Two-stage liquid ring vacuum pump and assembling method thereof

A liquid ring vacuum pump and secondary pump technology, which is applied to the components, pumps, and pump components of the pumping device for elastic fluids, and can solve the problems of difficulty in ensuring the consistency of the four gaps, long assembly hours, and damage. , to achieve the effect of improving performance, safety and stability, simplifying assembly process, and improving assembly efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0042] Embodiments of the present invention are further described below in conjunction with accompanying drawings:

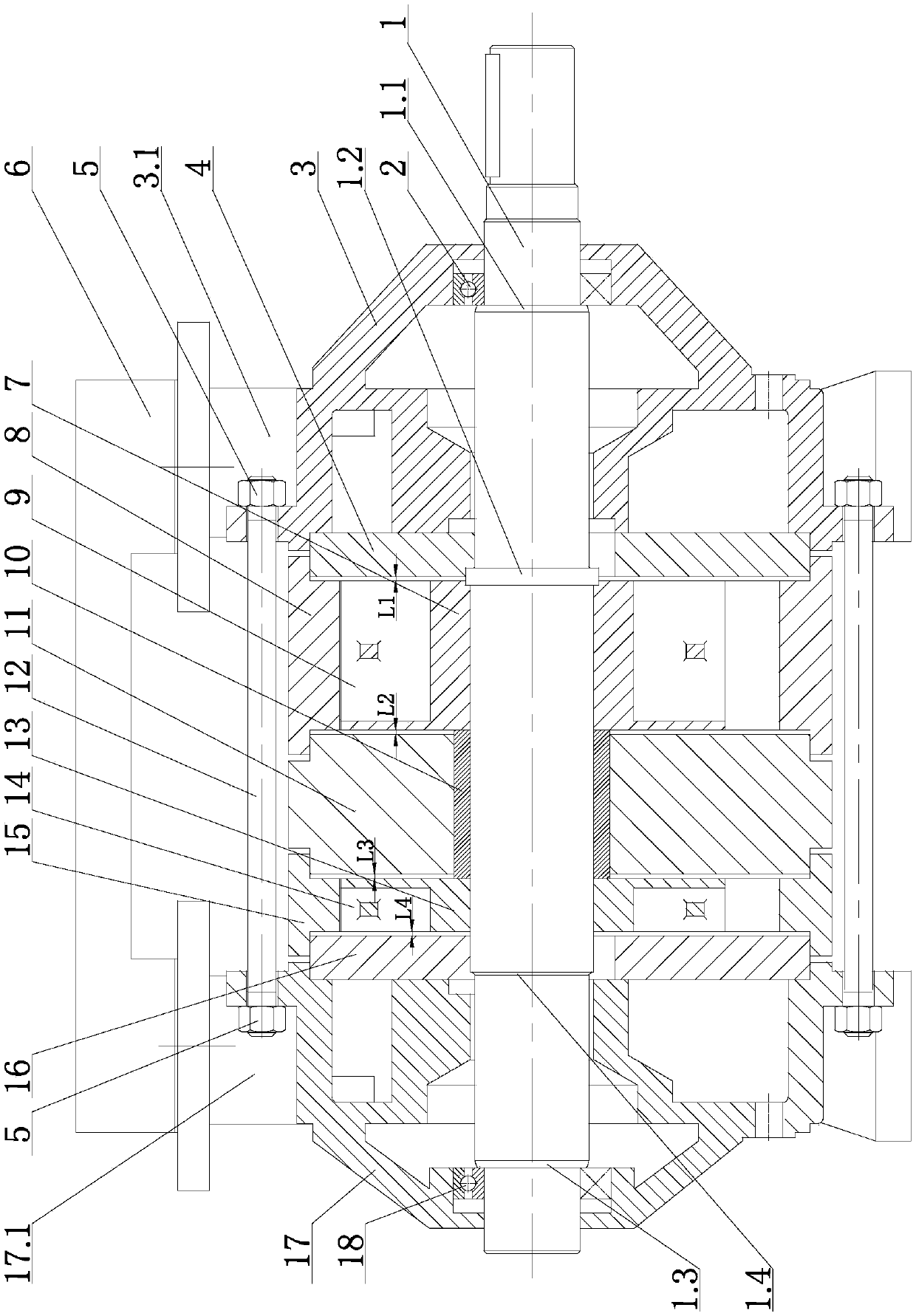

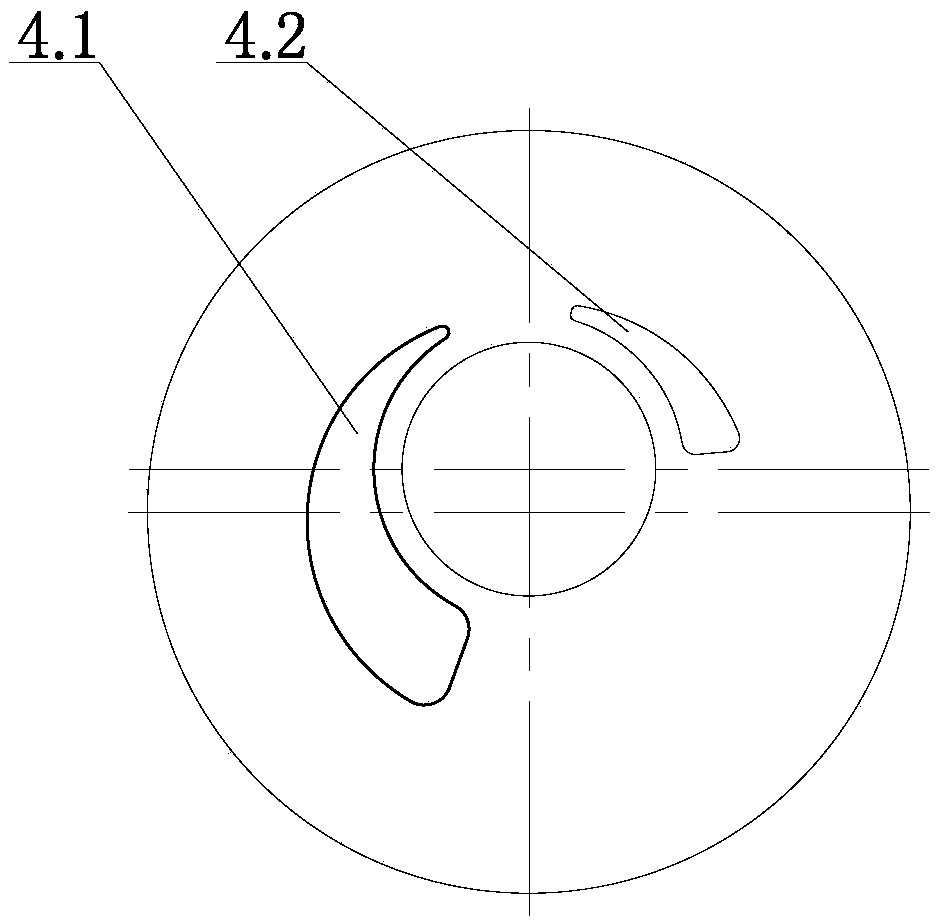

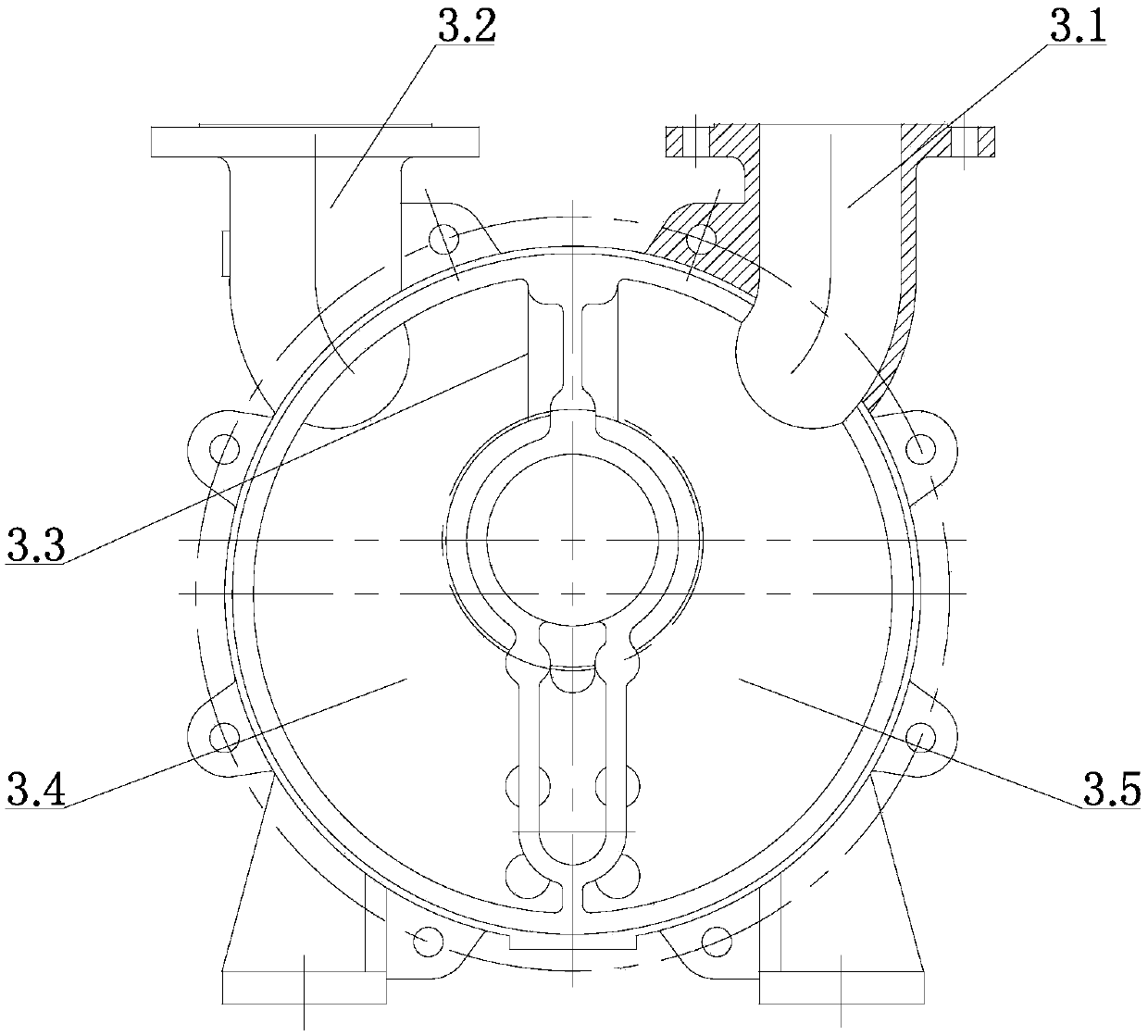

[0043] Such as Figure 1~6 As shown, the two-stage liquid ring vacuum pump of the present invention includes a primary pump body and a secondary pump body assembled on the same main shaft 1 . in:

[0044] The first-stage pump body is composed of the first-stage pump casing 8, the front pump cover 3, and the middle wall 11, and the second-stage pump body is composed of the second-stage pump casing 15, the rear pump cover 17, and the middle wall 11, that is, the two-stage pump bodies share a middle wall. The wall 11, the intermediate wall 11 and the first-stage pump casing 8 and the second-stage pump casing 15 on both sides thereof are fixedly assembled by using seams, and the limiting bushing 10 is installed on the main shaft 1, and the intermediate wall 11 and the limiting bushing 10 are in clearance fit. . Because there is no gas channel on the intermediate ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com