Macromolecule resistance type humidity sensor element and its production method

A humidity sensor and manufacturing method technology, applied in the direction of material resistance, etc., can solve the problems of poor consistency of polymer temperature sensors, unsatisfactory long-term reliability, hindering practical application, etc., achieve excellent long-term stability, simple and reliable manufacturing process, The effect of good chemical atmosphere resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] Preferred embodiments of the present invention will be described in detail below in conjunction with the accompanying drawings.

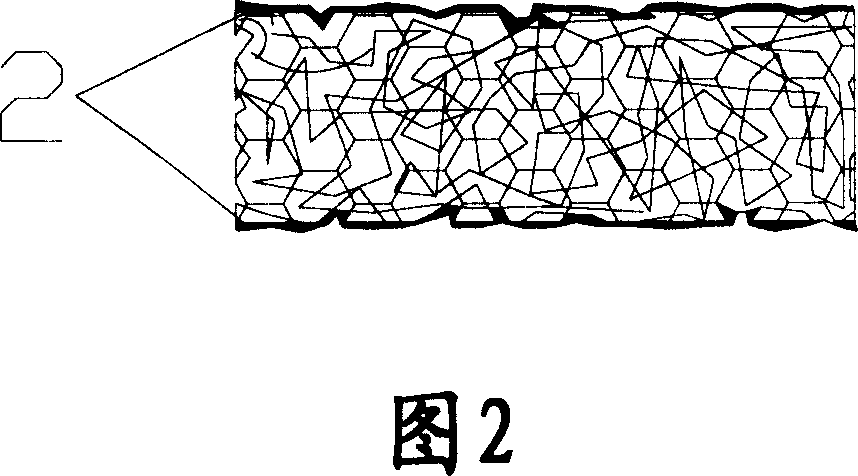

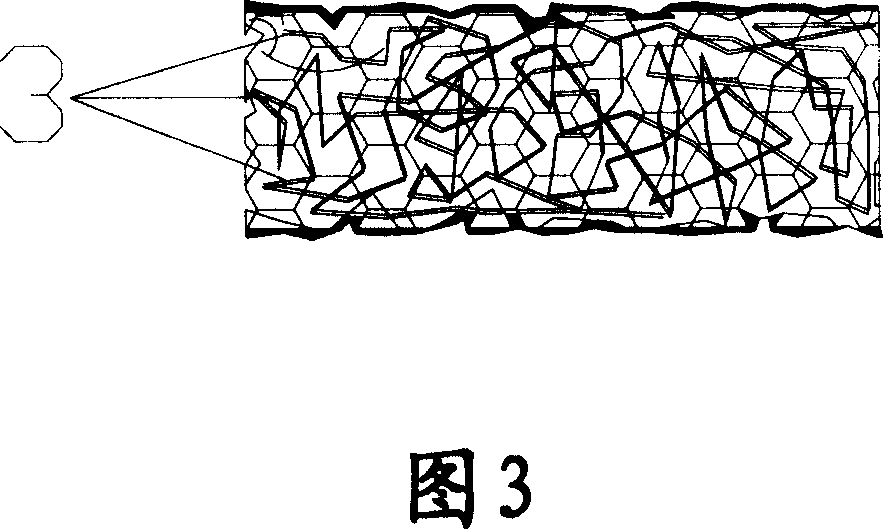

[0030] Fig. 3 is a cross-sectional view after electrodes are arranged on the upper and lower surfaces of the ceramic substrate and immersed in a moisture-sensitive medium, Fig. 4 is a top view of the humidity sensor element of the present invention, and Fig. 5 is a side view of the humidity sensor element of the present invention. As shown in Fig. 3, Fig. 4 and Fig. 5, polymer resistance type humidity sensor element of the present invention comprises:

[0031] The porous ceramic substrate 1, the electrode 2 and the three-dimensional humidity sensitive film 3 also include soldered pins 4. In the present embodiment, the porous ceramic substrate 1 is a silicon dioxide-doped aluminum oxide porous ceramic substrate (but not limited thereto, it can also be known to those skilled in the art and can be used for humidity sensors Any porous ceramic ma...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com