Assembled chassis and fan

An assembled, chassis technology, applied in heating methods, non-variable capacity pumps, space heating and ventilation details, etc., can solve problems such as weak structural strength at clip joints, unstable tower fan support, and loose joints. The assembly method is simple and easy to use, the quantity is small, and the weight is increased.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

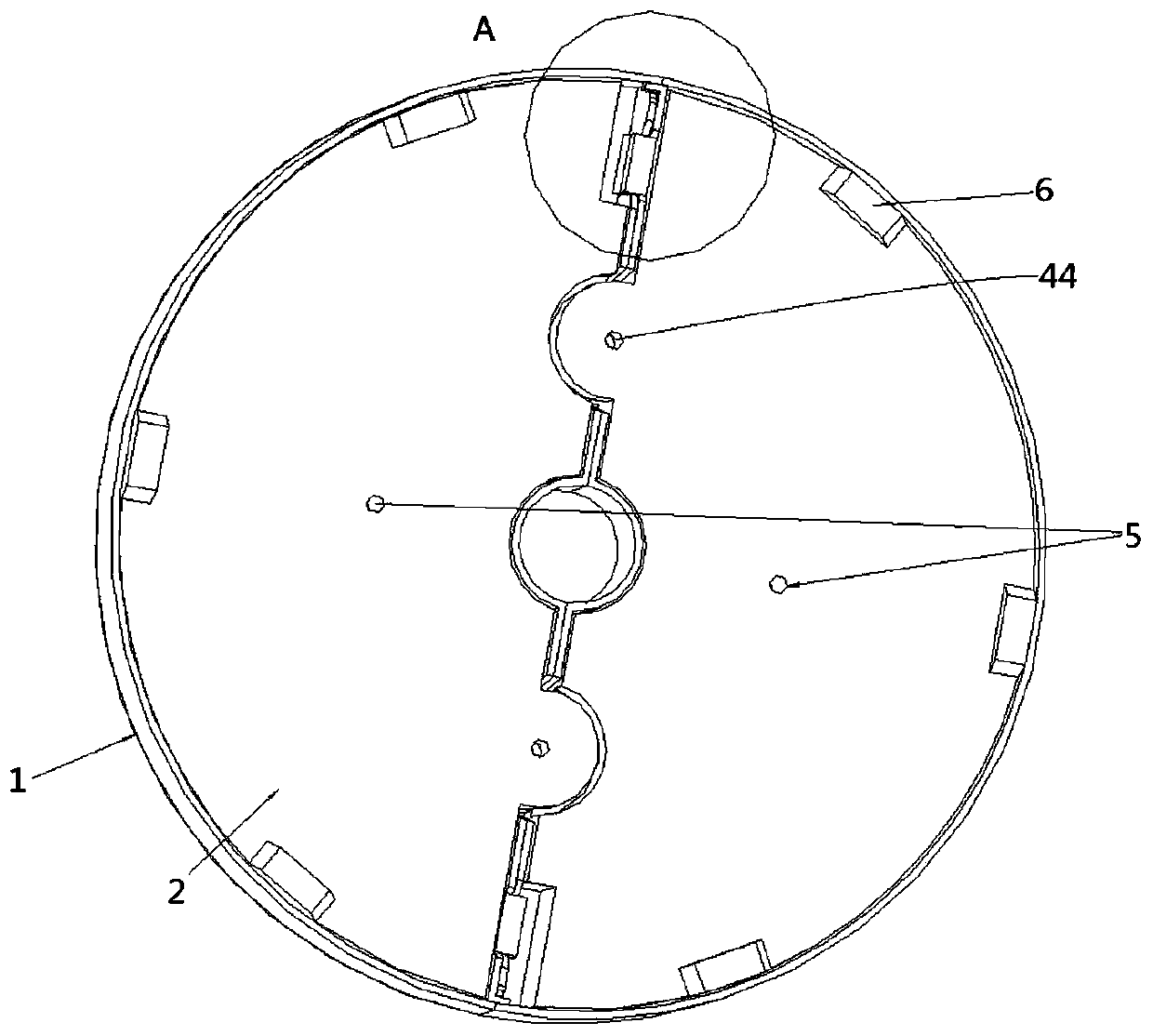

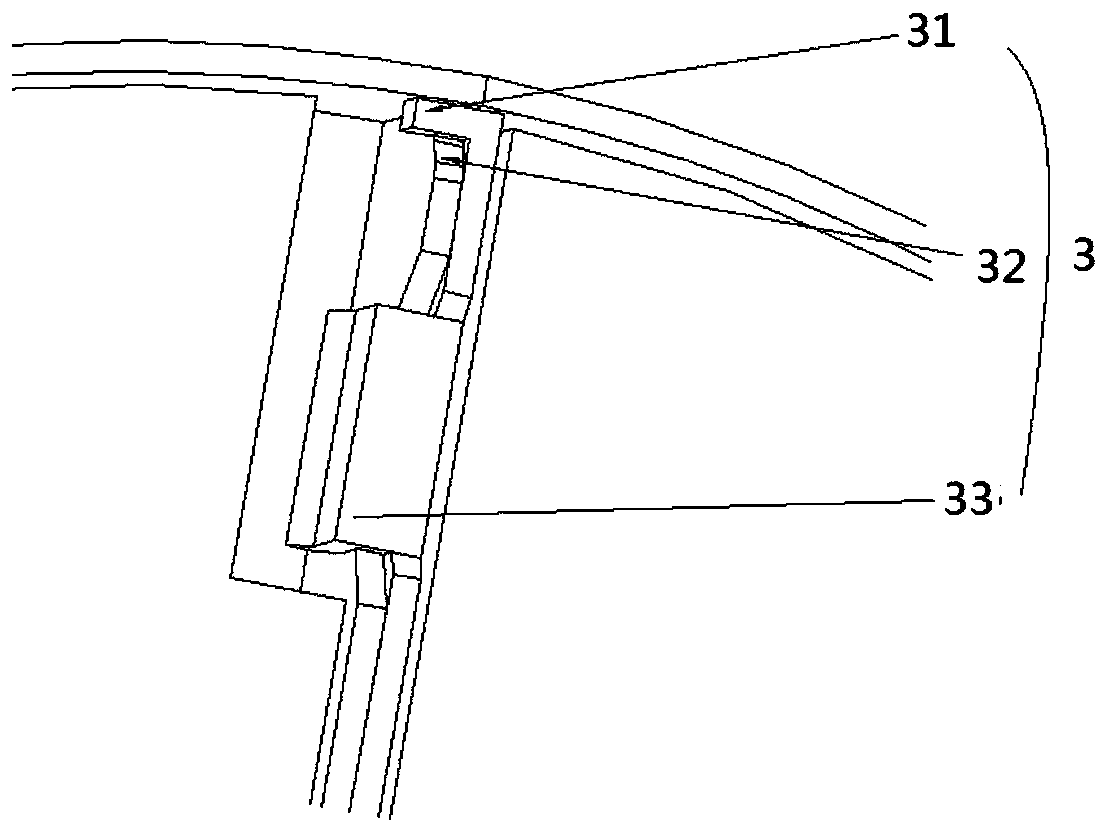

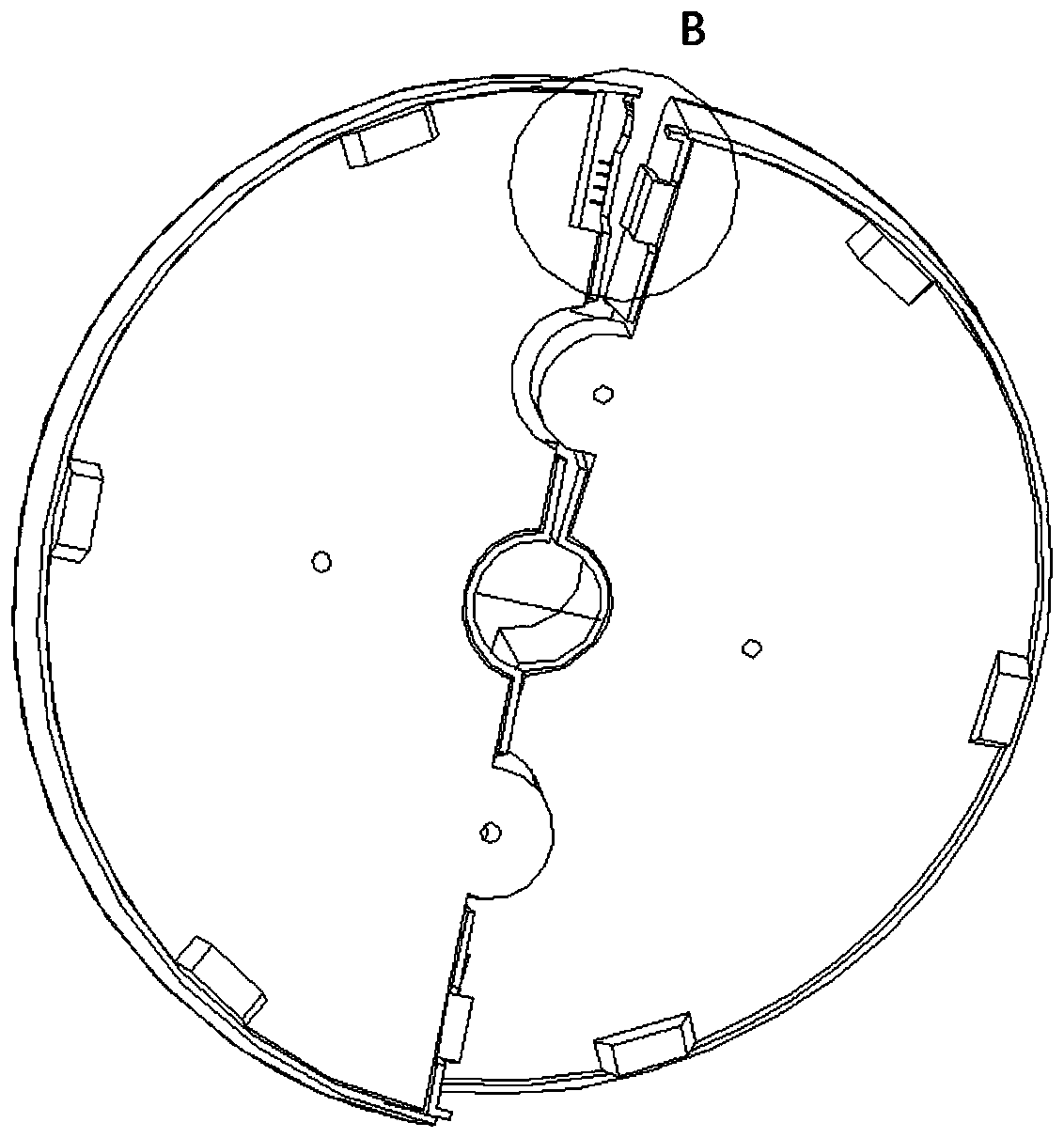

[0051] like Figure 1 to Figure 5 As shown, an assembled chassis provided for this embodiment includes a sub-chassis 1, and a housing groove 11 is arranged on the sub-chassis 1; Assembled into one body through the first connecting part 3; the counterweight 2 is arranged in the accommodating groove 11; the second connecting part 4 is arranged on the counterweight 2, and several identical counterweights 2 pass through the second connecting part 4 assembled into one.

[0052] The assembled chassis in this embodiment is used for fans, specifically the chassis of tower fans. Of course, it can also be used in other technical fields, such as the chassis of cabinet air conditioners.

[0053] The assembled chassis in this embodiment is made of plastic, which is processed and formed by injection molding.

[0054] First of all, in this embodiment, the entire chassis of the original fan is designed as a plurality of sub-chassis 1 that can be assembled with each other. In terms of packag...

Embodiment 2

[0079] This embodiment provides a fan, specifically a tower fan, which uses the assembled chassis structure described in Embodiment 1, and has all the technical advantages of the assembled chassis, so details will not be repeated here.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com