Workshop building provided with electric welding room and capable of preventing dust from diffusing

A dust-proof and plant-based technology, applied in space heating and ventilation, household heating, lighting and heating equipment, etc., can solve problems such as harsh environment, lack of assembly line work, poor ventilation effect, etc., to optimize the overall function, The structure is simple and the effect of improving production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

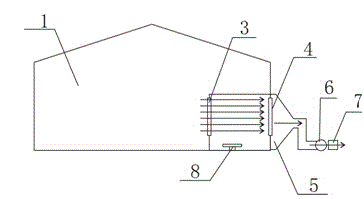

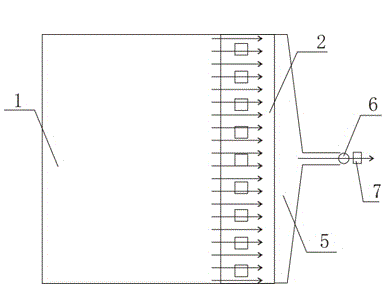

[0013] Embodiment 1: see figure 1 , figure 2 , a factory building with an electric welding room and dust-proof, including a workshop 1, a welding room 2 is arranged in the workshop 1, and the welding room 2 is airtight, located on one side of the workshop 1 and sharing a wall with the workshop 1 , the wall shared by the welding room 2 and the workshop 1 is provided with an exhaust air outlet 4, and the corresponding position on the wall parallel to the wall of the welding room 2 is provided with an air inlet 3, and a row of welding stations is also arranged in the welding room 2 8. Outside the workshop 1, there is a cover body 5 for collecting smoke and dust corresponding to the air outlet 4. The cover body 5 includes an air inlet end and an air outlet end. The direction of the room 2 is provided with an exhaust fan 6 and an air cleaner 7 successively, the air outlet 4 and the air inlet 3 are arranged horizontally, the welding station 8 is parallel to the air inlet 3 and clo...

Embodiment 2

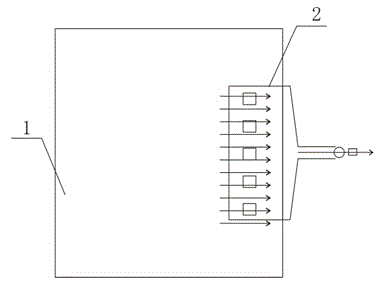

[0017] Example 2: see image 3 , the welding room 2 is located on one side of the workshop 1 and only shares a wall with the workshop 1, and the other sides are not in contact with the workshop 1. Other than that, the rest is the same as that of the embodiment 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com