Method for preparing metal nanobelt array with tip

A metal nanometer and cutting-edge technology, applied in the field of preparation of metal nanobelt arrays, can solve the problems of being unsuitable for large area of nanoarray structures, repeatable preparation, expensive manufacturing cost, strong dependence, etc., to improve electromagnetic properties and optical properties. Features, low cost, and promising effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0038] The method for preparing a sharp-pointed gold nanobelt array of the present invention includes the following steps:

[0039] (1) Preparation of densely arranged single-layer ordered PS nanospheres:

[0040] a) Prepare silicon wafers: select silicon wafers with a size of 25mm×25mm×0.5mm as the substrate, and put the silicon wafers in acetone, ethanol and deionized water for 30 minutes ultrasonic cleaning respectively, and then mix hydrogen peroxide and 98% concentrated sulfuric acid Prepare the solution and heat it to 80°C. Put the ultrasonically cleaned silicon wafers into it and soak for 1 hour. After soaking, rinse repeatedly to remove acidic substances. Then put the silicon wafers into a solution of ammonia, hydrogen peroxide and water, and heat to 80 ℃, soak for 1 hour, take out the silicon wafer and rinse repeatedly to obtain a clean and hydrophilic surface of the silicon wafer, which is placed in absolute ethanol for use;

[0041] b) Configure the PS nanosphere suspensi...

