Coating scraper with automatic abrasion alarming switch

An automatic alarm and alarm switch technology, which is applied to the device and coating of the surface coating liquid, can solve the scraper blade wear, unfavorable product stability, product quality consistency, and reduce the controllability of the film layer thickness. Uniformity and other issues to achieve the effect of improving stable production

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

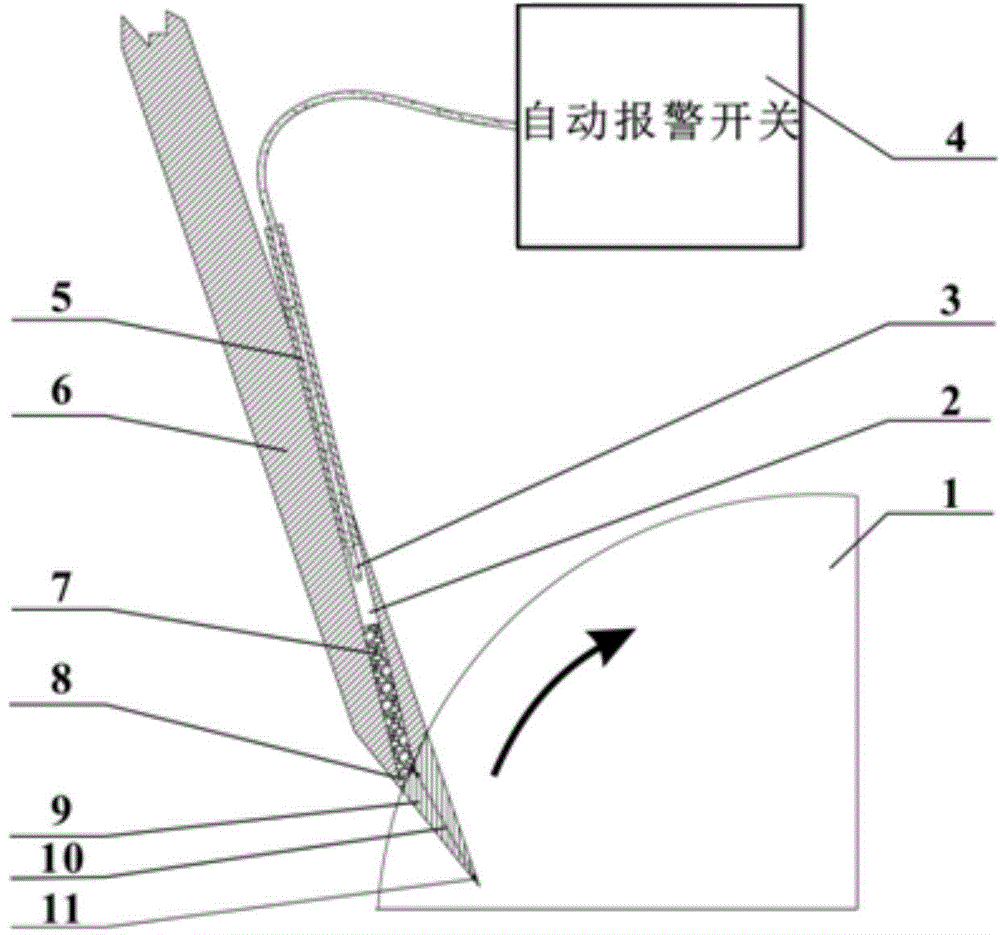

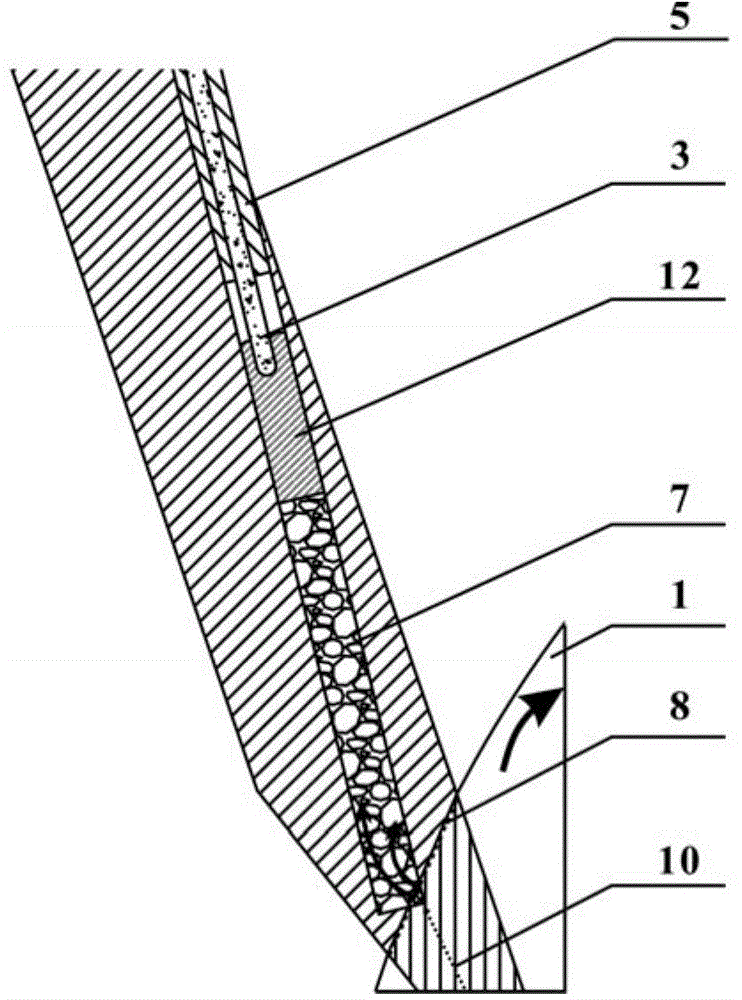

[0028] like figure 1 As shown, a coating scraper with an automatic wear alarm switch, especially a contact coating scraper or blade for scraping and modifying the solution on the roller 1 in the gravure coating / printing, letterpress coating / printing process, The coating scraper has a microhole 2, the microhole 2 is a straight blind hole, the bottom of the straight blind hole reaches the critical line 8 of the blade wear amount of 10 when the scraper is scrapped, and an alarm switch lead is set at the opening of the microhole 3. The bottom of the microhole is provided with a liquid-absorbing core 7, and the alarm switch lead wire 3 is connected to the automatic alarm switch 4. When the blade of the scraper is worn to the critical line 8, the worn area 9 of the scraper has been removed, and the bottom of the blind hole is worn through It is a through hole, and after the solution 12 enters the through hole, it contacts with the lead wire of the alarm switch to trigger the automat...

