Patents

Literature

35results about How to "Small quality deviation" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Iron based powder for powder metallurgy

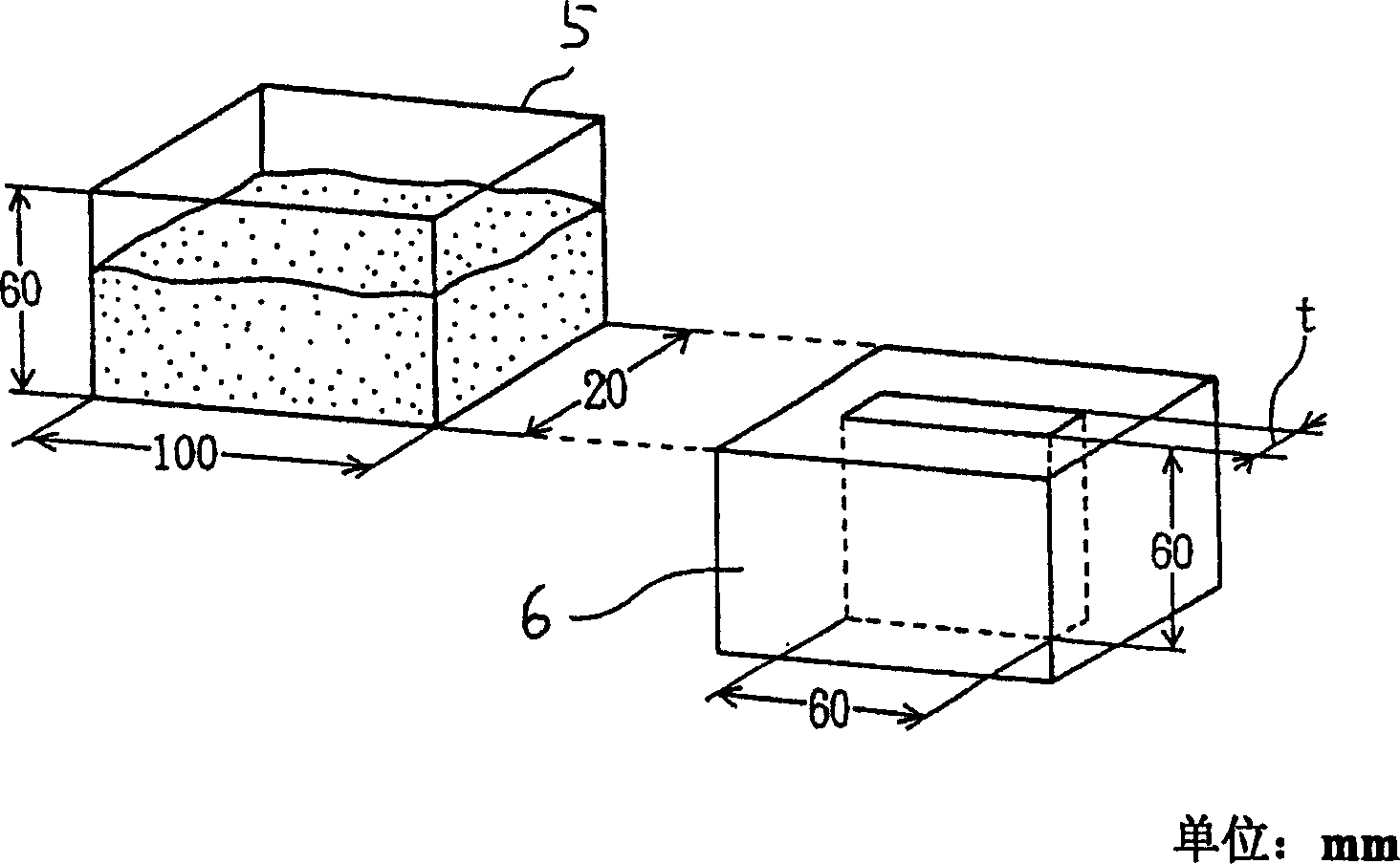

An iron-based mixed powder for powder metallurgy, the powder is composed of pulverized iron powder adhered to the surface by partially alloying copper powder and preferably pulverized pure iron powder, at least graphite powder and free A lubricant for fixing graphite powder and machinability-improving powder on the surface of an iron-based powder with a binder, the iron-based powder having a particle size distribution of 18.5% by mass of particles having a particle diameter of less than 45 μm relative to the total amount of the iron-based powder Less than 46% by mass of particles with a particle size of 75 μm or more and less than 150 μm; less than 10% by mass of particles with a particle size of 150 μm or more and less than 180 μm; 0.5% by mass of particles with a particle size of 180 μm or more. By making such a powder, it is possible to obtain an iron-based powder mixed powder for powder metallurgy with good compressibility and good filling properties.

