Motorcycle and after-frame assembly thereof

A technology for motorcycles and rear frames, applied in the field of motorcycle parts and motorcycles, can solve the problems of lack of universality and standardization of connecting parts, difficulty in mass production of motorcycles, and insufficient installation of components, and achieve tight clearance, Increase the ability to resist bending moment, the effect of good firmness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

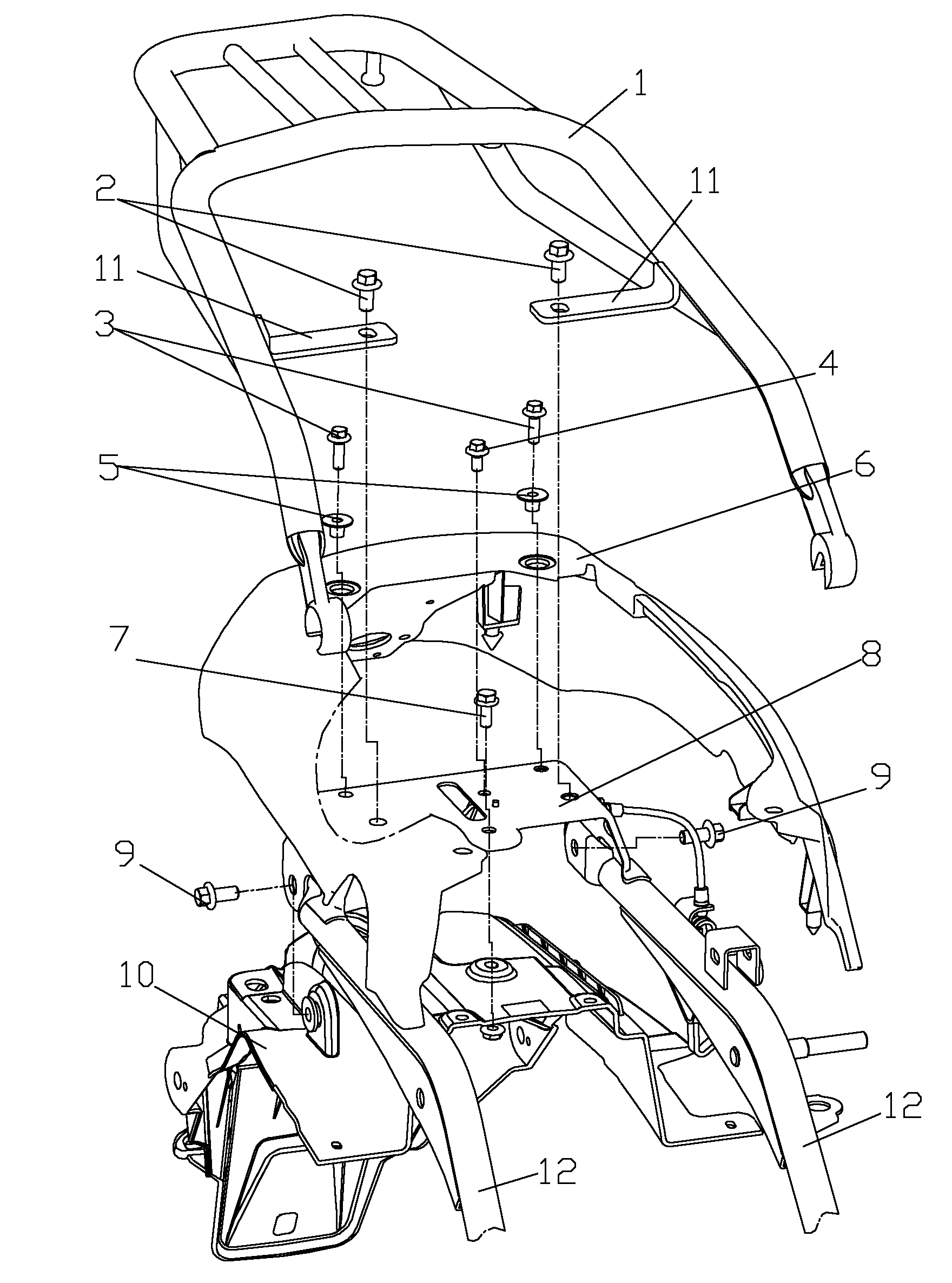

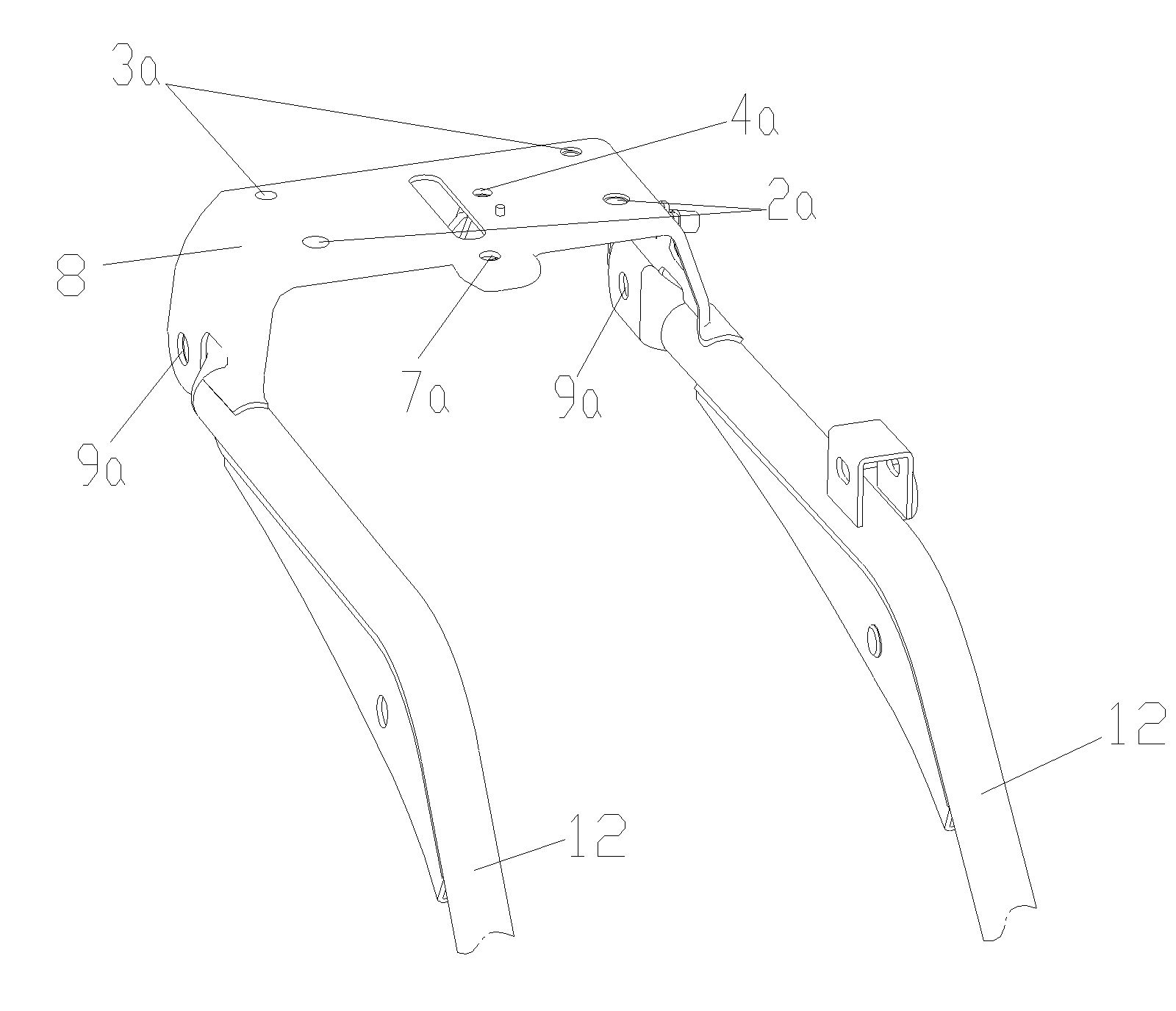

[0016] figure 1 For the installation structure explosion diagram of the present invention, figure 2 It is a structural schematic diagram of the tail pipe of the vehicle frame, as shown in the figure: the rear frame assembly of the motorcycle of the present embodiment includes a seat cushion lock seat (not shown in the figure), a rear fender 10, a rear carrier 1, a tail cover 6 and frame tail pipes 12, the frame tail pipes 12 are two parallel in the transverse direction, and also include a connecting plate 8 that is transversely between the two frame tail pipes 12 and fixedly connected with them, and the seat cushion lock seat , the rear fender 10, the rear carrier 1 and the tail cover 6 are detachably fixedly connected to the connecting plate 8.

[0017] In this embodiment, the left and right ends of the connecting plate 8 are respectively bent downwards and correspondingly fixedly connected to the two frame tail pipes 12 to form an upwardly protruding door-shaped structure,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com