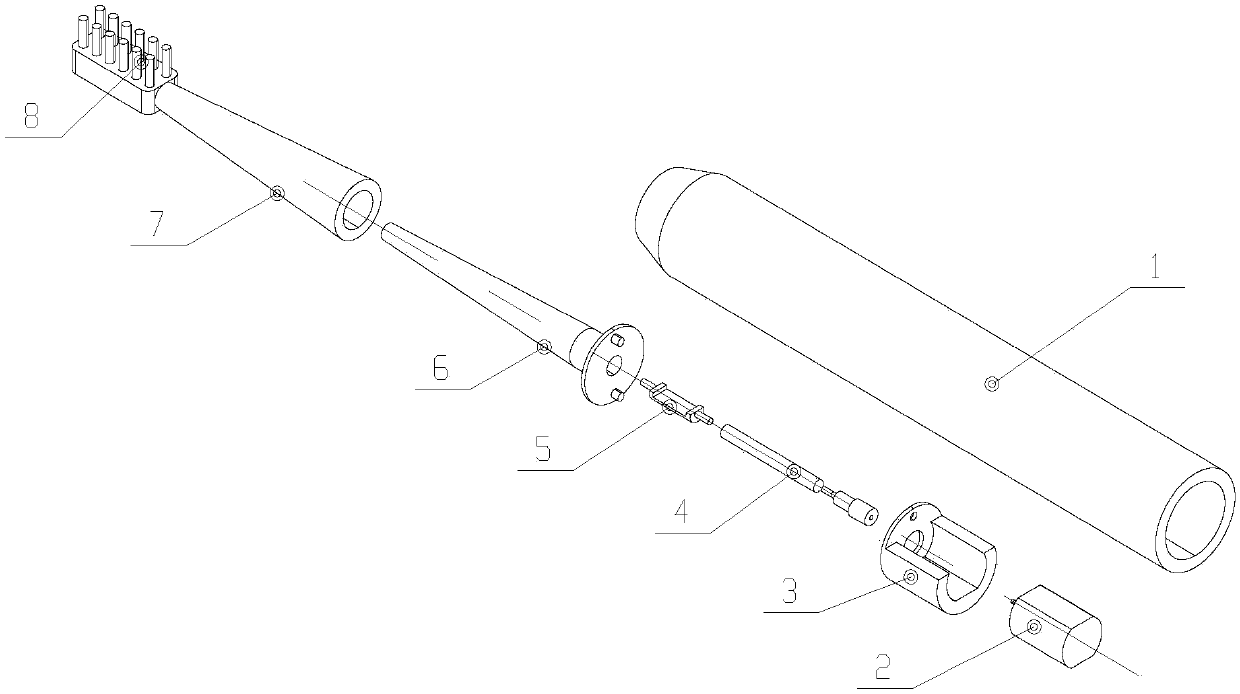

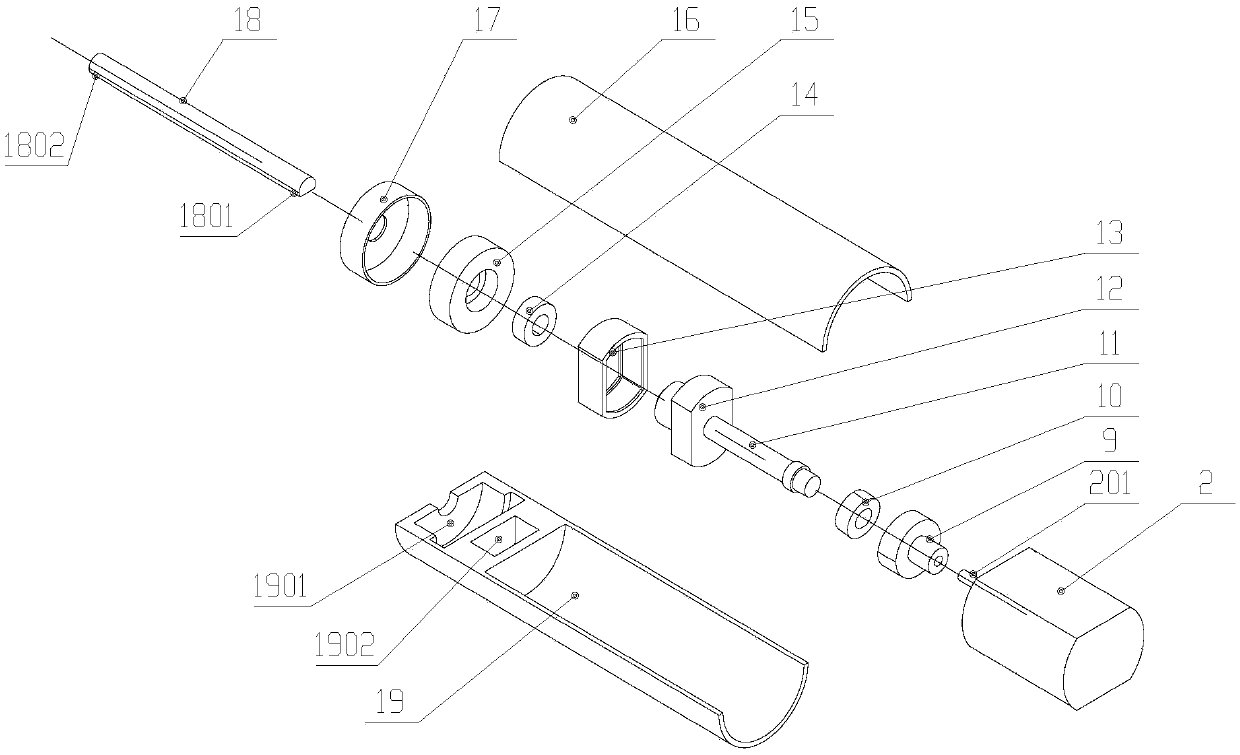

[0046] Embodiment 1, the assembly method of the present invention: the micromotor 2 is 3.7V, the bearing A10 is installed on the motor shaft 201, and it must be fixed and fixed; the soft rubber sleeve 13 of the positioning connection shaft seat is sleeved on the positioning connection shaft seat 12, and the bearing A10 Install it on the positioning connection shaft 11, and then install it in the positioning connection shaft seat 12; the bearing B14 is installed in the concentric bearing seat 15, the concentric bearing seat soft rubber sleeve 17 is set on the concentric bearing seat 15, and the metal shaft 18 is inserted into the bearing B14, the lower key pin 1801 of the metal shaft is installed in the positioning connection shaft seat 12, and is tightly matched with the inner hole of the positioning connection shaft rod 11. Mounting hole B1902, the soft rubber sleeve 17 of the concentric bearing seat is put into the mounting hole A1901, and the upper shell 16 of the partial ro...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com