Aluminum vertical shaft and manufacturing process thereof

A preparation process and vertical shaft technology, applied in the field of aluminum vertical shafts and their preparation, can solve the problems of parts failure, damage, potential safety hazards, etc., and achieve the effects of low production cost, strong practicability, and improved efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] The present invention will be described in further detail below by means of specific embodiments:

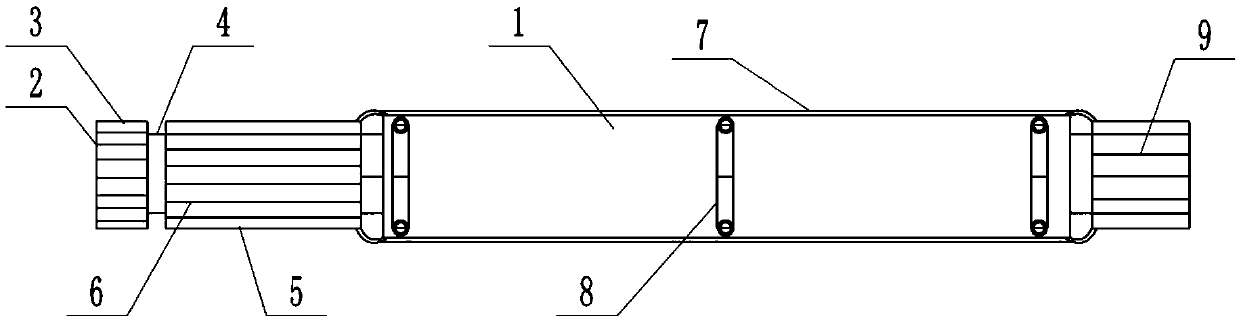

[0023] The reference signs in the accompanying drawings of the specification include: shaft core main body 1 , connecting end 2 , anti-slip layer 3 , buffer section 4 , anti-slip block 5 , anti-slip strip 6 , anti-oxidation layer 7 , reinforcing ring 8 , and fixed end 9 .

[0024] like figure 1 As shown, an aluminum vertical shaft and its preparation process include a shaft core main body 1, one end of the shaft core body 1 is provided with a connecting end 2, and the other end is provided with a fixed end 9, and the connecting end 2 and the shaft core An anti-slip block 5 is provided between the main body 1, and the surface of the anti-slip block 5 is provided with anti-slip thread strips, and the thread strips are evenly distributed along the circumference of the anti-slip block 5, and the connecting terminal 2 and the fixed terminal 9 are Anti-slip layers 3 are provid...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com