Automatic transporting device for pallets for building block forming machine

A block forming machine, automatic operation technology, applied to ceramic forming machines, manufacturing tools, etc., can solve problems such as fast speed, accidents, and reduced output

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0012] The specific implementation of the present invention will be further described below in conjunction with the accompanying drawings.

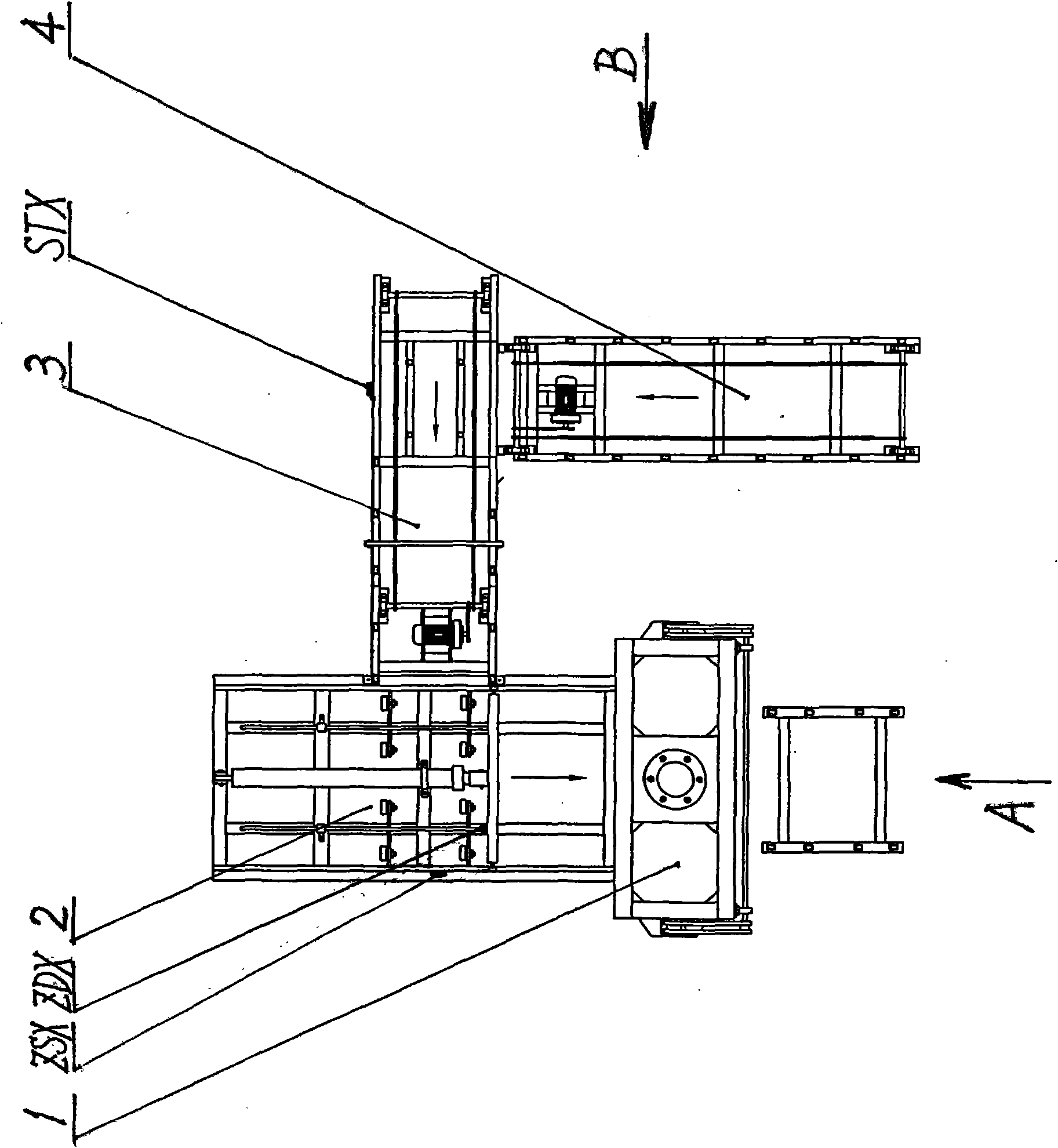

[0013] refer to figure 1 , the pallet transfer frame 3 and the pallet conveying frame 4 are arranged in a "T" shape, and are connected and installed with the block forming machine 1 and the pallet moving device 2 to form a " ”-shaped plane layout, so that the distance between the block forming machine 1 and the pallet conveying frame 4 is close, the structure is compact, the floor space is small, and the pallet T is conveniently transported. A conveying stop travel switch is arranged on the outer frame of the pallet transfer frame 3 STX, the front end inboard of shifting board device 2 is provided with transshipment start travel switch ZDX, and the rotation stop transmission travel travel switch ZSX is installed on the outer frame of board shifting device (2).

