Stepless self-balancing variable speed drive disk unit of pedal type motorcycle

An automatic balancing, variable-speed drive technology, applied in the transmission device, portable lifting device, hoisting device, etc., can solve the problems of reducing the transmission ratio, easy to break, uneven force of left and right sliding, etc. The effect of small vibration and low fuel consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0011] specific implementation plan

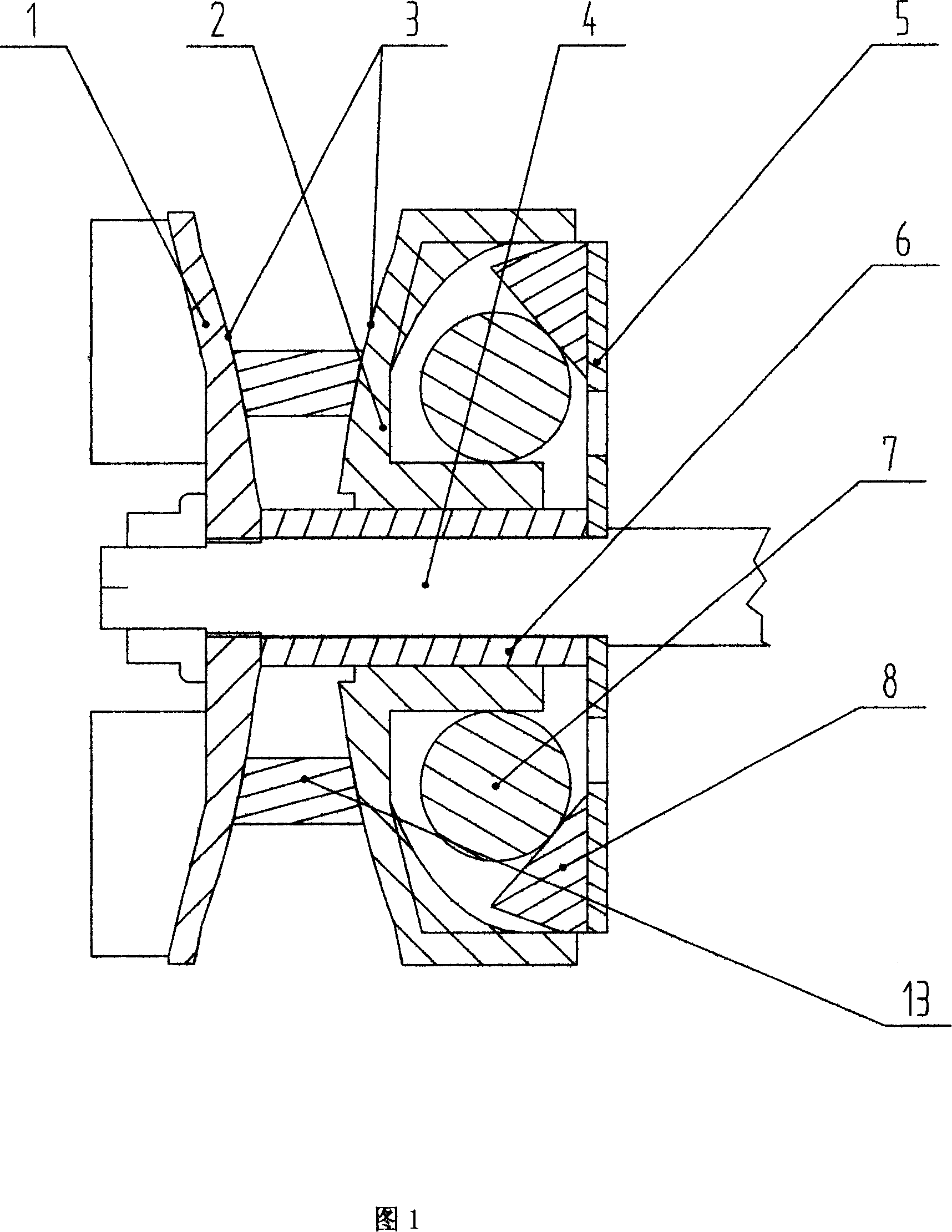

