Micro spiral pump system

A screw pump, miniature technology, applied in the direction of pumps, pump devices, pump components, etc., can solve the problems of increased vibration between the connecting shaft and the screw, disconnection and separation of the connecting shaft and the screw, severe vibration of the pump head, etc., to increase durability , Reduce shock, slight vibration effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] The embodiments of the present invention are described in detail below. This embodiment is implemented on the premise of the technical solution of the present invention, and detailed implementation methods and specific operating procedures are provided, but the protection scope of the present invention is not limited to the following implementation example.

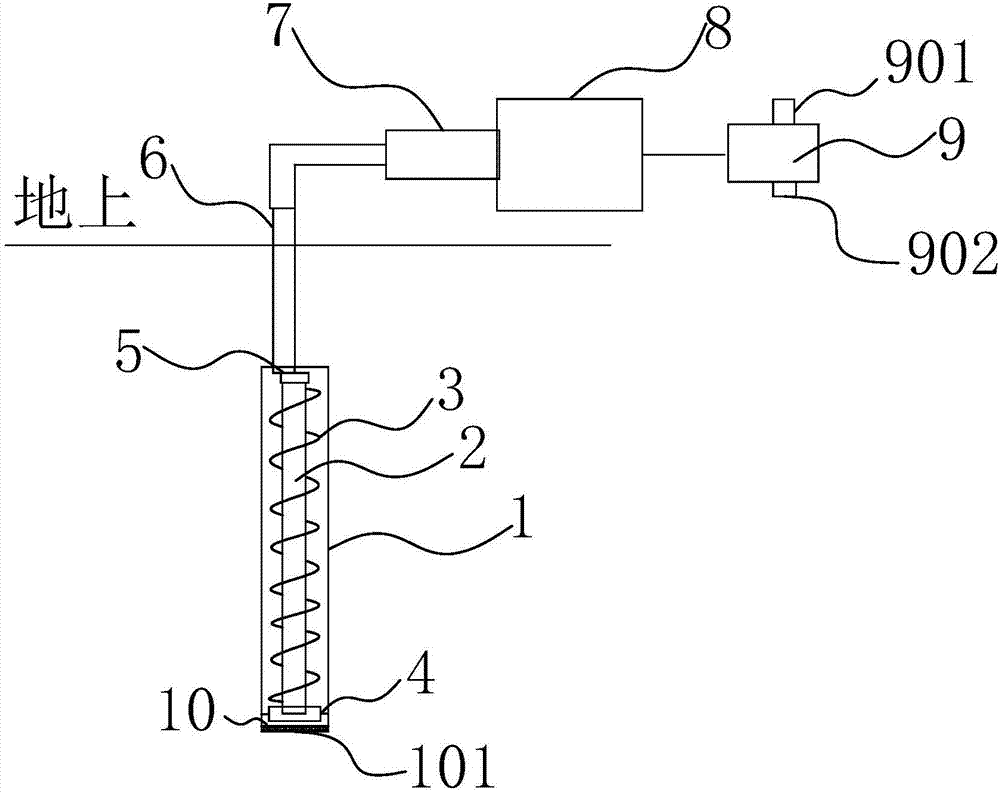

[0017] A miniature screw pump system, comprising a pump head (1) and a pump body (7) connected through a connecting pipe (6), the pump head (1) is provided with a helical rotating shaft (2).

[0018] As one of the preferred modes of the present invention, the pump body (7) is drivingly connected to the motor (8).

[0019] As one of the preferred modes of the present invention, one end of the spiral rotating shaft (2) communicates with the connecting pipe (6) through a universal joint (5), and the other end cooperates with the bearing (4).

[0020] As one of the preferred modes of the present invention, a water inl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com