Cobalt and nitrogen doped carbon nanorod catalyst as well as preparation method and application thereof

A nitrogen-doped carbon, nanorod technology, applied in nanotechnology, solid electrolyte fuel cells, electrical components, etc., can solve the problems of high cost, limited battery industrialization and large-scale application, limited platinum resources, etc. The catalyst has the effect of low cost and uniform structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

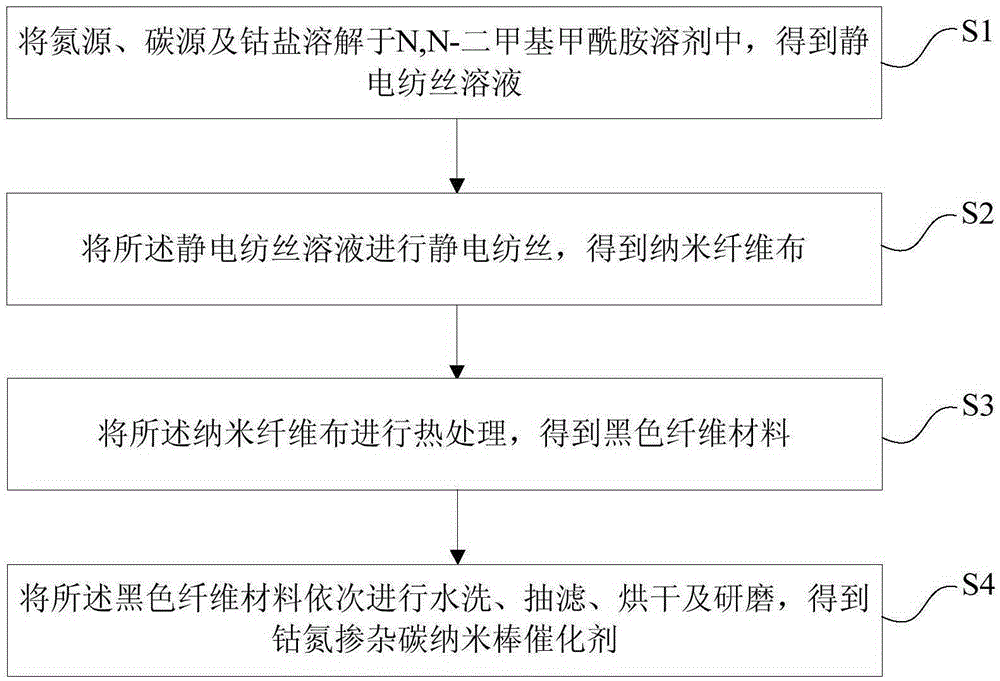

[0050] see figure 1 , the invention provides a method for preparing a cobalt-nitrogen-doped carbon nanorod catalyst, the preparation method of the cobalt-nitrogen-doped carbon nanorod catalyst comprises the following steps:

[0051] 1) dissolving nitrogen source, carbon source and cobalt salt in N,N-dimethylformamide solvent to obtain electrospinning solution;

[0052] 2) Electrospinning the electrospinning solution to obtain nanofiber cloth;

[0053] 3) heat-treating the nanofiber cloth to obtain a black fiber material;

[0054] 4) The black fiber material is sequentially washed with water, suction filtered, dried and ground to obtain a cobalt nitrogen-doped carbon nanorod catalyst.

[0055] In step 1), see figure 1 In the S1 step, the nitrogen source, the carbon source and the cobalt salt are dissolved in N,N-dimethylformamide (DMF) solvent to obtain an electrospinning solution.

[0056] As an example, the nitrogen source is dimethylaminopyridine (DMPA), tetrazolium, dic...

Embodiment 1

[0079] 1. Weigh 2.0g DMAP powder and ultrasonically dissolve it in 12.5g N,N dimethylformamide (DMF) solvent, ultrasonic time 10min, add 1.0g PAN powder, stir and dissolve for 2 hours in a water bath at 60°C, and form a light yellow transparent solution. Finally, add 100 mg of cobalt acetate, stir and dissolve at room temperature for 2 hours, and finally make a homogeneous electrospinning solution;

[0080] 2. Electrospinning the electrospinning solution to form a nanofiber cloth. The electrospinning voltage (i.e. the voltage of high voltage static electricity) is 17kV, the spinning rate (i.e. the advancing speed of the electrospinning solution) is 0.7ml / h, and the distance between the injection end of the syringe and the surface of the receiving plate is 12cm;

[0081] 3. Place the nanofiber cloth in an open quartz boat and dry it in a vacuum oven at 60°C for 12 hours under vacuum;

[0082] 4. Transfer the dried nanofiber cloth to a muffle furnace, raise the temperature to ...

