Self-moving steel structure workshop

A self-moving, steel structure technology, applied in building construction, industrial construction, construction, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

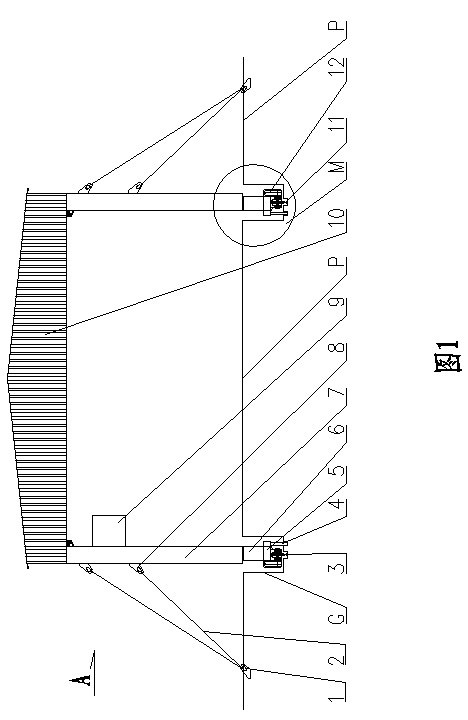

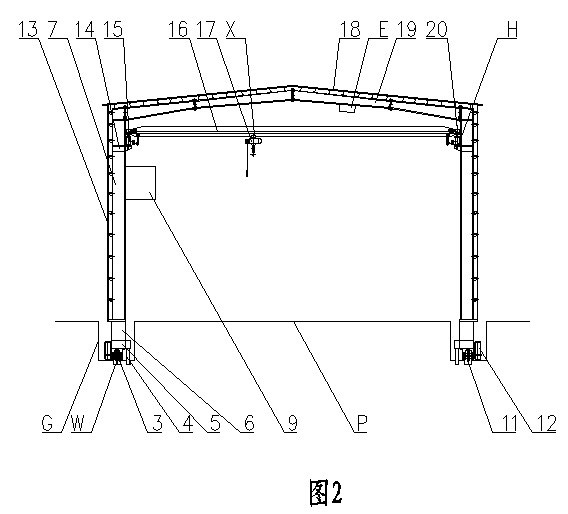

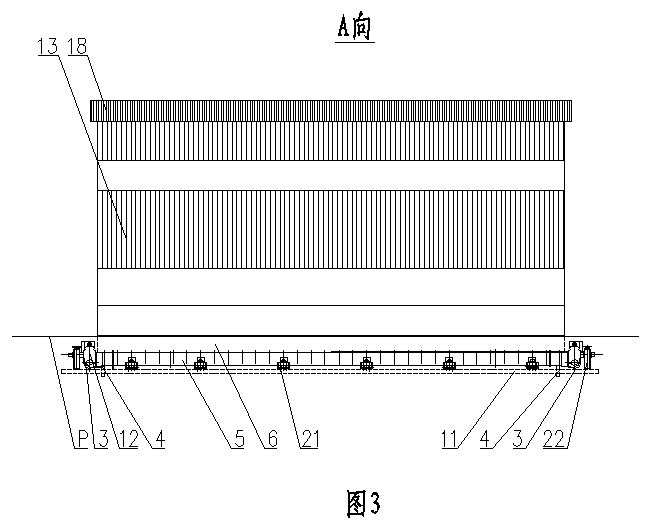

[0018] The specific implementation of the present invention will be described below in conjunction with the accompanying drawings.

[0019] refer to figure 1 , figure 2 , image 3 , excavate two parallel base trenches G on the ground P, lay track 11, install traction roller 3 and load roller 21 on the ground beam 5 bottom surface of movable base, cooperate with track 11 and be installed in the base trench G. The positioning oil cylinder 4 is installed inside the end of the ground beam 5, and the speed reducer 12 is installed outside. The steel column 7 of the steel structure workshop is fixed and vertically installed on the joist 6, and the top is connected with the top beam 19 to form a portal frame structure, which is manufactured by welding H steel. The top beam 19 is a herringbone-shaped steeple slope with a slope of 10%. The top surface is paved with a top panel 18 made of a hot-dip galvanized color steel plate, and the outside of the steel column 7 is equipped with ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com