Patents

Literature

66 results about "Workshop building" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Industrial golden cicada breeding method

The invention relates to an inset breeding technology, in particular to an artificial golden cicada breeding method. The method includes the steps of industrial hatching workshop building, wood planting and specific breeding methods. The industrial hatching workshop building includes the steps that (1) a cicada egg branch storage chamber is built, wherein the cicada egg branch storage chamber is a plastic greenhouse, greenhouse cloth of the cicada egg branch storage chamber is double layers of plastic films, one layer of the plastic film is black, and multi-layer storage racks used for storing cicada egg branches are arranged in the cicada egg branch storage chamber; (2) a larvae hatch room is built, wherein the larvae hatch room is built beside the cicada egg branch storage chamber or integrally connected with the cicada egg branch storage chamber, the larvae hatch room is a common plastic greenhouse, a plurality of hatch pools are built in the larvae hatch room, and the dimension of an inner cavity of each hatch room is 100 cm*100 cm*50 cm. The industrial golden cicada breeding method enables the growth period of golden cicadas to be 18 months ahead of the growth period of original wide golden cicadas, the hatching period is shortened to about 35 days from original one year, and the survival rate can reach above 80%. The golden cicadas bred through the method are large in size, meaty, full and high in yield.

Owner:XUZHOU GUANGQIN RICE IND

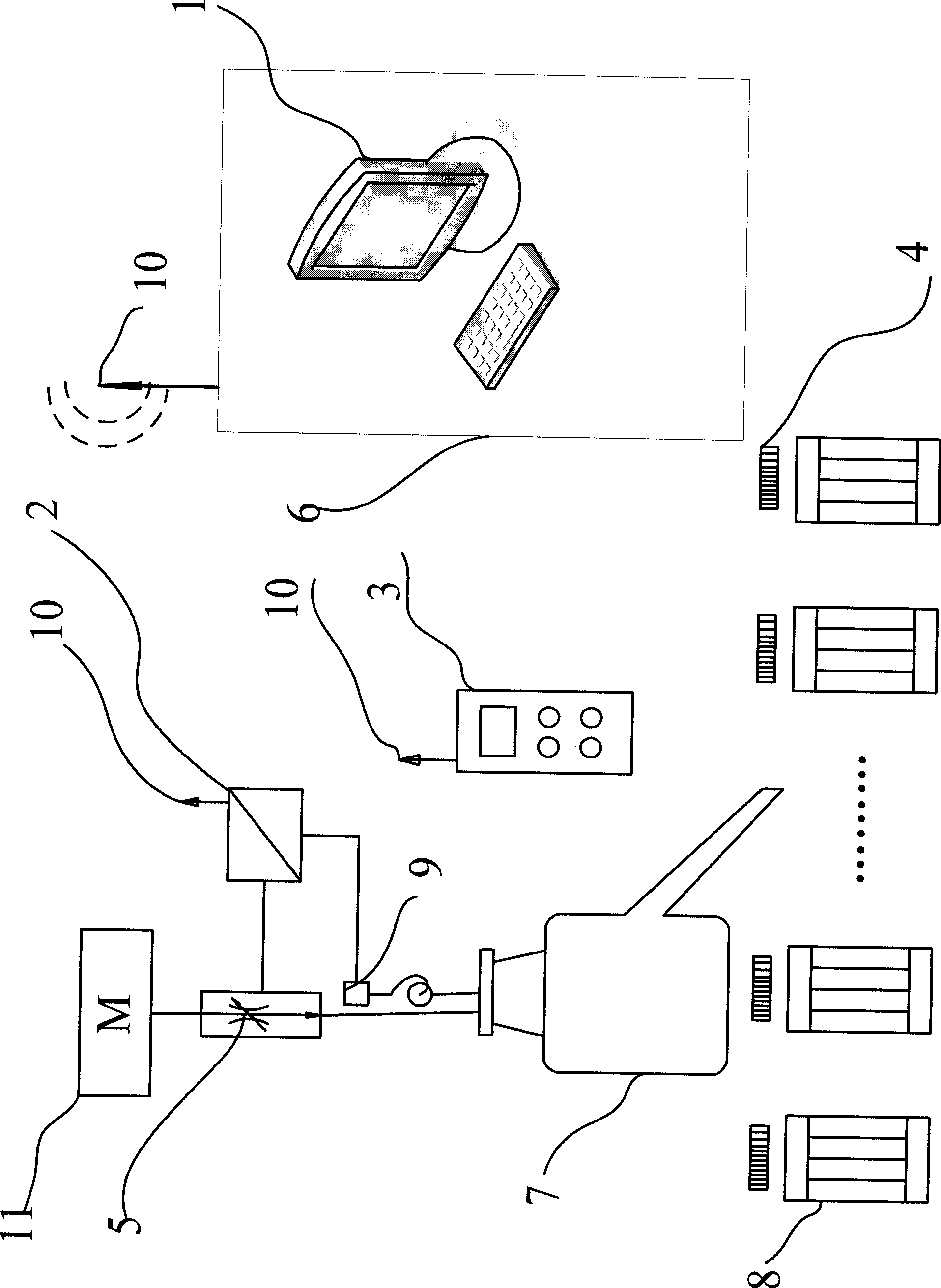

Aluminum cell wireless automatic aluminum discharging control appliance

InactiveCN101423963AControl automatic aluminum tapping workRealize automatic collectionCurrent cellEngineering

The invention discloses a wireless automatic aluminum discharge control device for an aluminum cell, which comprises a control computer and database analysis software, an aluminum discharge control device, a wireless operating control handle, a cell number recognizer and a controllable electric control valve, wherein the wireless automatic aluminum discharge control device is arranged inside an electrolytic aluminum workshop and used for realizing wireless communication with the control computer, executing the aluminum discharge control task, acquiring aluminum discharge data and being communicated with the wireless operating control handle; the cell number recognizer is arranged on a workshop building girder corresponding to each cell in the electrolytic aluminum workshop and used for automatically judging the current cell number; the controllable electric control valve is arranged on the aluminum discharge control device and used for adjusting the actual pressure in an aluminum discharge ladle; the wireless operating control handle is provided with a display screen and control keys; and the control computer and the aluminum discharge control device adopt the wireless means for data switching. The wireless automatic aluminum discharge control device for the aluminum cell can realize automatic acquisition and real-time remote transmission of aluminum discharge data of the cell, controls the automatic aluminum discharge operation of a single electrolytic cell, improves the aluminum discharge control precision of the cell, is simple to use and convenient to operate, and has a friendly interface.

Owner:北京核心动力科技有限公司

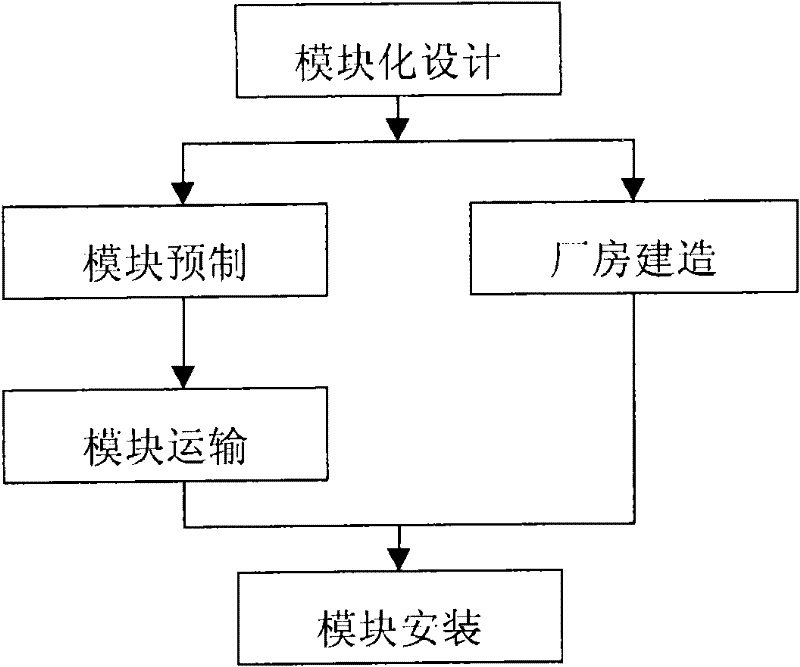

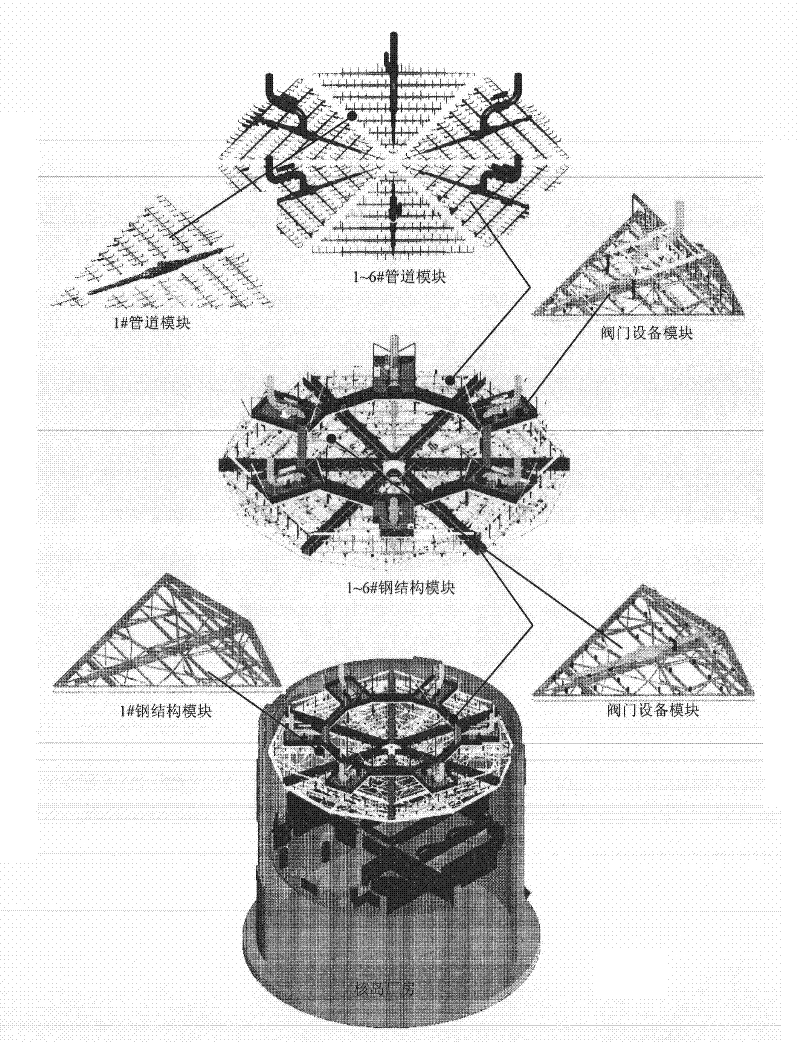

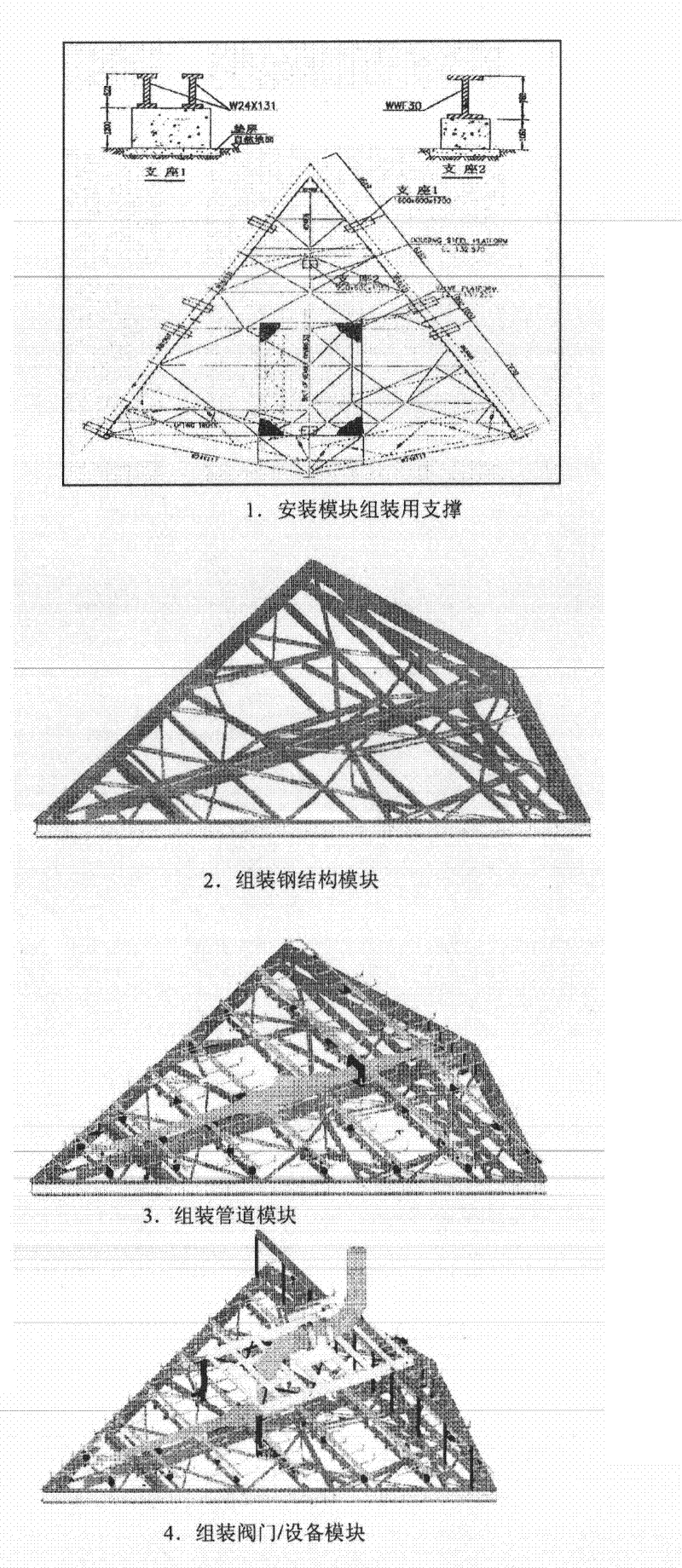

Modularization construction method for nuclear power station nuclear island

InactiveCN101752017AImprove construction qualityGuarantee the construction qualityNuclear energy generationNuclear power plant detailsNuclear powerArchitectural engineering

The invention discloses a modularization construction method for a nuclear power station nuclear island, comprising the following steps: a modularization design step, carrying out the modularization design on an upstream engineering design of the nuclear power station nuclear island so as to divide and / or combine a plurality of units in the nuclear power station nuclear island into a plurality of modules and connecting units among the modules and between the modules and the outside; a module prefabrication step, prefabricating each module in a workshop manufacturing manner; a workshop building step, building workshops of a nuclear island building by an open-top construction method; and a module installation step, installing the prefabricated modules at the pre-designed positions of the workshops. The invention greatly improves the prefabrication rate of workshop manufacture of the nuclear power station nuclear island engineering, improves the construction quality of the nuclear island engineering, accelerates the engineering progress and achieves the purpose of reducing the whole construction cost.