Embodiment 2

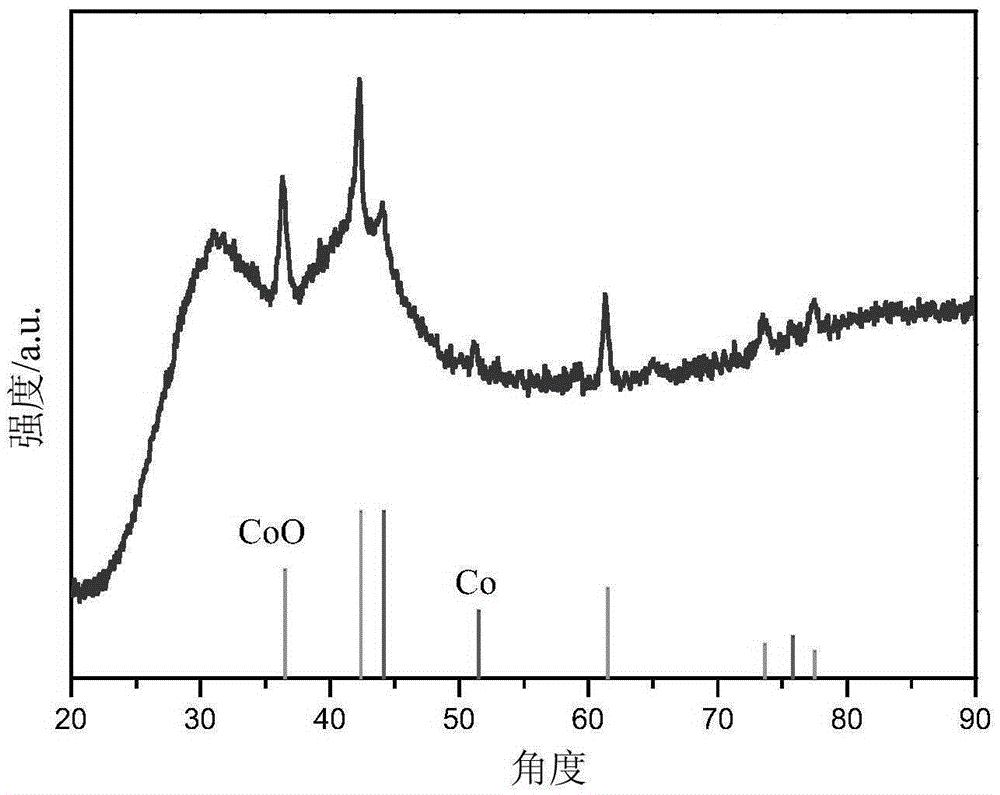

[0093] 1. Place the Co / N / C nanorod catalyst prepared by the steps described in Example 1 in 0.5M sulfuric acid solution, stir at 60°C for 24 hours to completely dissolve the nanoparticles of metal cobalt and its oxides on the surface .

[0094] 2. Wash the acid-washed Co / N / C catalyst with ultrapure water to neutrality, filter with suction to obtain a filter cake, and vacuum-dry it at 60°C for 12 hours to obtain the acid-washed A-Co / N / C nanorod catalyst .

[0095] see Figure 10 to Figure 13 , Figure 10 It is the TEM figure of the cobalt-nitrogen-doped carbon nanorod catalyst after acidification in the present embodiment; Figure 11 It is the element mapping diagram under the dark field of the acidified cobalt-nitrogen-doped carbon nanorod catalyst in this embodiment; Figure 12 It is the XPS full spectrum of the cobalt-nitrogen-doped carbon nanorod catalyst after acidification in the present embodiment; Figure 13 for Figure 12 The XPS diagram of N1s in the middle.

...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com