Owner:JFE STEEL CORP

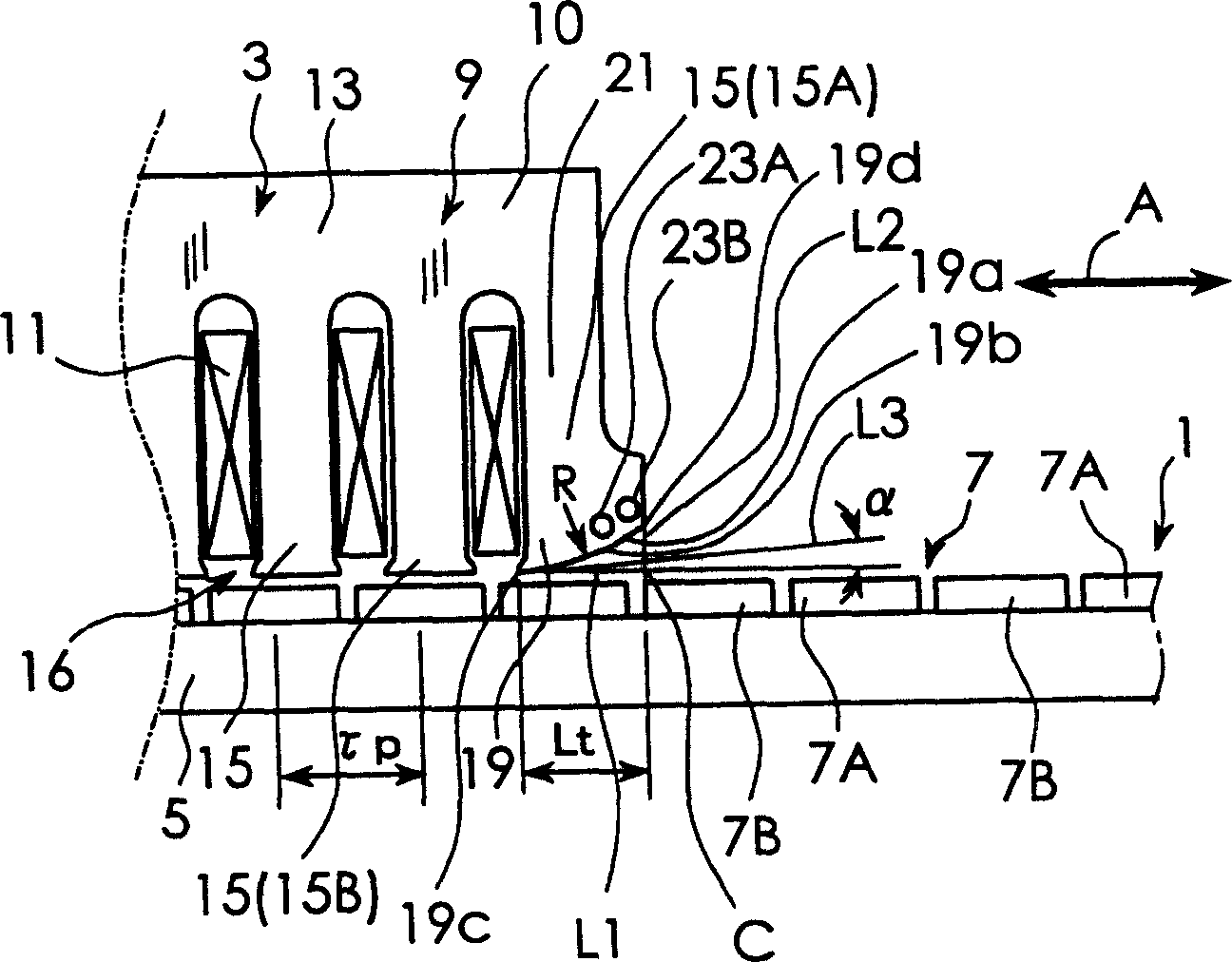

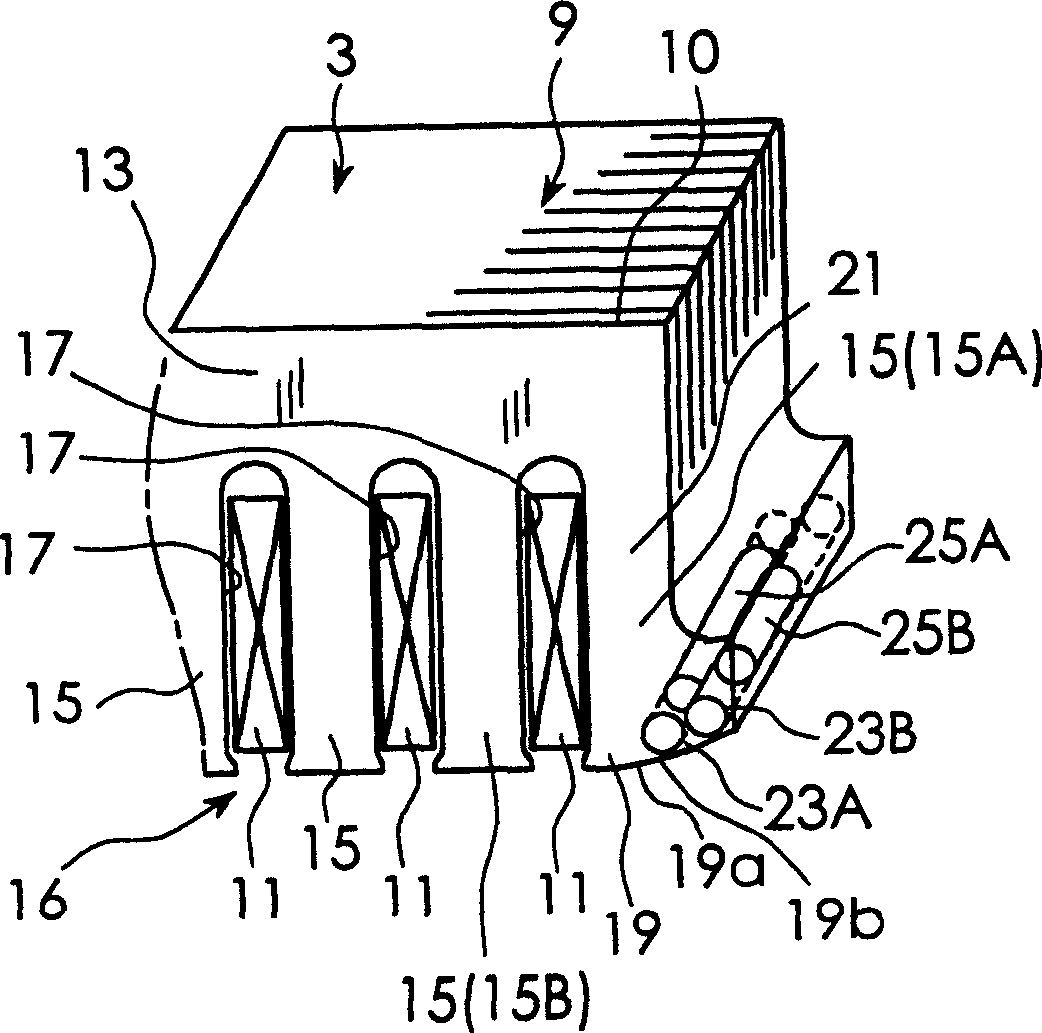

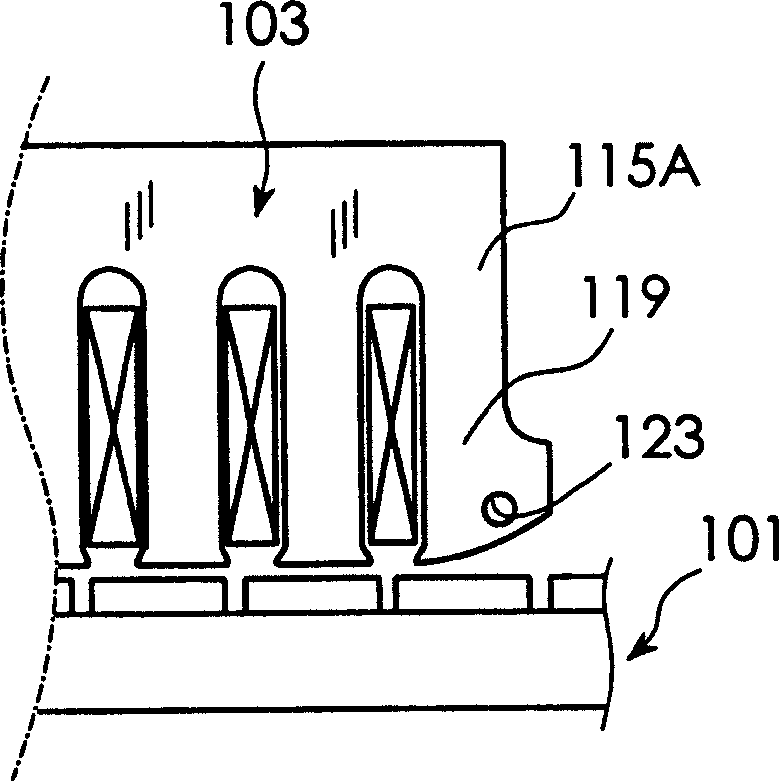

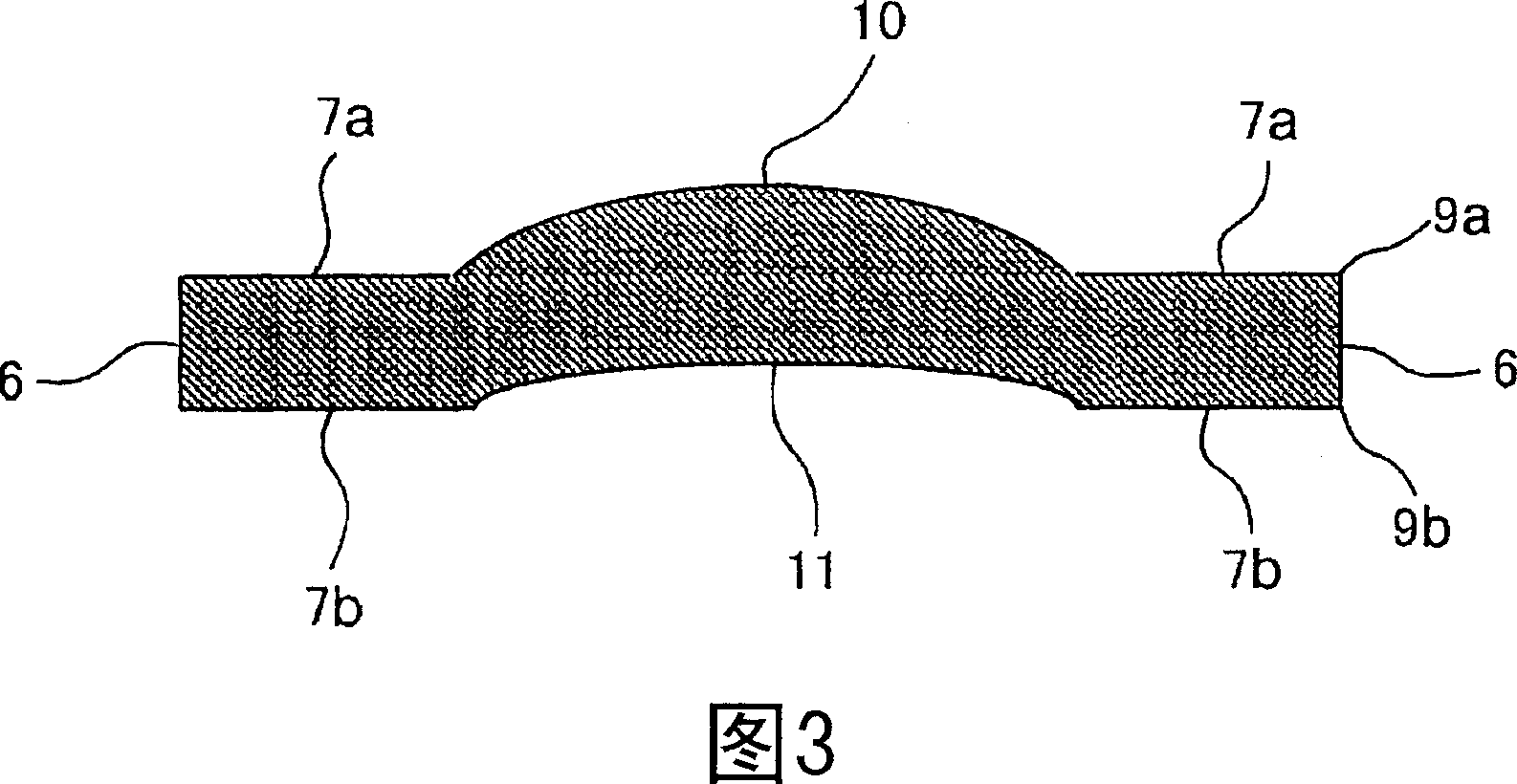

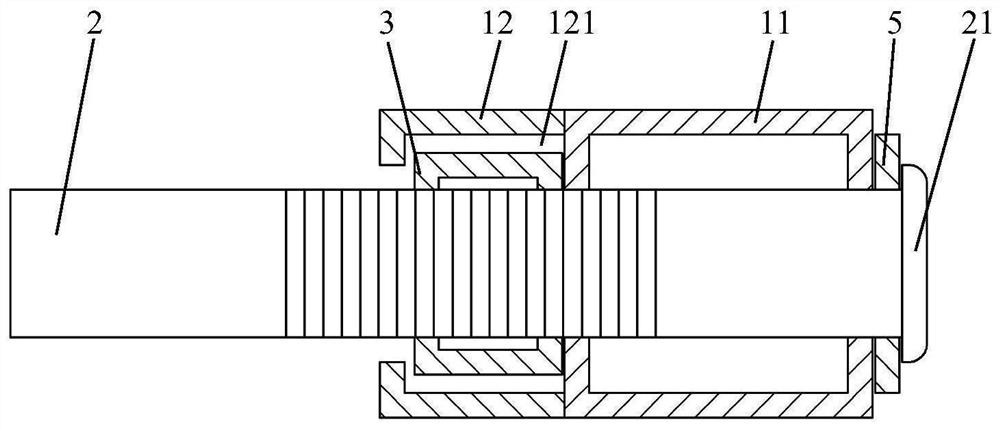

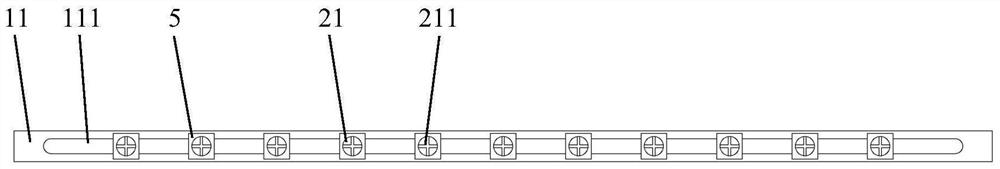

Linear motor

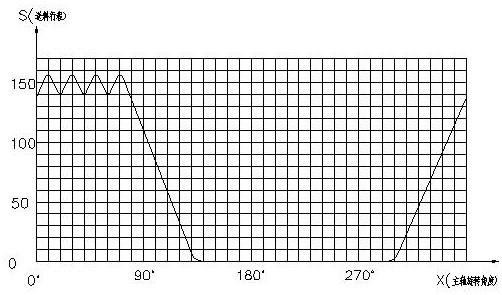

InactiveCN1592051AReduce stressWell formedManufacturing dynamo-electric machinesPropulsion systemsMagnetic polesLinear motor

There is provided a linear motor in which the shape of magnetic pole surfaces of pole teeth located at both ends of a plurality of pole teeth can be easily formed to be suitable for reducing cogging force. Each of magnetic pole surfaces 19a of pole teeth 15A located at both ends of a plurality of pole teeth 15 is constituted by an arc-shaped curved surface so curved that a gap from a stator 1 increases with increasing distance from other adjacent pole tooth 15B. Through holes 23A and 23B that extend in the laminating direction of electromagnetic steel plates 10 are formed in the vicinity of the magnetic pole surfaces 19a of the pole teeth 15A. Inside the through holes 23A and 23B, magnetic pieces shorter than the thickness of the electromagnetic steel plates in their laminating direction are so arranged as to leave spaces at both ends of the through holes 23A and 23B.

