Modular airtight cold guide case

A modular and airtight box technology, which is applied in the direction of cooling/ventilation/heating transformation, electrical components, electrical equipment structural parts, etc., can solve the problems of difficult universality of electronic chassis, large task load, increased cost, etc., to achieve Save labor costs and production costs, simplify design tasks, and improve the effect of heat dissipation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0032] The principles and features of the present invention are described below in conjunction with the accompanying drawings, and the examples given are only used to explain the present invention, and are not intended to limit the scope of the present invention.

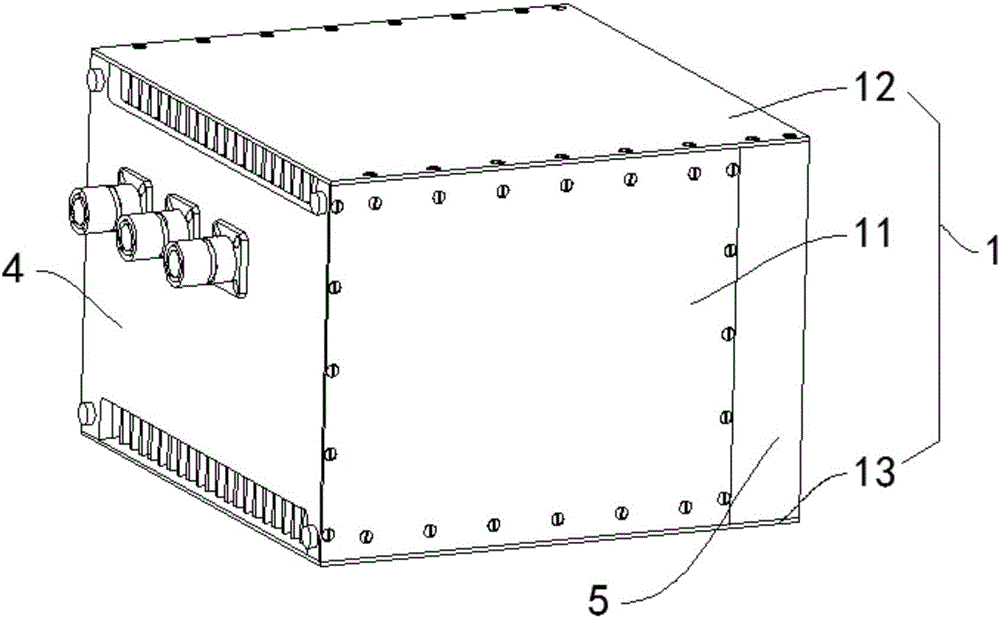

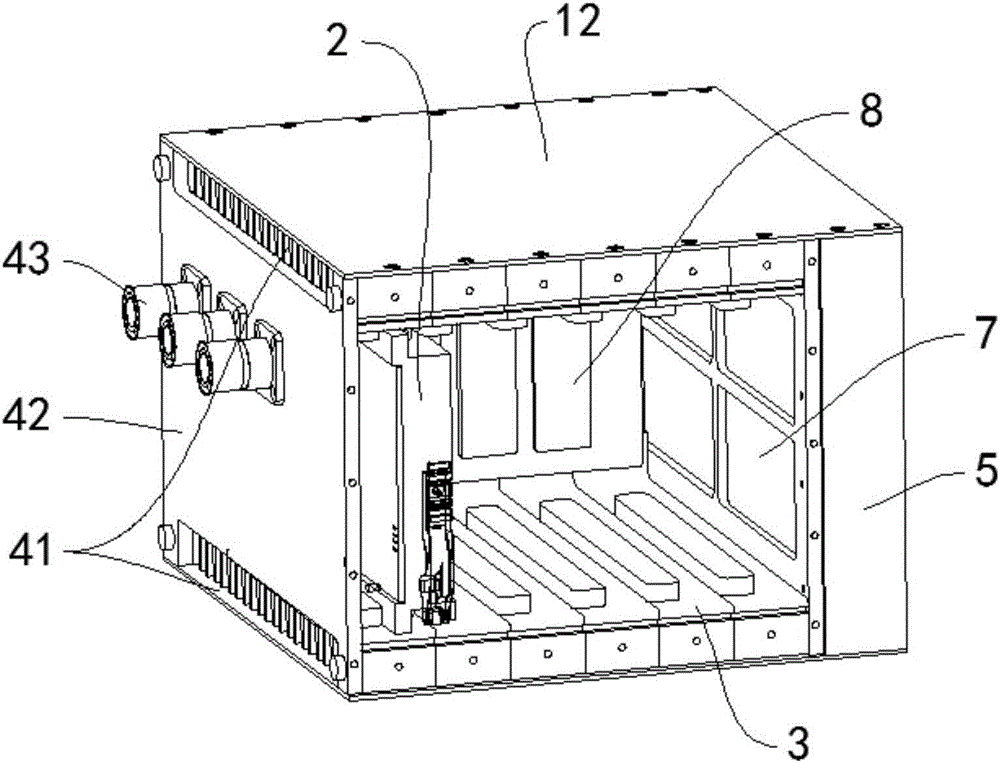

