Building glass curtain wall

A technology of architectural glass and glass curtain wall, which is applied to buildings, building components, building structures, etc. It can solve the problems of inconvenient disassembly, complex overall structure, and easily damaged curtain walls, and achieve the effect of convenient disassembly and assembly.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

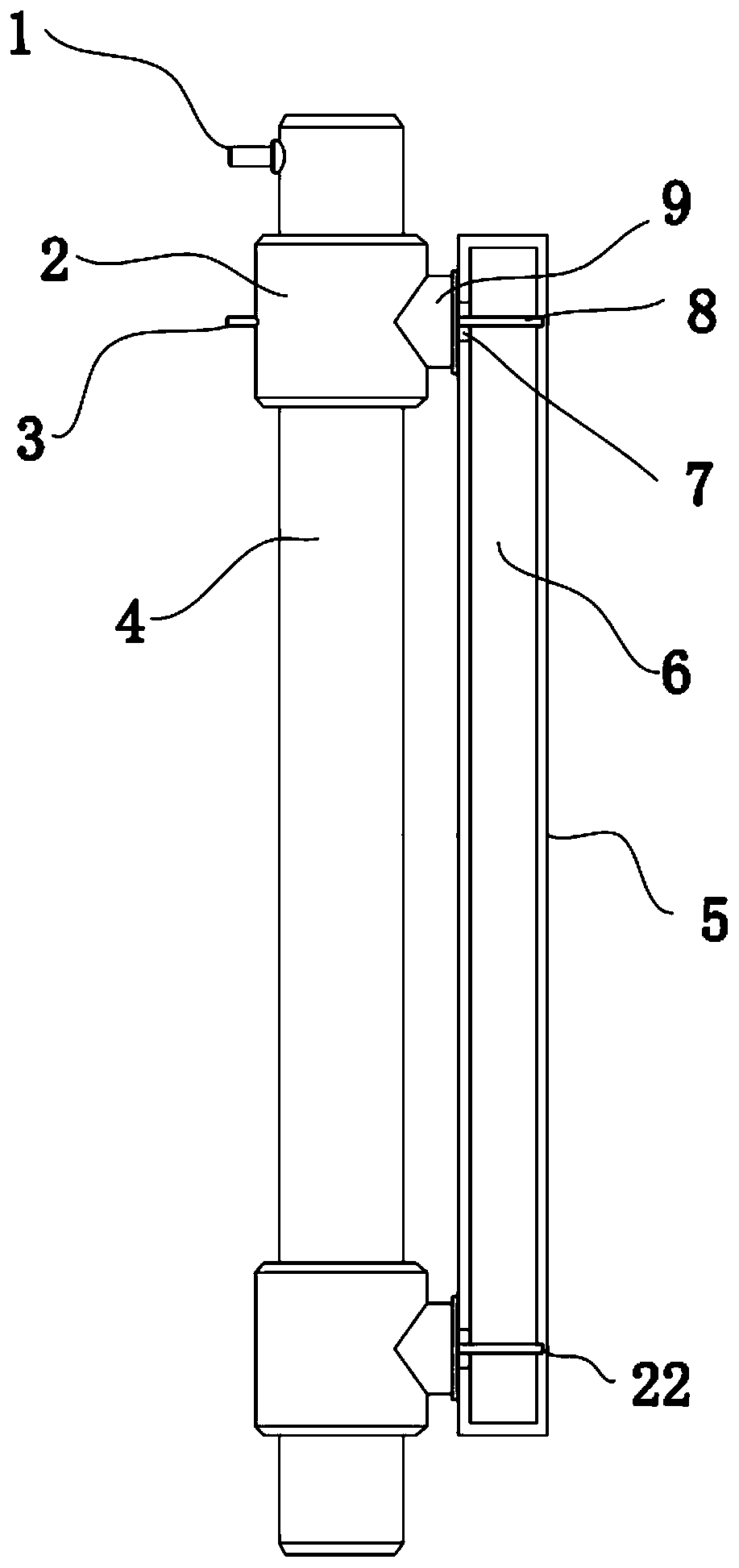

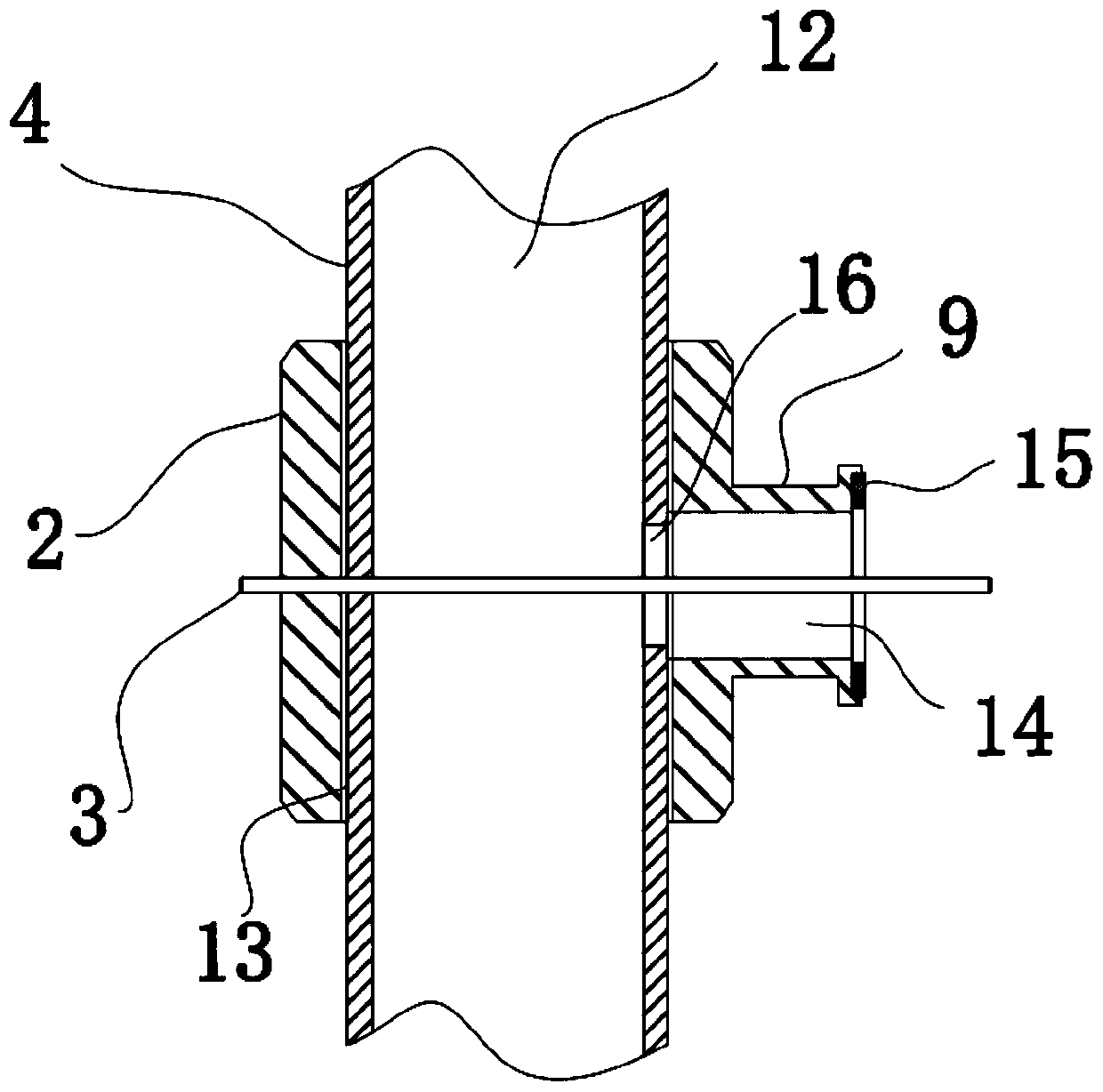

[0015] like figure 1 As shown, the glass curtain wall of this building includes more than one supporting column 4 arranged side by side. The supporting columns 4 are all hollow columns, and a closed hollow cavity 12 is arranged in the middle. The glass curtain wall 5 is arranged at the front end of each supporting column 4 It is connected and fixed by the connectors 2 installed on each support column 4, and each connector 2 has an assembly cavity, the support column 4 passes through the assembly cavity and protrudes from both sides of the connector 2, and the glass curtain wall 5 has a vacuum chamber inside 6. A small hole 7 is opened at the position where the glass curtain wall 5 faces the connecting piece 2. The small hole 7 communicates with the internal vacuum chamber 6. A suction head 9 is set at the position of the connecting piece 2 relative to the small hole 7, and the suction head 9 is sealed. The small hole 7, the connecting piece 2 and the glass curtain wall 5 are p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com