Workshop building method capable of effectively shortening construction period and workshop built by same method

A construction method and factory building technology, applied in industrial buildings, building structures, buildings, etc., can solve problems such as long construction period and inability to satisfy the iteration cycle, and achieve the effect of shortening construction period, shortening construction period, and improving construction quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

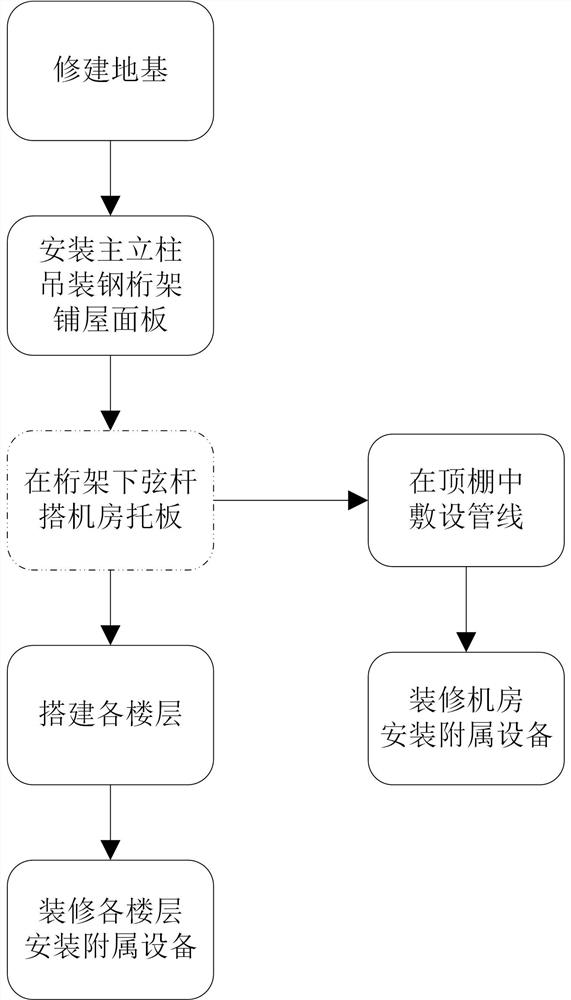

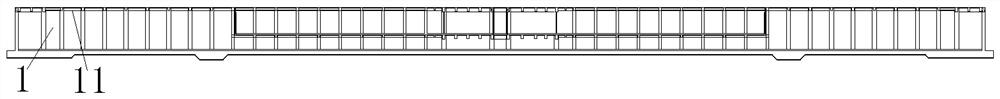

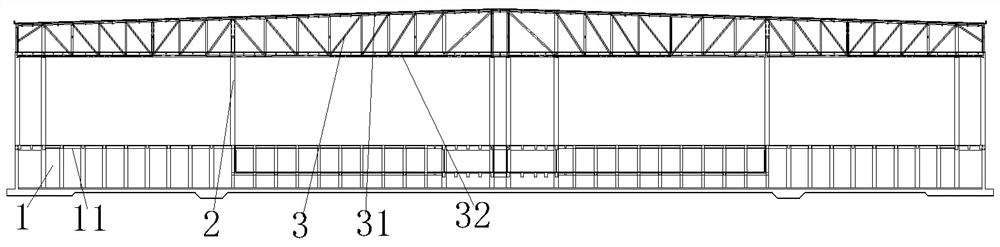

[0037] A factory building construction method that effectively shortens the construction period, and is used for building a multi-storey factory building with complex pipelines in the roof 3. The roof 3 of the multi-storey factory building is a steel truss structure, and is erected on the foundation 1 through the main column 2; The roof 3 is first installed in the multi-storey factory building, and then each floor is built under the roof 3 and pipelines are laid in the roof 3 at the same time. In this way, not only the time-consuming long pipeline laying work can be carried out in advance, without waiting for the completion of other floors, but also the subsequent construction process is protected by the roof 3 and can be continuously constructed without being affected by bad weather. The multi-storey factory building in this example is located in the TSMC wafer factory in Nanjing. During the rainy season, the construction process will be seriously affected by the weather, ofte...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com