Full-automatic door used in workshop

A fully automatic, large door technology, which is applied to the layout of wing leaves, door/window accessories, window/door frames, etc., can solve the problems of low service life and poor durability, and achieve long service life, excellent strength and rigidity, Good safety performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

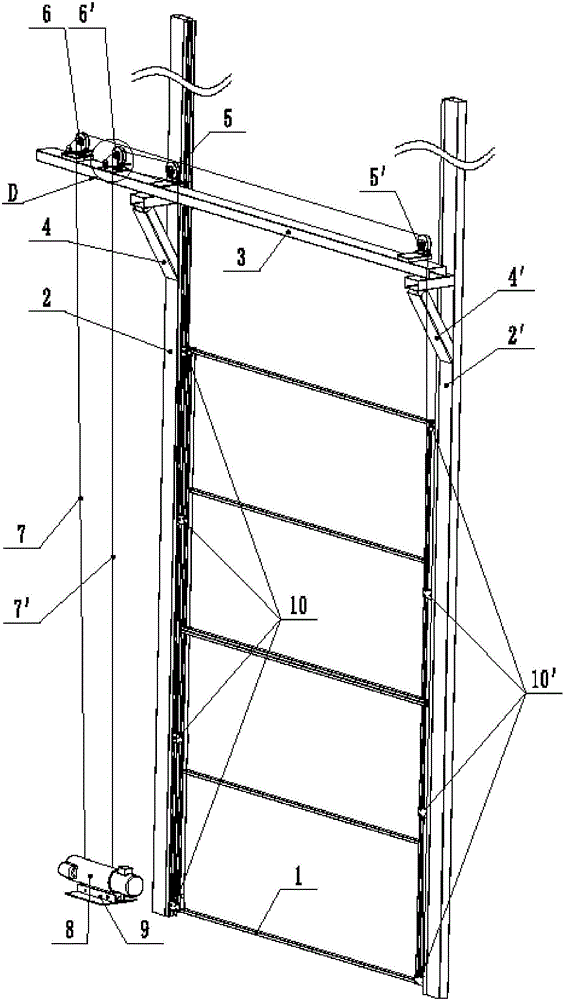

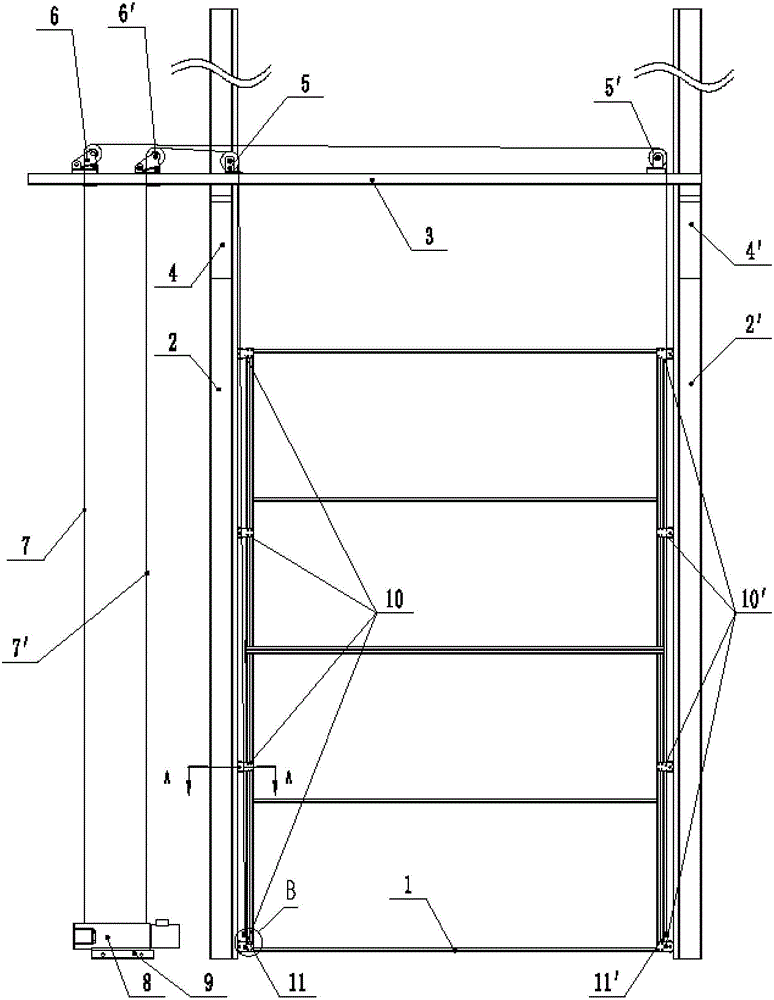

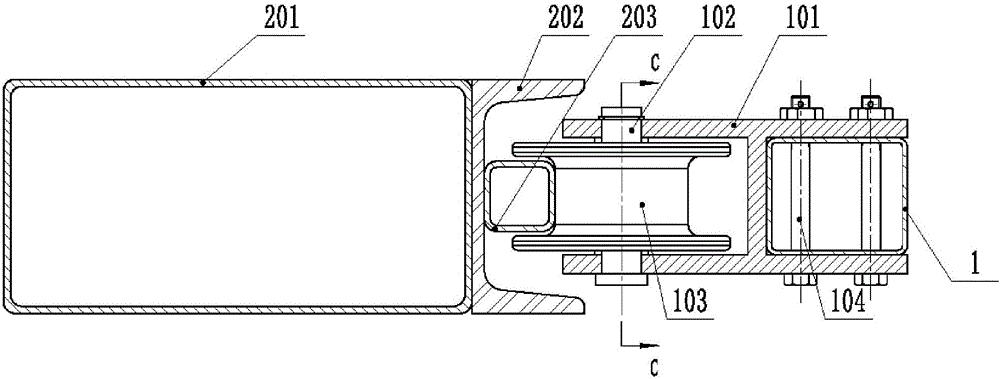

[0019] The structure of the present invention is figure 1 , 2 As shown, when the electric hoist 8 installed on the foundation is started to rotate by the remote controller, the left and right steel wire ropes 7, 7' wound in the electric hoist 8 rise or fall, and the left and right steel wire ropes 7, 7' all bypass the left and right tensioning pulleys respectively. Parts 6, 6' and left and right support pulley assemblies 5, 5', the door frame 1 is lifted or lowered in the grooved track 202 of the left and right door posts by the track pulleys installed on the left and right sides. Easy to operate, flexible, safe and reliable.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com