Steel structure factory building bearing column and manufacturing method thereof

A manufacturing method and technology of load-bearing columns, applied in the direction of manufacturing tools, columns, pier columns, etc., can solve the problems of limited connection tightness, limited bearing capacity, and inconvenience in pre-manufacturing, so as to avoid adjustment, enhance bearing capacity and stability, The effect of reducing cumulative error

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] The technical solution of the present invention is further described below, but the scope of protection is not limited to the description.

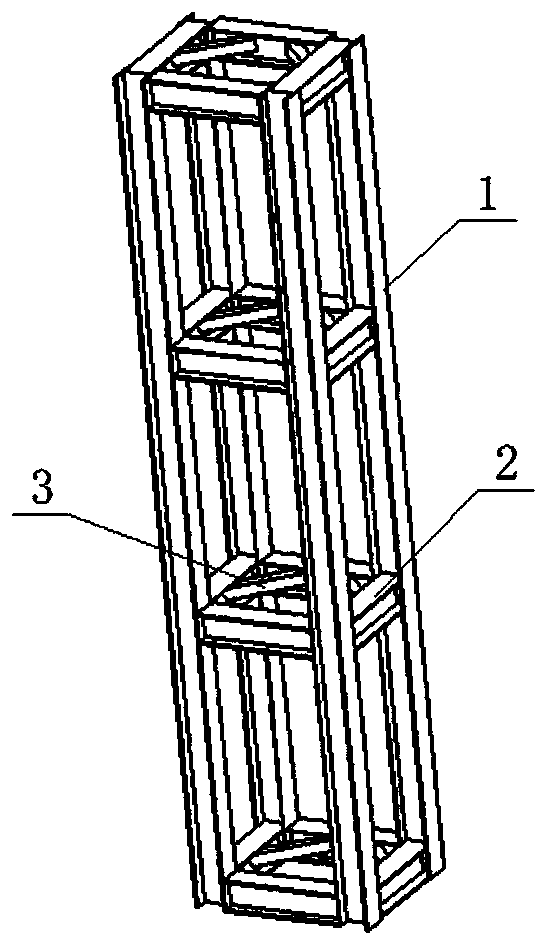

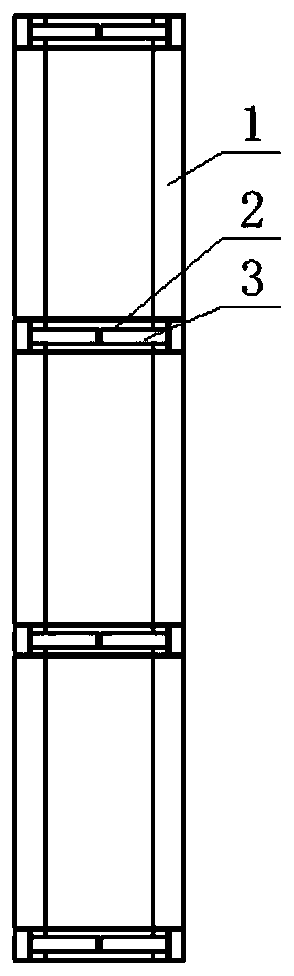

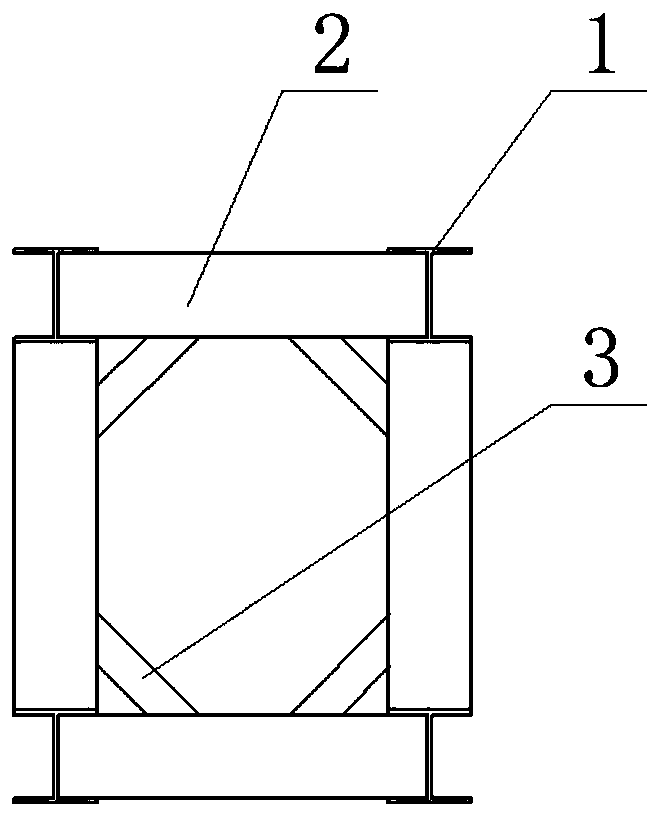

[0029] Such as Figure 1 to Figure 4 As shown, the present invention provides a load-bearing column of a steel structure factory building and a manufacturing method thereof, comprising four support beams 1 erected on the ground, and a plurality of connecting beams 2 are welded and connected between two adjacent support beams 1, The two ends of the connecting beam 2 are welded and fixed between two adjacent supporting beams 1, wherein at least one connecting beam 2 bottom surface is flush with the lower end surface of the supporting beam 1, and at least one connecting beam 2 top surface is flush with the supporting beam 1 upper end flush.

[0030] Adopting the technical scheme of the present invention, the supporting beam and the connecting beam are all made of "H" shaped steel, which lays a foundation for improving the load-bearin...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Length | aaaaa | aaaaa |

| Surface roughness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com