Owner:CHINA NUCLEAR IND 23 CONSTR

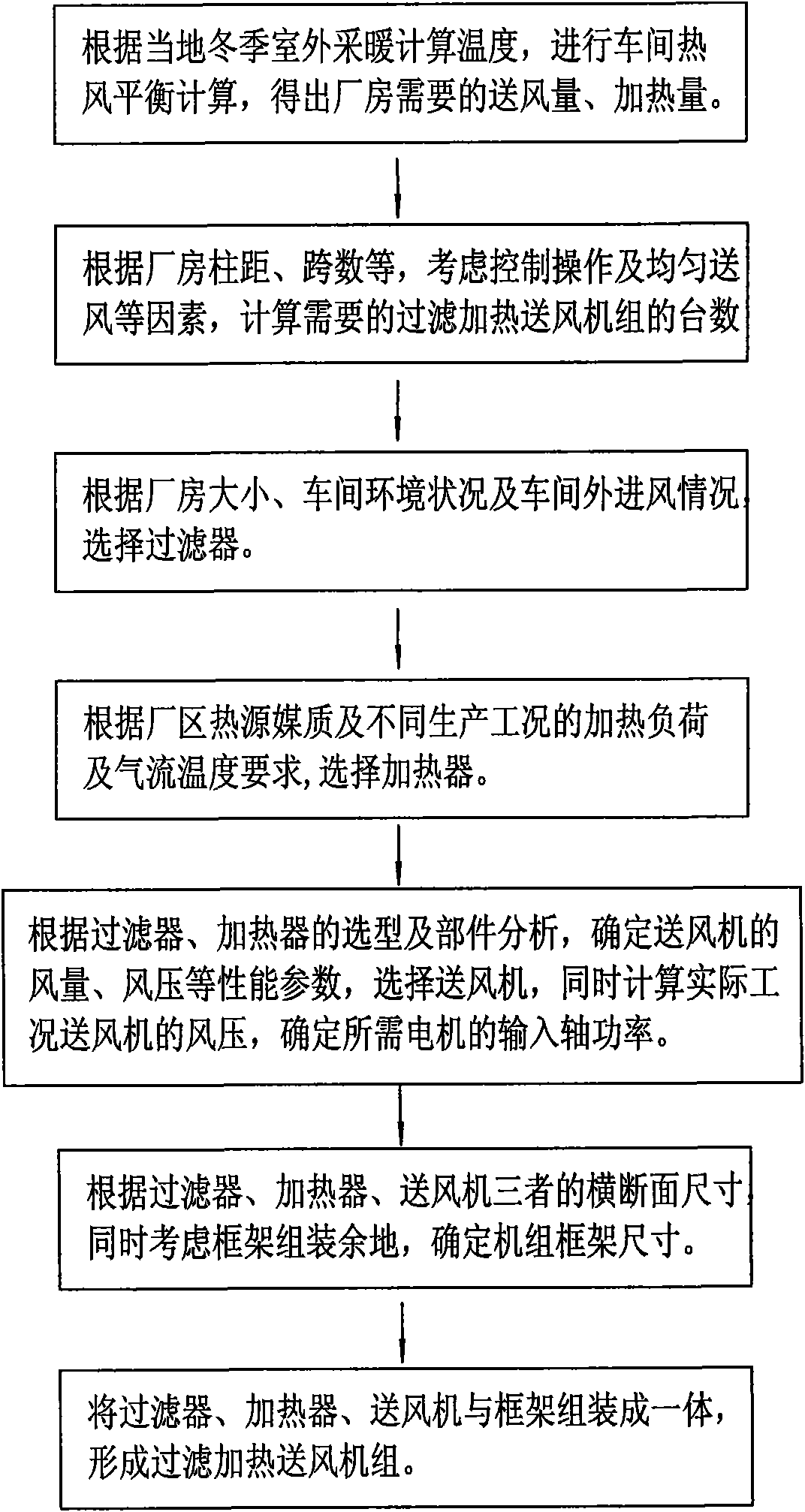

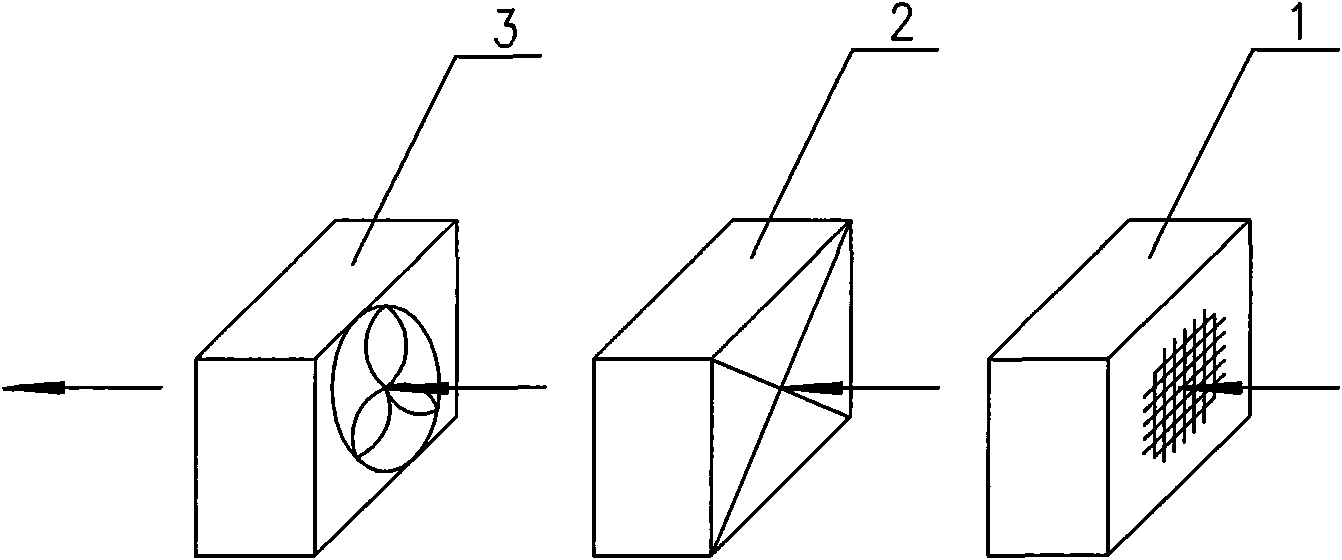

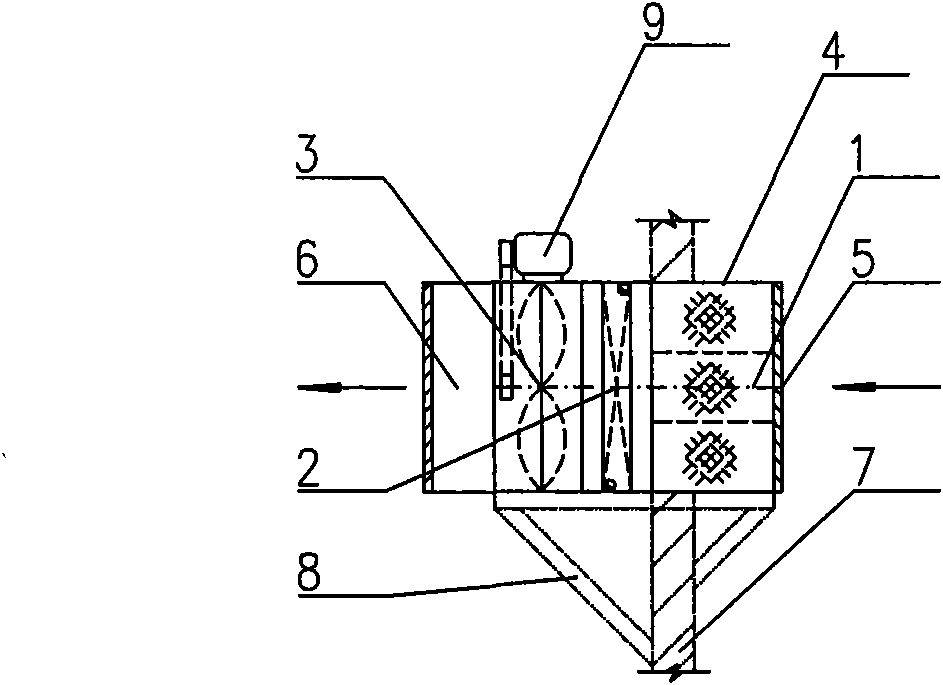

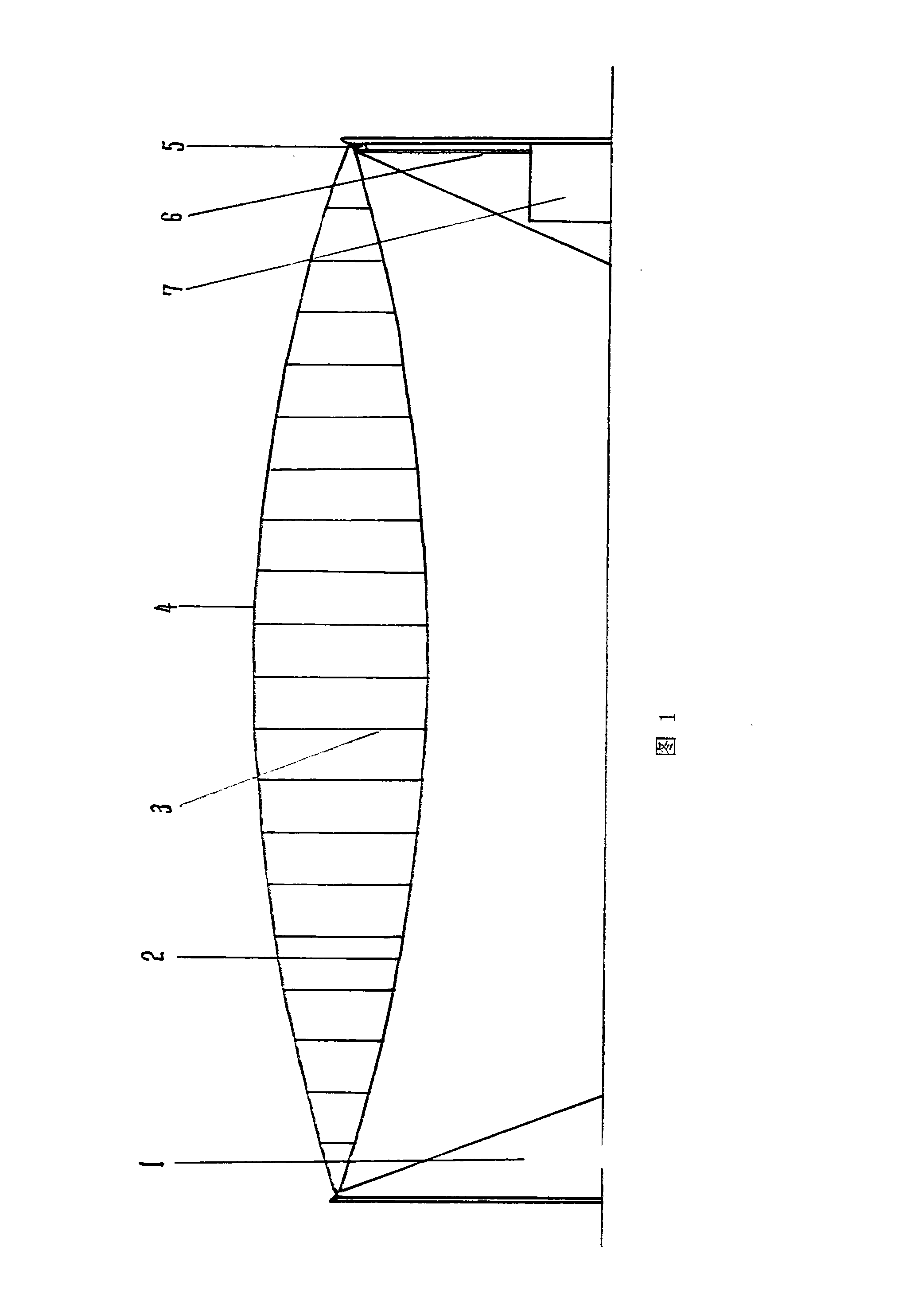

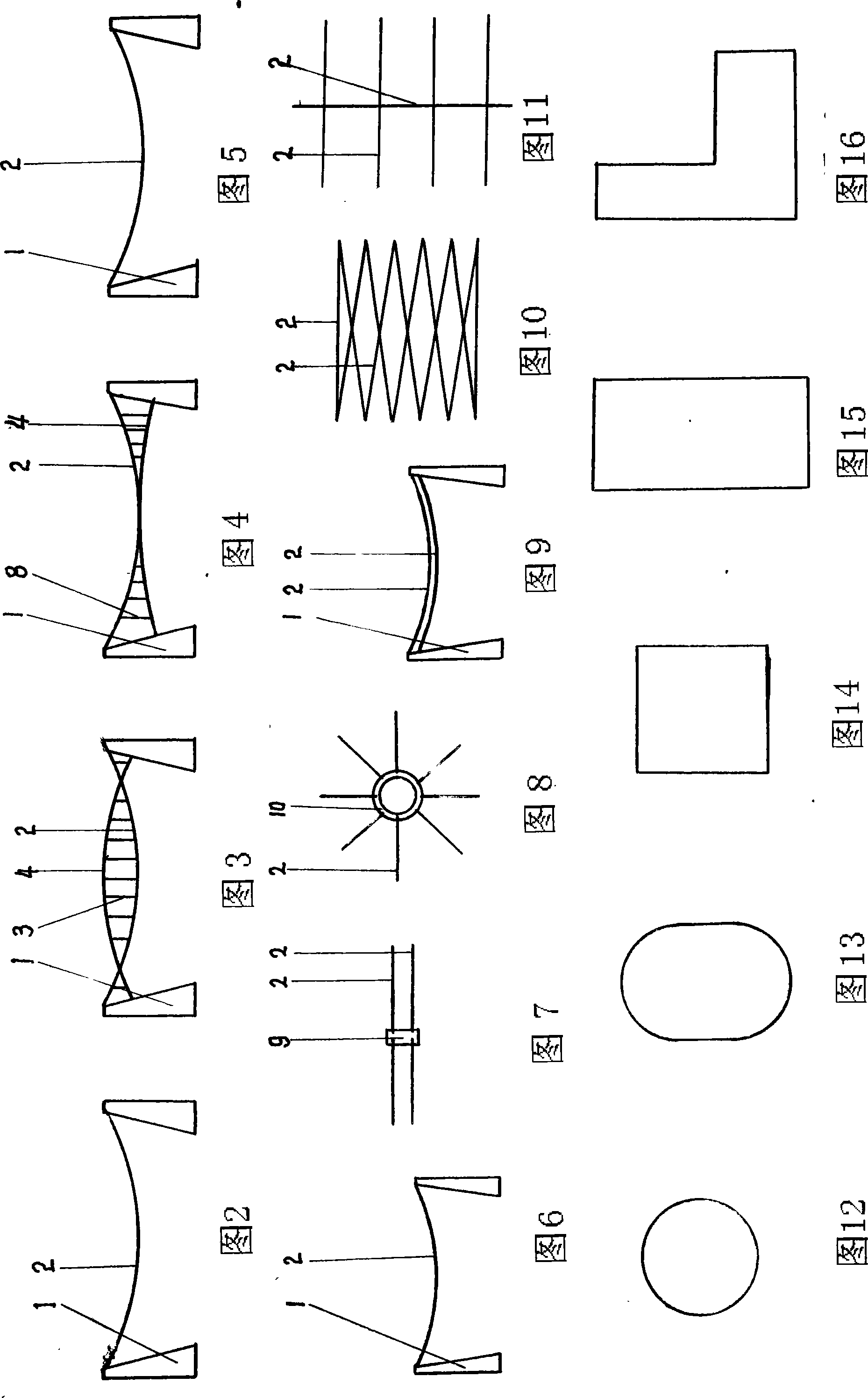

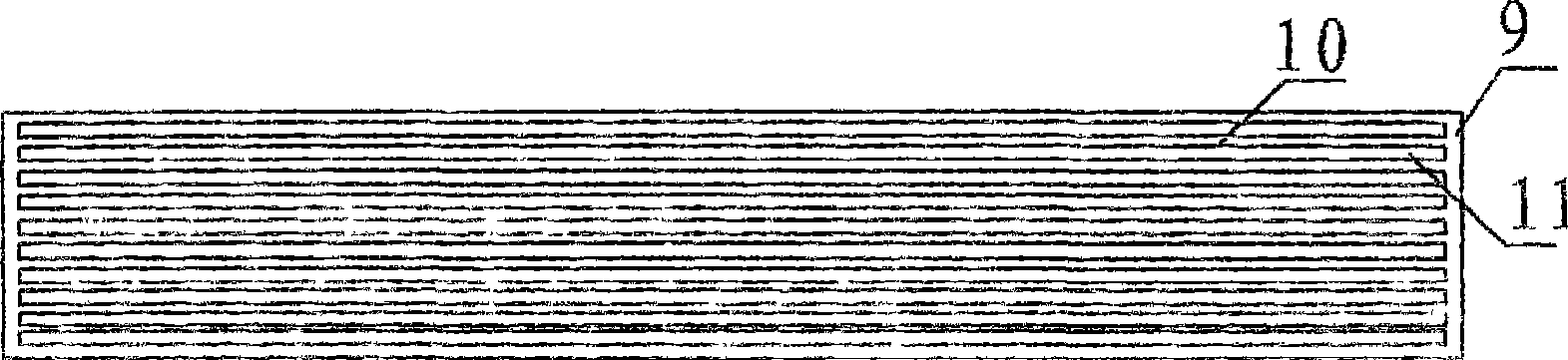

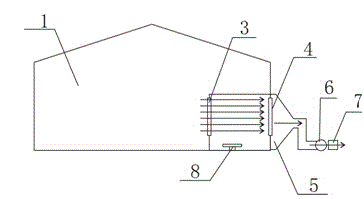

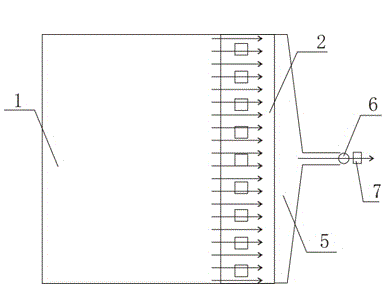

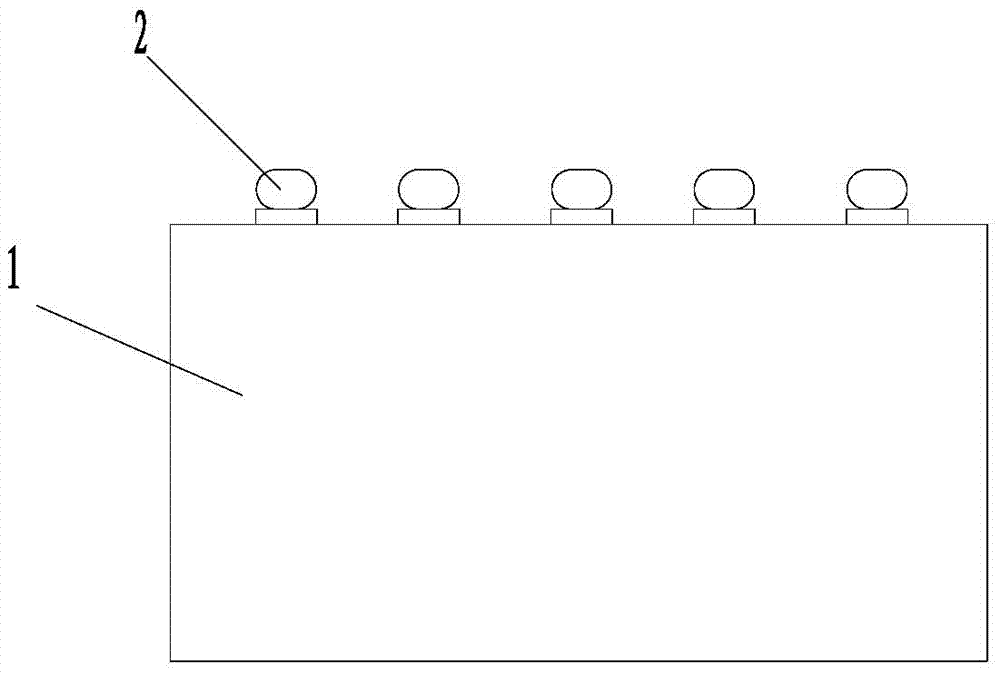

Assembling unit for filtering, heating and blowing and configuration method thereof

InactiveCN101539317AReduce energy consumptionAvoid inhalationLighting and heating apparatusSpace heating and ventilation detailsFresh airEngineering

The invention discloses an assembling unit for filtering, heating and blowing and a configuration method thereof. The assembling unit for filtering, heating and blowing comprises a filter, a heater and a blower which are arranged in the same frame, wherein, the air outlet of the filter is communicated with the air inlet of the heater; the air outlet of the heater is communicated with the air inlet of the blower; the blowing motor of the blower is arranged at the top of the frame; a counter-flow louver is arranged at the air inlet of the filter; and a static-pressure tank is arranged at the air outlet of the blower. By arranging the assembling unit for filtering, heating and blowing according to the requirements for the ventilation system of a factory , the invention has the advantages of compact, small and exquisite structure and convenient and flexible layout; by combining with the outer wall of the workshop building structure, the pipelines for the ventilation system are dispensable, so that the interior floor is not occupied and the workshop is less occupied; and the fresh air is filtered, heated and fed to the workshop directly, so that the process facilities are not affected.

Owner:CINF ENG CO LTD

Large span non-support suspended cable arch ceiling technique and application

InactiveCN101250916AReasonable designMature application technologyBuilding roofsArched structuresEngineeringBusiness activities

Owner:董兰田

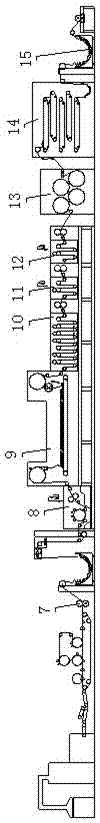

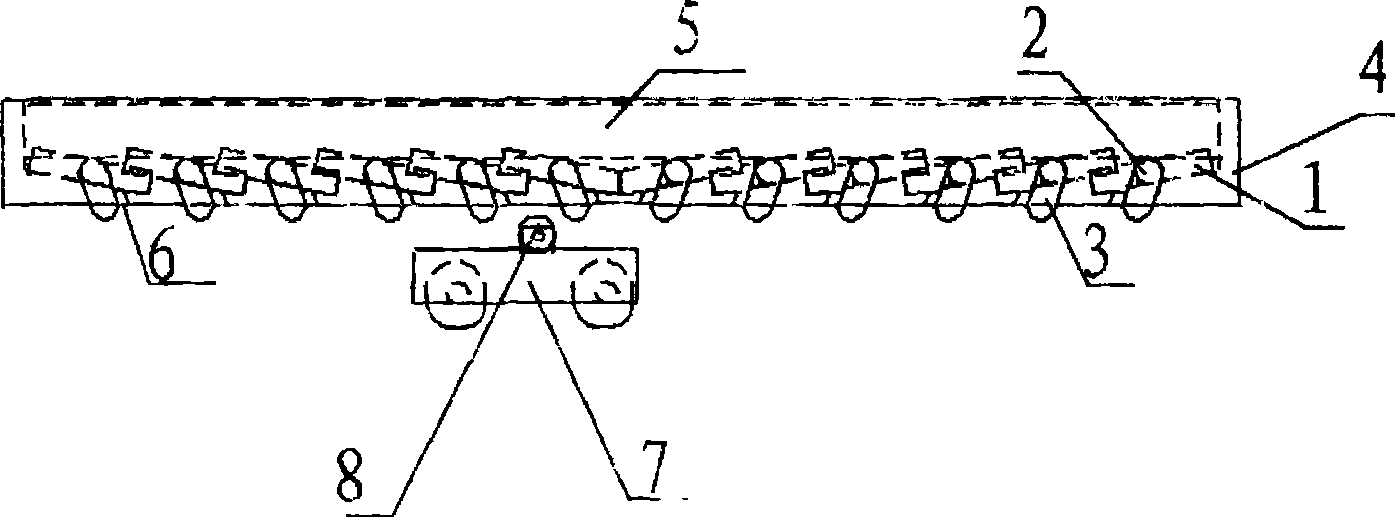

Continuous production method and device for purified-cotton bleached non-woven fabrics

ActiveCN108004676AReduce labor intensityReduce pollutionLiquid/gas/vapor removalTextile treatment machine arrangementsCardingNonwoven fabric

The invention relates to a continuous production method and device for purified-cotton bleached non-woven fabrics. The method includes the following steps of raw cotton opening, carding, cross lapping, prewetting compaction, drafting, positive and negative spunlace, high-efficiency squeezing, boiling and bleaching liquid padding, a steaming reaction, high-efficiency rinsing, PH adjustment, softening, roller drying, multi-layer loose drying and finished-product packaging. The method and the device have the advantages of saving energy, reducing labor intensity of workers, shortening production time, improving production environment, improving product quality, reducing discharge of sewage and pollution of waste gas to the environment, improving utilization of land, workshop buildings and equipment, and reducing investment of factories, and are beneficial to currently-advocated energy conservation, emission reduction, clean production and intelligentized factory construction.

Owner:无锡市艾克斯染整设备有限公司

Strip steel waste output device

InactiveCN102358523AImprove carrying capacityGuaranteed uptimeLoading/unloadingStrip steelEngineering

The invention relates to a strip steel waste output device. The strip steel waste output device comprises an online switch guide plate platform. A plate-type conveying chain is arranged on the lower part of the online switch guide plate platform; both ends of the plate-type conveying chain are used for controlling the motion of the plate-type conveying chain through a front plate-type conveying and tensioning chain wheel and a rear plate-type conveying and tensioning chain wheel; a waste hopper is arranged below the tail part of the rear plate-type conveying and tensioning chain wheel; the online switch guide plate platform comprises a fixed guide plate; a moveable guide plate is hinged with the upper part of the fixed guide plate; a cylinder is used for controlling the ascending and descending of the moveable guide plate; and an inclined free roller is arranged on the lower part of the fixed guide plate. The strip steel waste output device has the advantages of: 1, guaranteeing convenience for waste output and plate unobstructed performance, realizing automatic and continuous production conveniently, saving labor power and labor hours and improving work efficiency; 2, prolonging the service life of a unit profitably by using the plate-type chain with strong bearing capacity for intermediate transport, reducing maintenance labor, labor hours and cost and improving production efficiency; and 3, hoisting the waste hopper conveniently by arranging the waste hopper outside a workshop building to ensure smooth linkage with next working procedure.

