Production method of medium-chromium ferrite stainless steel cold-rolled strip steel

A technology of cold-rolled strip steel and production methods, applied in the direction of rolls, metal rolling, metal rolling, etc., which can solve the problems of low surface roughness, dirty surface pickling, and difficult configuration of roll roughness, etc., and achieve process stability High reliability, high product quality consistency, and improved yield

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

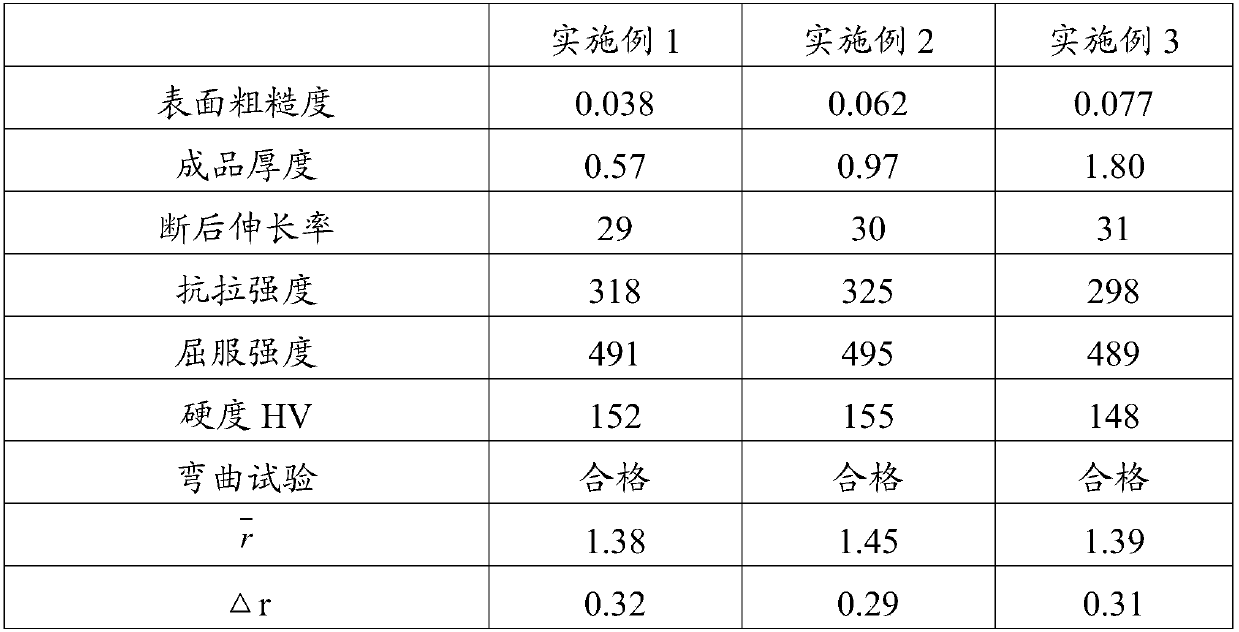

Embodiment 1

[0046] The thickness of 430 type hot-rolled coil is 3.0mm. After being welded by laser welding machine, it is rolled by six-high five-stand continuous rolling mill. The total deformation rate of rolling is 81%, the thickness of the finished product is 0.57mm, and the deformation rate of 1# to 5# racks gradually decreases, which are 30%-35%, 27%-33%, 25%-30%, 22%-27% , 18%-23%. The work roll diameter of the six-high five-stand continuous rolling mill is 460mm, and the roughness of the work rolls corresponding to the 1# to 5# stands is 0.8μm, 0.5μm, 0.5μm, 0.2μm, 0.06μm.

[0047] The rolled steel strip is subjected to continuous annealing treatment, the final annealed steel strip temperature is 880°C, cooled to room temperature by air cooling and water cooling, the annealing TV value is 95, and the annealing speed is 105m / min.

[0048] After annealing, the steel strip is subjected to continuous pickling treatment, and first uses a sodium sulfate aqueous solution to conduct neut...

Embodiment 2

[0052] The thickness of 430 type hot-rolled coil is 4.0mm. After being welded by laser welding machine, it is rolled by six-high five-stand continuous rolling mill. The total deformation rate of rolling is 76%, the thickness of the finished product is 0.97mm, and the deformation rate of 1# to 5# racks gradually decreases, which are 28%-33%, 26%-31%, 23%-28%, 20%-25% , 16%-21%. The work roll diameter of the six-high five-stand continuous rolling mill is 465mm, and the roughness of the work rolls corresponding to the 1# to 5# stands is 0.9μm, 0.5μm, 0.5μm, 0.2μm, 0.1μm.

[0053] The rolled steel strip is subjected to continuous annealing treatment, the final annealed steel strip temperature is 880°C, cooled to room temperature by air cooling and water cooling, and the annealing TV value is 95.

[0054] After annealing, the steel strip is subjected to continuous pickling treatment, and first uses a sodium sulfate aqueous solution for neutral salt electrolysis, with a density of ...

Embodiment 3

[0058] The thickness of 430 type hot-rolled coil is 6.0mm. After being welded by laser welding machine, it is rolled by six-high five-stand continuous rolling mill. The total deformation rate of rolling is 70%, the thickness of the finished product is 1.80mm, and the deformation rate of 1# to 5# racks gradually decreases, which are 25%-30%, 24%-29%, 20%-25%, 17%-23% , 16%-21%. The work roll diameter of the six-high five-stand continuous rolling mill is 462mm, and the roughness of the work rolls corresponding to the 1# to 5# stands is 1.0μm, 0.6μm, 0.6μm, 0.3μm, 0.12μm.

[0059] The rolled steel strip is subjected to continuous annealing treatment, the final annealed steel strip temperature is 880°C, cooled to room temperature by air cooling and water cooling, and the annealing TV value is 95.

[0060] After annealing, the steel strip is subjected to continuous pickling treatment, firstly using sodium sulfate aqueous solution for neutral salt electrolysis, with a density of 1....

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

| concentration | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com