Charge combustion chamber shell and forming method thereof

A molding method and combustion chamber technology, which can be applied to jet propulsion devices, rocket engine devices, machines/engines, etc., can solve problems such as mismatching assembly surfaces of demoulding, deformed winding mandrels, high requirements for equipment conditions, and complicated process , to achieve the effect of simple and reliable manufacturing process, uniform spraying thickness and simple process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0051] The present invention will be described in further detail below in conjunction with the accompanying drawings and embodiments.

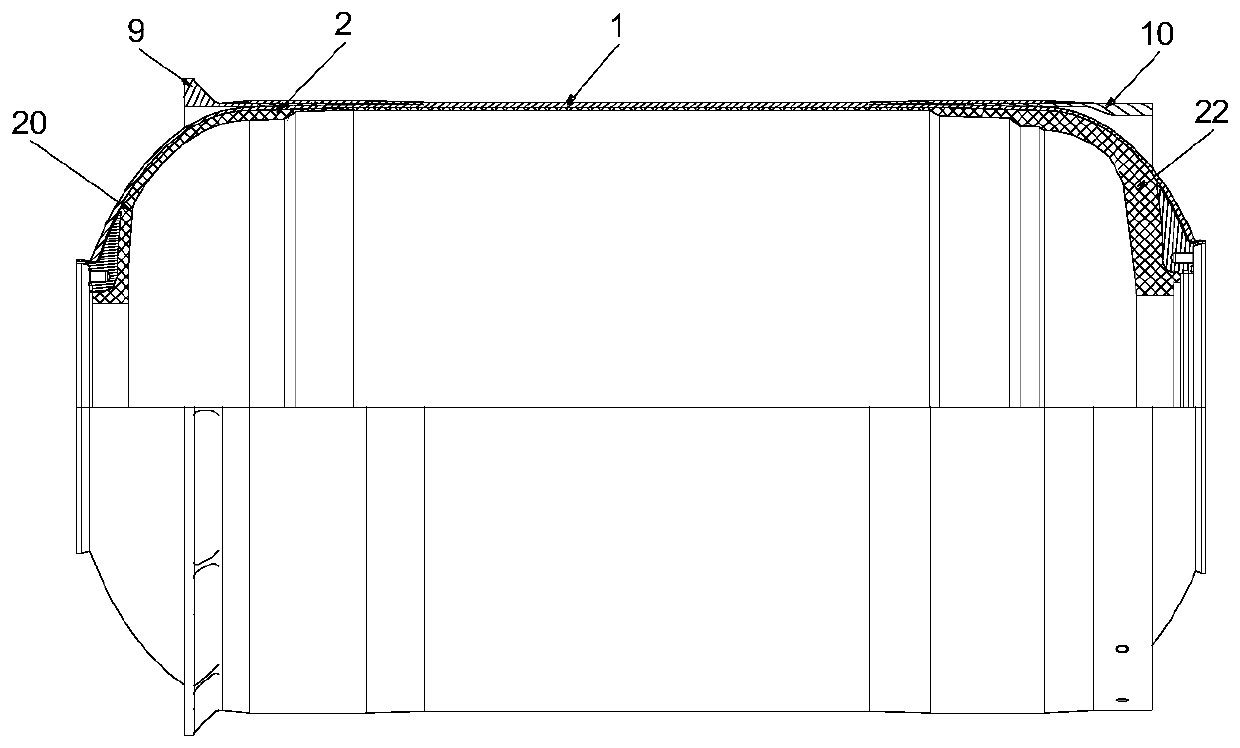

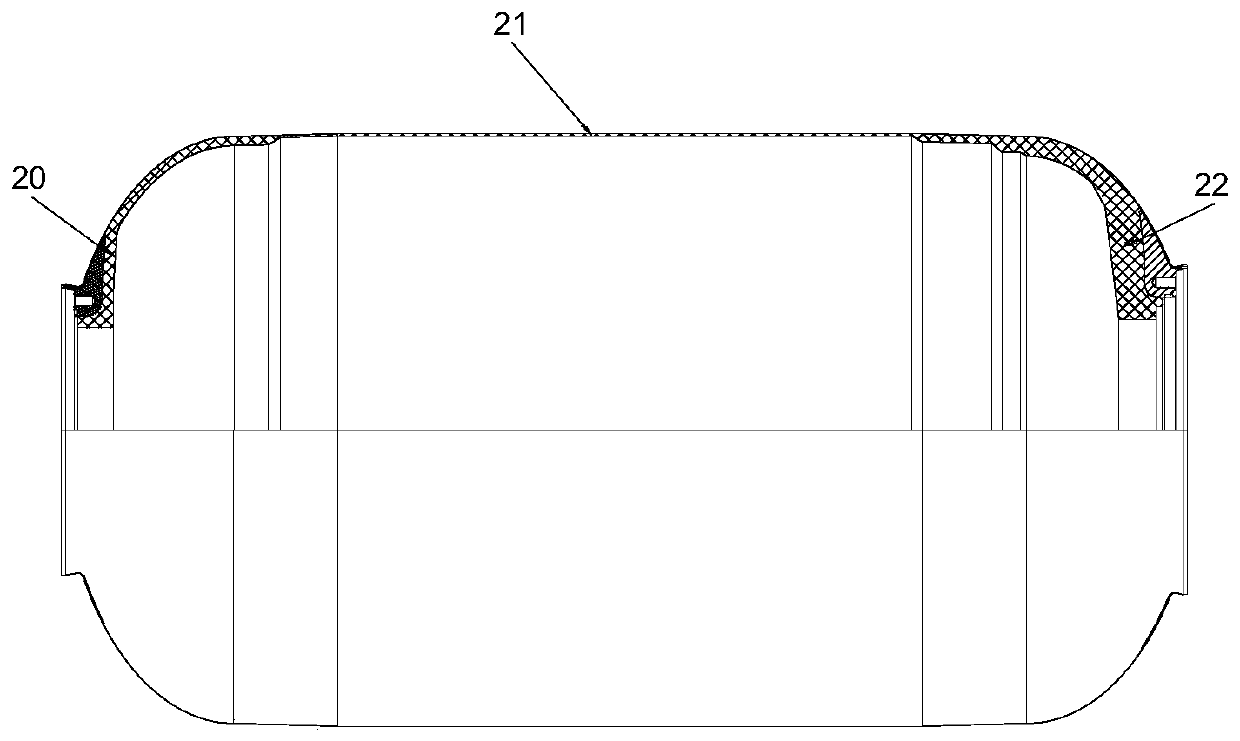

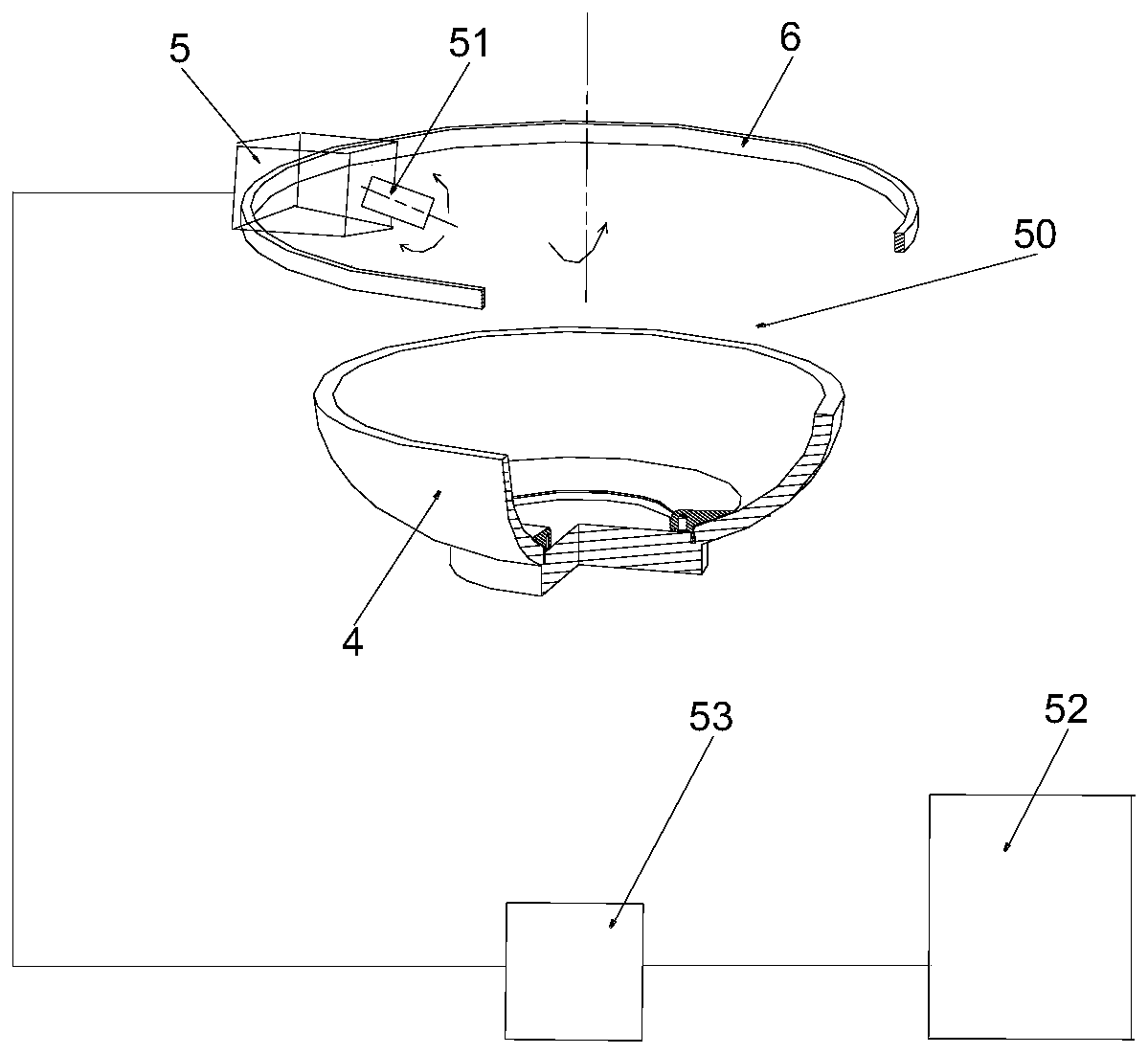

[0052] An embodiment of the present invention provides a method for forming a charge combustion chamber shell, see figure 1 and figure 2 As shown, the shell of the charge combustion chamber includes an outer shell 1 and a heat insulating layer 2, the heat insulating layer 2 is arranged on the inner surface of the outer shell 1, and the heat insulating layer 2 includes a front head heat insulating structure that is sequentially distributed and connected along the length direction of the outer shell 1 20. The thermal insulation structure 21 of the column section and the thermal insulation structure 22 of the rear head, wherein the thermal insulation structure 20 of the front header and the thermal insulation structure 22 of the rear header are formed separately, assembled on the winding mandrel 3, and then the thermal insulation structure 21 of...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com