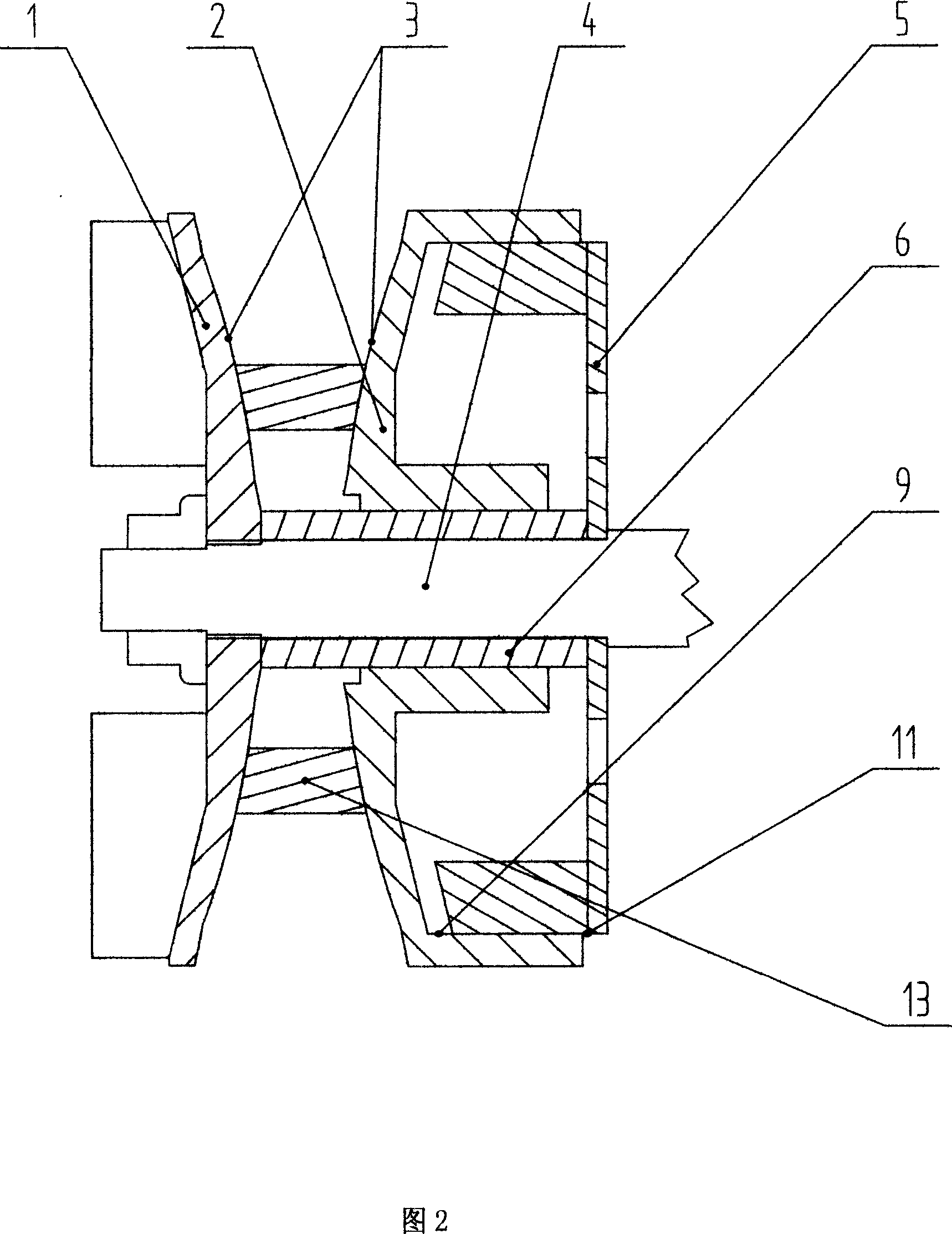

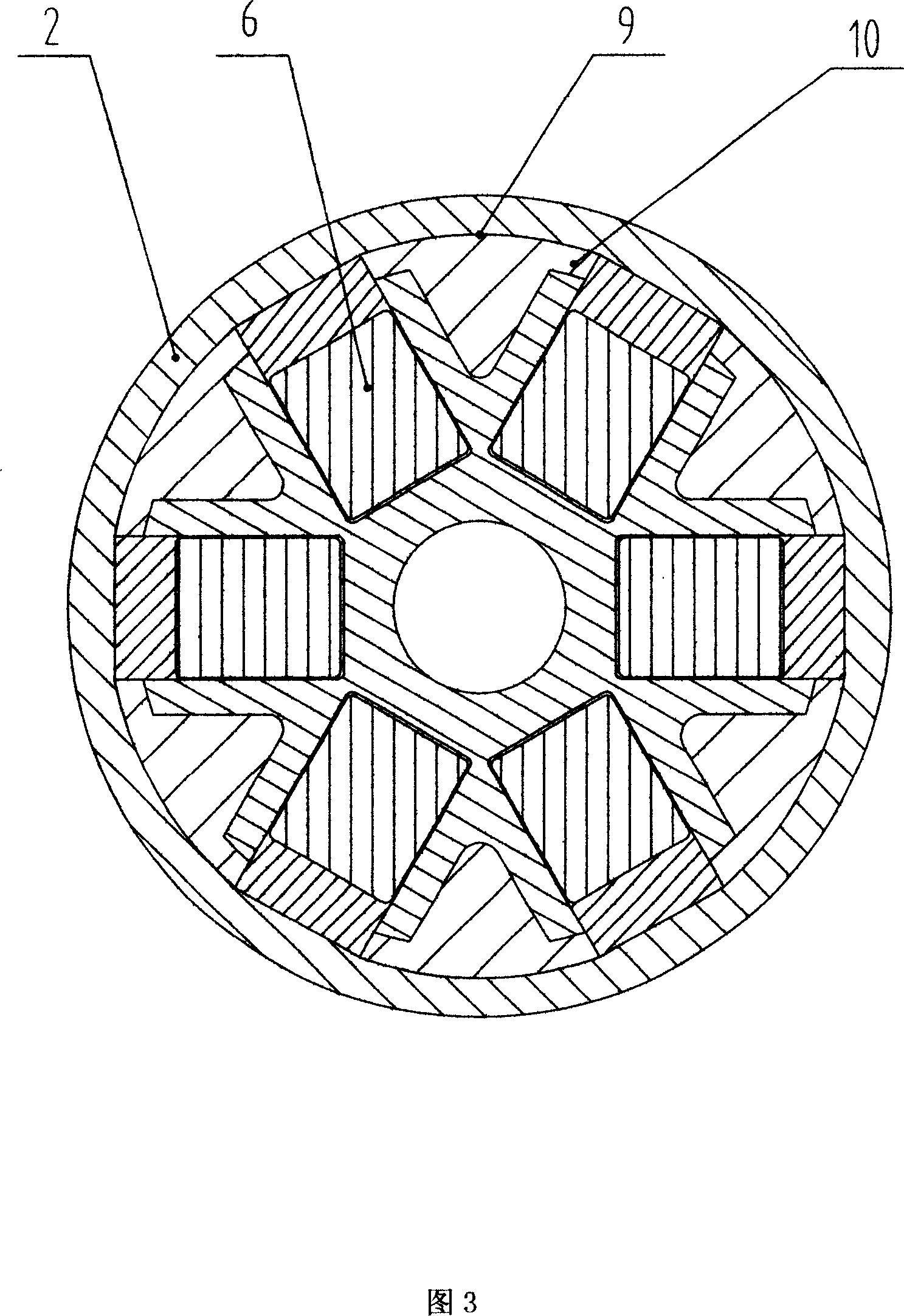

[0012] Examples of embodiments are as shown in the accompanying drawings: in Fig. 1, the transfer contact surfaces of the existing conical surface drive disk, the conical surface sliding disk and the drive belt (13) of the scooter are improved into a spherical surface (3), respectively spherical surface drive Disc (1) and spherical sliding disc (2), the direction of its spherical radian is determined by the maximum balance between the power generated by the engine fuel and the power required for safe driving speed. The spherical driving disc (" is fastened to the engine crankshaft (4) through a spline, the sliding edge retaining disc (5) and the bushing (6) are set on the engine crankshaft (4), and the spherical sliding disc (2) is slipped on the shaft Cover (6). Improve the existing three pairs of rollers (7) with a weight of less than 30 grams each to a weight of more than 30 grams, so as to achieve the maximum balance between the power ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com