Method for producing latex bed mattress

A latex and mattress technology, used in mattresses, spring mattresses, light therapy, etc., can solve the problems of uneven spine stress, lack of ventilation, easy infiltration of water and air, etc., to meet individual needs and reduce financial pressure. , the effect of simple process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0037] In order to make the technical means, creative features, goals and effects achieved by the present invention easy to understand, the present invention will be further described below in conjunction with specific embodiments.

[0038] A kind of preparation method of latex mattress

[0039] see figure 1 , a kind of preparation method of latex mattress, comprises the following steps:

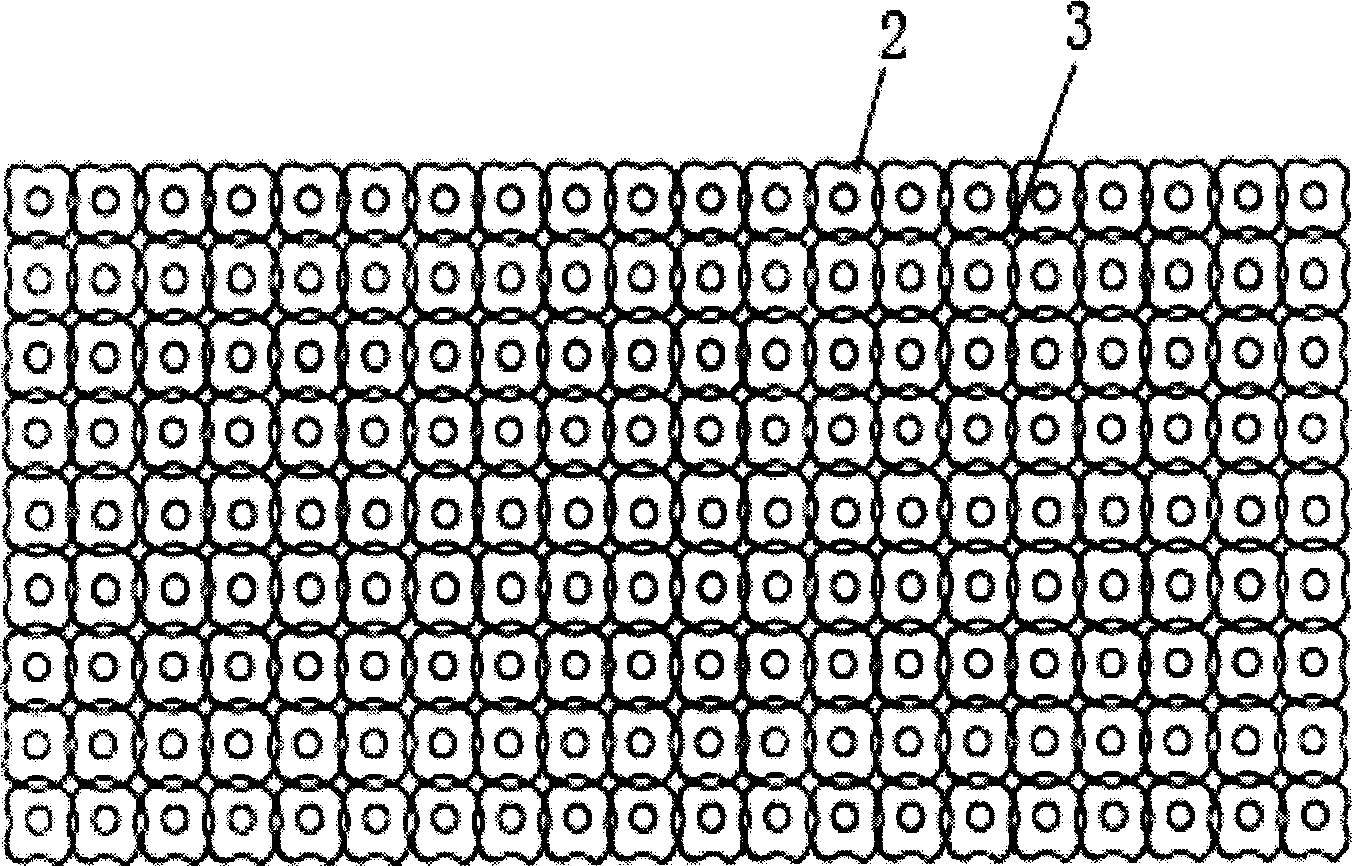

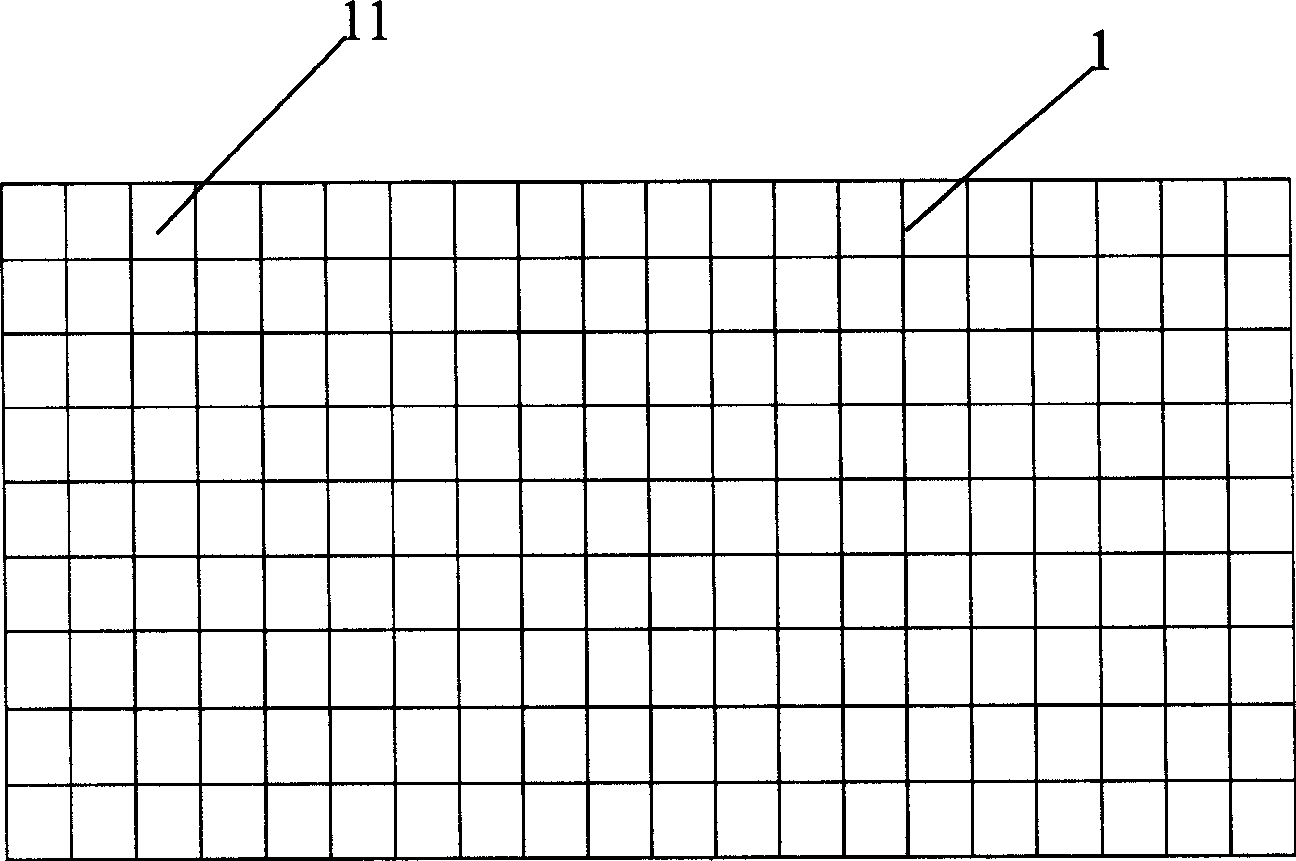

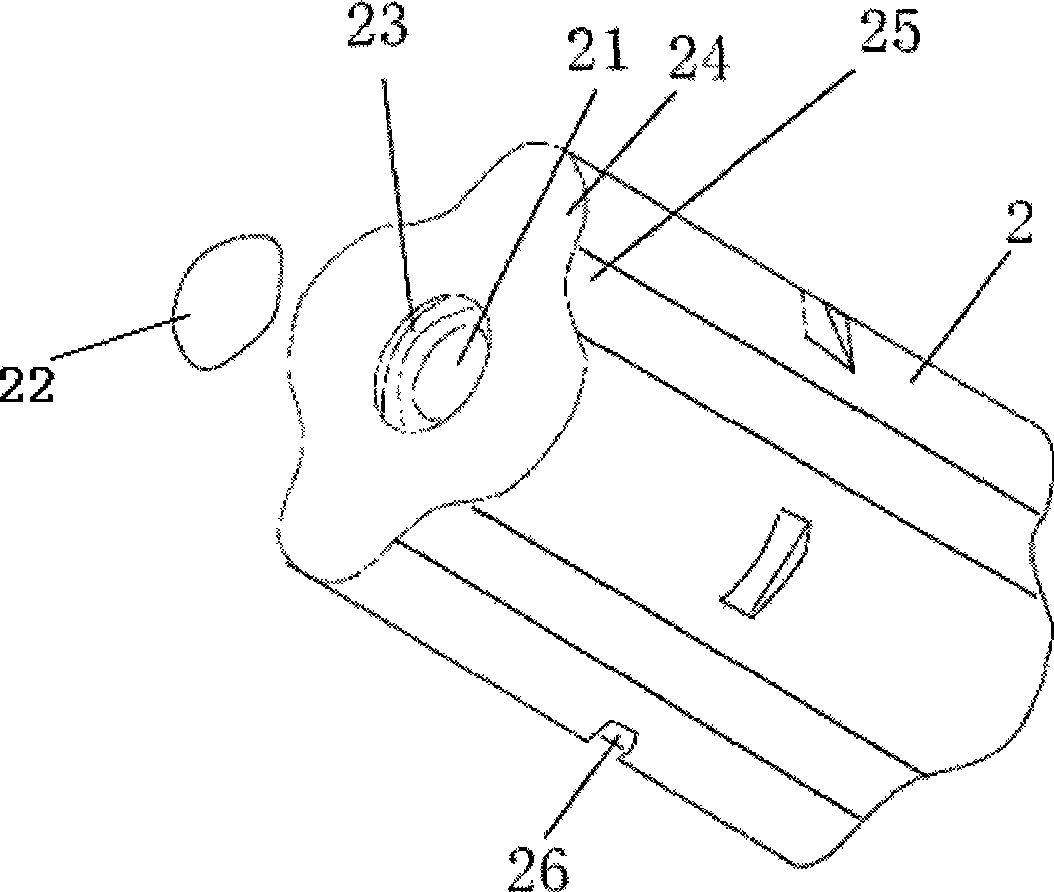

[0040] First construct a mattress outer frame 1; then in the mattress outer frame, construct an elastic grid 2; latex column unit 3 is placed in each space 21 of the elastic grid 2, thereby forming a latex mattress .

[0041] The size of the whole latex mattress can be the same as the existing 1.2m x 2m or 1.5m x 2m or 1.8m x 2m mattress specifications, and there is a mattress cover (not shown) in the latex mattress overcoat, usually the mattress The cover is made of cotton to improve sleeping comfort. The cotton cover can be printed or dyed.

[0042] see figure 2 , the elastic networ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com