Elastic heat-insulating breathable moisture-absorbing insole and manufacturing method thereof

An insole and elastic technology, which is applied in the field of elastic warm-keeping, breathable and moisture-absorbing insoles and its production, can solve the problems of no heat preservation, poor hygroscopicity, and poor air permeability, etc., and achieve high product quality consistency, reliable combination, and craftsmanship mature effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] The present invention will be described in detail below in conjunction with the accompanying drawings and embodiments.

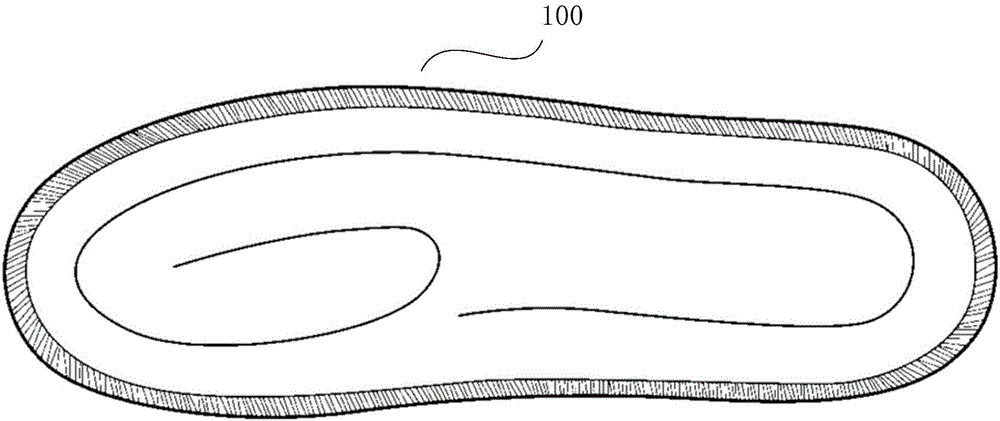

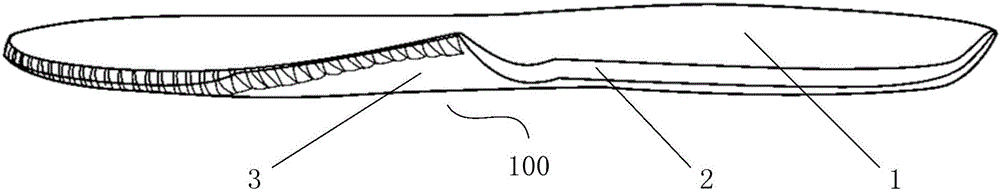

[0017] Such as figure 1 , figure 2 As shown, the elastic, warm, breathable and moisture-absorbing insole 100 provided by the present invention includes a flat-cut velvet fabric layer 1, an open-cell foamed polyurethane layer 2, and a needle-punched polyester fiber felt layer 3 that are sequentially integrated from top to bottom. .

[0018] In the above-described embodiment, the flat-cut velvet fabric 1, the open-cell foamed polyurethane 2 and the needle-punched polyester fiber felt 3 are formed by pressing and cold pressing, and by sewing and seaming, so as to obtain the elastic warm-keeping fabric of the present invention. Breathable and moisture-absorbing insole 100.

[0019] In the above-mentioned embodiment, the flat-cut velvet fabric layer 1 is made of 55.6dtex polyester filament knitted fleece; the quality of the flat-cut velvet fabric layer...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com