Owner:WISDRI ENG & RES INC LTD

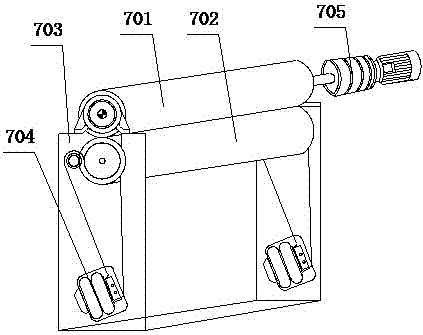

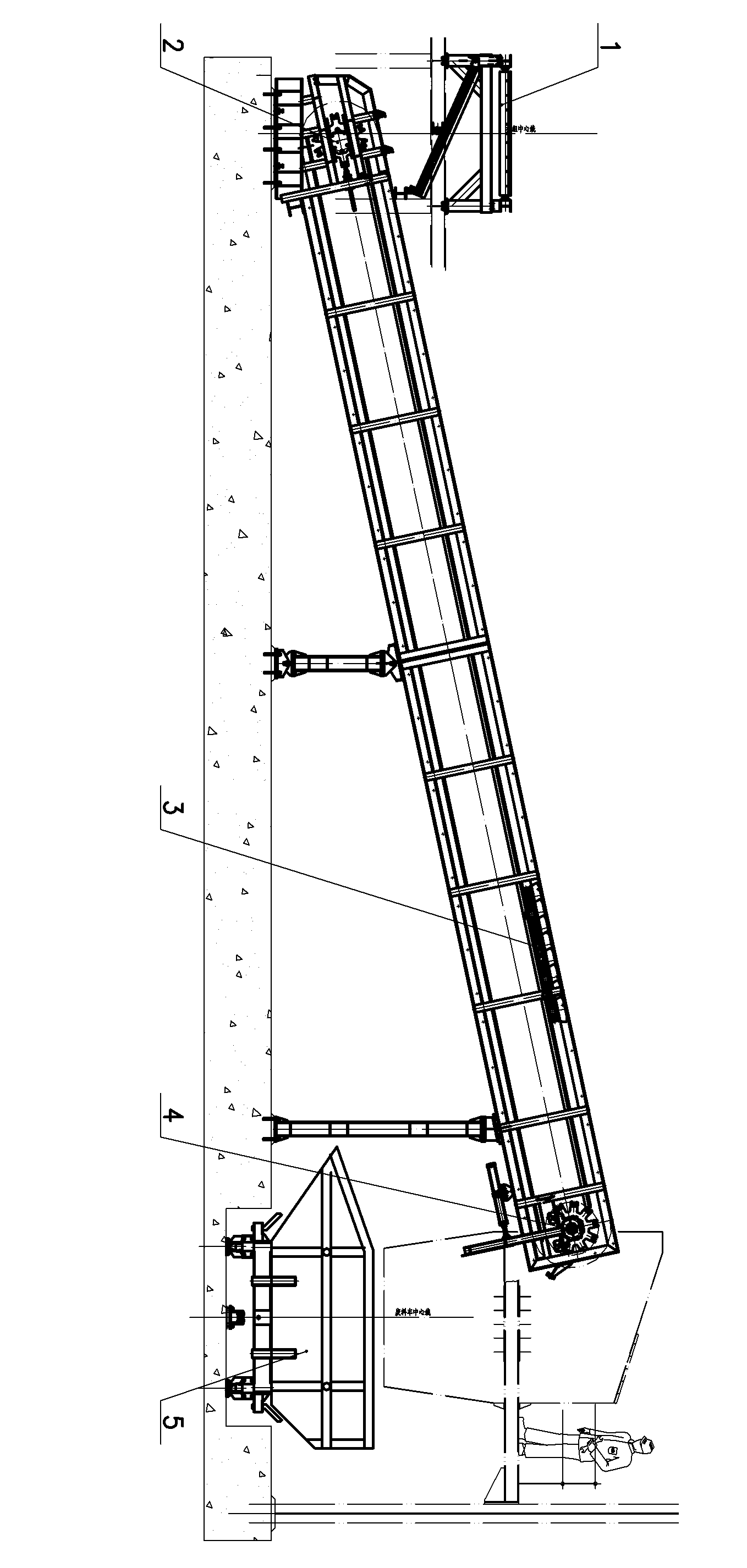

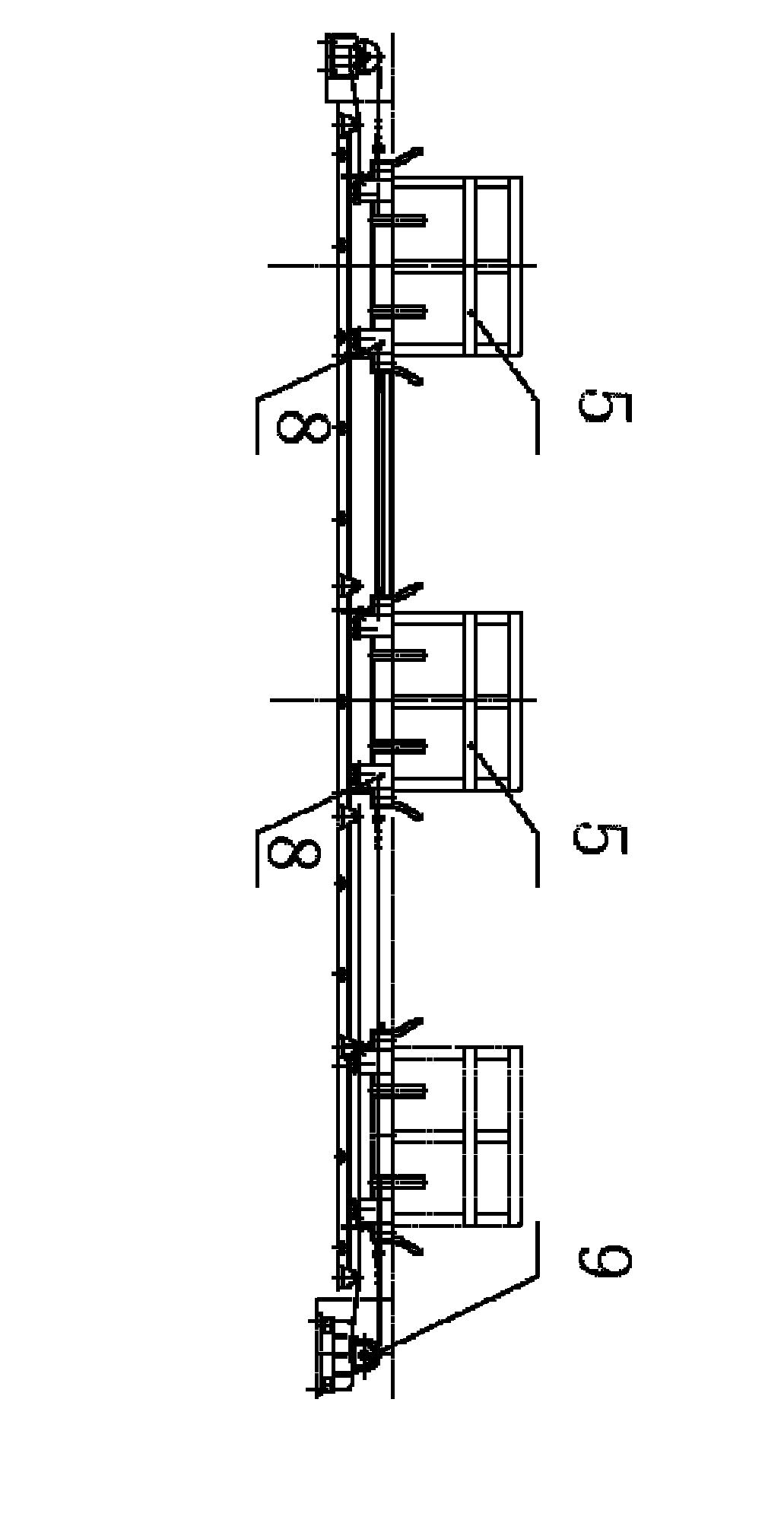

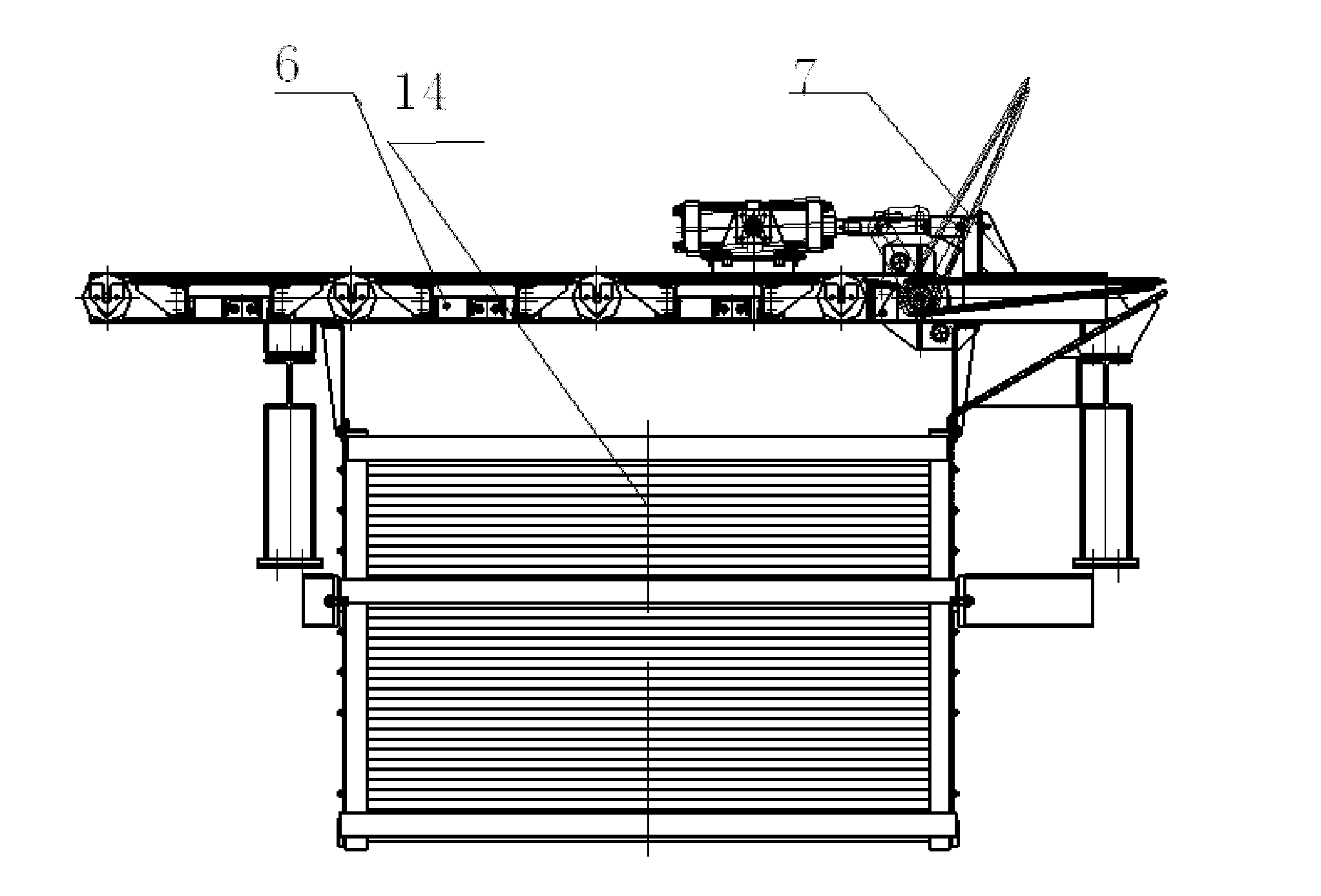

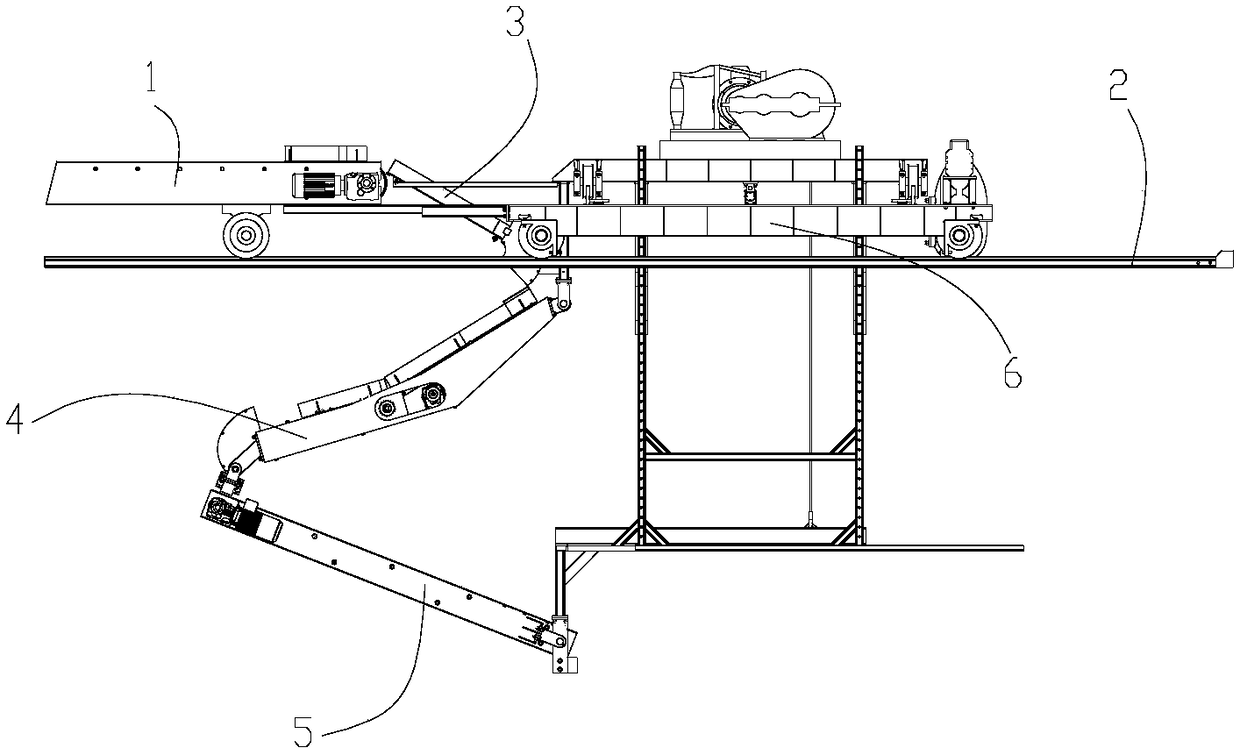

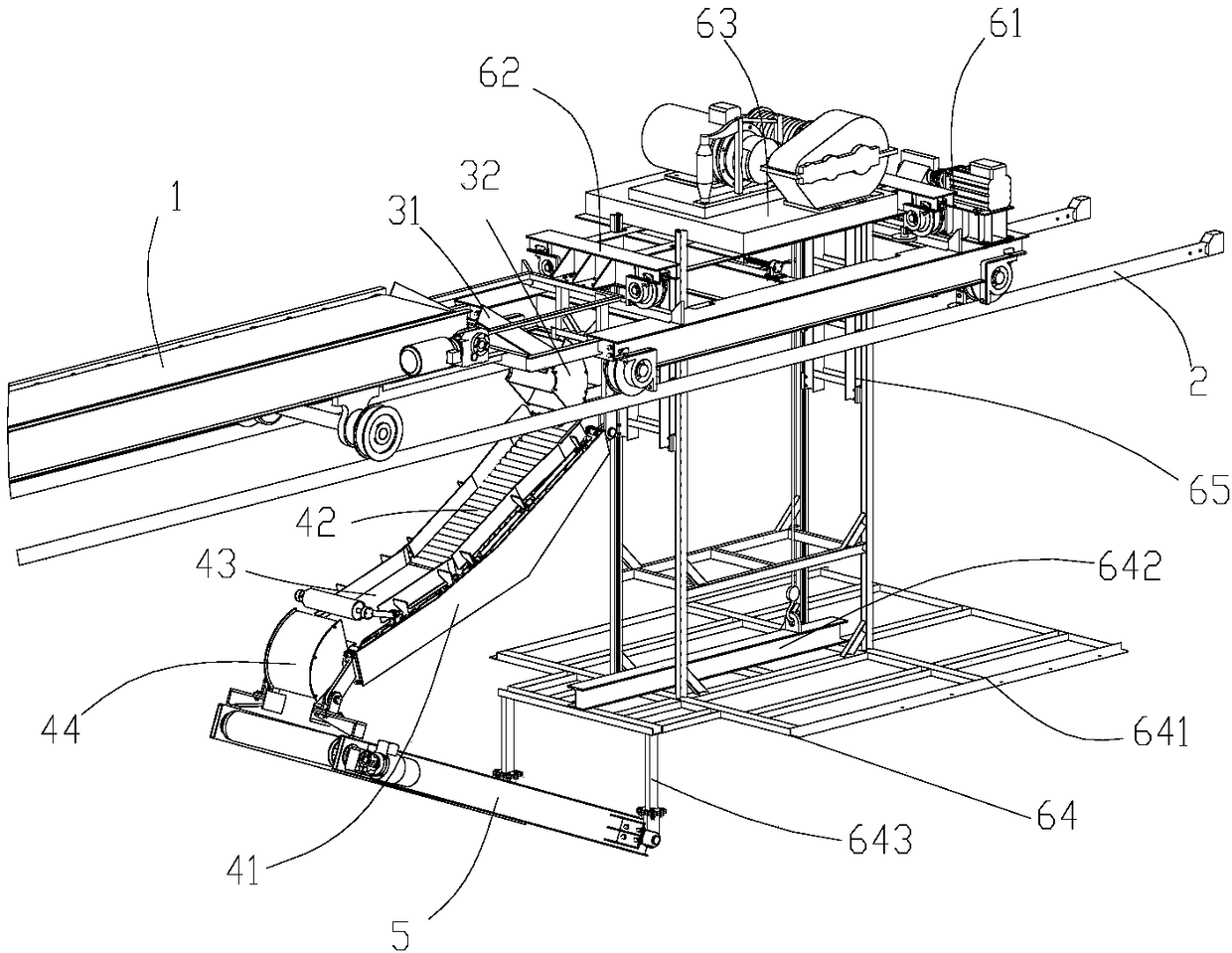

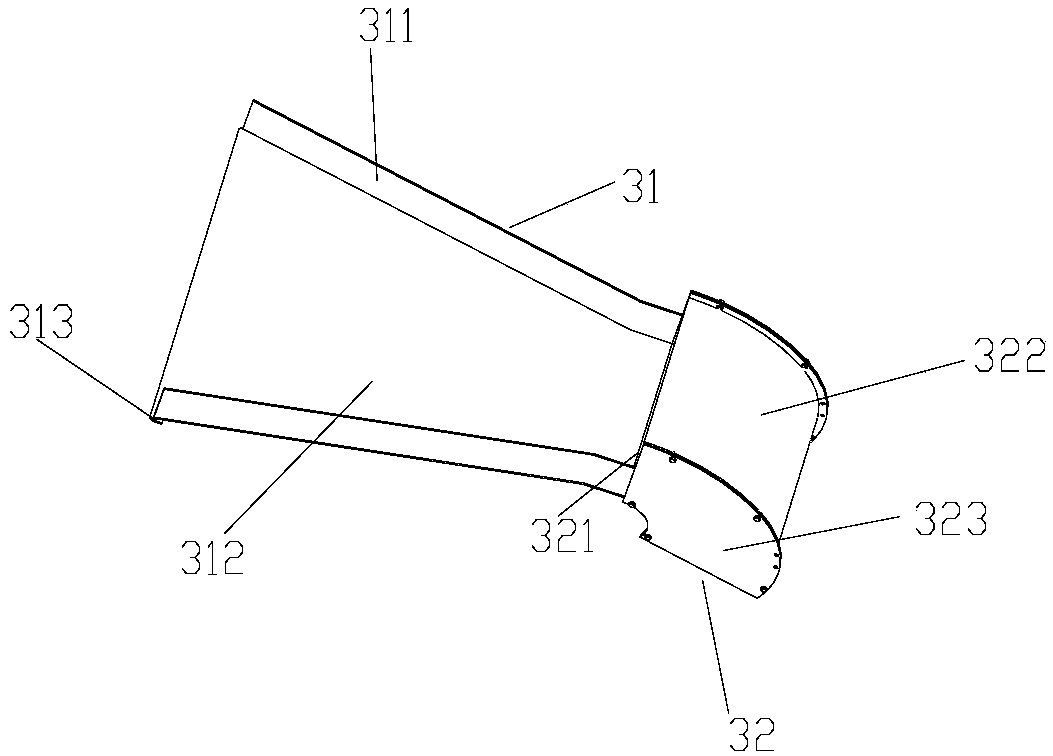

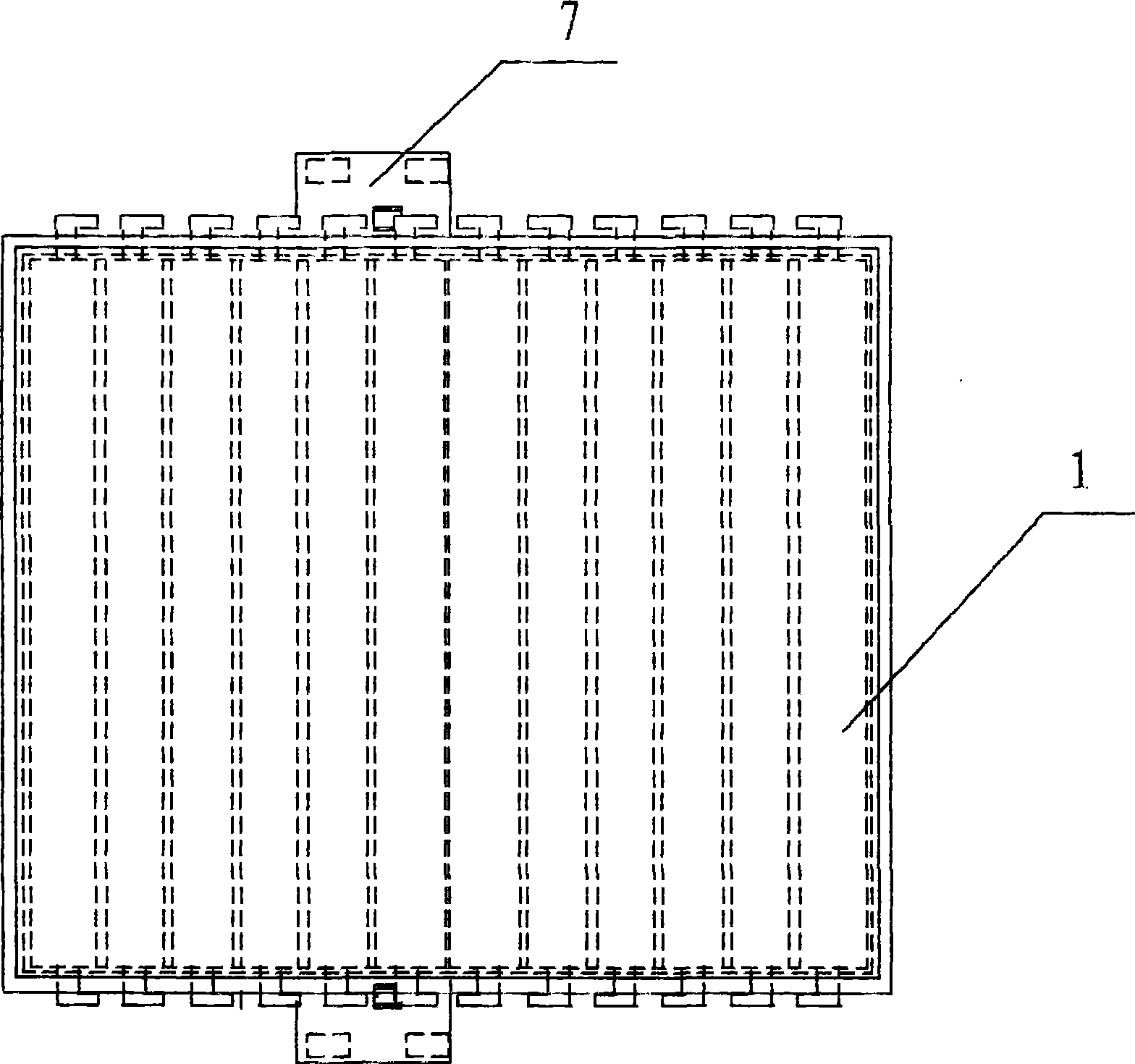

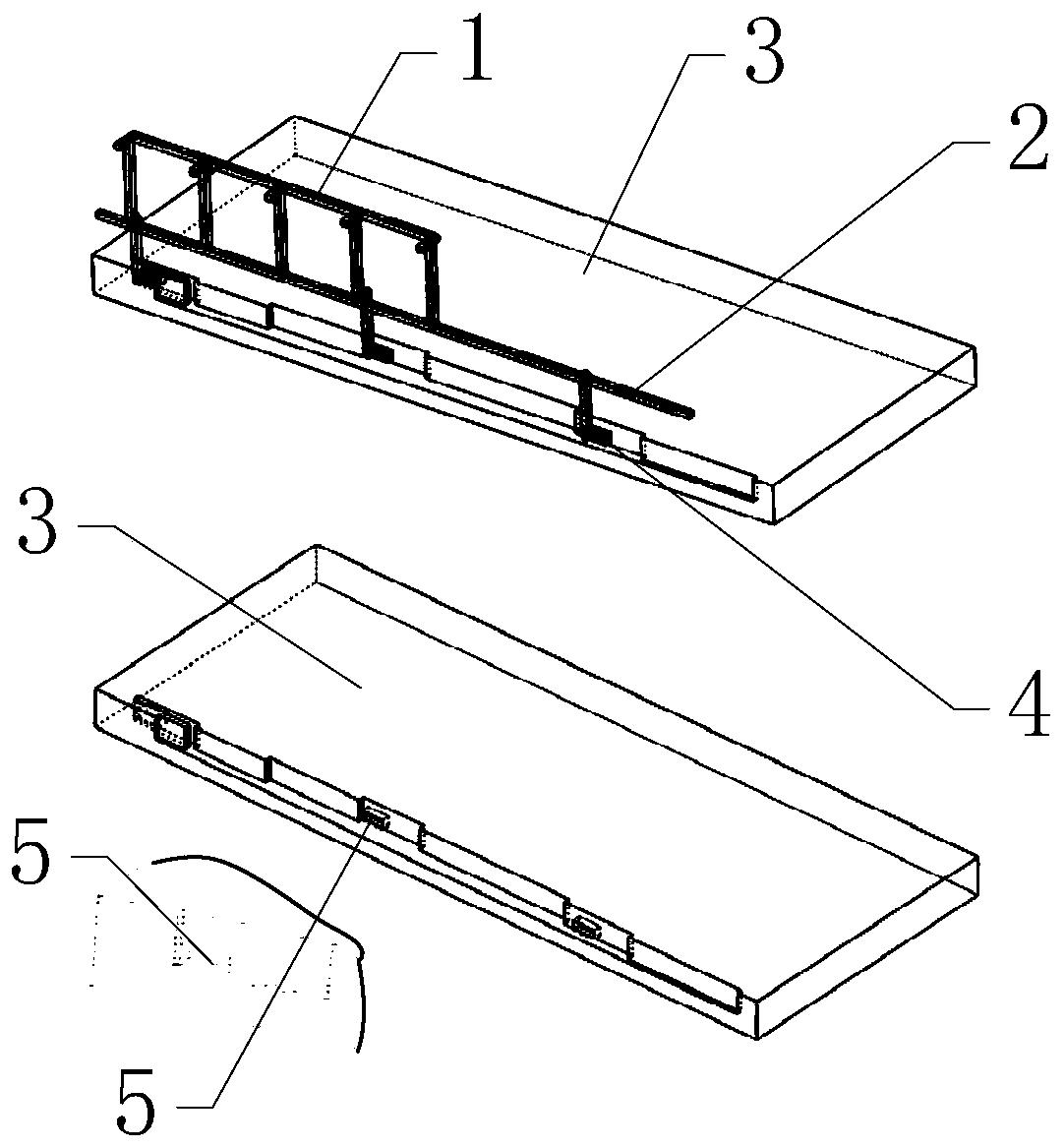

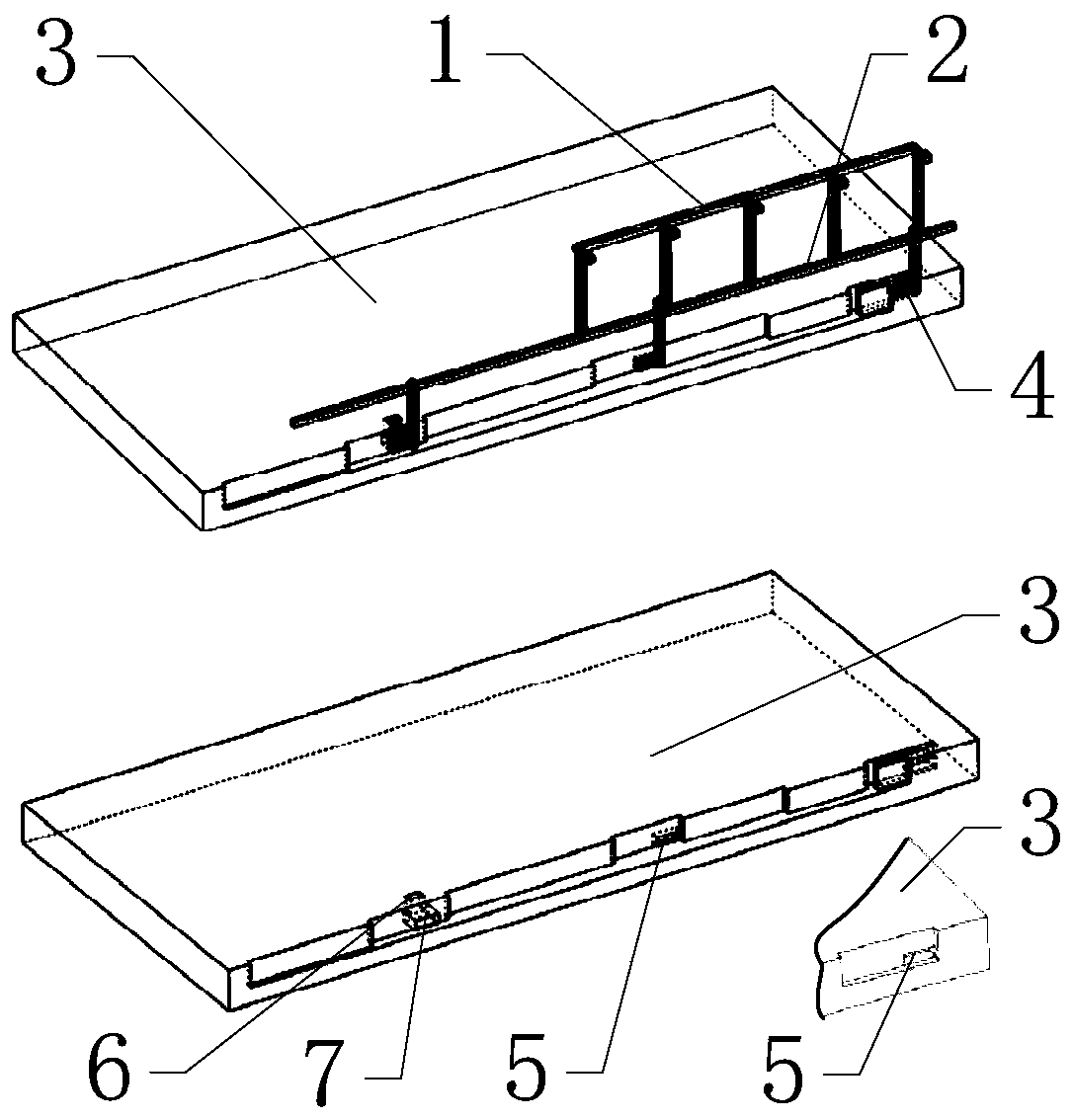

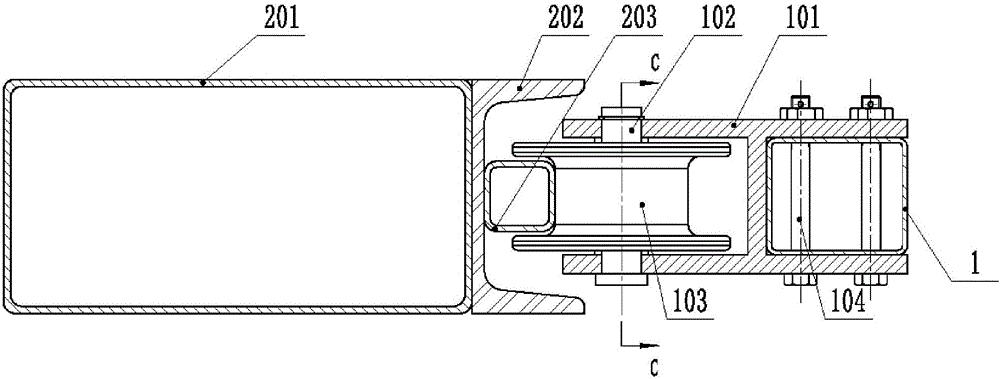

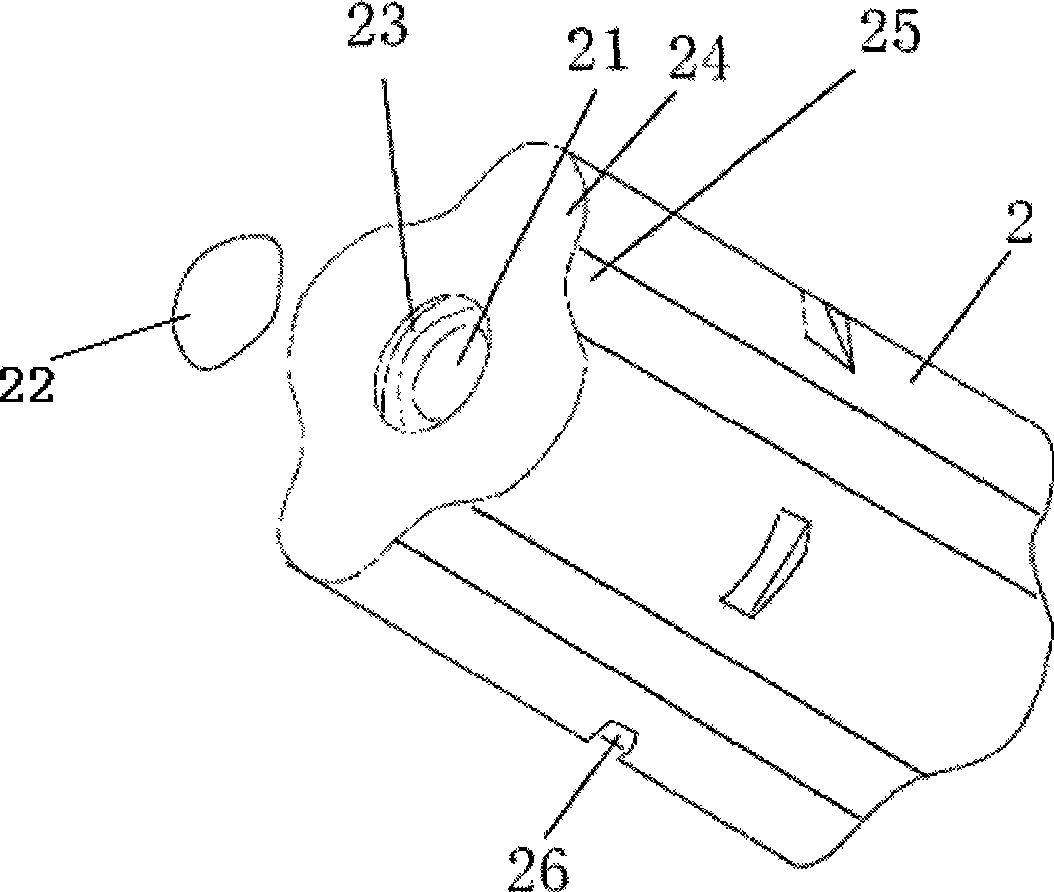

Folding type conveying device on bagged material loading machine in workshop building

ActiveCN108163576ARealize palletizingOvercome the disadvantage of longer lengthConveyorsStacking articlesEngineeringMechanical engineering

The invention provides a folding type conveying device on a bagged material loading machine in a workshop building. The folding type conveying device comprises a guide rail installed on the workshop building and a conveying mechanism on the guide rail, the guide rail is connected with a three-dimensional moving mechanism driving the conveying mechanism to slide on the guide rail, the tail end of the conveying mechanism is provided with multiple segments of folding conveying mechanisms, the multiple segments of folding conveying mechanisms comprise a reversing slide rail, a bag receiving component and a bag delivering component, wherein the reversing slide rail is connected with the three-dimensional moving mechanism, the bag receiving component is arranged at the lower portion of the reversing slide rail and connected to the three-dimensional moving mechanism, the bag delivering component is connected with the bag receiving component, and the bag delivering component is connected to the lower end of the three-dimensional moving mechanism. According to the folding type conveying device on the bagged material loading machine in the workshop building, folding type conveying of baggedmaterials is realized by means of the multiple segments of folding conveying mechanisms, the defect that a traditional conveyor belt is long is overcome, the multiple segments of folding conveying mechanisms are connected with the three-dimensional moving mechanism, and the multiple segments of folding conveying mechanisms can be made to move in the horizontal, lengthways and up and down positionsto realize material stacking for carriages of any length and width.

Owner:CNBM HEFEI POWDER TECH EQUIP CO LTD

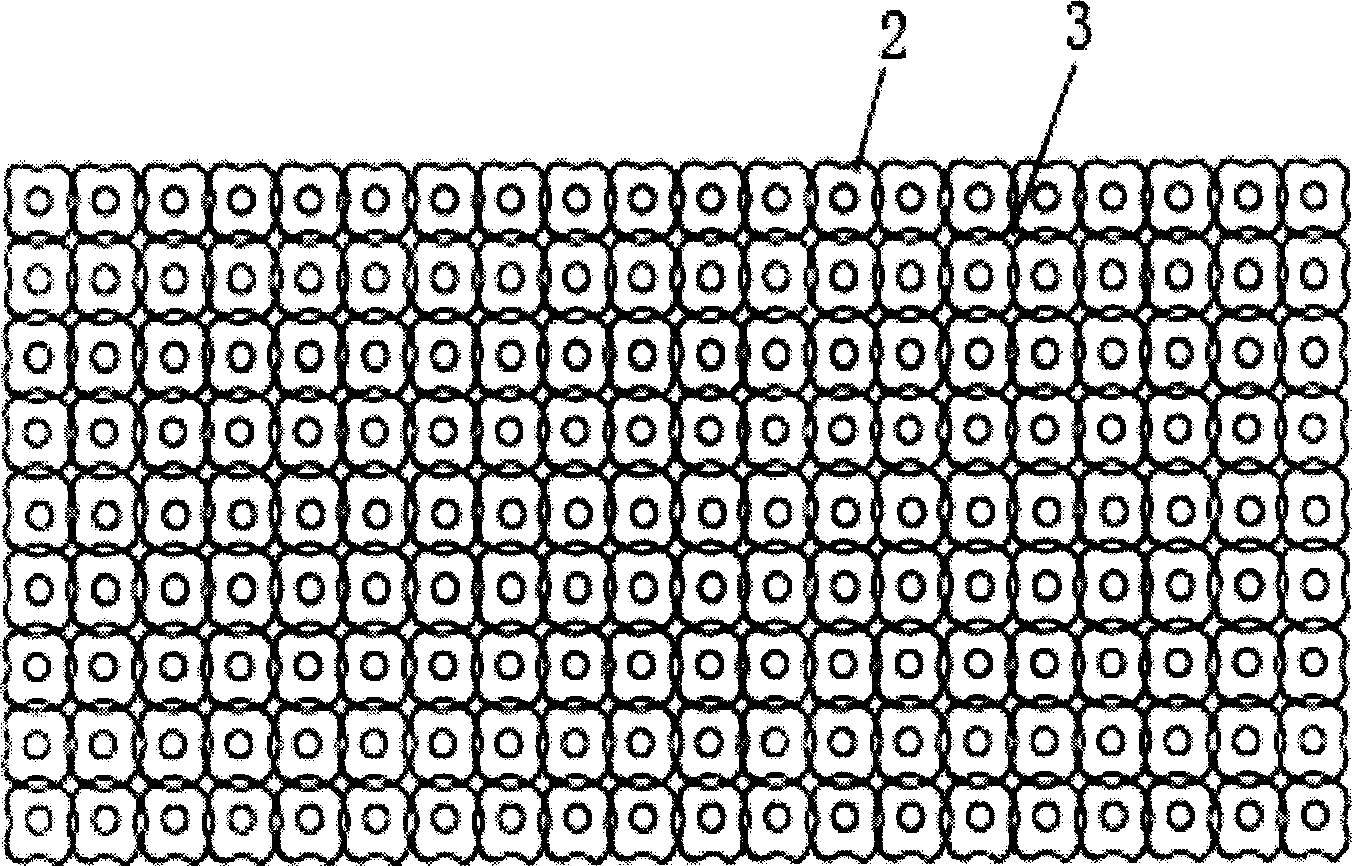

Configuration method of combined factory building for producing anode carbon brick for electrolysis of aluminum

