High vacuum valve of large diffusion pump vacuum set

A technology of vacuum unit and diffusion pump, which is applied in the direction of valve lift, valve details, valve device, etc., can solve the problems of high requirements on the height of the factory building, and achieve the effect of reducing the overall height, reducing the cost of use and making the cost cheap

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

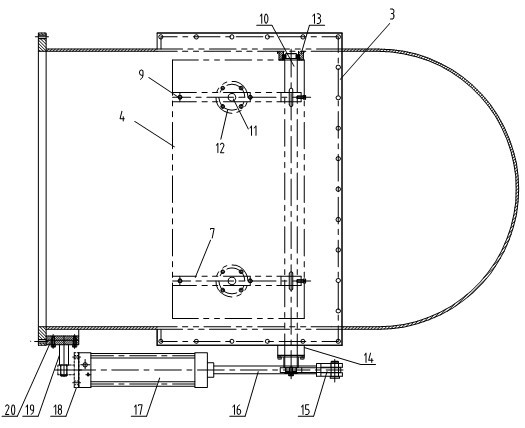

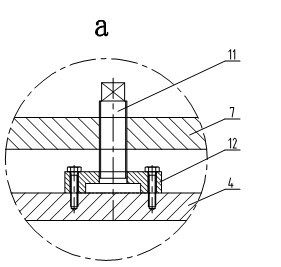

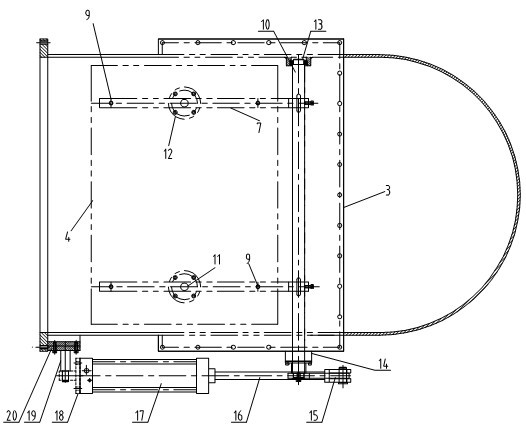

[0026] The present invention will be further described below in conjunction with accompanying drawing:

[0027] Such as figure 1 , 2 As shown, the high vacuum valve of the preferred embodiment of the present invention includes a valve body, the valve body is composed of an upper valve body 5 and a lower valve body 2, the upper and lower valve bodies 5, 2 are at the same level, and the two nozzle axes of the valve body Vertical, one side of the nozzle is circular, the direction is downward, and a connecting flange 1 is welded, through which the connection flange 1 is connected to the diffusion pump, and the other side of the nozzle is a rectangular opening, which is connected to the coating chamber of the coating machine through the connecting flange 6 .

[0028] The lower valve body 2 is a cylinder with a U-shaped horizontal cross-section, and the U-shaped horizontal part is a wide, long, high-short square transition tube connected to the upper valve body 5, and the nozzle...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com