Core fixing type pinch roll guide

A pinch roller and core type technology, applied in the field of guides and guards, can solve problems such as difficult core positioning, scratches and scratches on the surface of the rolled piece

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The present invention will be further described below in conjunction with accompanying drawing:

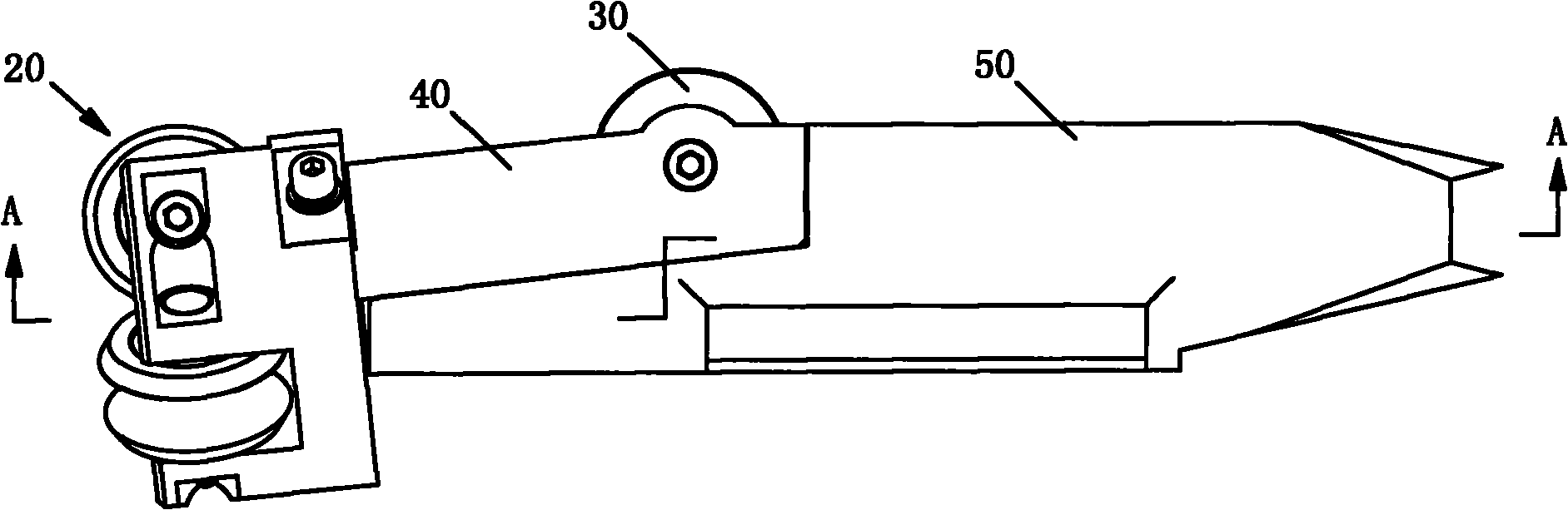

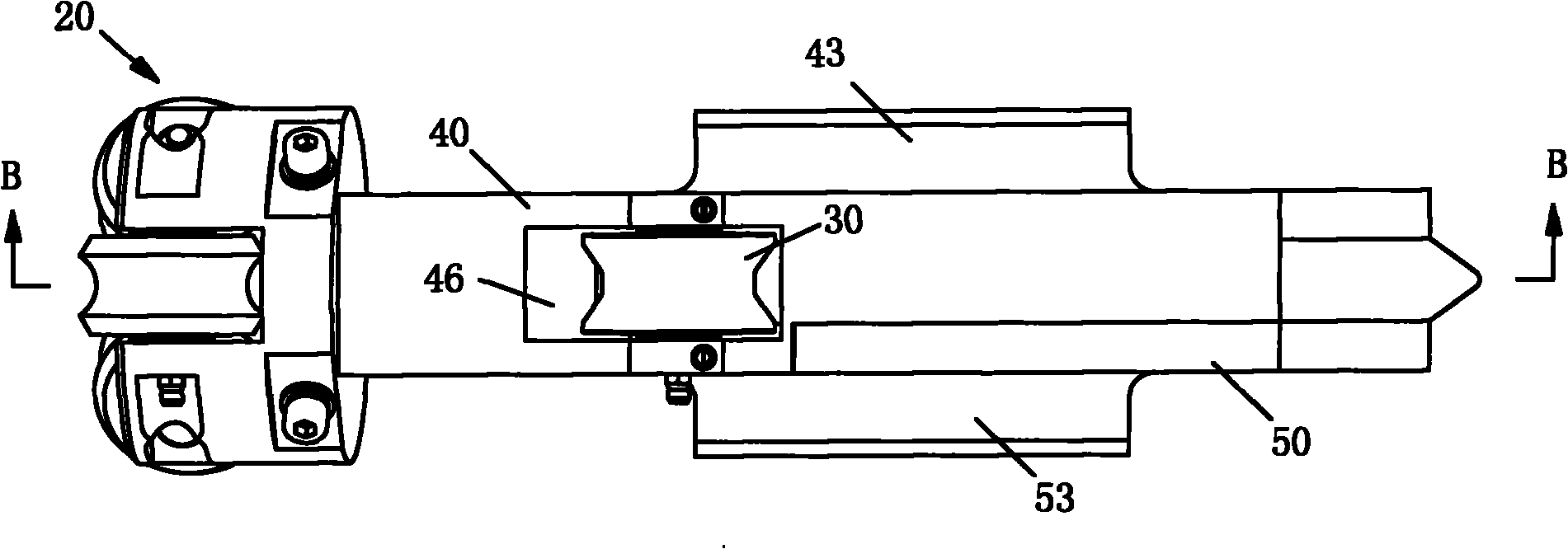

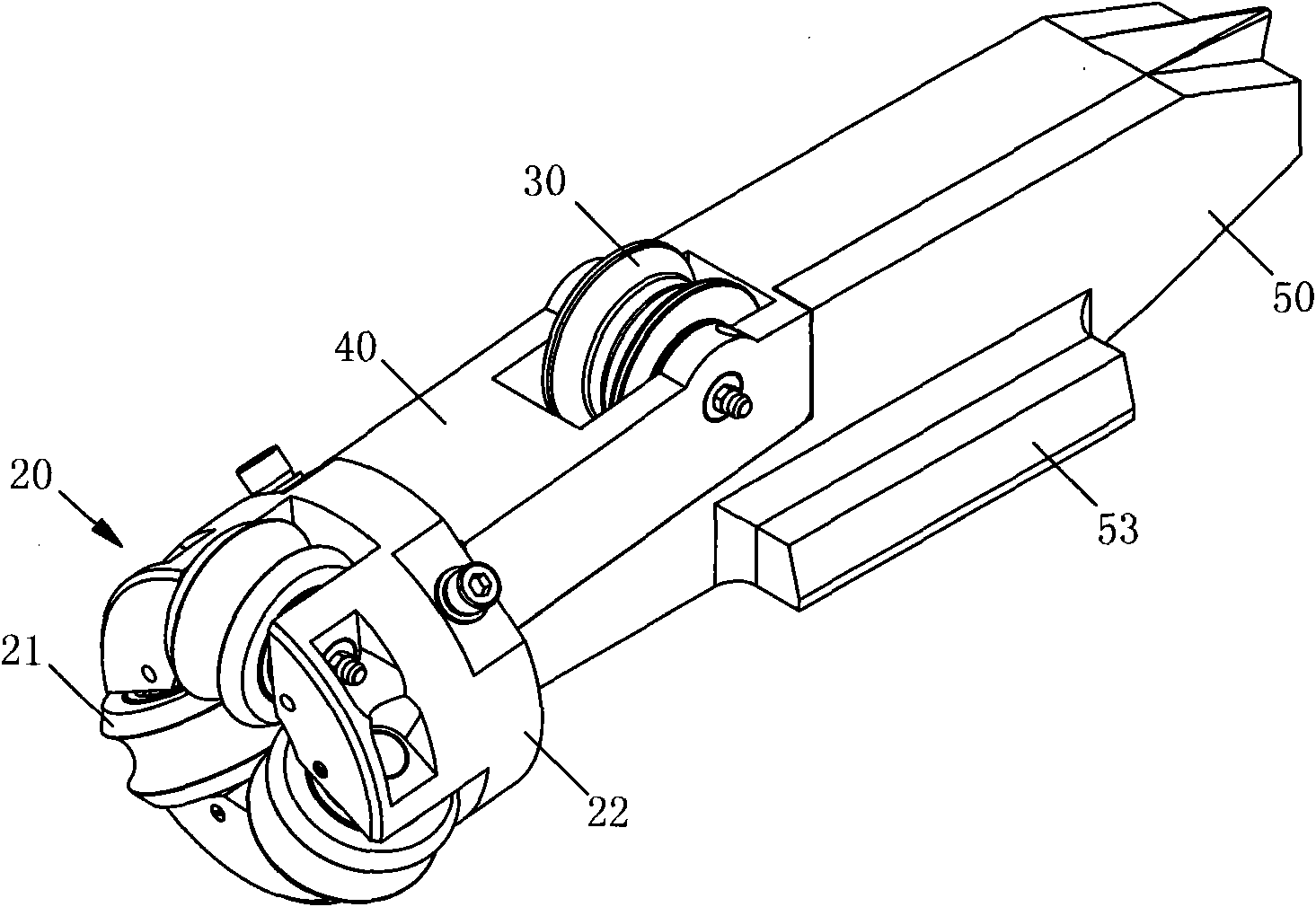

[0021] Such as figure 1 , figure 2 , image 3 , Figure 4 , Figure 5 As shown, the inside of the guide is provided with a guide groove 10 for the rolling piece to pass through, and the guide groove 10 communicates with the entrance and exit of the guide. In other words, the front and rear ends of the guide groove 10 naturally constitute the entrance and exit of the guide. , the tail of the guide guard is provided with a tail guide roller group 20, and the tail guide roller group 20 is composed of a number of sub-guide rollers 21. The groove surface 212 of groove 211 encloses the full circle for rolling piece to pass through, and sub-guiding roller 21 is fixed on the guiding roller seat 22, forms rigid fit between the guiding roller axis of sub-guiding roller 21 and guiding roller seat 22.

[0022] The so-called rigid fit specifically means that the guide roller 21 is...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com