The present invention discloses the configuration method of the composite workshop building for producing anode carbon block for electrolyzing aluminum. The configuration method includes setting the carbon block transferring section in the center position, setting the anode manufacturing and cooling section in the position perpendicular to the carbon block transferring section and near the material entrance, setting the anode assembling section in the position perpendicular to the carbon block transferring section and near the product exit, setting the roasting section in the position perpendicular to and adjacent to the carbon block transferring section, and completing the material conveyance between different sections with conveyer. The present invention has the advantages of reducing land consumption, shortening material conveying distance, etc.

Owner:GUIYANG AL-MG DESIGN & RES INST

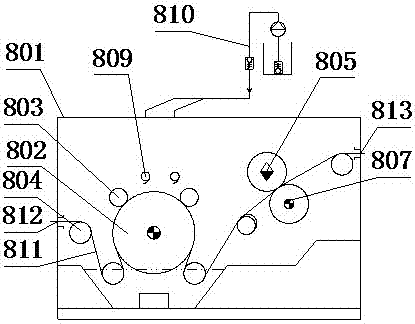

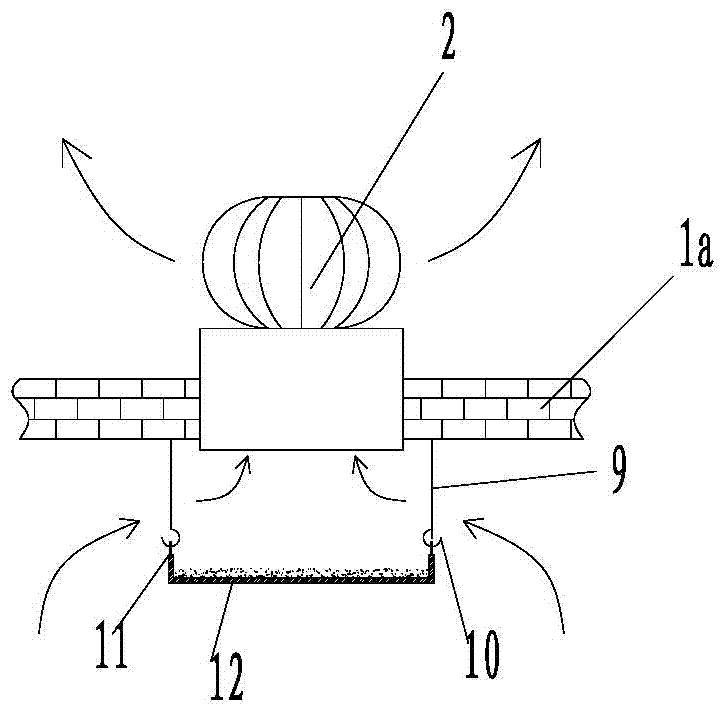

Attic type gravity dust collector

InactiveCN101530702AHigh dust concentrationImprove use valueDispersed particle filtrationWaste heat treatmentRecovery periodTemperature difference

The invention discloses an attic type gravity dust collector which consists of a settling chamber and a soot cleaning car. The gravity dust collector is characterized in that the settling chamber is installed on the house beam of a workshop building and composed of a circumferentially closed metal head cover and a bottom consisting of clapboard type filter group, and the soot cleaning car is installed on the track of a crane and provided with a soot cleaning car touch wheel. The attic type gravity dust collector has the advantages that the metallic structure is high temperature resistant; the soot self circulation is completed by using the soot temperature difference as dynamic force; the higher the soot temperature, the better the dust removing effect; the soot can enter the dust collector for treatment without cooling and has small volume; the dust content is high, the dust removing efficiency is high and the exhaust soot amount is small; the dust collector is installed in the air of the workshop building with compact structure and no land occupying; the soot cleaning is carried out mechanically without maintenance management by specially-assigned persons; the disposable investment is small; the operating cost is low with economy and practicability, and the energy-saving and emission-reduction effect is obvious; and the utility value of the recovered dust is high and the recovery period of the invested capital is short.

