Air purification system for electrically fused zirconia alumina brick assembling workshop

A technology of air purification system and assembly workshop, applied in separation device, chemical instrument and method, separation method, etc., to achieve the effect of simple and reasonable, good effect, novel and unique structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] The specific implementation manners of the present invention will be described in further detail below in conjunction with the accompanying drawings.

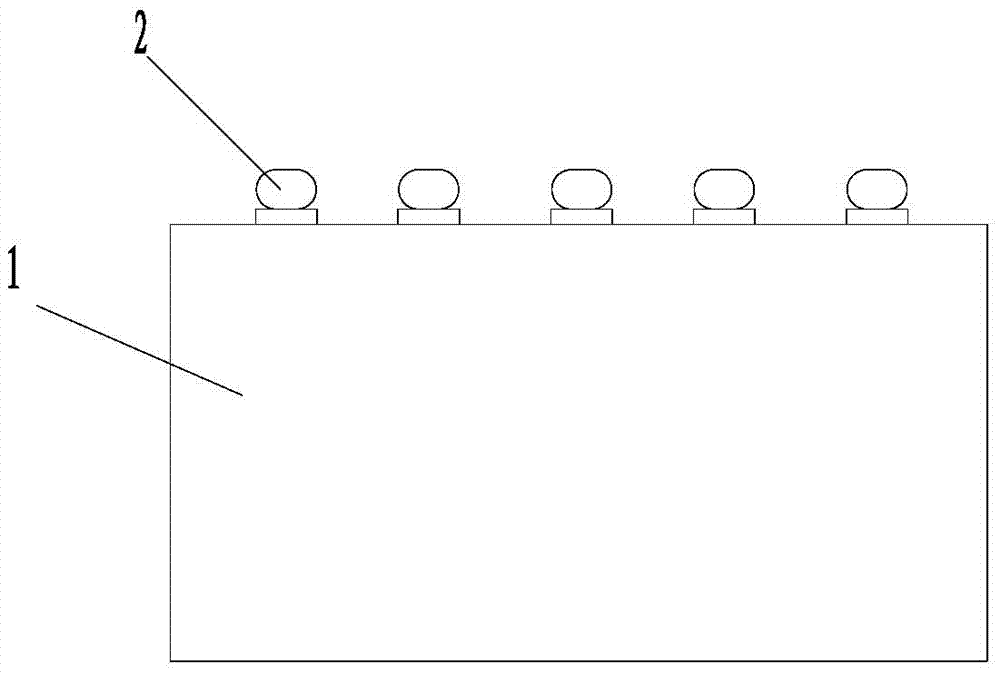

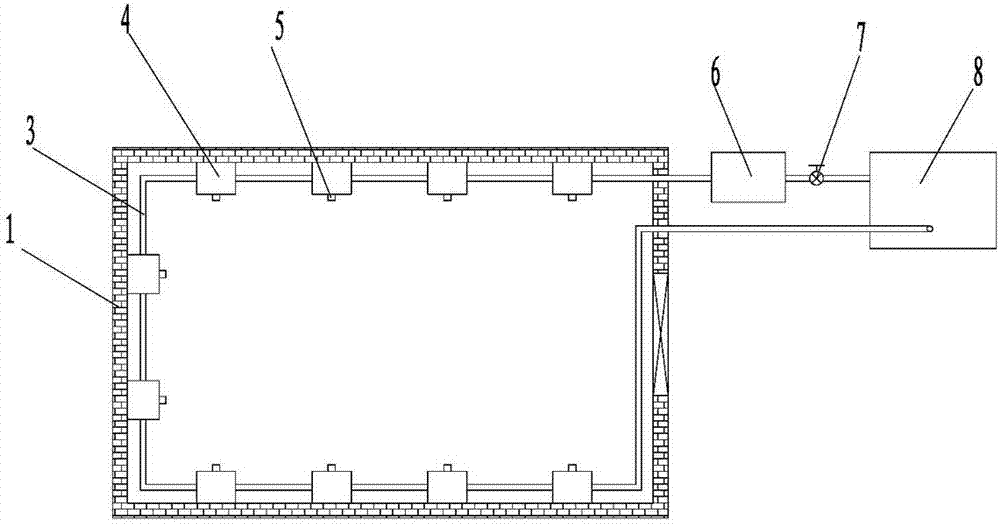

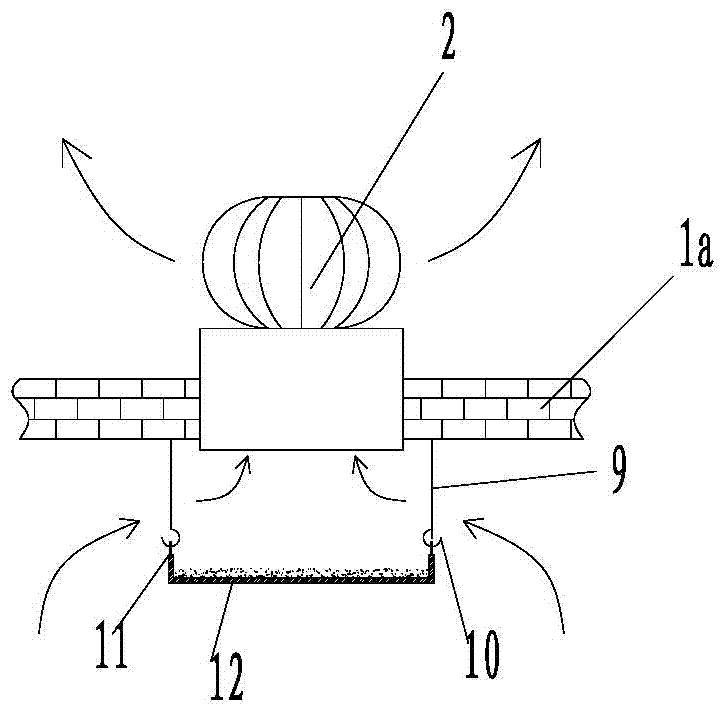

[0017] Such as Figure 1-8 As shown, the present invention includes a factory building 1 of an assembly workshop. A circulation pipeline 3 is arranged in the factory building 1. A uniformly distributed injection chamber 4 is arranged on the circulation pipeline 3. A heater 12 is arranged in the injection chamber 4. The injection chamber 4 is equipped with There is a fine water mist nozzle 5 connected to the water inlet and its inner cavity, the water inlet of the circulation pipeline 3 is connected to the water outlet of the high-pressure pump group 6, and the water inlet of the high-pressure pump group 6 is connected to the water outlet of the water tank 8 through the valve 7 The water outlet of the circulation pipeline 3 is connected with the water inlet of the water tank 8, and the roof 1a of the factory building 1 is...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com