Composite material anti-layering composite adhesive membrane and preparation method of membrane

A composite material and anti-delamination technology, applied in the field of materials, can solve problems such as difficult control of product quality consistency, low degree of standardization of production process, serious fiber damage, etc., to improve anti-delamination ability and improve product quality consistency , improve the functional effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

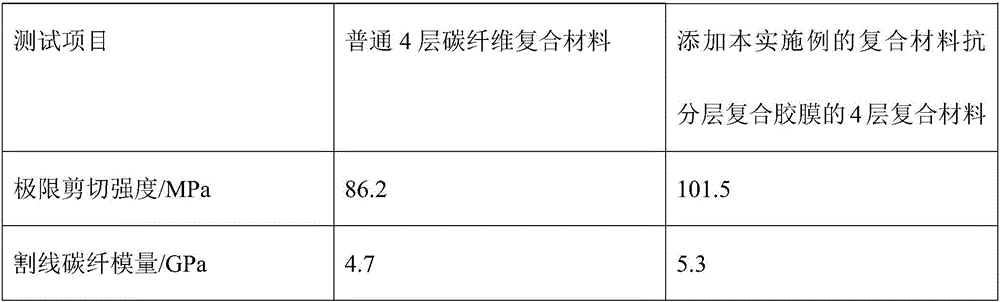

Embodiment 1

[0020] Step 1: Grind the chopped carbon fiber with a length of 10-30 mm into a ground carbon fiber through a ball mill. The ground carbon fiber is a rigid needle-like body with sharp ends, and its length is between 0.1-2 mm. The degree is between 0.5 and 6 μm (microns).

[0021] Step 2: by mass fraction, with 10% ground carbon fiber, 75% thermosetting epoxy resin, 12% polyurethane TPU micropowder, 3% reaction accelerator (acid anhydride curing agent and potassium hydroxide, the quality of both The ratio is 55:45) to form a mixed material, and then placed at 70 ° C for 30 minutes of continuous heat treatment to form a mixture, which is sandwiched between the upper release film and the lower release paper, and passed through the pressure roller to form a 3mm thick The composite adhesive film is the anti-delamination composite adhesive film of the composite material. The anti-delamination composite adhesive film of composite material is torn off the upper release film and the lo...

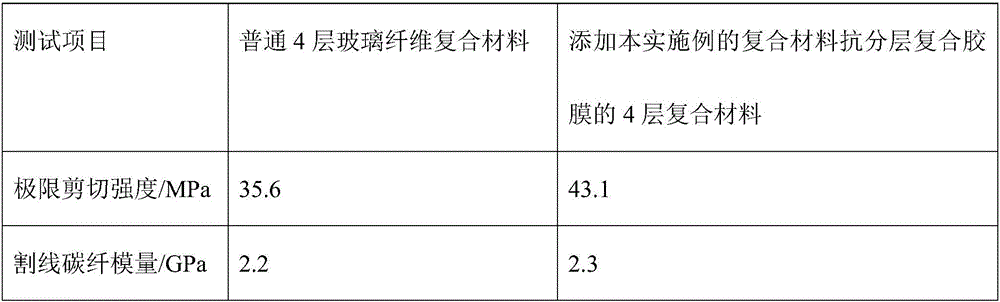

Embodiment 2

[0028] Step 1: use a ball mill to grind the chopped glass fibers with a length of 10-30mm through a ball mill grinding process, and grind them into ground glass fibers with an average length of 0.1mm-2mm, which are characterized by sharp rigid needles at both ends, and The length is between 0.1 and 2 mm, and the fineness of the ground glass fiber is between 1 and 8 μm (micrometer).

[0029] Step 2: by mass fraction, with 15% ground carbon fiber, 65% phenolic resin, 18% modified polypropylene PP adhesive film, 2% reaction accelerator (acid anhydride curing agent and potassium hydroxide, both The mass ratio is 55:45) to form a mixed material, and then placed at 60 ° C for 30 minutes of continuous heat treatment to form a mixture, which is sandwiched between the upper release film and the lower release paper, and formed by pressing rollers The 3.5mm thick composite adhesive film is the anti-delamination composite adhesive film of the composite material. The anti-delamination com...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com