Owner:倪桂龙

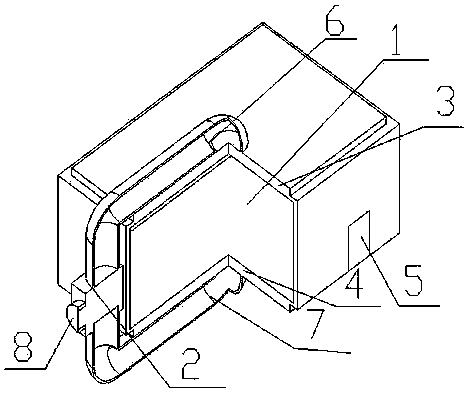

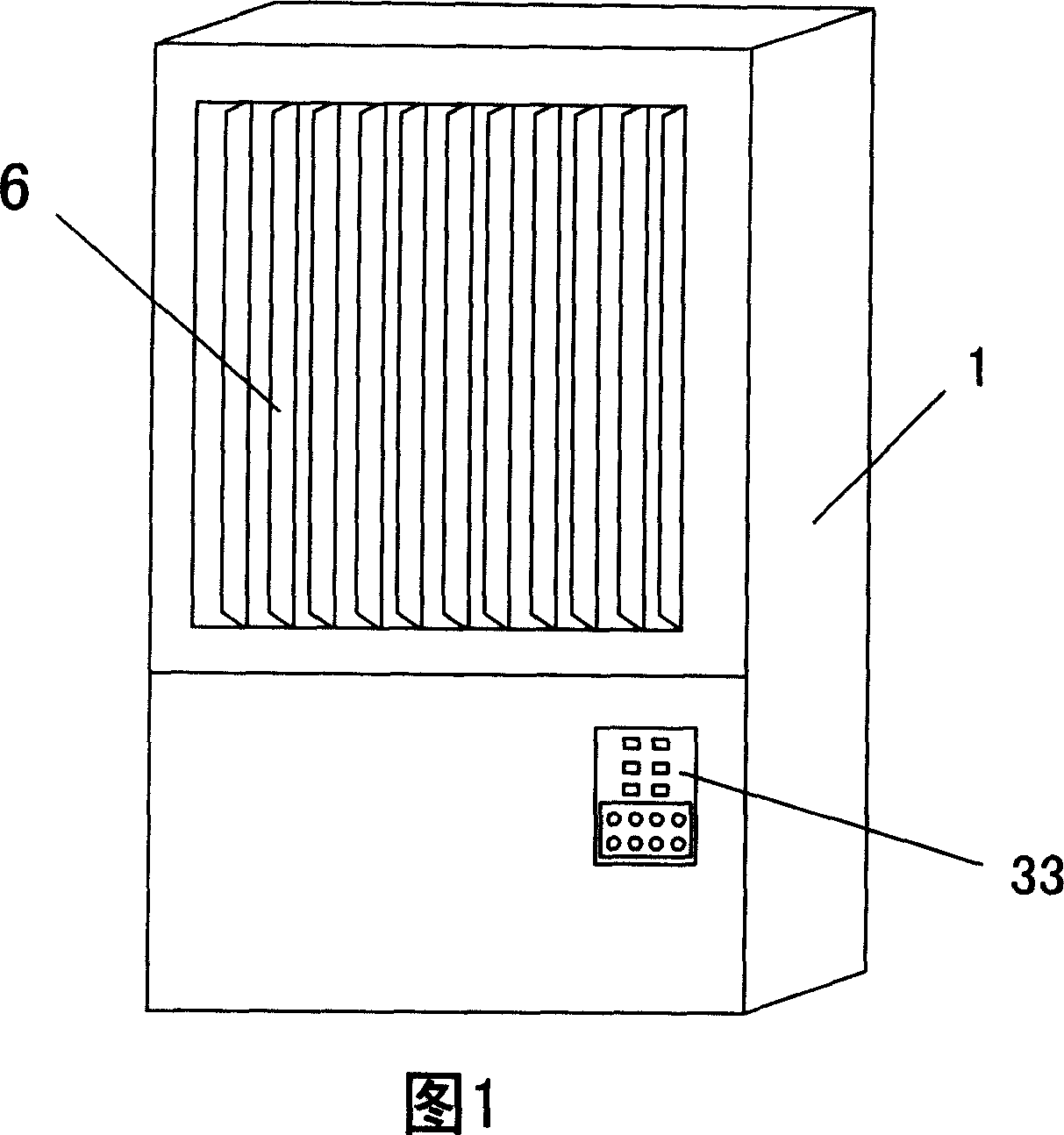

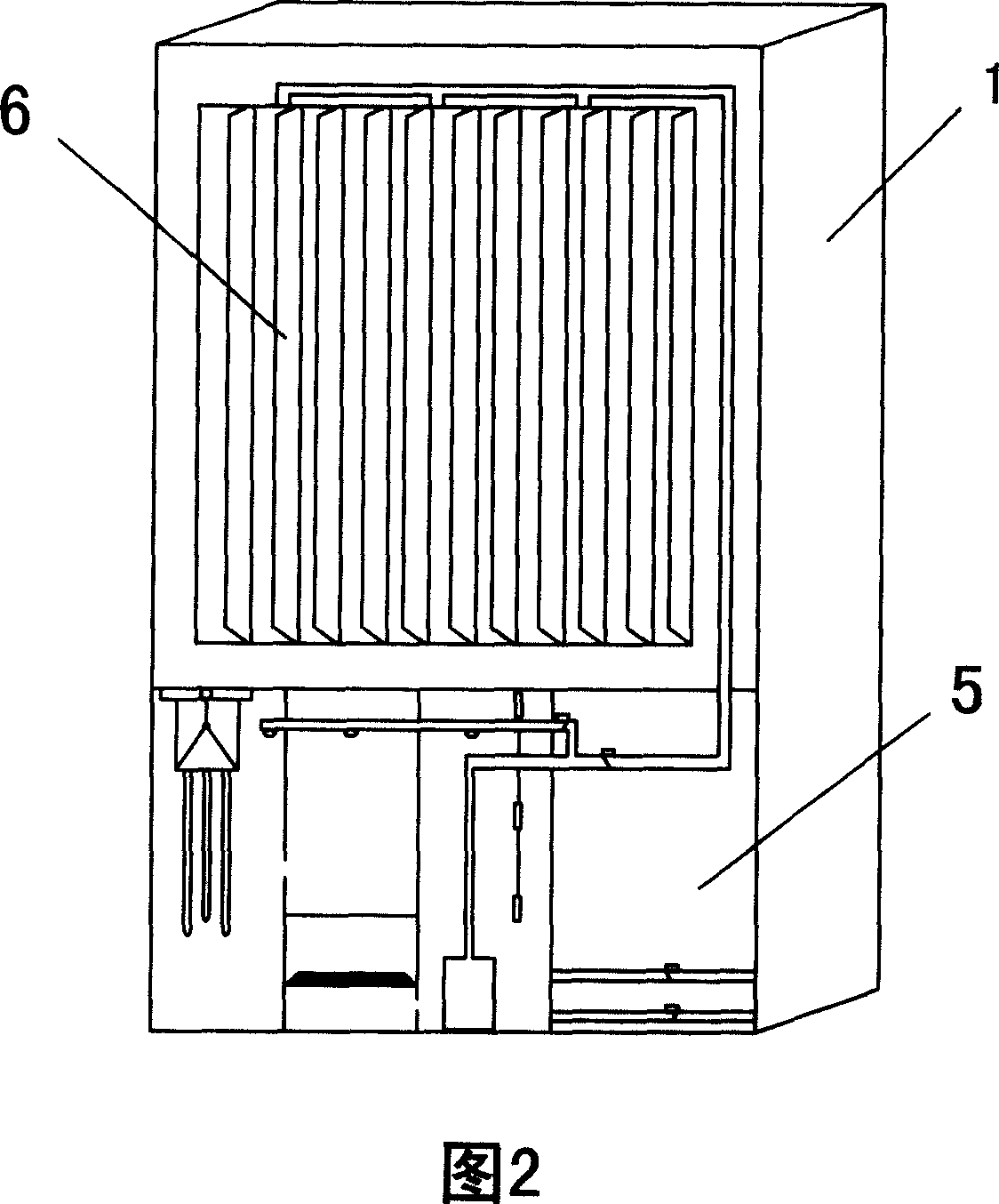

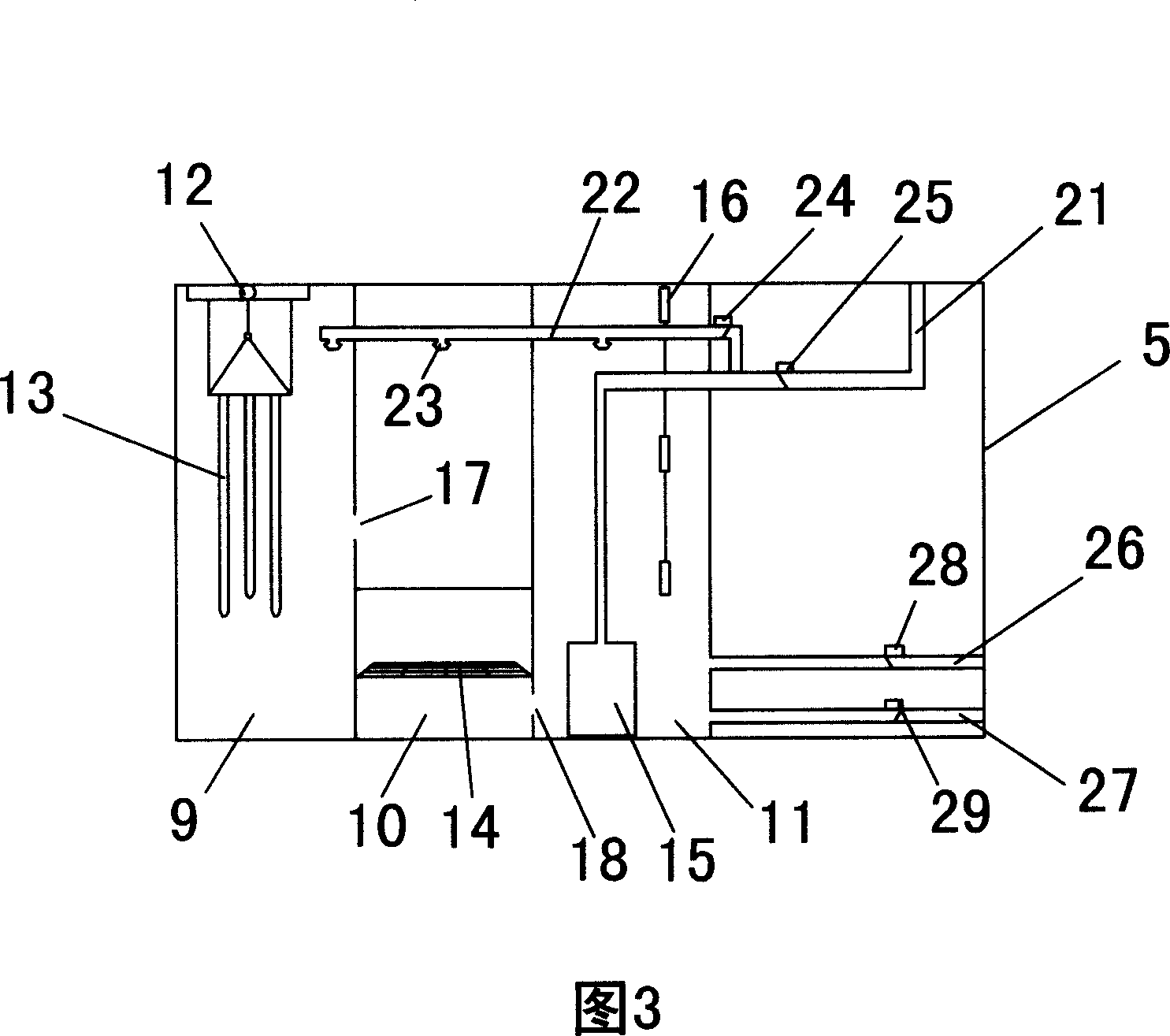

Ultra-clean workshop

InactiveCN103438537AGuaranteed anti-static effectStable air pressureLighting and heating apparatusSpace heating and ventilation detailsFiltrationAir pump

The invention discloses an ultra-clean workshop which comprises a workshop building, a boosting air pump, a dust filtration net, a closed door and a ventilation system, wherein one side of the workshop building is provided with the boosting air pump; the boosting air pump is provided with an air inlet pipeline connected with the upper part of the workshop building; the air inlet pipeline is internally provided with the dust filtration net; the wall of the workshop building is provided with the closed door; the ventilation system is arranged at the lower part of the workshop building; the air return pipeline of the ventilation system is arranged on the top of the workshop building; an exhaust system is connected to the outer side of the workshop building. By adopting the mode, the ultra-clean workshop disclosed by the invention has the advantages of high cleanliness, good air ventilation, no dust entrance, good reliability, and the like and has wide market prospect in the field of purification.

Owner:SUZHOU NEW DISTRICT FENGQIAO PURIFICATION EQUIP FACTORY

Environment protection water cooling equipment

InactiveCN101067507AReduce consumptionLighting and heating apparatusAir conditioning systemsWater flowEngineering

The invention discloses a kind of environment protection water cooling equipment it concludes a water curtain, a water tank at the bottom of water curtain, and a water running duct and at the two sides of water curtain have the wind inlet and the wind outlet. The water tank said above concludes a horizon array and connecting in sequence disinfection tank and filter tank, and a recovery tank. The disinfection tank has a water inlet and at the internal of it has a sterilization and disinfection installment and the filter tank has a cleaning filter installment and the recovery tank has a pump which can lead the recovery water to the flow runner pipe; besides it also concludes a suction pressure extractor fan which can reduce the indoor noise and the suction pressure extractor fan sets up at the other side of room corresponding to the environment protection installment. Adopting the previous technology method it can make the outside hot air though the water curtain and filter installment cooled and cleaned and sterilized and when entering the internal of workshop building the suspended load and bacterium and virus in the outside hot air is impeded at the external of room and the air which is enter the room is the reduced temperature and cleaned air.

Owner:王伟光

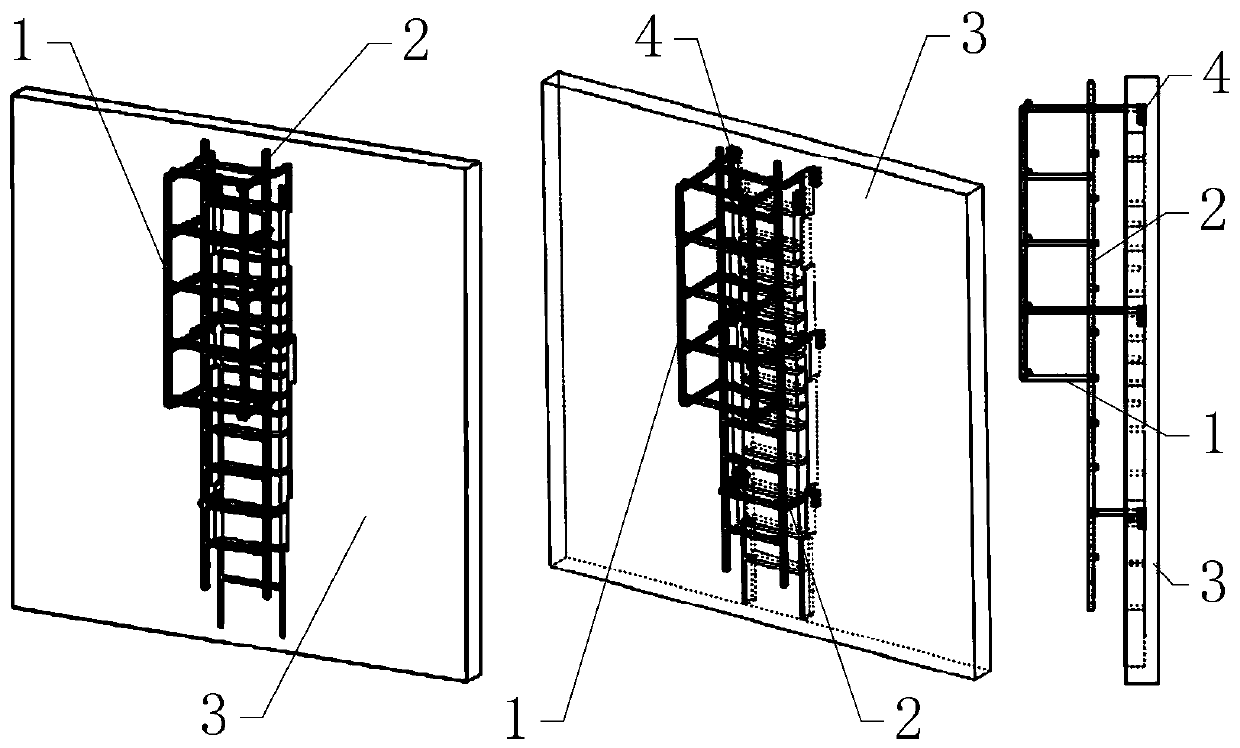

Crawling ladder with protection function for outdoor building or workshop building

ActiveCN110984841AAffect securityImprove corrosion resistanceLaddersArchitectural engineeringStructural engineering

The invention belongs to the technical field of crawling ladders, and particularly relates to a crawling ladder with a protection function for an outdoor building or a workshop building. The crawlingladder with the protection function for the outdoor building or the workshop building comprises a ladder frame and a guardrail for protecting a climber climbing to a high position. According to the crawling ladder, when the designed crawling ladder is not used, the crawling ladder is placed in a guardrail storing groove, a stop lever storing groove, a step lever storing groove and a ladder frame longitudinal rod storing groove which are formed in a building wall, and is sealed through corresponding sealing rubber layers, so that the crawling ladder is prevented from being corroded by externalair or rainwater, and the safety of the ladder frame and the guardrail is influenced; and during use, the crawling ladder is controlled by an adjusting mechanism to be opened upwards, the crawling ladder is limited and fixed by a first hinge mechanism and a second hinge mechanism, and after the crawling ladder is folded, the folded structures of the ladder frame and the guardrail are located in the same plane, so that storing grooves for storing the ladder frame and the guardrail of the building wall are saved, and the corrosion resistance of the ladder frame and the guardrail is improved.

Owner:山东鑫润机电安装工程有限公司

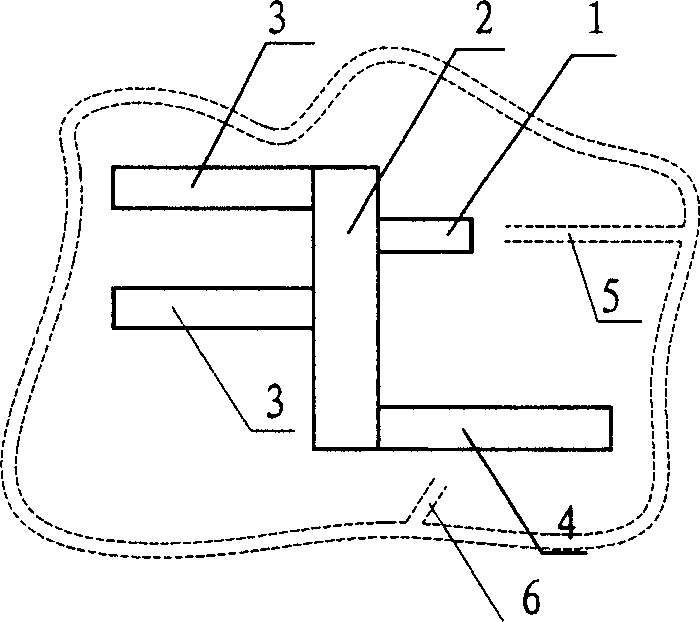

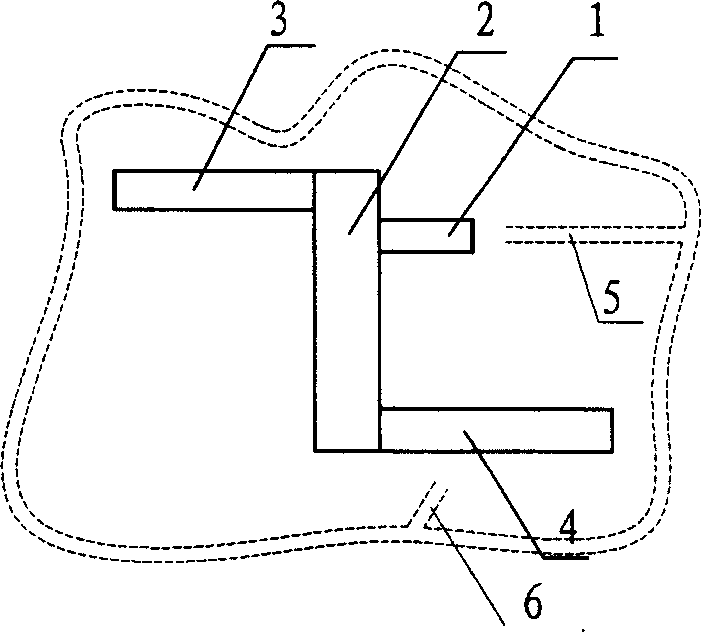

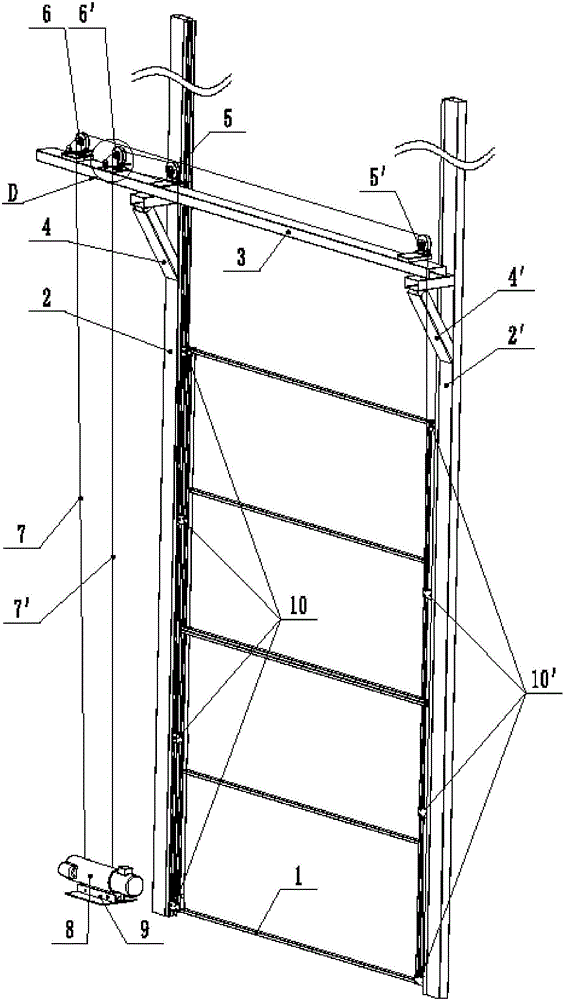

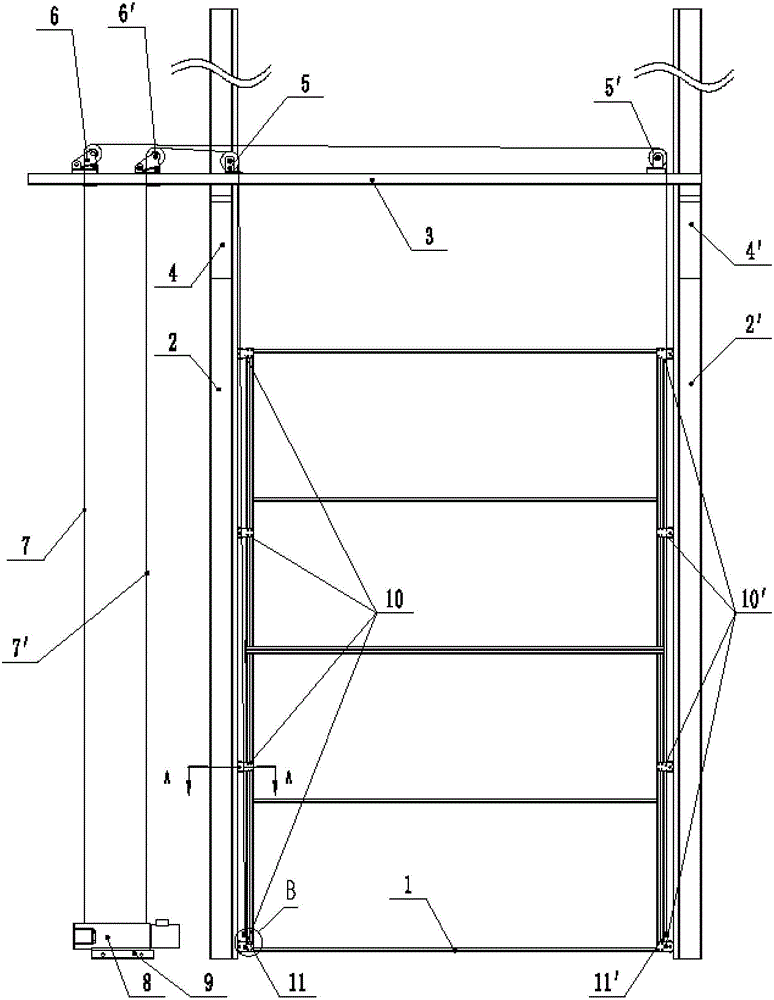

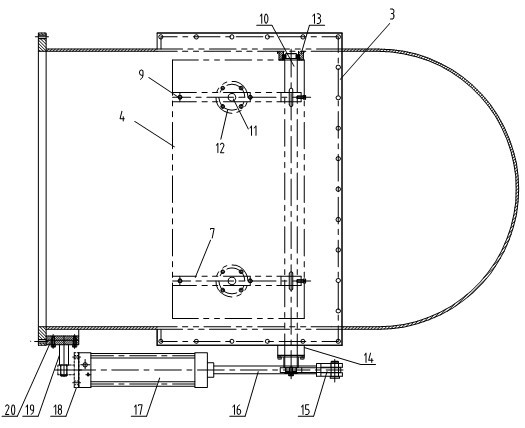

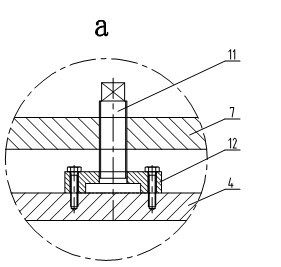

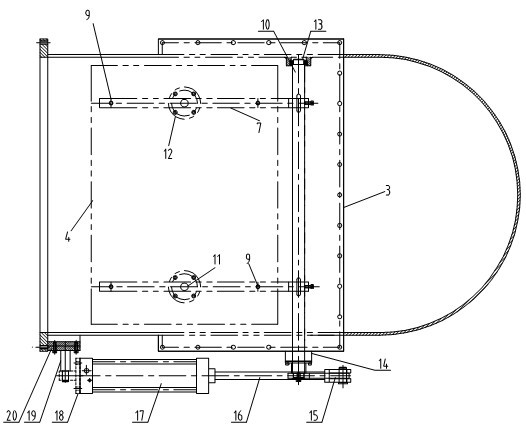

Full-automatic door used in workshop

ActiveCN105041129ASimple structureHigh strengthWindow/door framesPower-operated mechanismWire ropeWorkshop building

A full-automatic door used in a workshop belongs to the field of workshop buildings and is characterized in that pulley assemblies are arranged on the left and right sides of a frame type door rack; the pulley assemblies can slide up and down in tracks of the left and right door posts; the left and right sides of the door rack are fixedly connected with left and right steel wire ropes; left and right steel wires are connected with an electric hoist installed on a foundation via a supporting wheel and a tension wheel both arranged on a cross beam; and the door rack can be driven to go up and down in the tracks of the left and right door racks when the electric hoist is started. The full-automatic door used in the workshop is simply structured, convenient to operate and possesses safety and reliability.

