Working device hinging mechanism

A technology of hinge mechanism and working device, applied in mechanical equipment, pivot connection, bearing components, etc., can solve problems such as poor dustproof effect, and achieve the effect of reducing impact, reducing processing cost, and enhancing circulation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

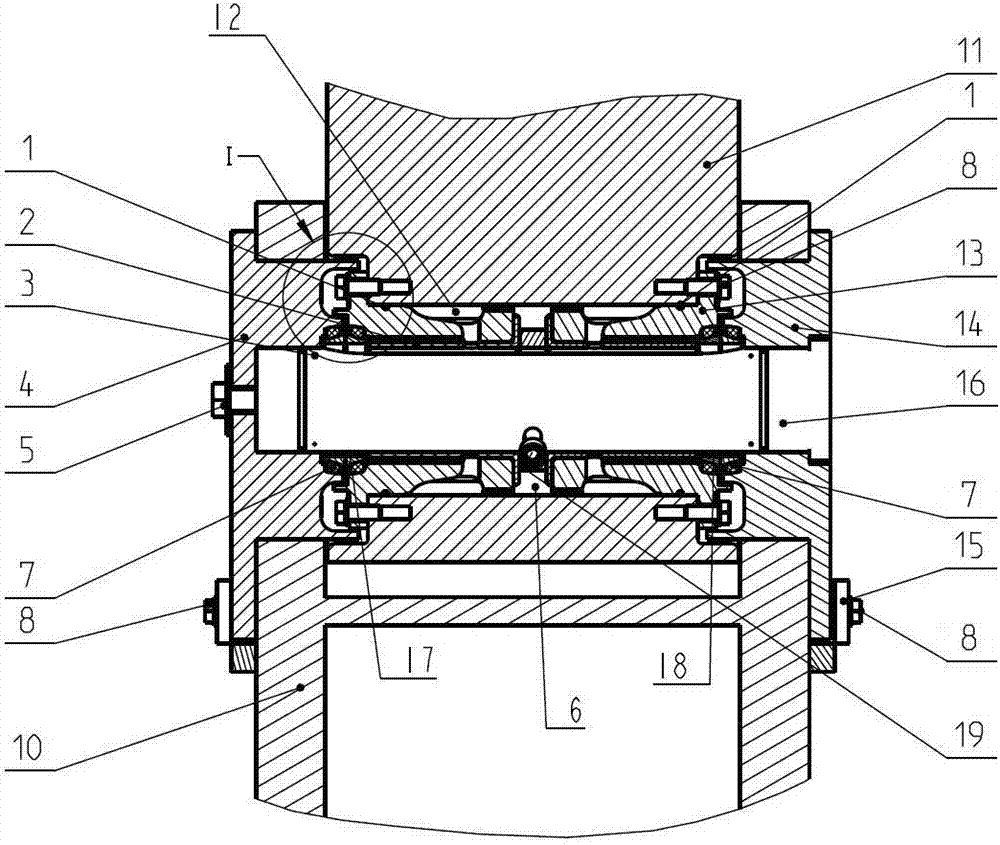

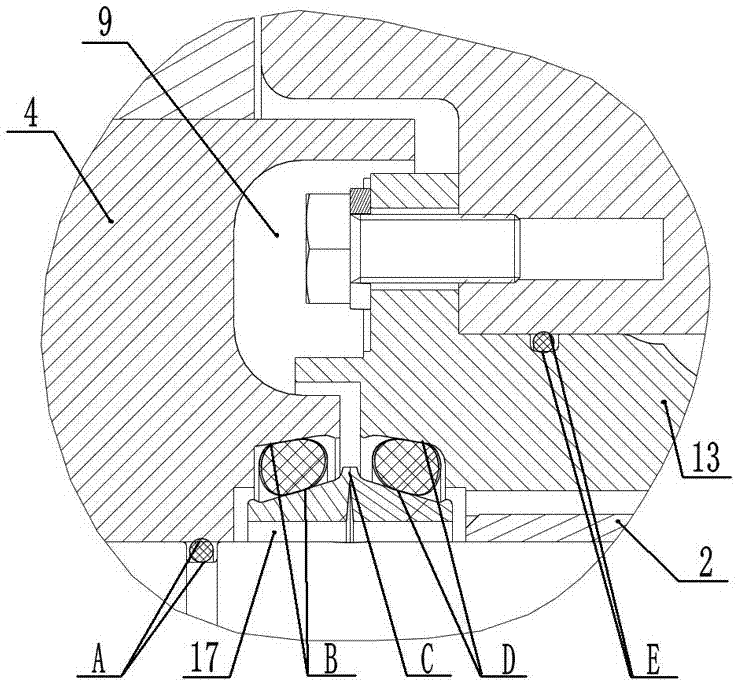

[0022] Below in conjunction with accompanying drawing example, the present invention is described in further detail:

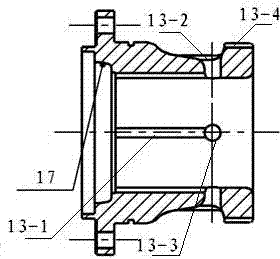

[0023] like figure 1 and Figure 5 In the shown embodiment, this embodiment is that the hinge mechanism is used in the assembly of the boom and the arm, the floating seal ring 7-1 and the sealing ring 7-2 form the floating oil seal 7, and two pairs of floating oil seals form a static sealing device , respectively installed on the inner surface of the end of the bushing 13 in contact with the inner end surface of the right floating seal seat 14, the second floating oil seal cavity 18, and the inner surface of the end head of the bushing 13 in contact with the inner end surface of the left floating seal seat 4 In the provided first floating oil seal cavity 17, the bushing 13 is fixed on the arm 11 by the bolt 8, so as to prevent the bushing 13 from rotating during the working process. The bearing bush 2 is press-fitted in the bushing 13, the shaft 16 passes th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com