Fluid control element

A technology for controlling components and fluids, which is applied to engine components, valve details, multi-way valves, etc., and can solve problems such as load breakage and high bearing capacity of sealing rings

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

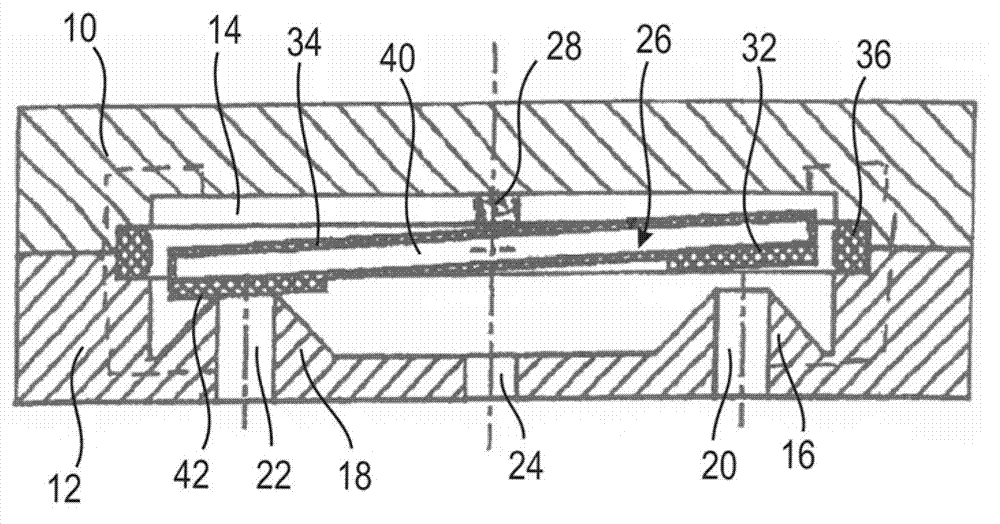

[0042] figure 1 Fluid control element showing 3 / 2-way function, which is part of a 3 / 2-way valve.

[0043] The control element comprises a preferably flat, cuboid housing consisting of two housing parts 10 , 12 pressed against each other.

[0044] Formed between the housing parts 10 , 12 is a fluid chamber 14 which is delimited by a recess in the housing parts 10 , 12 .

[0045] Two sealing seats 16 , 18 , also called valve seats, protrude into the fluid chamber 14 . The sealing seats 16 , 18 surround the inlets of the associated fluid channels 20 , 22 which start in the fluid chamber 14 or open into the fluid chamber. The fluid channels 20 , 22 pass through the housing part 10 and are connected to a piping system (not shown). This also applies to the fluid channel 24 which is formed without a valve seat and which preferably leads between the sealing seats 16 , 18 to the fluid chamber 14 or from the fluid chamber.

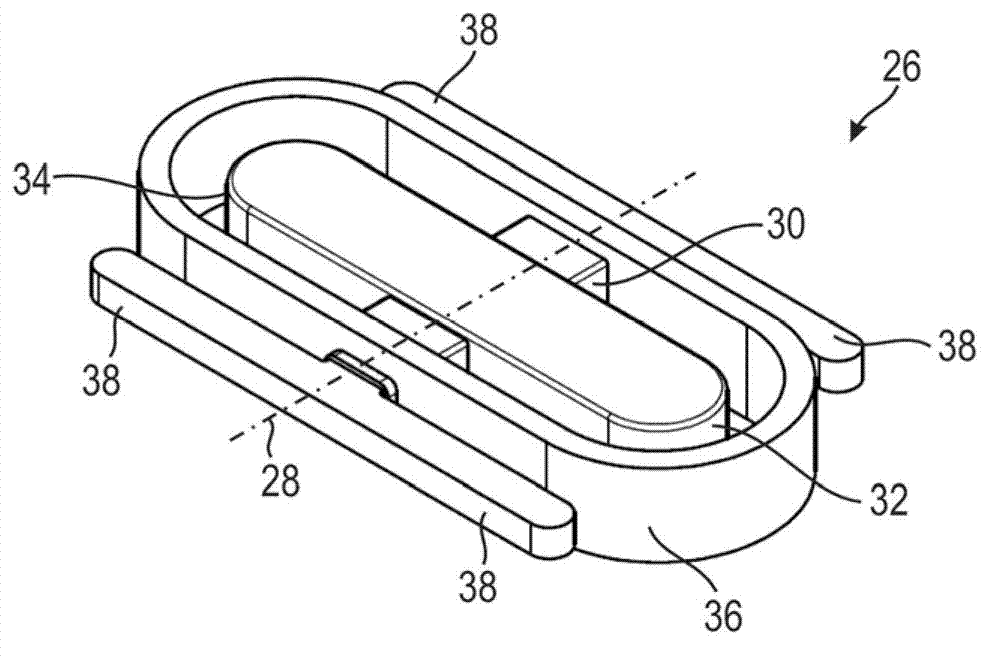

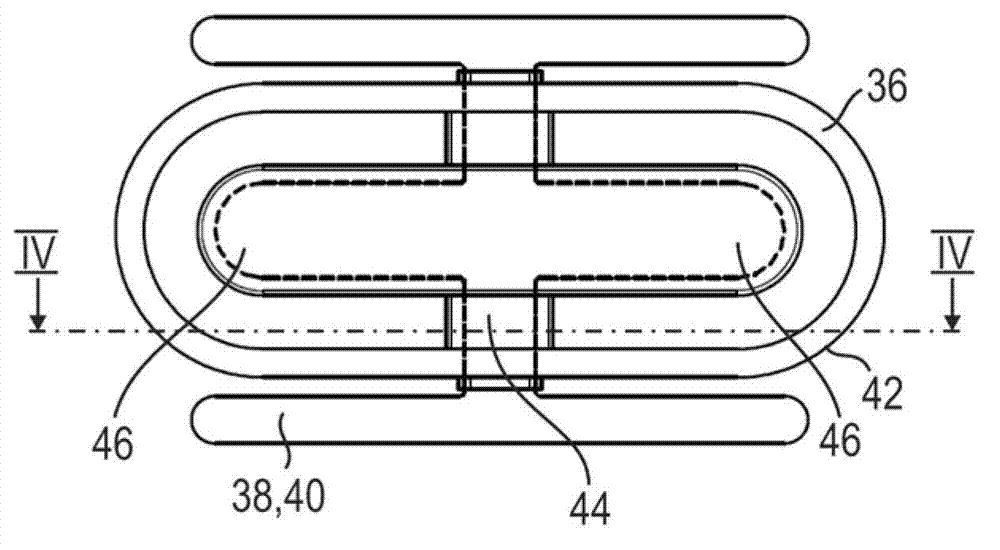

[0046] Located in the fluid chamber 14 is a valve body 26...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com