Owner:太原融盛科技有限公司

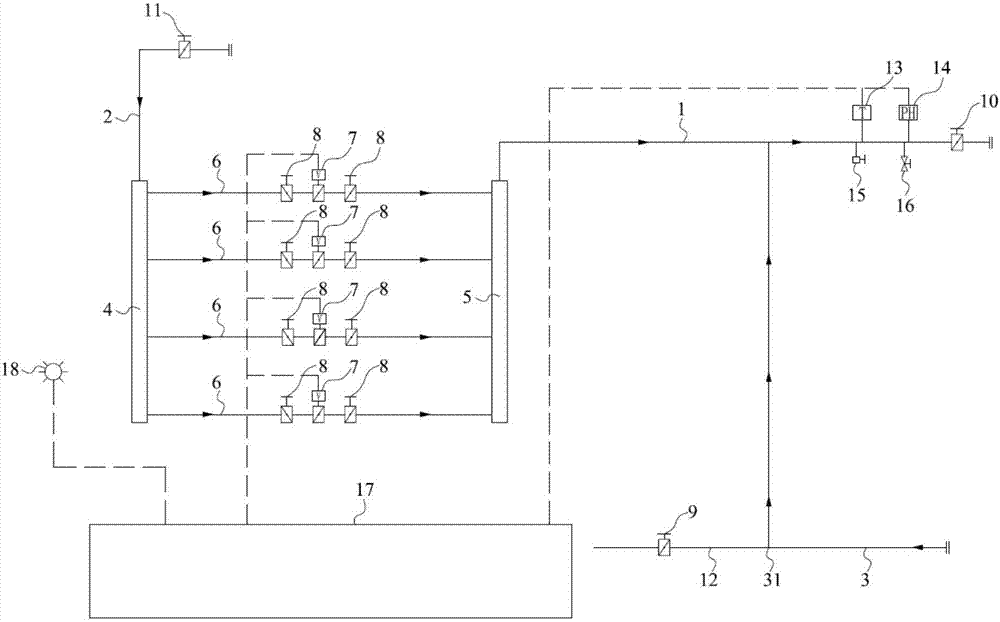

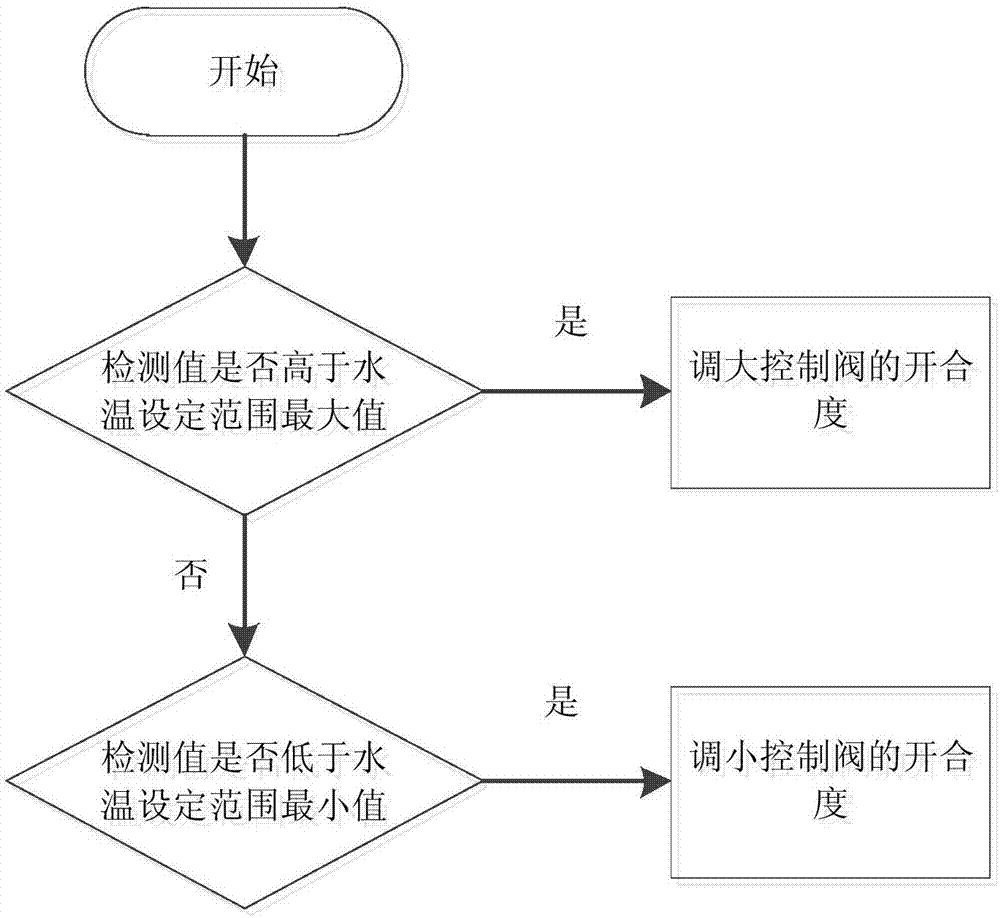

Return water cooling system and control method of return water cooling system

ActiveCN107576121ALarge opening and closingStable water temperatureDomestic cooling apparatusLighting and heating apparatusElectricityEngineering

The invention relates to the technical field of cooling and discloses a return water cooling system and a control method of the return water cooling system. The return water cooling system comprises acold water supply pipe, a cooling water supply pipe and a return water pipe. The cold water supply pipe comprises multiple water supply branch pipes. A control valve is mounted on each water supply branch pipe. The control valves are electrically connected with a PLC. One end of the cooling water supply pipe is connected with water outlet ends of the water supply branch pipes, and the other end of the cooling water supply pipe is connected with a water inlet of to-be-cooled equipment. The cooling water supply pipe is provided with a temperature sensor electrically connected with the PLC. Oneend of the return water pipe is connected with a water outlet of the equipment, and the other end of the return water pipe is connected with the cooling water supply pipe, and a water outlet is formedin the return water pipe. According to the return water cooling system, the opening of the control valves is controlled by the PLC so that return water of different flows can be mixed and cooled, theoperation is easy and convenient, no heat exchanger is needed, the equipment mounting space is reduced, the workshop building cost and the initial equipment investment cost are lowered, and the costin regularly maintaining and cleaning heat exchange boards is omitted.

Owner:KUNSHAN FLOWTECH ELECTROMECHANICAL ENG CO LTD

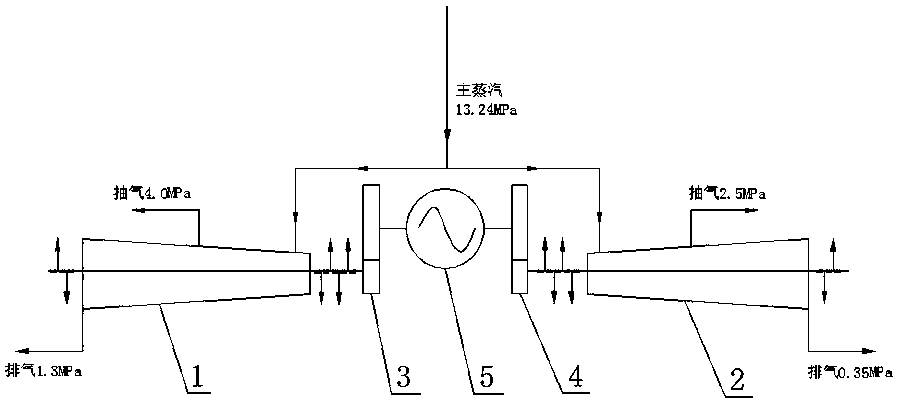

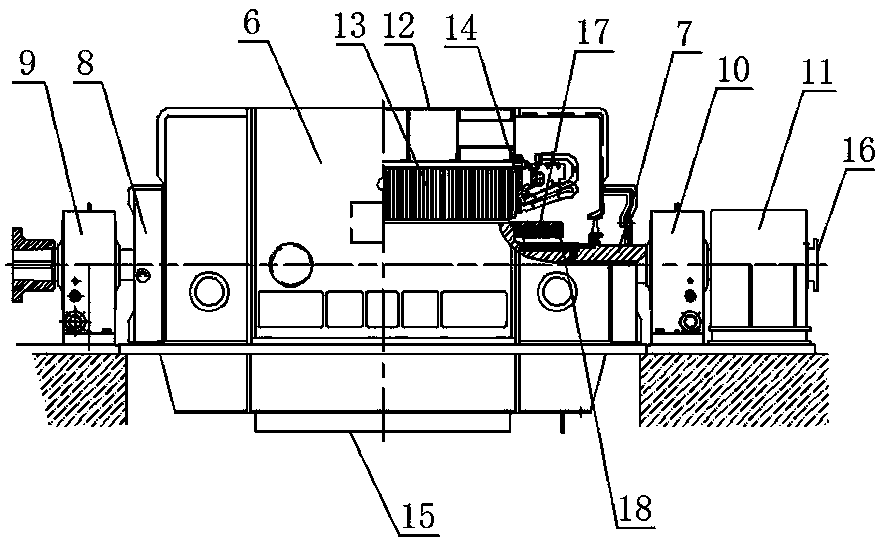

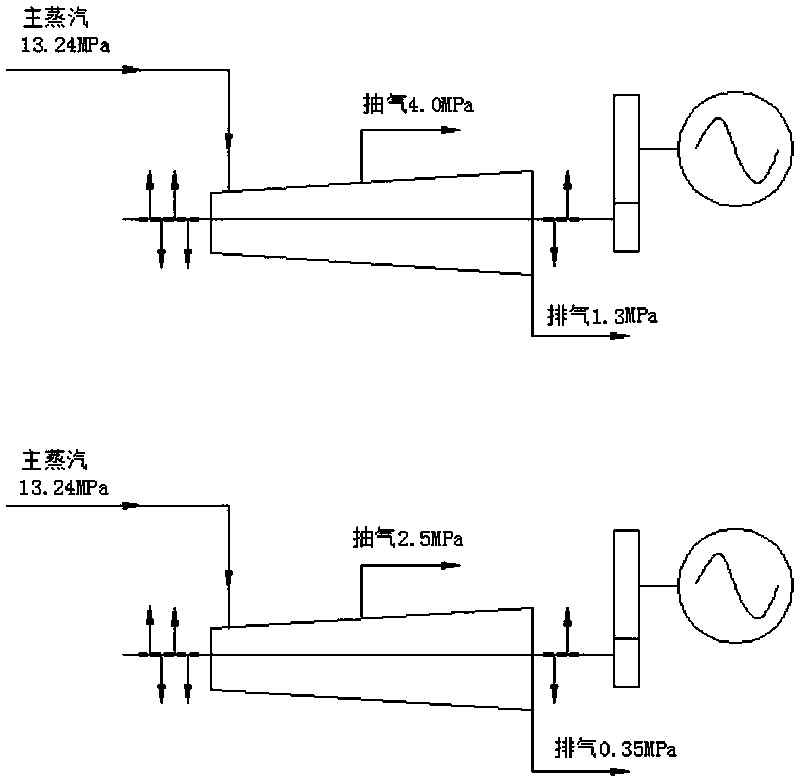

Turbo generator set device providing steam in different qualities

PendingCN108539881ALarge capacityHigh mechanical energy conversion efficiencyMagnetic circuit stationary partsMechanical energy handlingEngineeringTurbine

The invention discloses a turbo generator set device providing steam in different qualities. The turbo generator set device is characterized by comprising first and second steam turbines, first and second gear cases and a generator, the generator is a double-end driving type turbo generator, the first steam turbine is connected with the input end of the first gear case, the output end of the firstgear case is connected with one end of the generator, the second steam turbine is connected with the input end of the second gear case, and the output end of the second gear case is connected with the other end of the generator. Thus, a traditional turbo generator set device in which two sets of back pressure extraction turbine drive one generator to provide steam in four qualities is replaced, instead, two back pressure extraction turbines drive one generator to provide the steam in four qualities, the structure is simple and compact, a workshop occupies small space, and equipment and workshop building cost is reduced.

Owner:JIN TONG LING TECH GRP CO LTD

Method for producing latex bed mattress

InactiveCN101375760AReduce shipping costsRelieve pressureElectrotherapyStuffed mattressesEngineeringLarge size

The invention relates to the technical field of bedding products, particularly a method for manufacturing a latex bed mattress. The method comprises the following steps: firstly making a mattress frame, then making an elastic mesh inside the mattress frame, and fixing latex column units in each grid of the elastic mesh to obtain a latex bed mattress. The manufacturing method of latex bed mattresses is realized by combining various specifications of mattress frames and elastic meshes and batches of latex column units and has the advantages of simple process, less time consumption and no need of large-size processing equipment, workshop buildings or warehouses. Additionally, the manufacturing method of latex bed mattresses can rapidly produce personalized bed mattresses according to the customer's demand to meet the individualization requirement.

Owner:SHANGHAI LATEX INDAL

Elbow pushing device capable of pushing elbow

The invention relates to an elbow pushing device capable of pushing an elbow. The elbow pushing device comprises a base, a supporting sea, a main fixed wall, an auxiliary fixed wall, a movable wall, a sliding piece, a steel rail, a clamping device, a heating coil, a baffle and a hydraulic cylinder, and is characterized by also comprising an elbow oil cylinder, a pulling arm, a sleeve, a clamp, a connecting rod, a bearing, a bearing block and a positioning pin, and one end of the elbow oil cylinder is connected with the bearing block; the bearing is arranged in the bearing block, and the clamp is connected with one end of the pulling arm; the sleeve is sleeved on the pulling arm, and one end of the connecting rod is connected with the lower end of the sleeve; the other end of the connecting rod is arranged in the bearing, and a positioning hole is formed in the upper end of the sleeve; and a bolt hole, corresponding to the positioning hole of the sleeve, is arranged on the pulling arm, and the positioning pin is arranged in the positioning hole and the bolt hole. The elbow pushing device provided by the invention has the advantages of saving a large workshop building area and saving equipment cost.

Owner:ZHONGNAN RED CULTURE GRP CO LTD

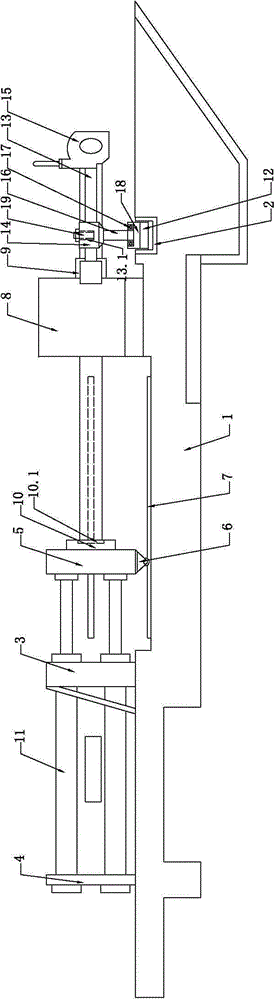

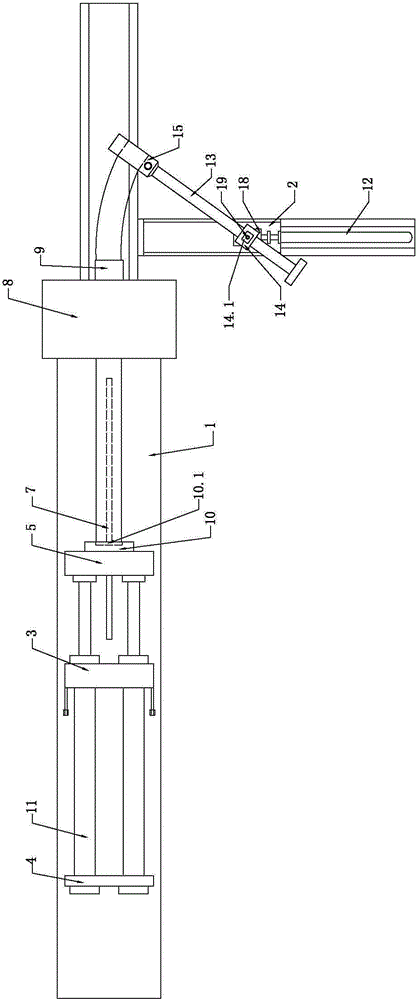

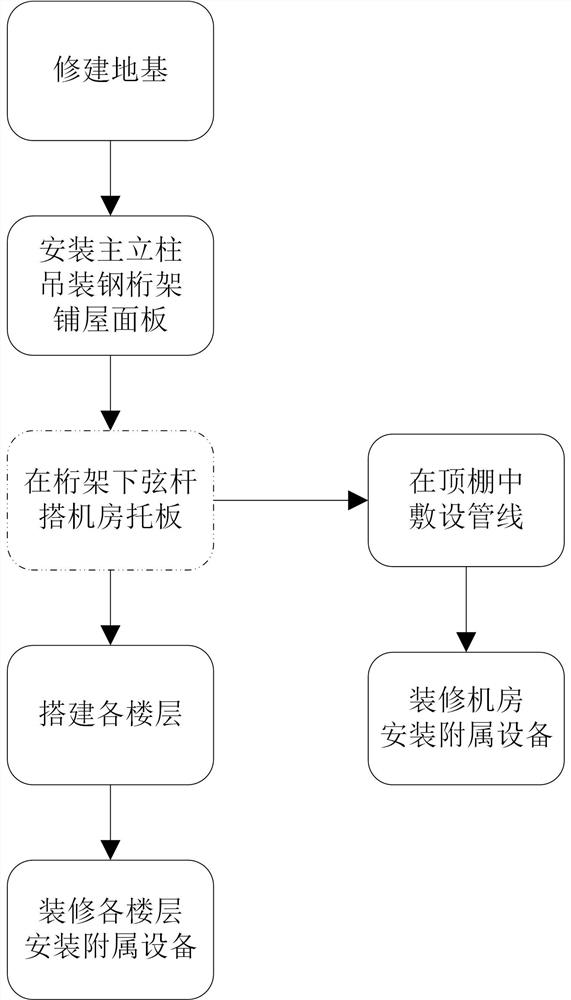

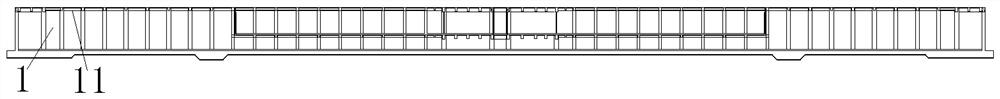

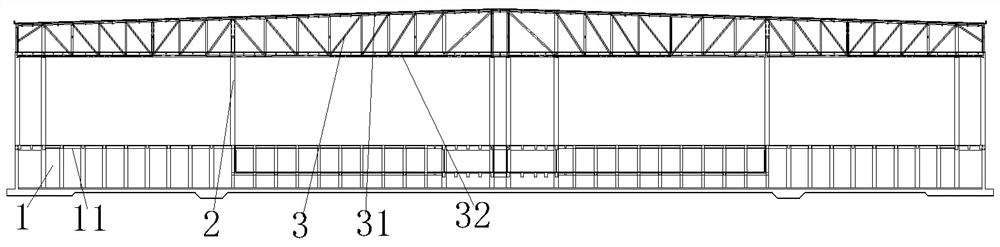

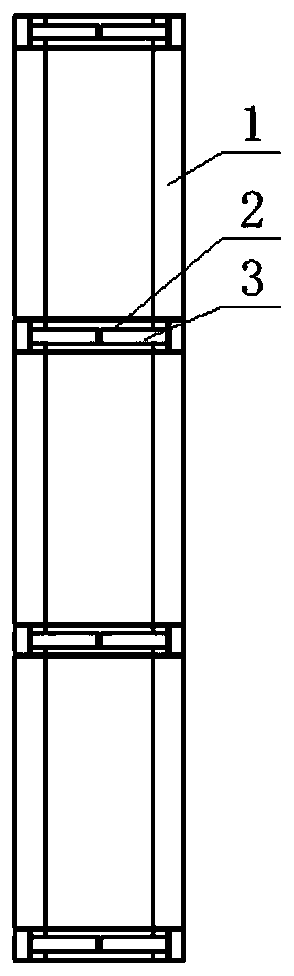

Workshop building method capable of effectively shortening construction period and workshop built by same method

InactiveCN112431416AShorten the construction periodMeet needsBuilding roofsStrutsLine tubingArchitectural engineering

The invention relates to the technical field of building structures covering large-area spaces, and discloses a workshop building method capable of effectively shortening a construction period and a workshop built by same method. A roof of a multi-layer workshop is of a steel truss structure and is erected on a foundation through main stand columns; and the roof is installed on the multi-layer workshop firstly, then floors are built under the roof, and meanwhile pipelines are laid in the roof. According to the workshop building method capable of effectively shortening the construction period and the workshop built by the same method, the roof needing to be laid with a large number of pipelines is built firstly, then the floors are built, so that the pipeline laying work with long time consumption can be started in advance, the construction period is greatly shortened, and as a result, the requirements of factories with strict requirements on the construction period of the workshop aremet; in the workshop building method capable of effectively shortening the construction period and the workshop built by the same method, the laying of the pipelines and the construction of the floorsare carried out under the protection of the roof, so that the construction can be continuously carried out without considering the influence of severe weather, and the construction period is furthershortened; and meanwhile, due to the fact that the construction is continuously carried out, the situation that the strength of poured concrete parts is influenced due to different ages can be avoided, and therefore the construction quality is improved.

Owner:CHINA CONSTR FIRST DIV GROUP CONSTR & DEV

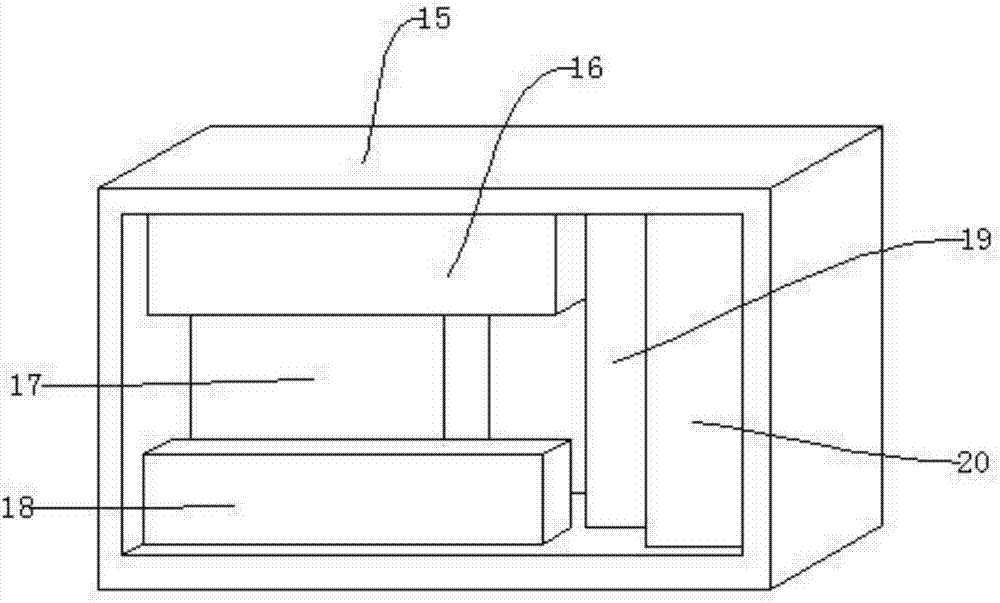

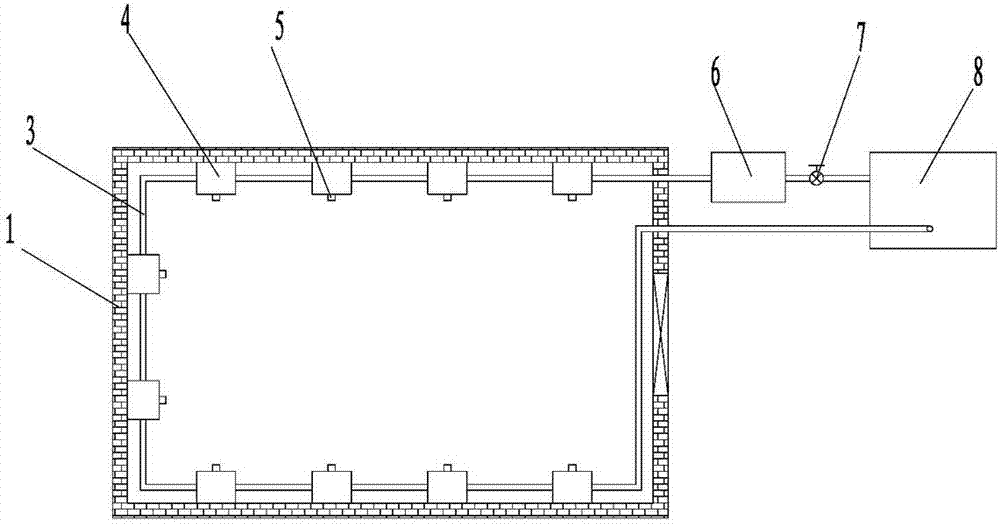

Workshop building provided with electric welding room and capable of preventing dust from diffusing

InactiveCN105317250AFunction increaseIncrease productivityLighting and heating apparatusIndustrial buildingsAir purifiersWorkshop building

The invention discloses a workshop building provided with an electric welding room and capable of preventing dust from diffusing. The workshop building comprises a workshop, wherein the closed welding room is arranged in the workshop, is located on one side in the workshop and shares one wall surface with the workshop; a row of air outlets are formed in the wall surface, shared with the workshop, of the welding room; air inlets are formed in the corresponding positions of a wall surface, parallel to the shared wall surface, of the welding room; a row of welding stations are further arranged in the welding room; a cover body for collecting smoke dust is arranged in the position, corresponding to the air outlets, outside the workshop and comprises an air inlet end and an air outlet end, the air outlets are totally covered with the air inlet end, and an exhaust fan and an air purifier are sequentially arranged at the air outlet end in the direction far away from the welding room. Workpieces are machined in the workshop and then enter the welding room on one side for welding, when the exhaust fan starts air exhausting, the air inlets and the air outlets form air channels, and dust can enter the cover body through the air channels, is purified by the air purifier and then is discharged.

