Reed coupler

A coupling and semi-coupling technology, applied in the direction of couplings, elastic couplings, engine components, etc., can solve the problems of cumbersome manufacturing process, complex structure of serpentine spring, inconvenient assembly operation, etc., to achieve The effect of compact structure, strong buffering and vibration reduction ability, and convenient assembly and operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

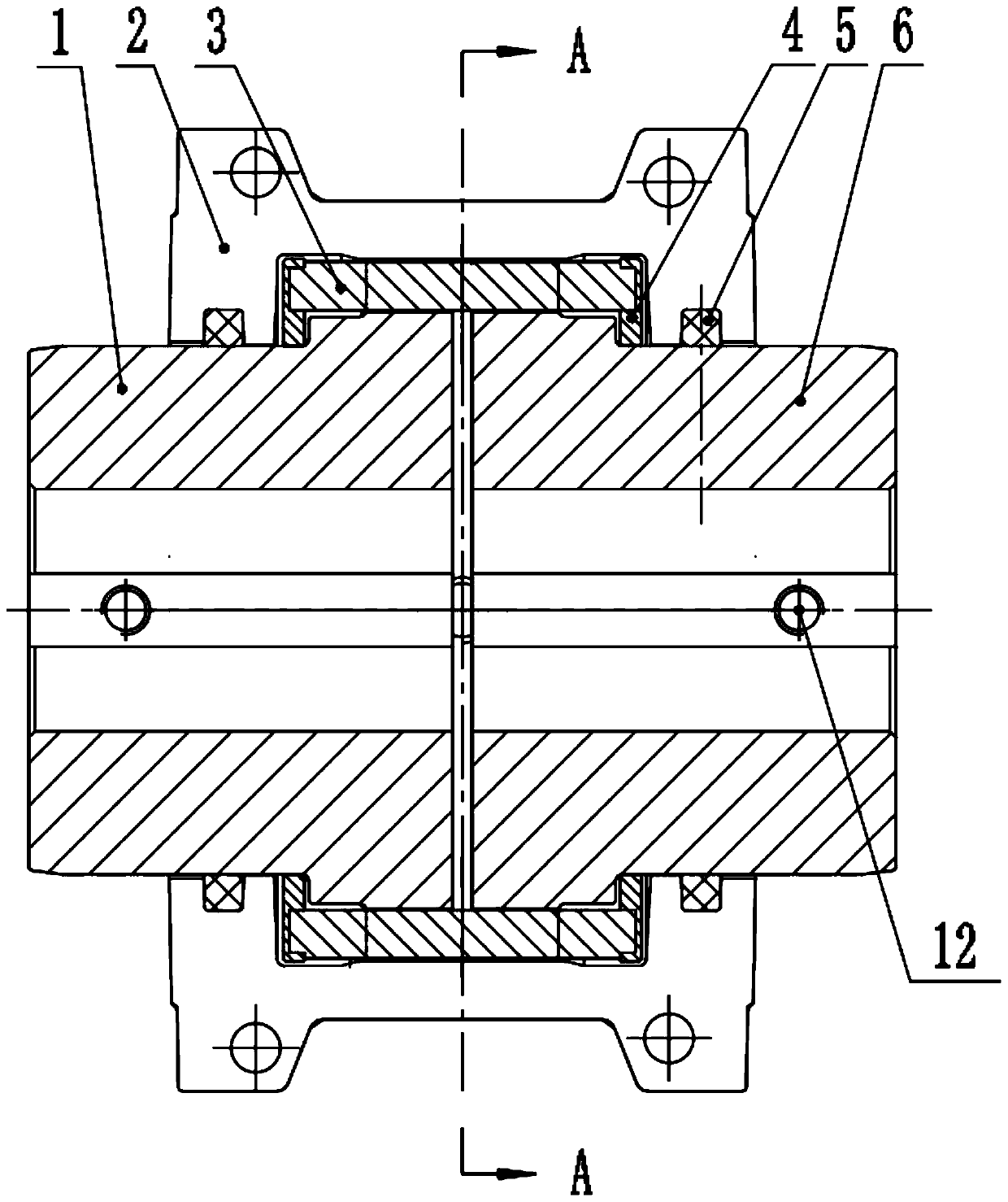

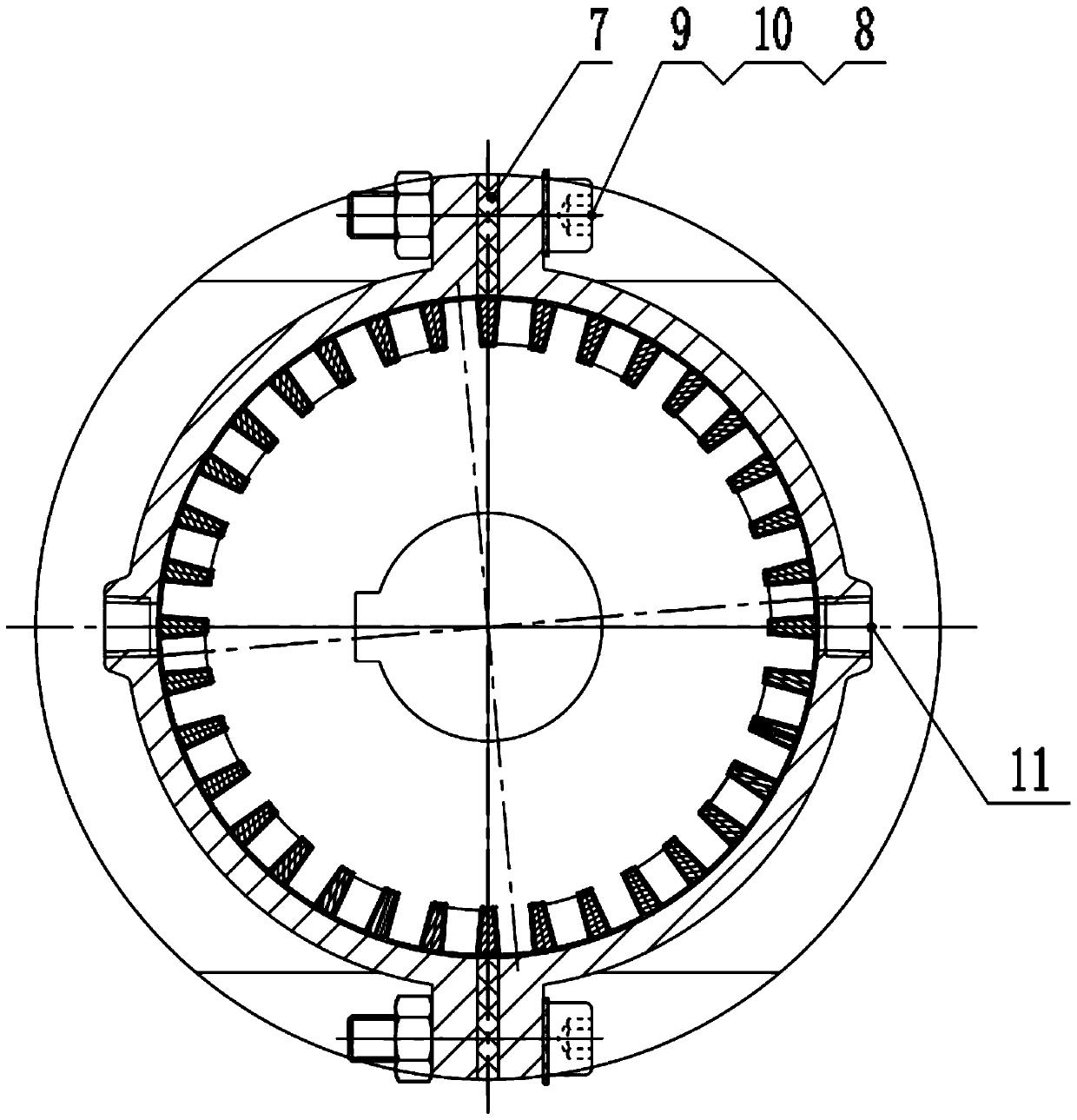

[0017] The invention discloses a leaf coupling. In the example,

[0018] 1. First process two semi-couplings 1 and 6 with arc-shaped teeth as shown in the figure, several spring pieces 3, two casings 2, reed holder 4, two sealing rings 5, two A sealing gasket 7, an oil plug 11 and screw nut gaskets 8, 9, 10, 12 are composed, and the spring leaf 3 is embedded between the tooth grooves of the arc-shaped curved tooth profiles of the two half-links 1, 6. When working, the torque is transmitted from one half-coupling 1 to the other half-coupling 6 through the spring piece 3; the reed holder 4 combines several spring pieces 3 into a flexible whole, so that the spring piece 3 and the half-coupling The arc-shaped curved tooth profiles of 1 and 6 have good contact to prevent the unexpected axial and radial movement of the spring leaf 3 in the tooth grooves of the arc-shaped curved tooth profiles of the half-couplings 1 and 6; the external The function of the two closed casings 2 is t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com