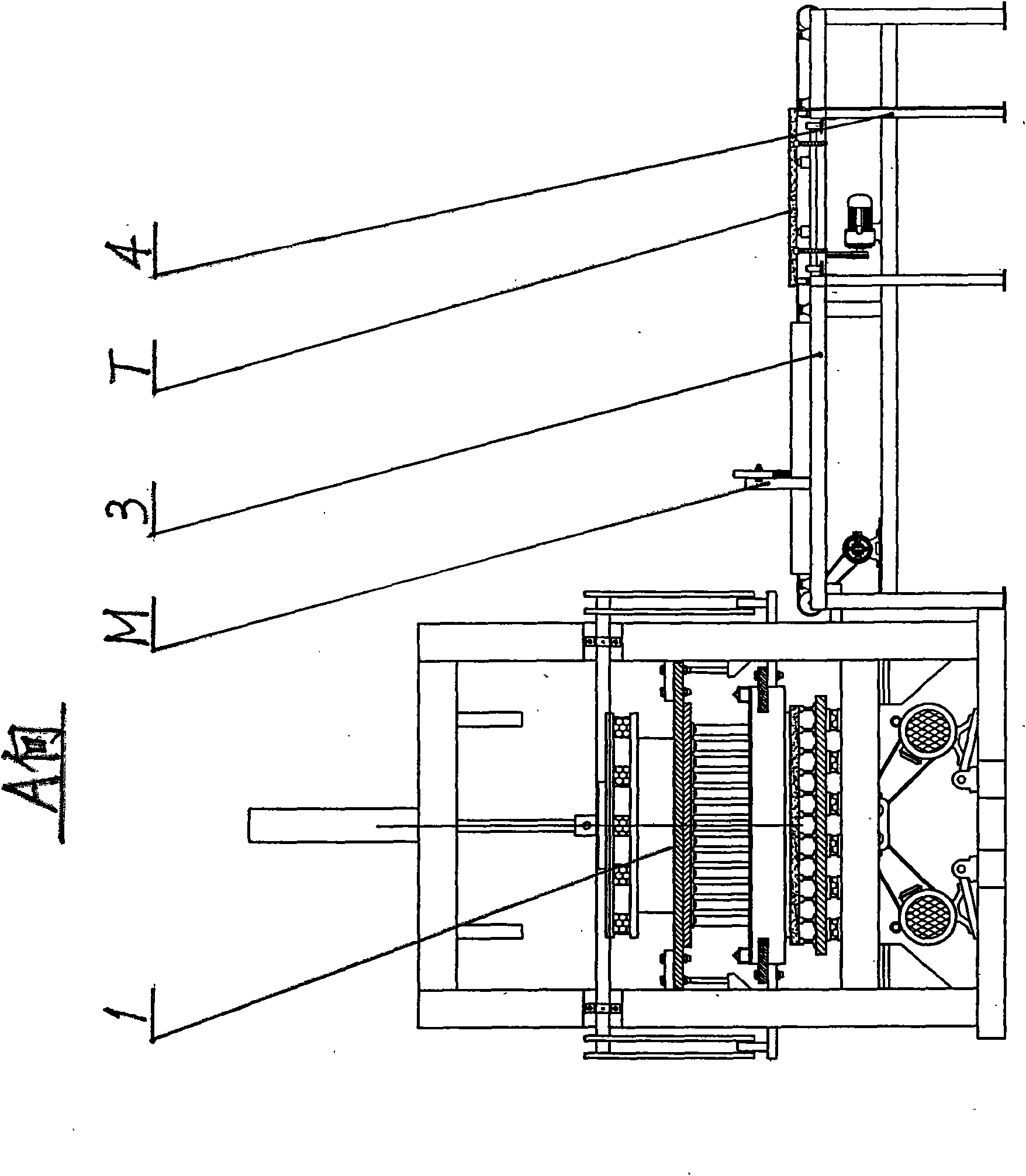

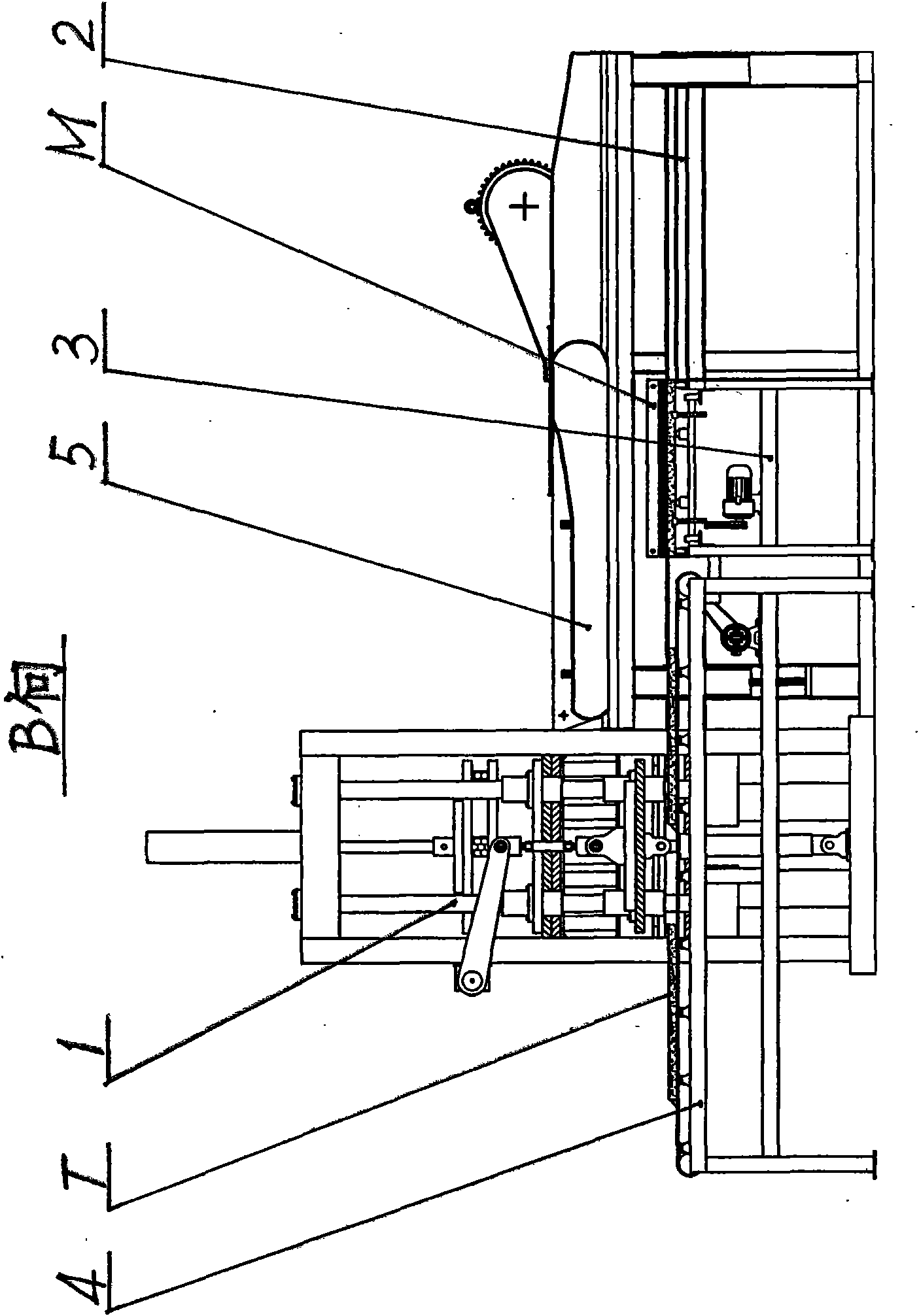

[0014] refer to figure 2 , the front view of the block forming machine 1 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com