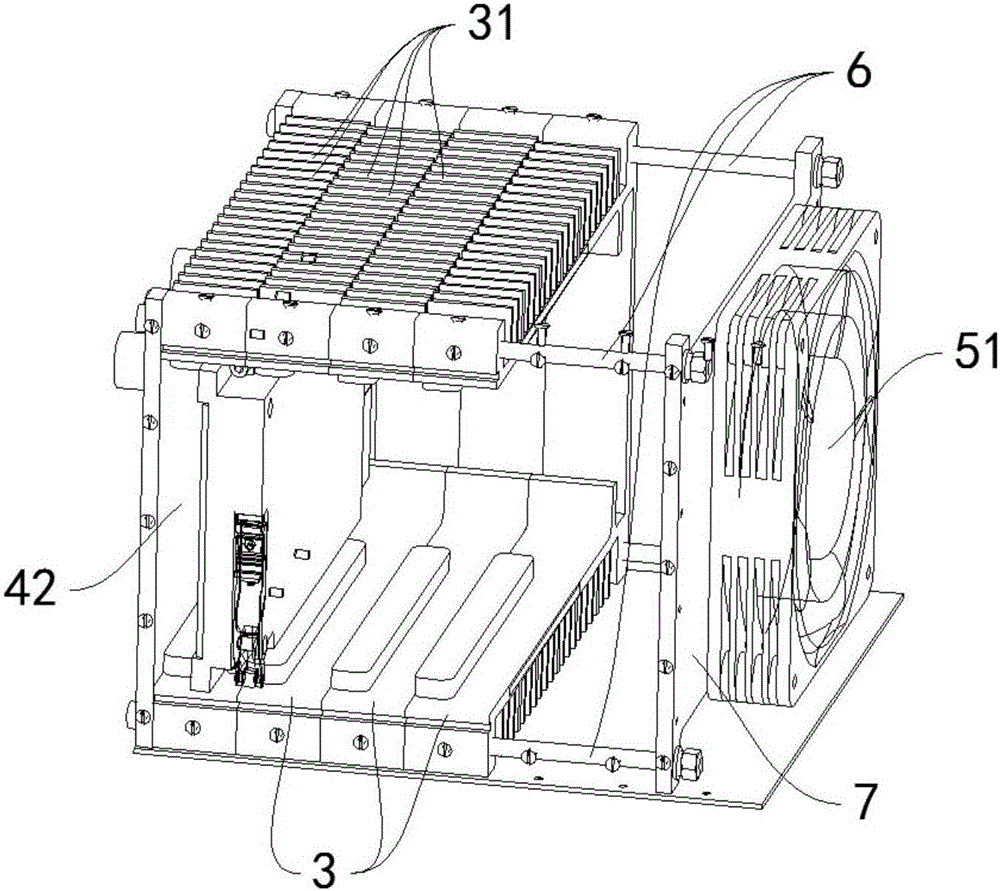

[0033] Such as figure 1 , figure 2 , image 3 , Figure 4 , Figure 7 As shown, the present invention discloses a modular airtight cold-conducting chassis, which includes an airtight box 1, a cold-conducting insert 2 and a plurality of cold-conducting modules 3; a plurality of cold-conducting modules 3 are arranged side by side in the airtight box 1, and Each cooling module 3 is set as a U-shaped structure with an open front; the cooling plug-in 2 is stuck in the cooling module 3, and the cooling plug-in 2 is a 3U standard VPX cooling plug-in, and the cooling plug-in 2 is placed along the cooling module 3 The guide rail (the protrusion 33 mentioned below) is inserted into the designated position of the backboar...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com