Embodiment 2

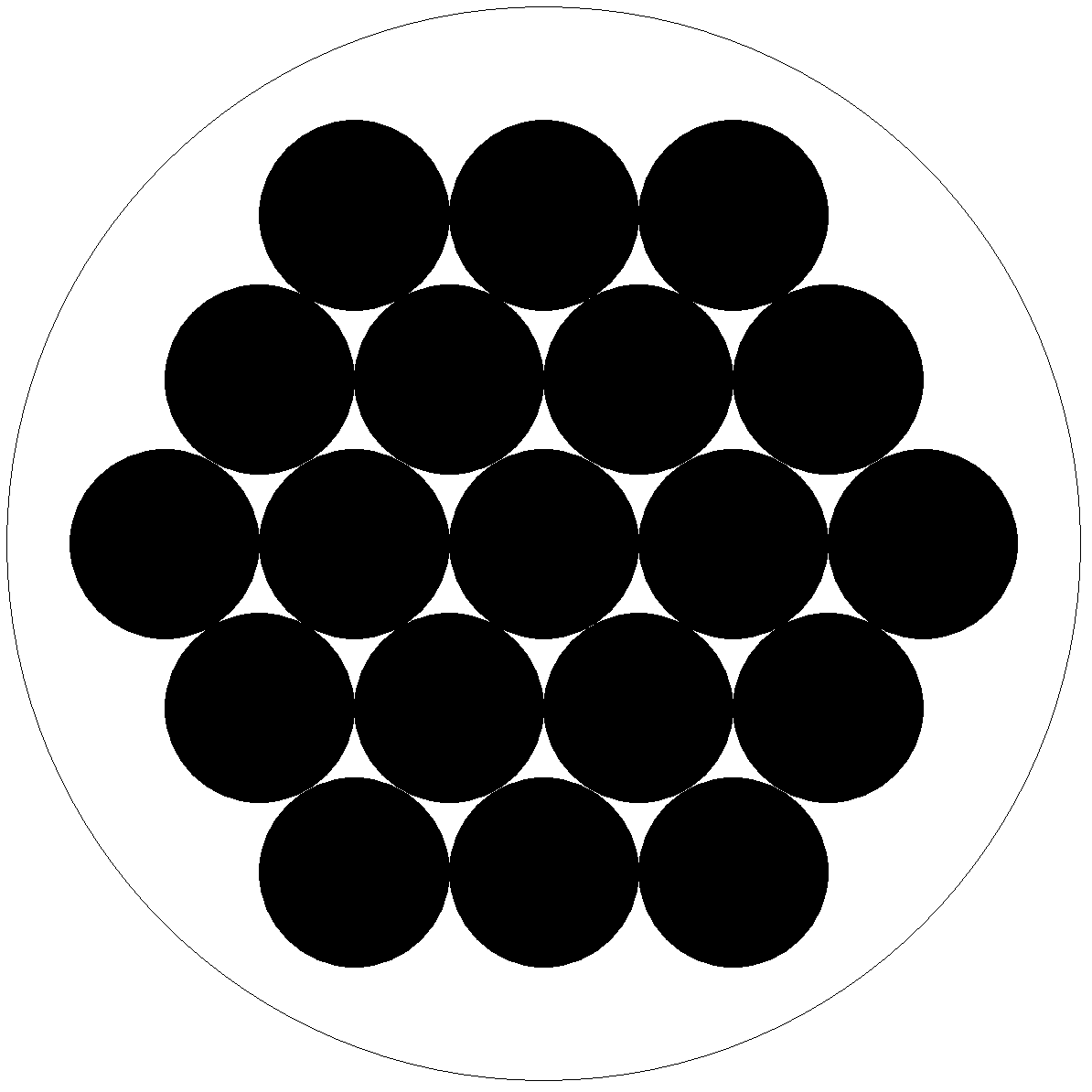

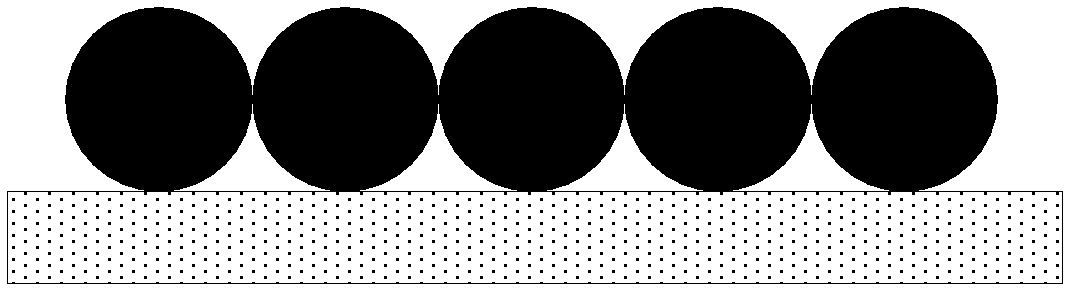

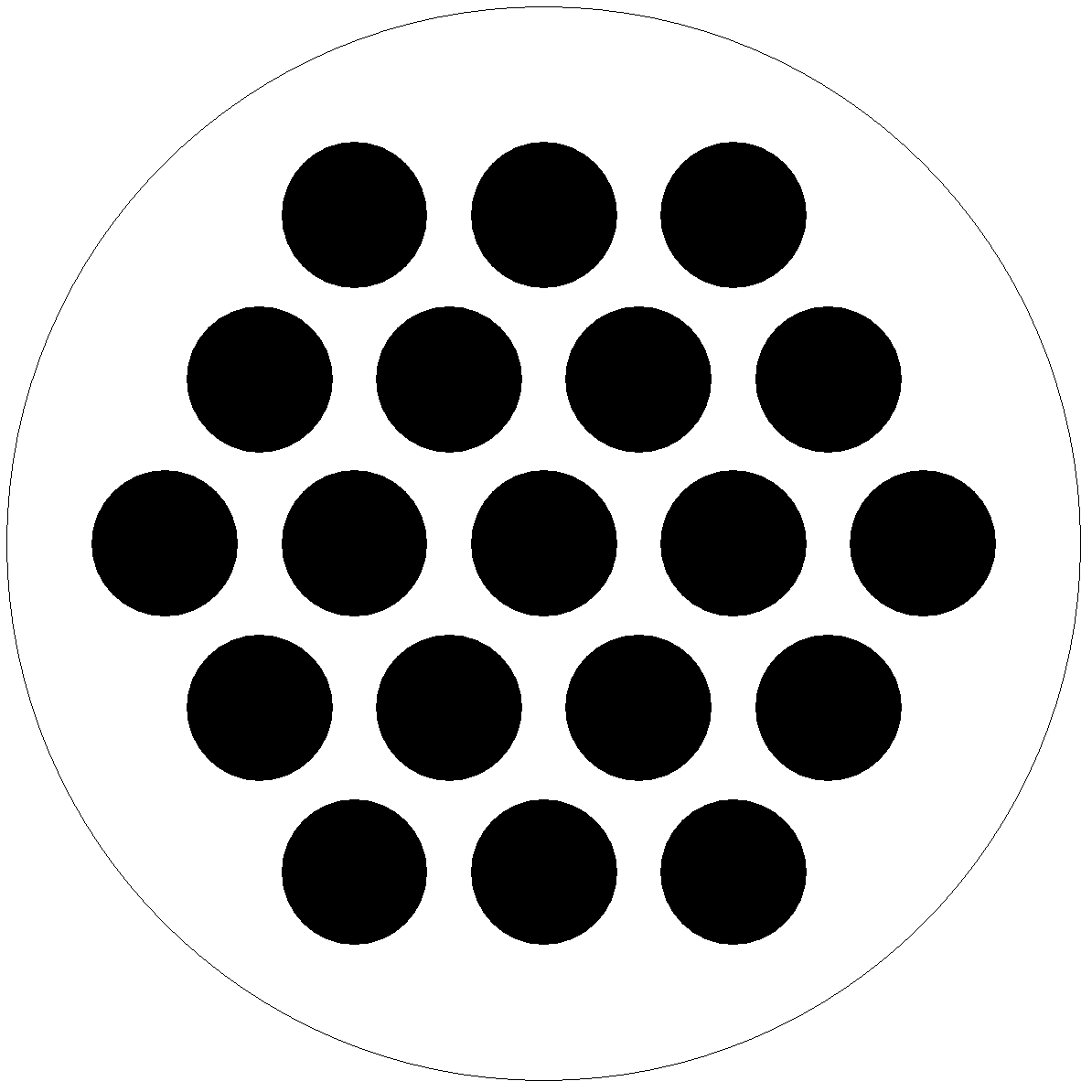

[0047] A method for preparing a gold nanobelt array with a tip on one side. The specific process steps and parameters are the same as in Example 1 (only in step (3) of the vapor deposition of the gold film, the silicon wafer is rotated 15° around its normal direction, See Picture 10 , The resulting gold-plated silicon wafer such as Picture 11 Shown), and finally get Picture 12 The gold nanoribbon array with a tip on one side is shown; Figure 13 As shown, because the silicon wafer is rotated 15° around its normal direction, there is a certain angle between the evaporation direction and the PS nanosphere (1, 0) or (0, 1) crystal orientation. Therefore, the metal nanobelt array obtained in this implementation has nanotips on one side.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com