Owner:CHENGDU MEISHITE ELECTROMECHANICAL CO LTD

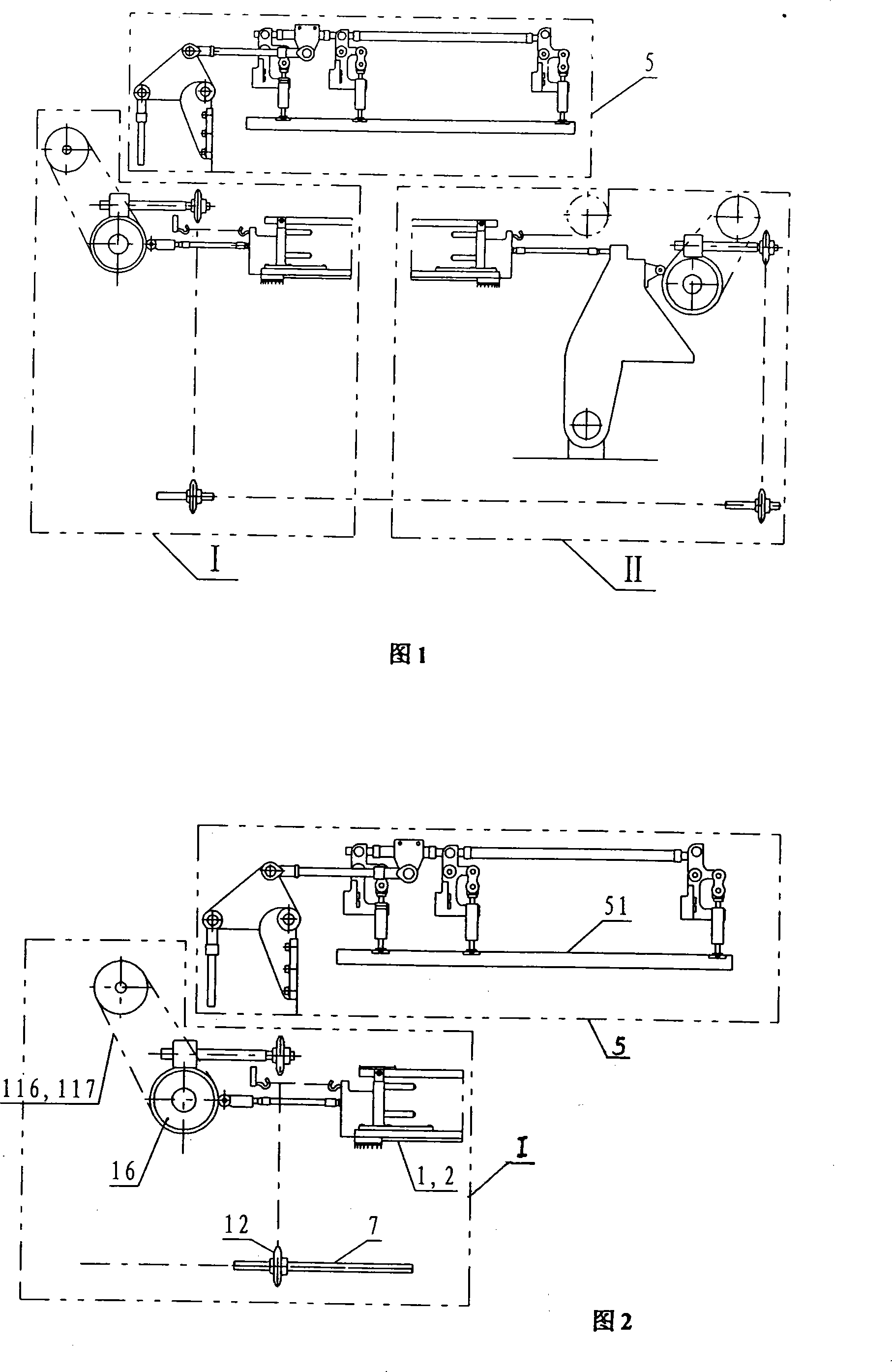

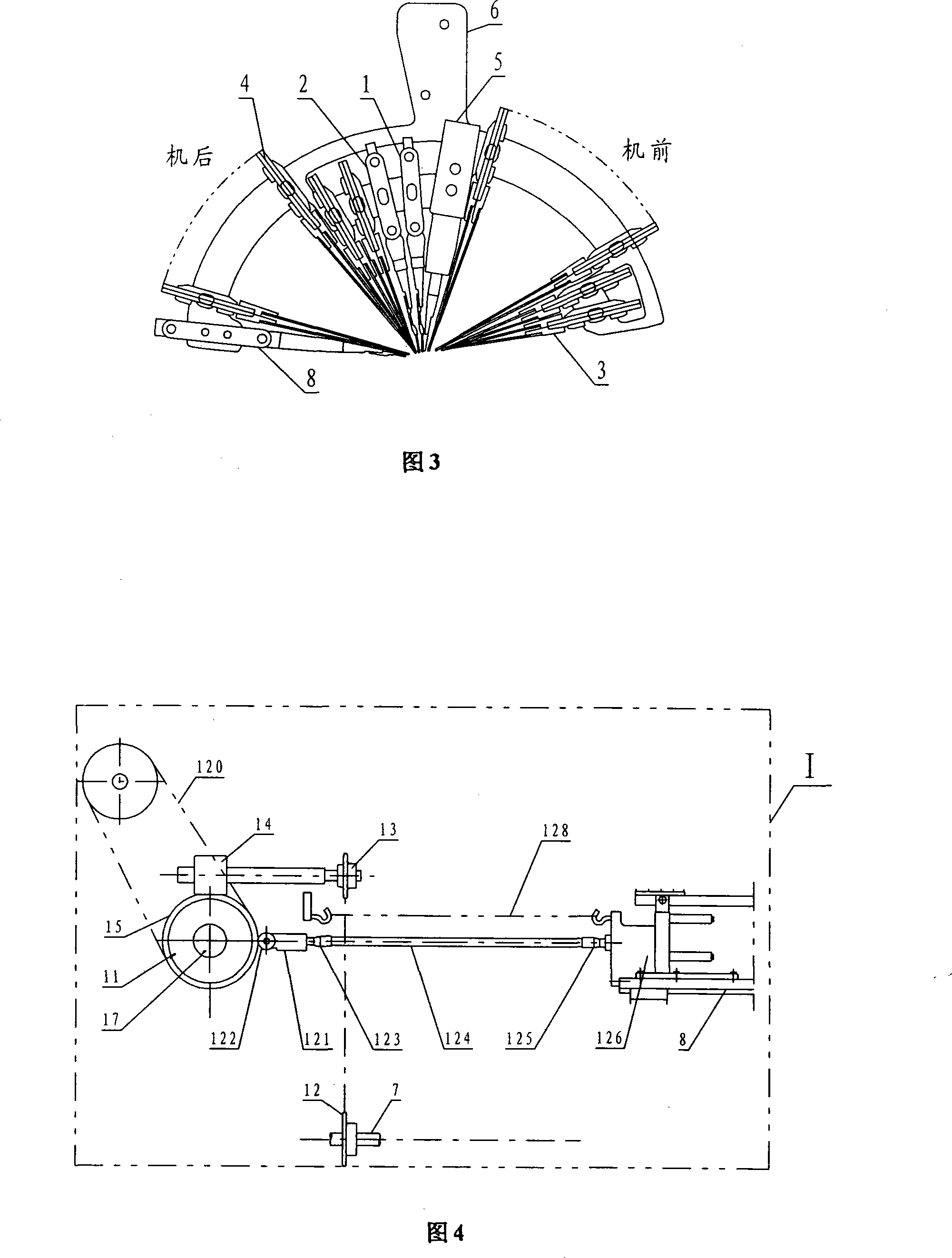

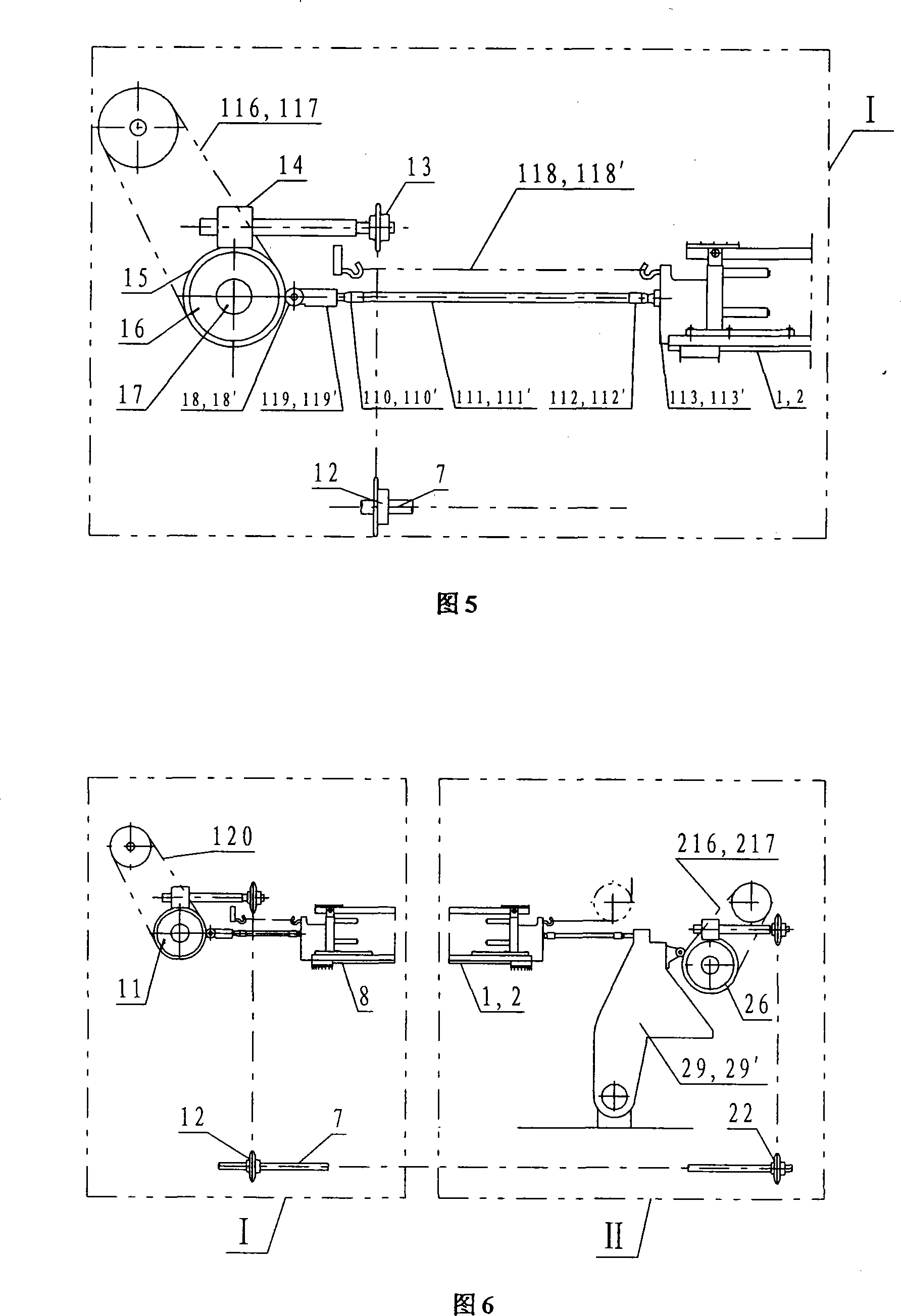

Multi-bar dual-purpose warp knitting machine

InactiveCN101225577ASave on construction costsSave floor spaceFlat warp knitting machinesDual purposeEngineering

The invention relates to a multi-bar and dual-purpose warp knitting machine, comprising three ground bars, a patterning bar, a fall plate mechanism, a guide bar cradle and a main shaft, which is characterized in that: a ground bar shogging mechanism I is arranged on the tail of the machine; a ground bar shogging mechanism II is arranged on the head of the machine; the multi-bar warp knitting machine with the fall plate is composed when the fall plate mechanism and the ground bar shogging mechanism I are arranged; wherein three ground bars are driven through the ground bar shogging mechanism I; the multi-bar warp knitting machine without the fall plate is composed when the ground bar shogging mechanism I and the ground bar shogging mechanism II are arranged, but the fall plate mechanism is disassembled; wherein the ground bar is driven through the ground bar shogging mechanism I; and other two ground bars are driven through the ground bar shogging mechanism II. The multi-bar and dual-purpose warp knitting machine has the advantages that: one machine for two uses can be conveniently realized without need of purchasing two warp knitting machines as long as the fall plate mechanism is arranged or disassembled for re-configuration and adjustment of the guide bar and partial components; various flower type fabrics can be obtained; and the equipment investment, the cost of the workshop building and the occupied area are saved.

Owner:CHANGZHOU DIBA TEXTILE MACHINERY

Method for efficiently breeding Australian freshwater lobsters

InactiveCN108719156AControl timeSmall sizeClimate change adaptationAnimal feeding stuffFresh water organismFishery

The invention provides a method for efficiently breeding Australian freshwater lobsters. In the method, mating time of male and female parents can be controlled, lobster larvae are of the same size, larvae emergence time is synchronous, and waste of the lobster larvae is effectively reduced. The method includes the steps of 1, workshop building; 2, construction of a thermal heating cycle system; 3, environmental construction of workshop and a lobster pond; 4, selection of the parents; 5, the parents into the pond; 6, spawning and hatching.

Owner:海宁市鸿海养殖有限公司

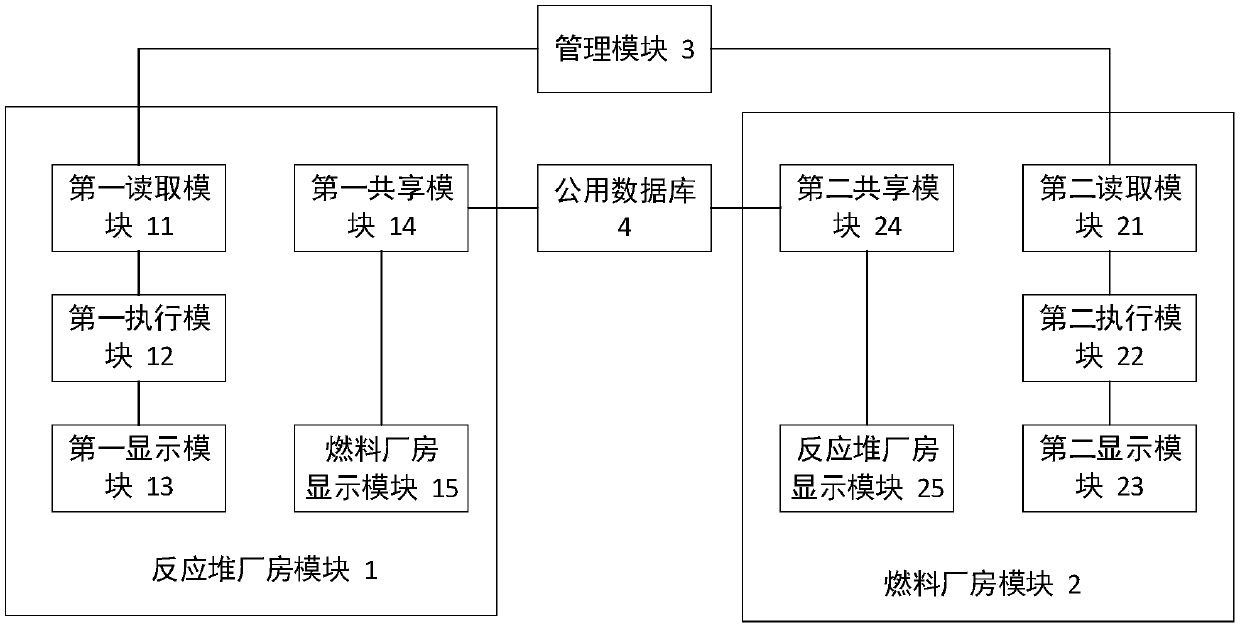

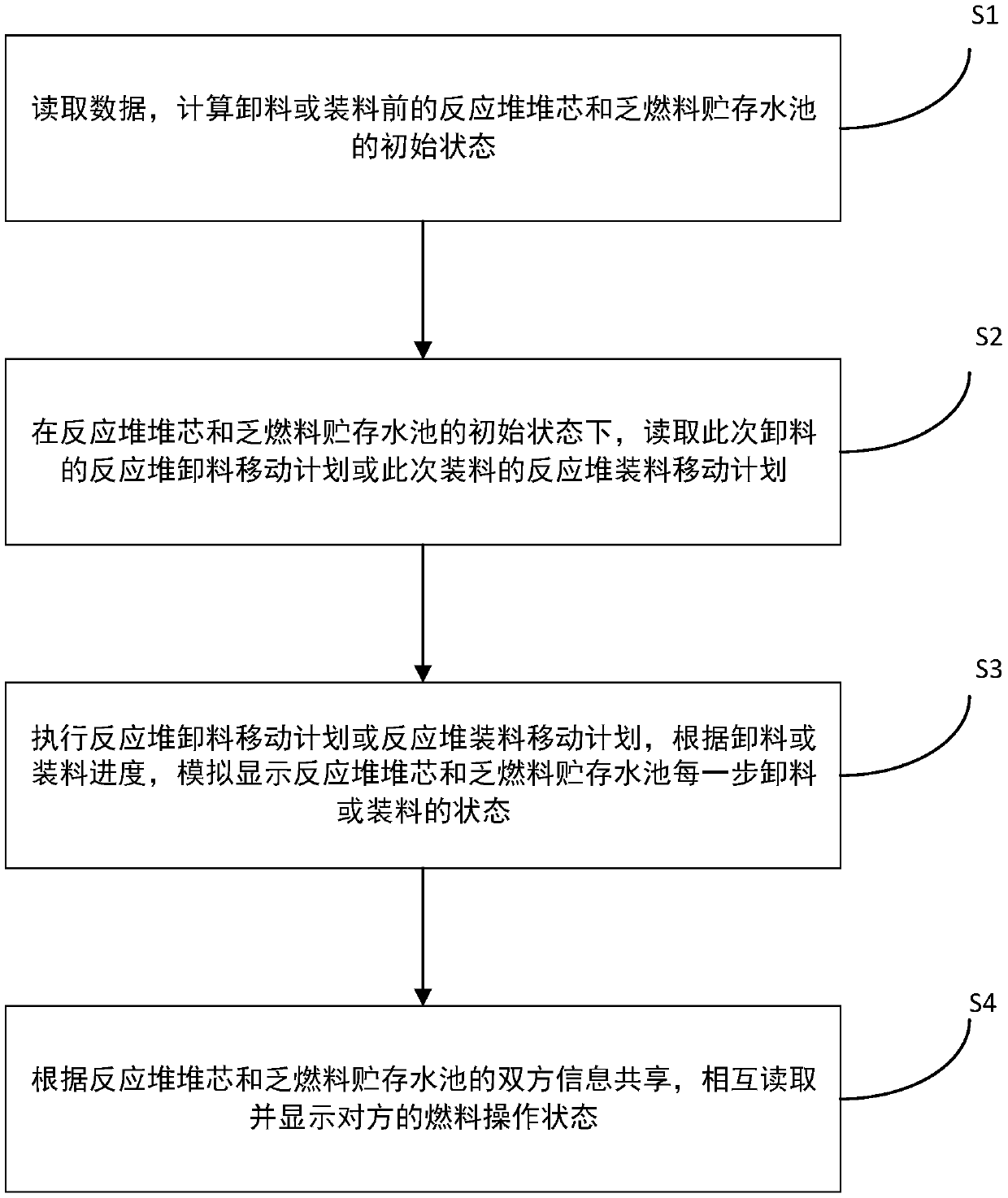

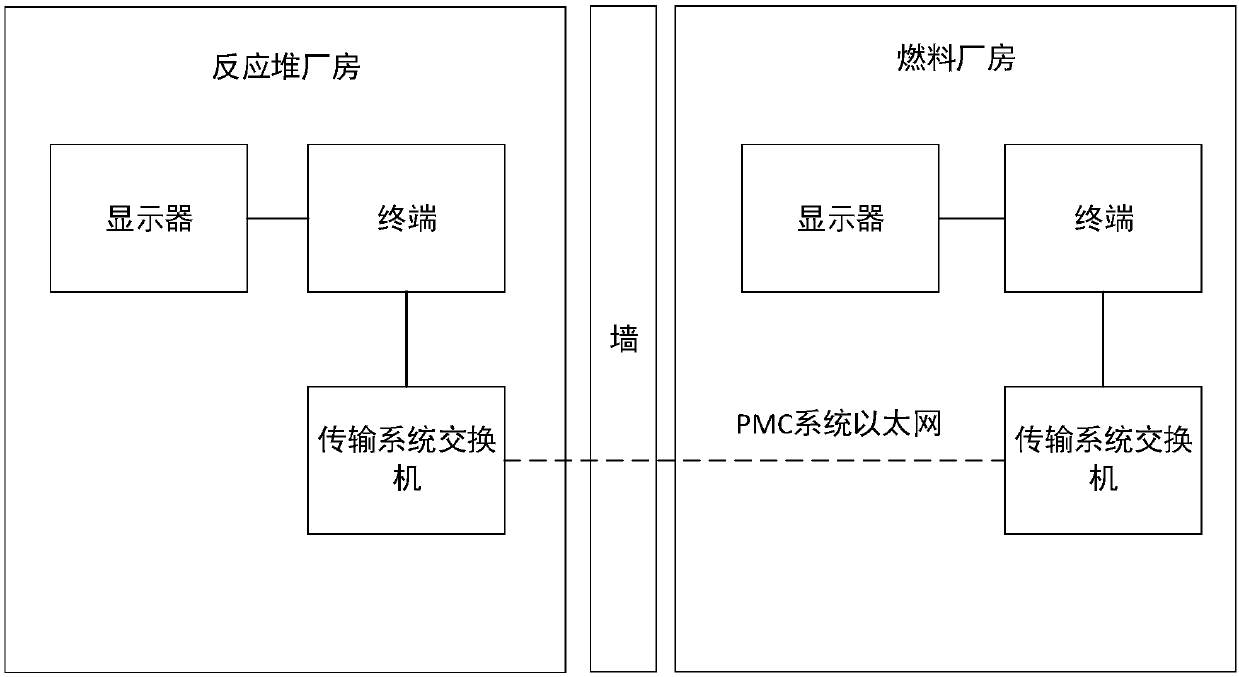

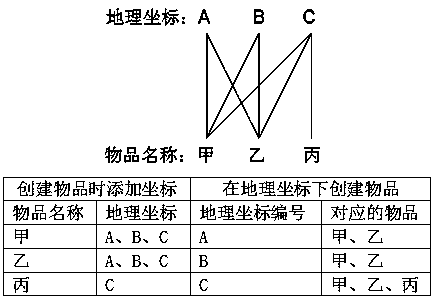

Nuclear power plant reactor loading and unloading state simulation system and method

ActiveCN109649995ASimulation is accurateFast simulationControl devices for conveyorsInformation sharingNuclear engineering

The invention discloses a nuclear power plant reactor loading and unloading state simulation system and method. The system comprises a management module, a reactor workshop building module and a fuelworkshop building module; the management module is used for storing the historical storing states, fuel component serial numbers, related component serial numbers and reactor loading and unloading moving plans of a reactor core and a spent fuel storing water pool; the reactor workshop building module is arranged in a reactor workshop building, the fuel workshop building module is arranged in a fuel workshop building, and the reactor workshop building module and the fuel workshop building module are used for reading data in the management module and calculating the initial states of the reactorcore and the spent fuel storing water pool before loading and unloading; in the initial states, the reactor loading and unloading moving plans for loading and unloading are read and executed from themanagement module, and the states of the reactor core and the spent fuel storing water pool in all steps are simulated and displayed according to the loading and unloading progress; and the fuel operation states of the opposite workshop buildings are read and displayed according to information sharing of the reactor workshop building module and the fuel workshop building module. According to thenuclear power plant reactor loading and unloading state simulation system and method, accurate and quick simulation of the reactor loading and unloading process and states is achieved, and the operation efficiency is improved.