Embodiment 2

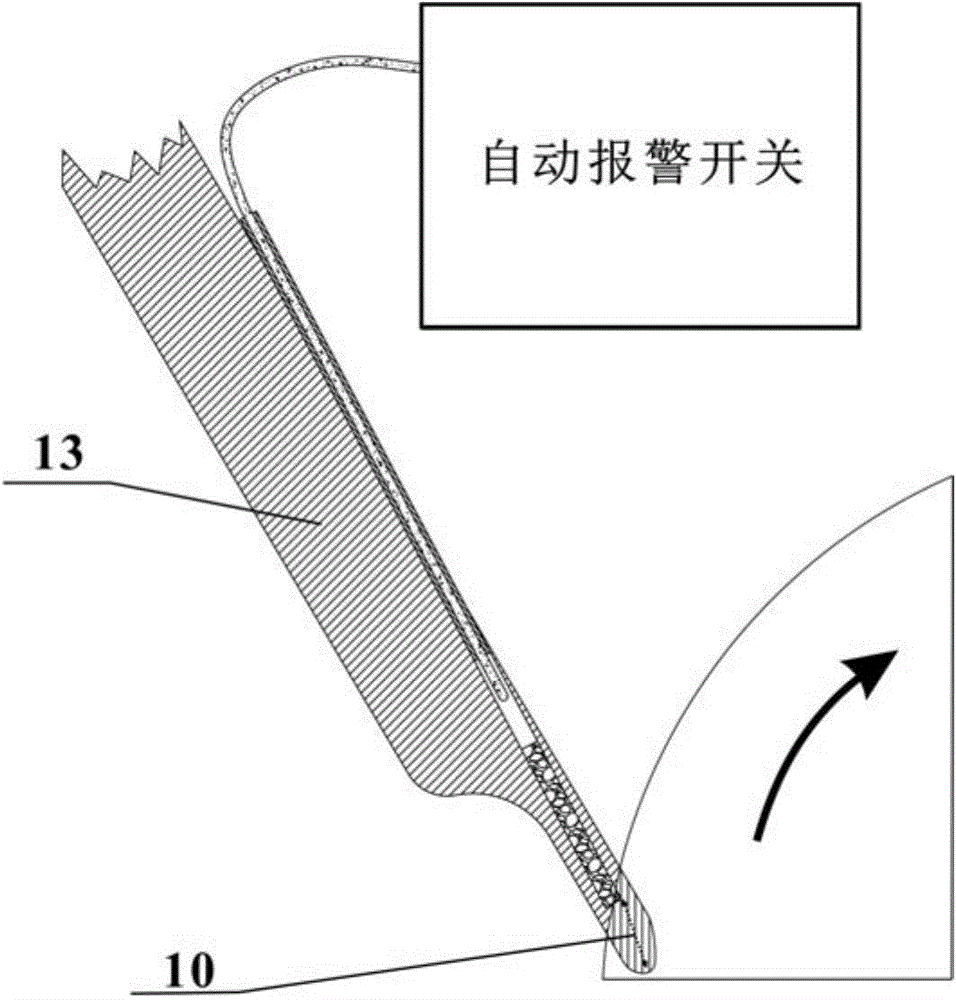

[0039] like image 3 As shown, a coating scraper with an automatic wear and tear alarm switch, the scraper is a thin-layer scraper 13, and there are two micropores placed in the thin-layer scraper body, which are respectively the first micropore 16 and the second micropore. Hole 17 is a straight blind hole. The bottom of the blind hole reaches the critical line of 2mm blade wear when the scraper is scrapped. The cross-sectional shape of the micro-hole is circular, and the minimum circumscribed circle diameter of the cross-sectional shape is 0.9mm. The micro-hole is a cylindrical hole. The length of the coating blade is 1000mm, and the two micro-holes are located on both sides of the center line of the blade, such as Image 6 As shown, the adjacent distance between two micropores is 200mm, the alarm switch lead wire 3 exposes the insulating through hole plug 5 to be 1.2mm, and the distance between the alarm switch lead wire and the liquid-absorbing core is 1.5mm, and other feat...

Embodiment 3

[0041] like Figure 4 As shown, a coating scraper with an automatic wear alarm switch, the scraper is an arc scraper 14, the arc scraper body is provided with micro-holes, specifically, the micro-holes are straight blind holes, and the bottom of the blind holes reaches The critical line of blade wear amount 1.5mm when the scraper is scrapped; the angle θ formed between the microhole axis 15 and the blade 11 is 90°.

[0042] The micropores placed in the scraper body have a circular cross-sectional shape. The minimum circumscribed circle diameter Φ of the cross-sectional shape is 0.5 mm. The micropore is a cylindrical hole, the thickness H of the arc scraper is 1 mm, the end of the alarm switch lead wire exposed the insulating through hole plug 5 is 2 mm, the distance between the alarm switch lead wire and the liquid-absorbing core is 1.5 mm, and other features are the same as in Embodiment 1 .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com