Intelligent final assembly production line for metering instrument

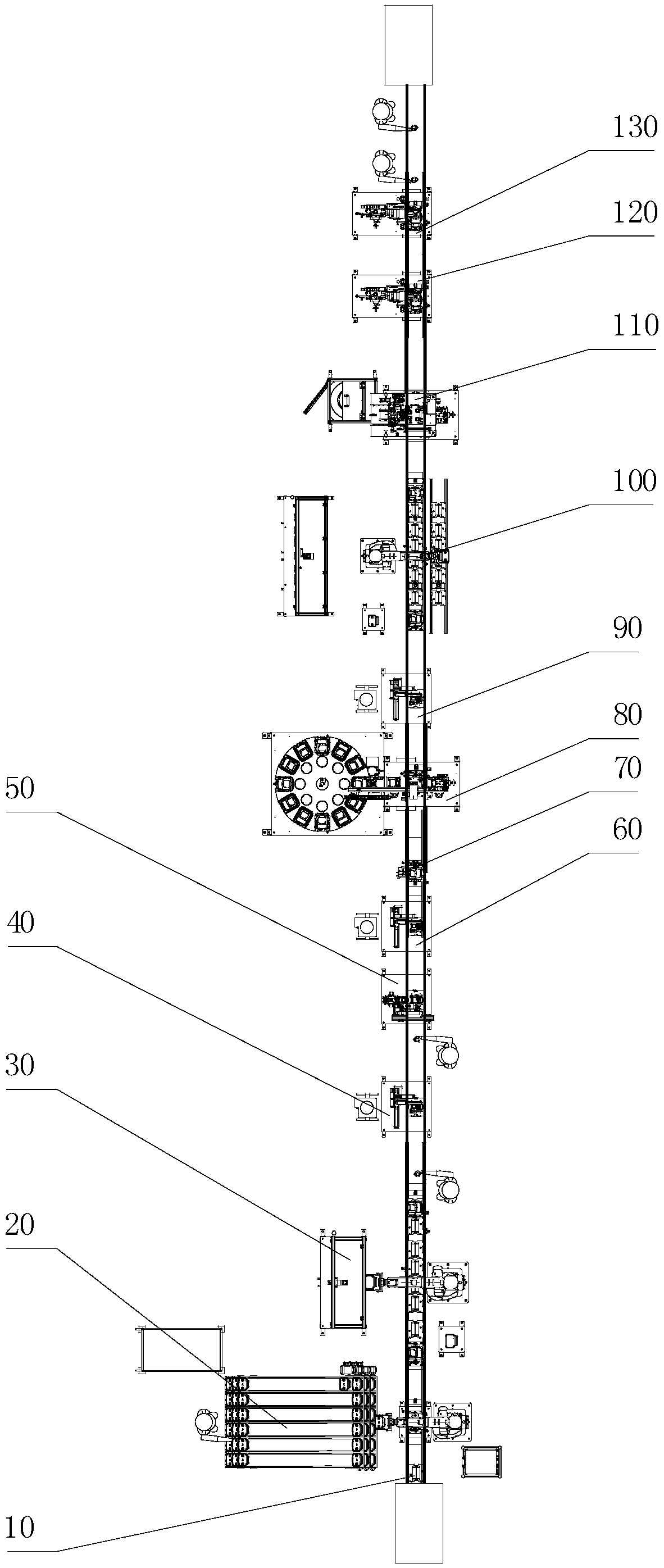

A measuring instrument and production line technology, which is applied in the field of intelligent assembly and testing of measuring base meters, can solve problems such as low manual production efficiency, poor equipment compatibility, difficulty in ensuring assembly accuracy and testing accuracy, and achieve improved product quality consistency, The effect of improving production efficiency and reducing the number of operators

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0091] The present invention will be further described in detail below in conjunction with the accompanying drawings and specific preferred embodiments.

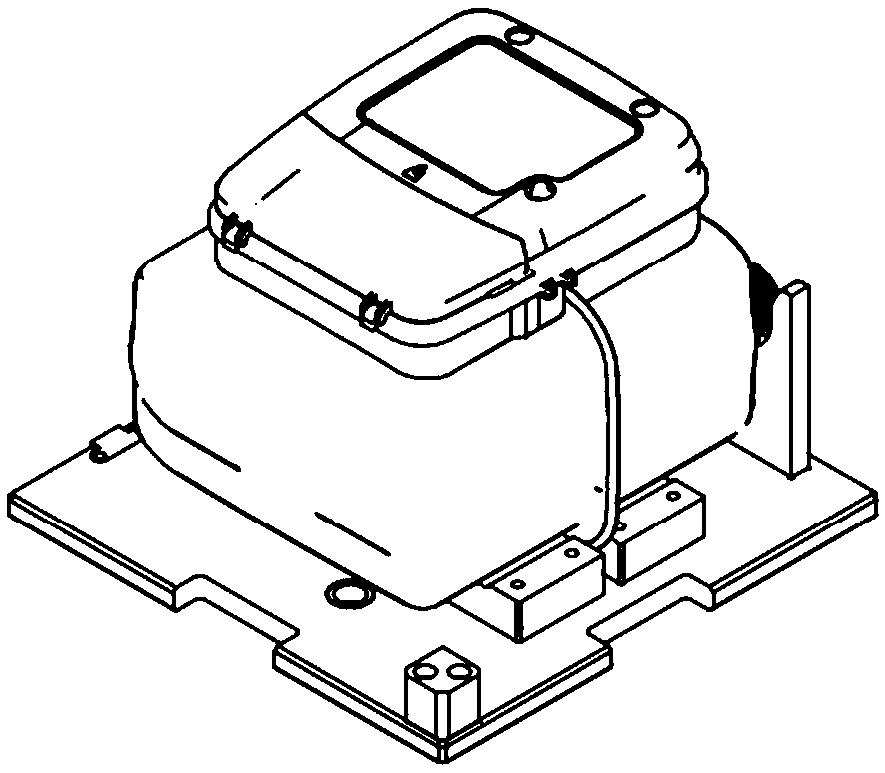

[0092] Such as Figure 25 , Figure 28a and Figure 28b As shown, the measuring instrument 12 includes a base meter body, a nameplate 126 to be assembled with the base meter body, a main control board 127 , a cover 128 and a plastic seal 129 .

[0093] The front panel of the base meter body is provided with a character wheel 124 and a card groove 122, the middle part of the base meter body is provided with a waist line 125, and the top surface of the base meter body is provided with two air vents 121; the nameplate is provided with a nameplate screw hole 1261 The cover is provided with a cover screw hole 1281, a battery cover hole 1283 and an openable battery cover 1282; the number of cover screw holes 1281 is preferably four, and the four cover screw holes are in an isosceles trapezoidal structure.

[0094] In addition, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com