Owner:CHINA GENERAL NUCLEAR POWER OPERATION +2

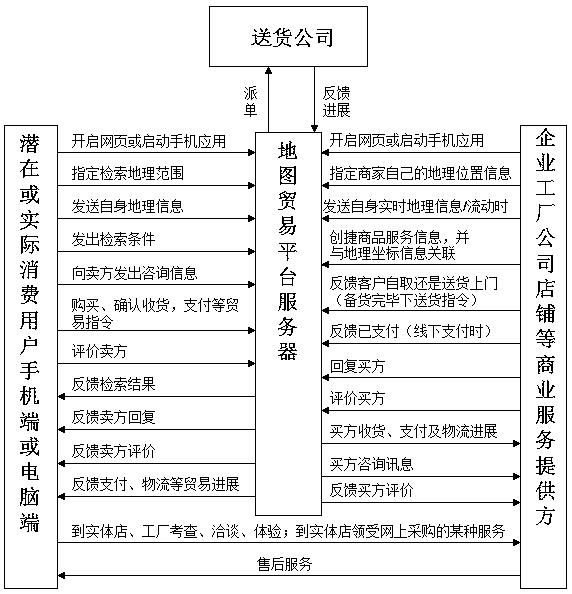

Digital map combined network trading platform

InactiveCN108305136AEasy to buyLow costBuying/selling/leasing transactionsGeographical information databasesWeb sitePayment

The invention relates to a digital map combined network trading platform. The platform calls a map, so that a user can set geographical position information for each article, service, organization orindividual and a related website, after setting of the geographical position information, information needed by the user in the trading platform can be obtained by screening within a specific geographic range according to searching conditions of the user, and displayed in the map in the form of highlight icons or a list, detail information can be displayed by clicking a search result in a plane, and an entity article or workshop building can be displayed in a 3D manner and the article can be tried virtually via scientific means as VR technology and holographic technology. The user can furthercarry out network payment after reaching agreement with a seller.

Owner:周现荣

Cold box exposed cooling-free construction method of large air separation device

ActiveCN107990631AReduce investmentImprove construction progressSolidificationLiquefactionAir separationWorkshop building

The invention discloses a cold box exposed cooling-free construction method of a large air separation device. The cold box exposed cooling-free construction method of the large air separation device comprises standard prefabricated workshop building, material stacking, modular pipeline prefabricating, mechanized hoisting, tracking type welding installation and overall checking and examining. Tracking type welding installation comprises pre-welding examining, end cap controlling during welding, pipeline checking after welding and 3A branched pipe connection examining of a pipeline. By means ofthe cold box exposed cooling-free construction method, the construction quality can be well guaranteed through strict process control, the investment of workers can be effectively reduced, the construction progress is accelerated, the construction period is shortened, the one-time turning process is reduced, turning of a cold box can be carried out after a unit is debugged to be qualified, it doesnot need to stop turning to wait pearlife loading, and after the whole debugging time is shortened, the turning expenditure can be effectively saved.

Owner:CHINA NAT CHEM ENG THIRD CONSTR

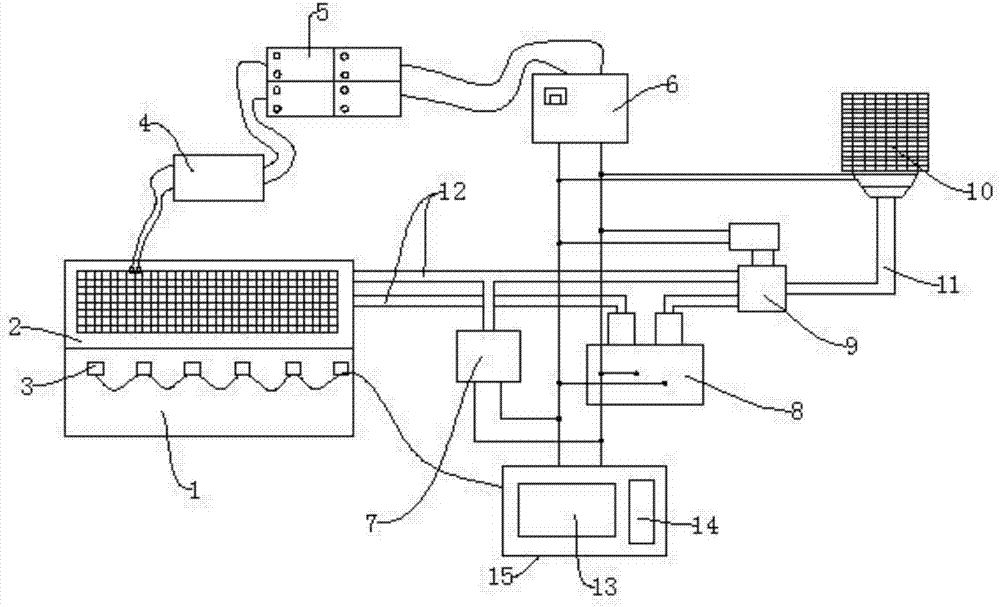

Workshop drying and ventilating system with humidity and temperature capable of achieving combined control

InactiveCN107023931AReduce areaDoes not consume electricityMechanical apparatusSpace heating and ventilation safety systemsElectricityEngineering

The invention discloses a workshop drying and ventilating system with the humidity and temperature capable of achieving combined control. The workshop drying and ventilating system comprises a workshop building. A solar panel is arranged on a roof of the workshop building. The solar panel is electrically connected with a solar power generation controller. The solar power generation controller is further electrically connected with a battery pack. The battery pack is further electrically connected with an inverter. The inverter is electrically connected with a main control computer, an industrial humidifier, a drying machine, a two-position three-way electromagnetic valve and an air conditioning unit. The workshop drying and ventilating system with the humidity and temperature capable of achieving combined control has the beneficial effects that the system depends on the solar panel to supply power for working, no mains supply can be consumed, and energy saving and environmental protection are realized; and moreover, there is no need to lay the humidifier inside the workshop building in a large-area mode, the industrial humidifier only needs to be additionally arranged on a gas conveying pipe, and therefore the workshop building area is decreased, production cost is reduced, and practicality is good.

Owner:长春电子科技学院

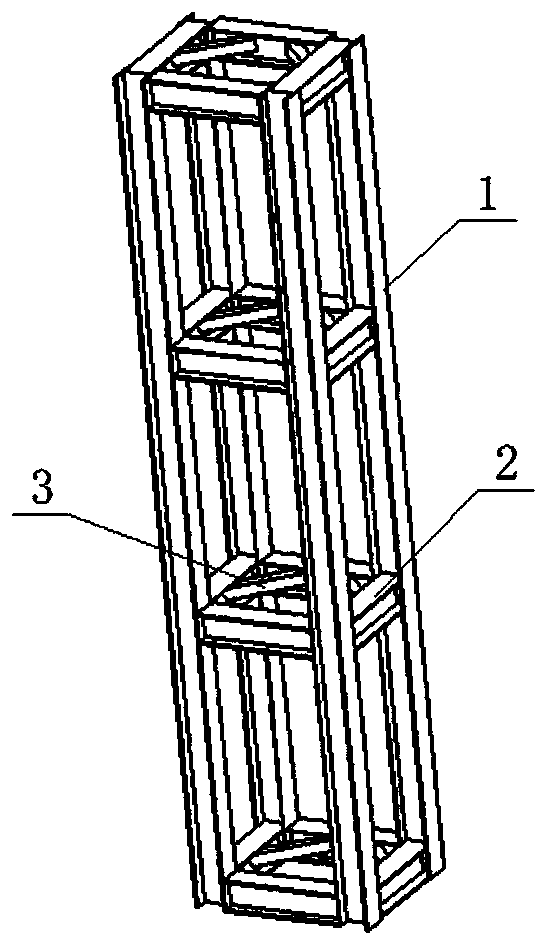

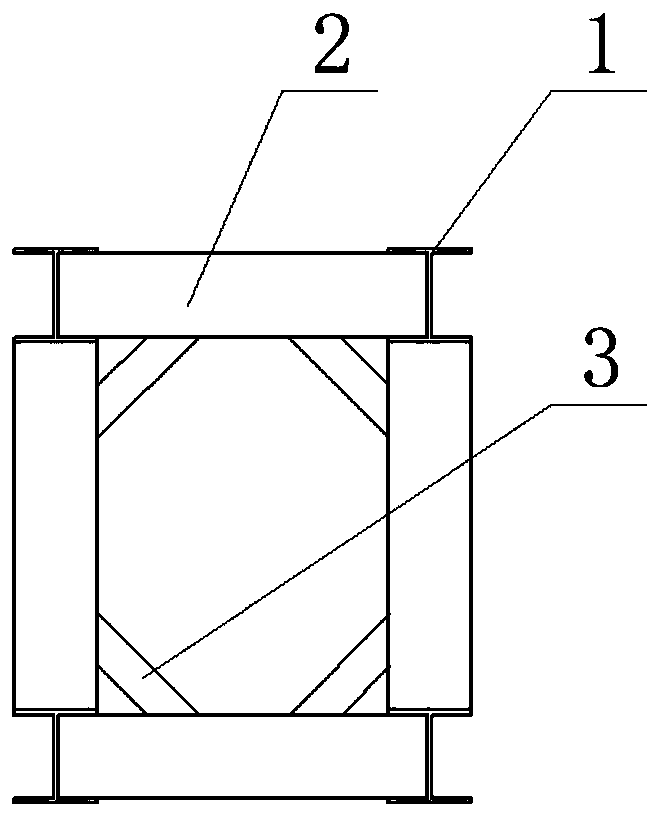

Steel structure factory building bearing column and manufacturing method thereof

InactiveCN109914694AImprove carrying capacityImprove stabilityStrutsArc welding apparatusEngineeringWorkshop building

The invention provides a steel structure factory building bearing column and a manufacturing method thereof. The steel structure factory building bearing column comprises four bearing beams verticallyarranged on the ground, a plurality of connecting beams are connected between every two adjacent bearing beams in a welded mode, the two ends of each connecting beam are fixed between the corresponding two adjacent bearing beams in a welded mode, and at least two connecting beams are flush with the upper end faces and the lower end faces of the bearing beams respectively. The manufacturing methodcomprises the steps that a working platform is provided, the bearing beams and the connecting beams are placed in groups, the perpendicularity of the connecting beams is detected, welding is conducted to obtain bearing frames, the connecting beams are placed between the bearing frames, and the perpendicularity of the connecting beams is detected, and welding is conducted to obtain the bearing columns. By the adoption of the technical scheme, the bearing capacity of the bearing columns is improved through H-shaped profile steel, prefabrication is facilitated, the key point is to control the perpendicularity between the connecting beams and the bearing beams in the prefabrication process, the manufacturing quality is guaranteed, adjustment in the workshop building process is avoided, and afoundation is laid for improving the construction efficiency.

Owner:NO 1 CONSTR ENG CO LTD OF GUIZHOU CONSTR & ENG GRP

Air purification system for electrically fused zirconia alumina brick assembling workshop

InactiveCN107469517ANovel structureSimple and reasonableUsing liquid separation agentSeparation devicesBrickWater vapor

The invention relates to an air purification system for an electrically fused zirconia alumina brick assembling workshop, which can effectively solve the rapid dust collection problem of the electrically fused zirconia alumina brick assembling workshop. According to the technical scheme, the air purification system comprises an assembling workshop building, a circulation pipeline is arranged in the building, jet cavities evenly distributed are arranged on the circulation pipeline, a heater is arranged in each jet cavity, a fine water mist spray nozzle with a water inlet end communicated with the inner cavity is arranged on each jet cavity, the water inlet end of the circulation pipeline is connected with a water outlet of a high-pressure pump group, a water inlet of the high-pressure pump group is connected with a water outlet of a water tank through a valve, a water outlet end of the circulation pipeline is connected with a water inlet of the water tank, a plurality of vortex ventilation hoods communicated with the inner cavity of the building are arranged on a top plate of the building. Water is heated and then sprayed out through the fine water mist spray nozzle to form water mist mixed flow of water mist and water stream, the higher the temperature is, the faster the ascending speed of wet-heat air is, the water mist mixed flow is adhered to dust when ascending upward, so that the purpose of carrying away dust through the upward power of the water mist can be achieved.

Owner:郑州远东耐火材料有限公司

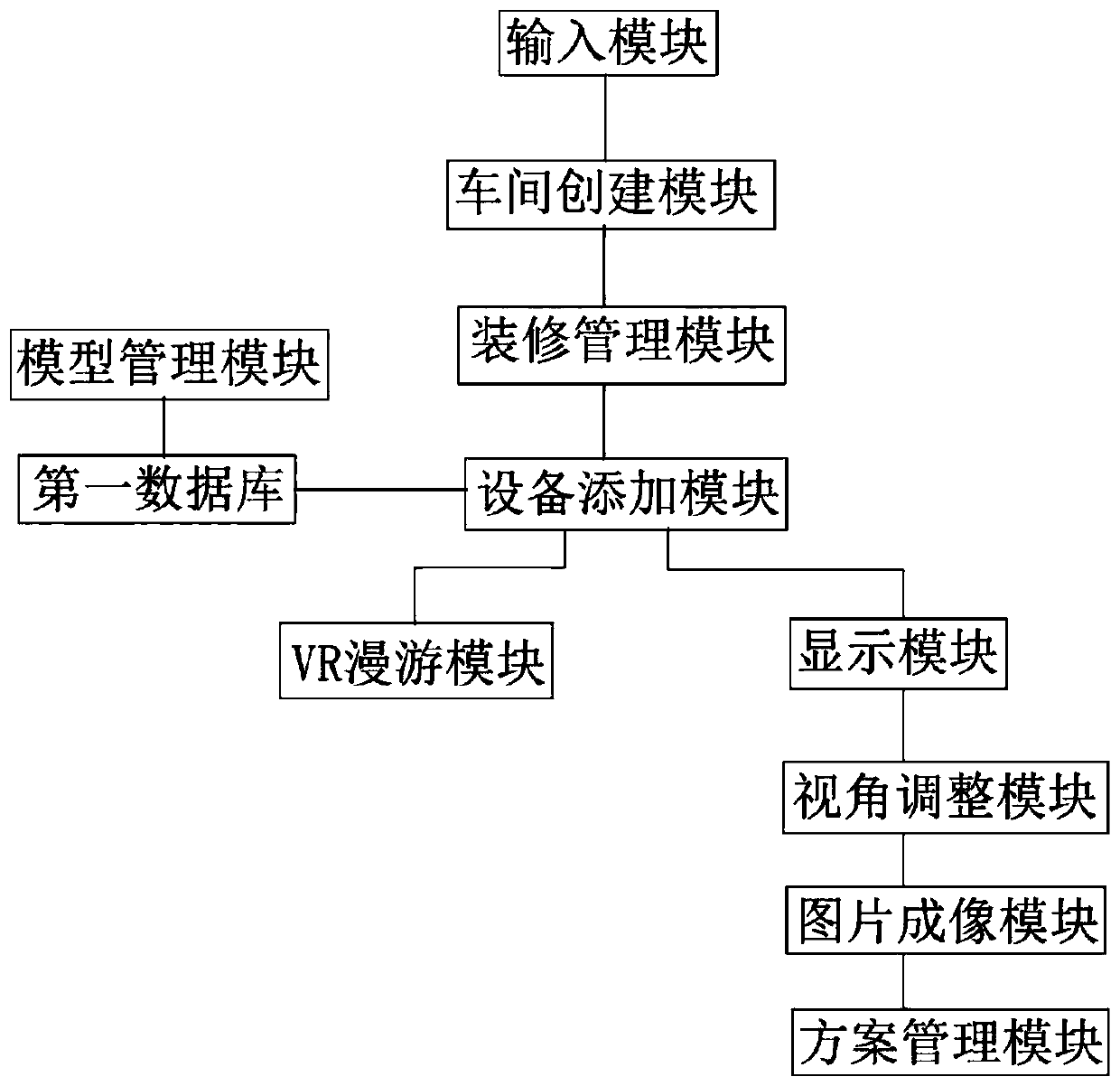

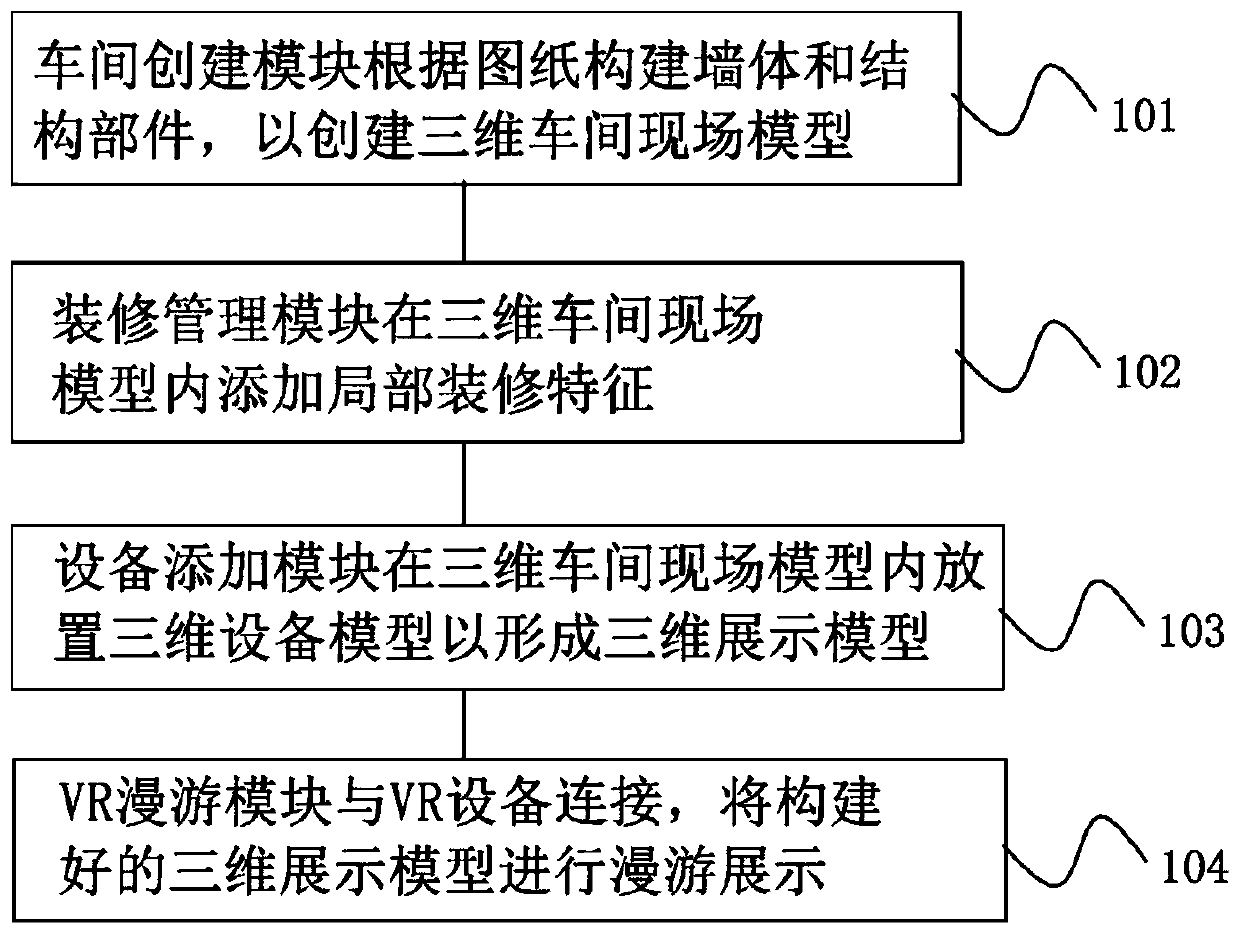

Workshop field three-dimensional effect graph construction display system and method

PendingCN110955334AShorten production timeImprove service experienceInput/output for user-computer interactionGraph readingSite modelProduction line

The invention discloses a workshop on-site three-dimensional effect graph construction display system and method, and the system comprises: a workshop building module which is used for building a walland a structural part according to a drawing, so as to build a three-dimensional workshop on-site model; a decoration management module used for adding local decoration features into the three-dimensional workshop on-site model; an equipment adding module used for placing a three-dimensional equipment model in the three-dimensional workshop on-site model to form a three-dimensional display model;and a VR roaming module used for being connected with VR equipment and carrying out roaming display on the constructed three-dimensional display model. According to the workshop on-site three-dimensional effect graph construction display system, workshop drawing can be efficiently completed by importing the drawing, the equipment model is clicked to quickly establish the production line, the three-dimensional rendering effect picture is obtained, the manufacturing time is shortened, and the service experience is improved. The workshop on-site three-dimensional effect graph designed by the system can be imported into VR equipment for immersive roaming display, and more visual experience and demonstration effects are brought to customers.

Owner:北京视桥数字科技有限公司

High vacuum valve of large diffusion pump vacuum set

ActiveCN102588618AGood technical effectLower the altitudeOperating means/releasing devices for valvesLift valveEngineeringWorkshop building

The invention discloses a high vacuum valve of a large diffusion vacuum set, comprising a valve body consisting of an upper valve body and a lower valve. A valve cover is arranged between the upper valve body and the lower valve body and is communicated with a perforated valve base plate or closes the upper valve body and the lower valve body, and the upper valve body and the lower valve body arepositioned on the same level; and the valve base plate is obliquely arranged at 45 degrees, and one side of the valve cover is hinged on the upper valve body through a horizontal shaft. According to the invention, the upper valve body and the lower valve body are horizontally arranged, and the valve cover is changed from vertical lifting movement perpendicular to the valve base plate to the open and close movement at a turning angle of 45 degrees relative to the valve base plate, which greatly reduces the height of the high vacuum valve, so as to greatly reduce the overall height of equipment, and solve the problem that a large-scale film coating equipment has high requirements on the height of a workshop building. In this way, the high vacuum valve can adapt to common floor height, so asto greatly improve the adaptability to large-scale film coating equipment.

Owner:DONGGUAN HUICHENG VACUUM TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com