Automatic acquisition device for stator positioning rib welding deformation measurement data

A technology for welding deformation and measuring data, which is applied in the field of hydropower unit equipment assembly, can solve the problems of long measurement period, affecting welding continuity, and difficult measurement, so as to avoid welding seam removal and rework operations, reduce human measurement errors, and avoid The effect of interspersed interference

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0040] The present invention is further described below in conjunction with specific embodiment, and specific embodiment is the further description of the principle of the present invention, does not limit the present invention in any way, and the identical or similar technology of the present invention all does not exceed the scope of protection of the present invention.

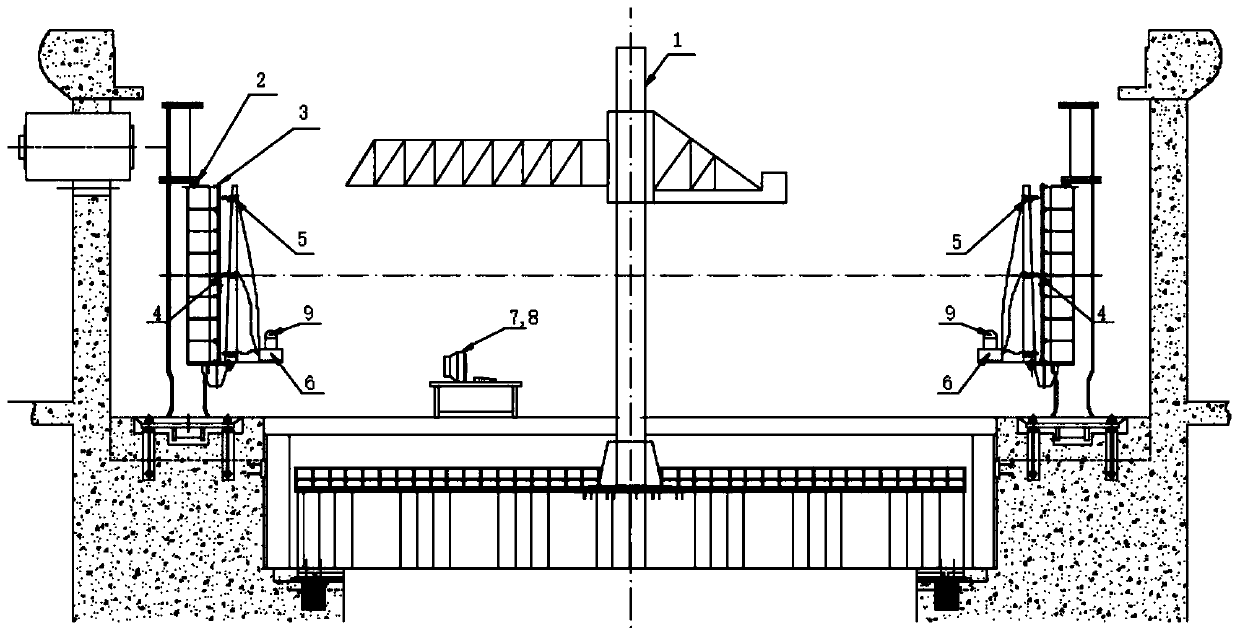

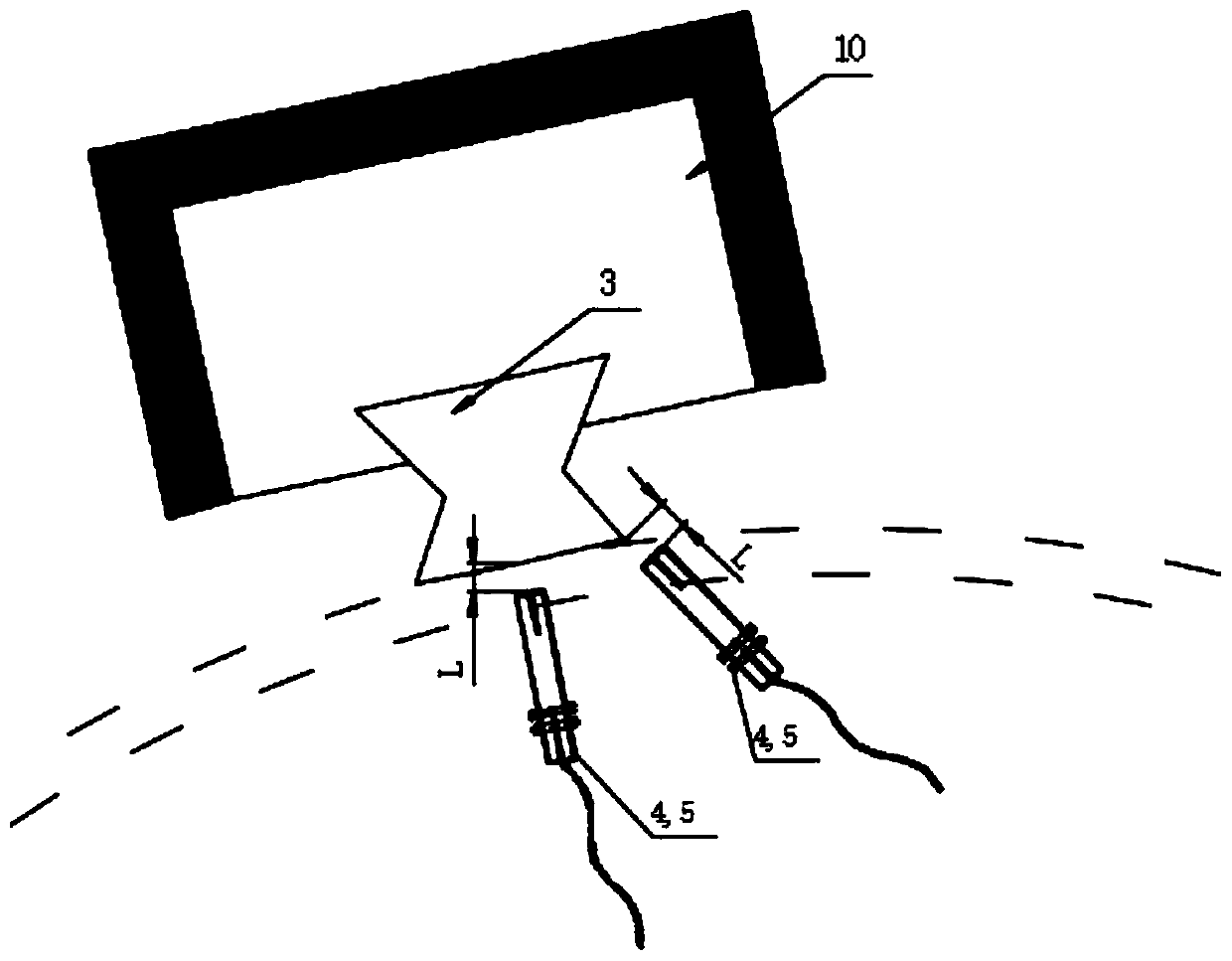

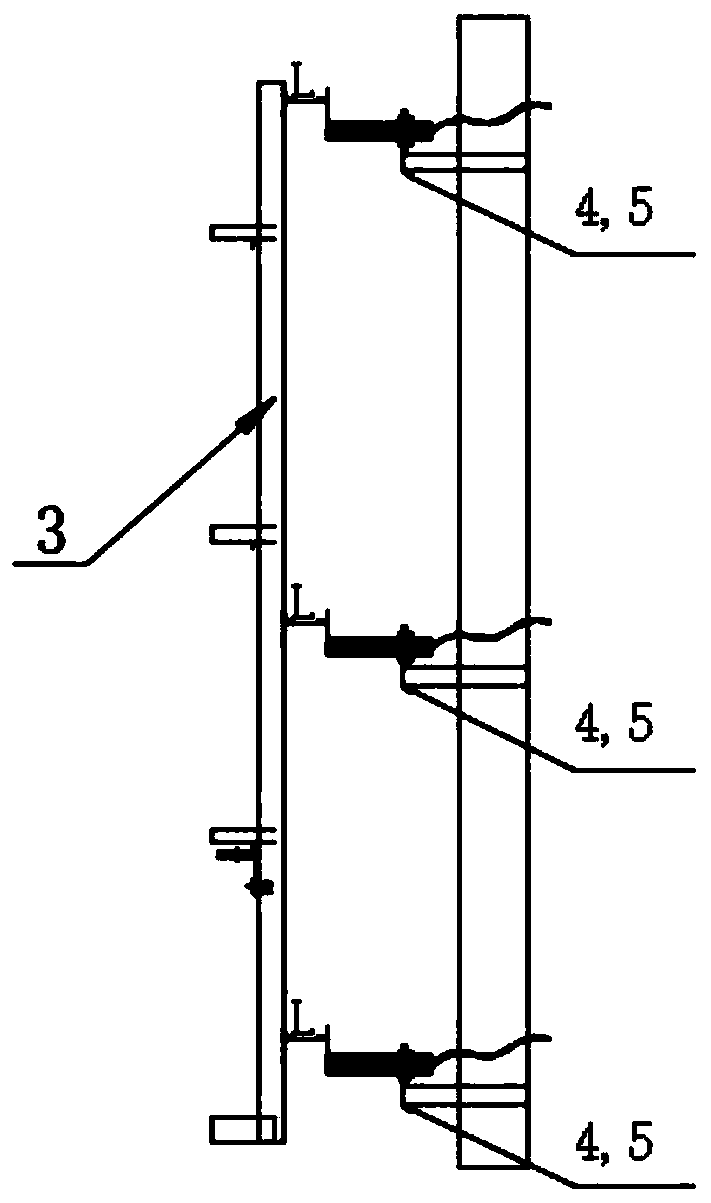

[0041] see Figure 1 to Figure 7 , the present invention provides an automatic acquisition device for measuring data of stator positioning rib welding deformation, the automatic acquisition device includes a probe 4, a probe fixing bracket 5, a signal acquisition device 6, a terminal computer 7, an automatic analysis software, an output device 8, and an alarm device 9 and monitoring brackets. The number of monitoring supports can be set according to the measurement requirements. In the present embodiment, the monitoring supports are provided with six sets, and each set of monitoring supports is composed of ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com