Owner:SANYO DENKI CO LTD

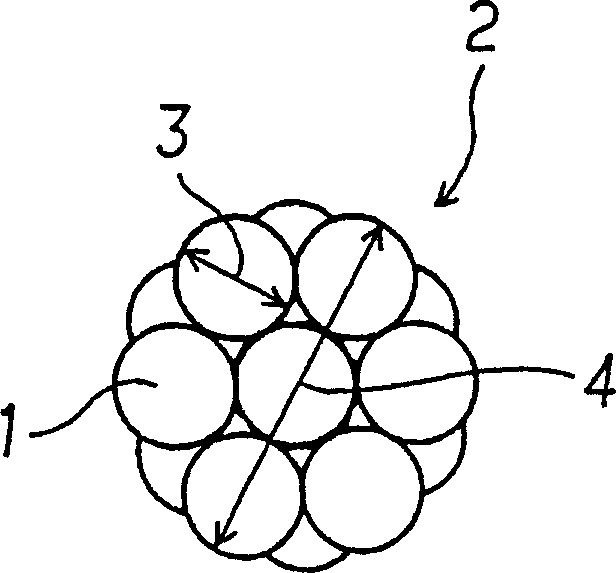

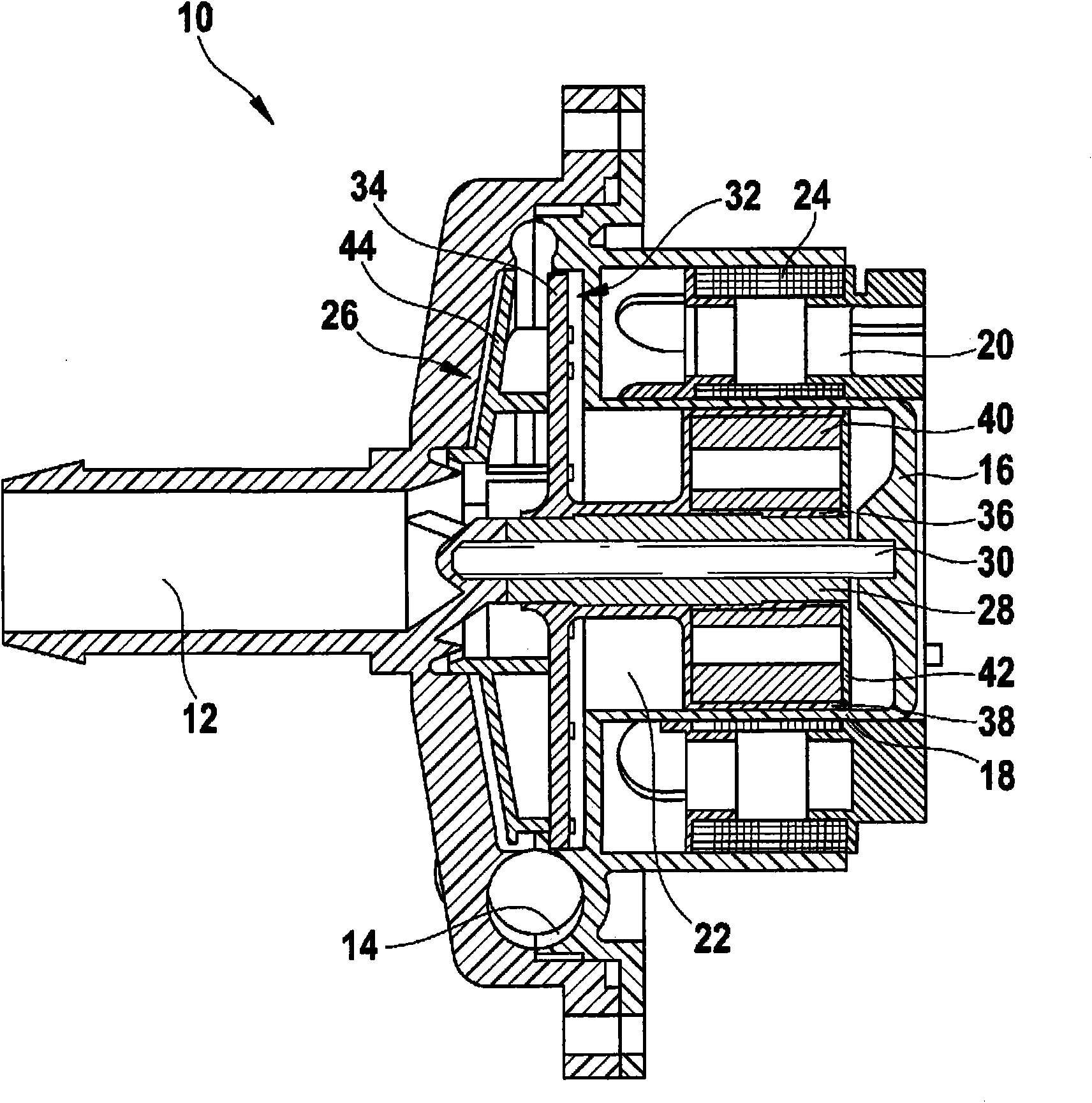

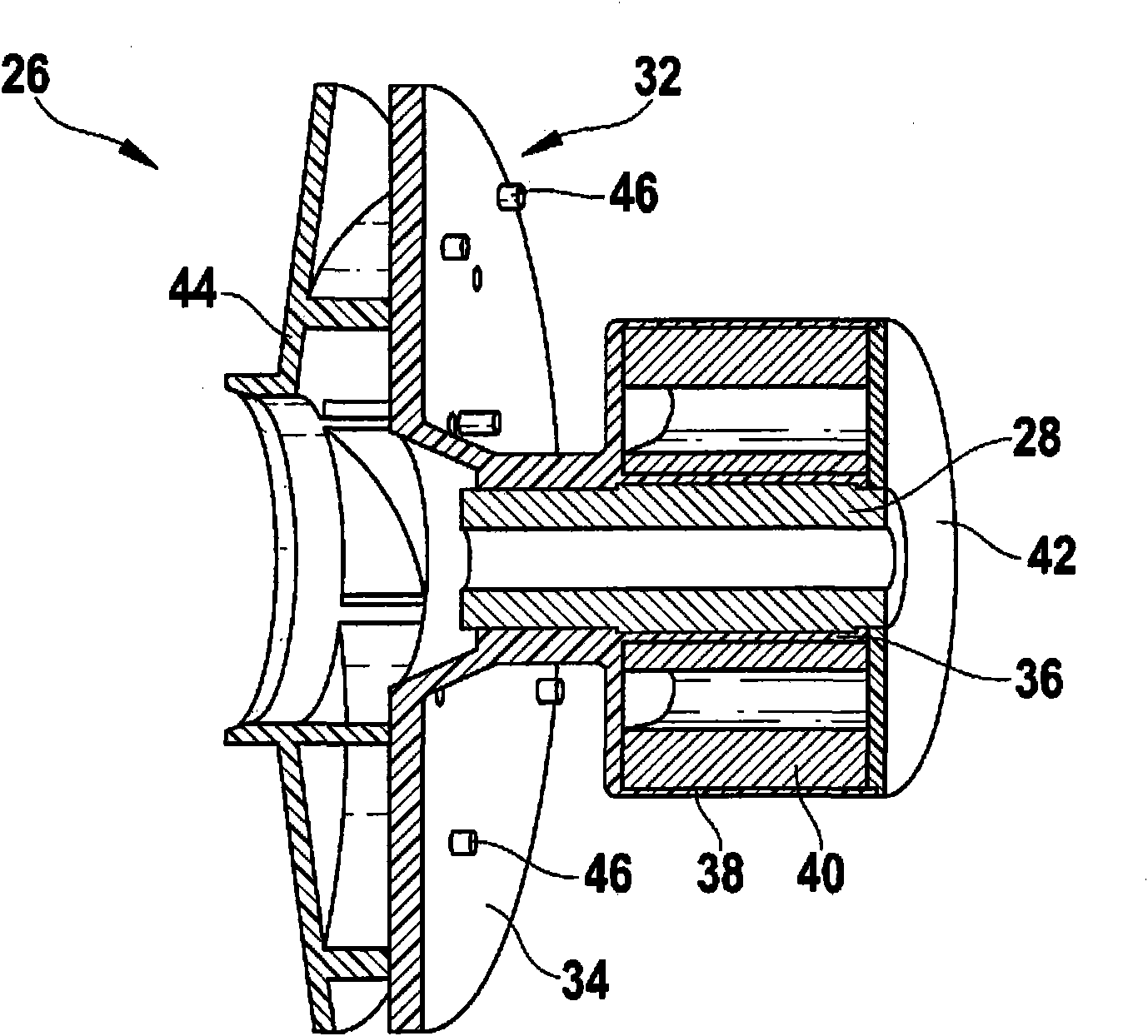

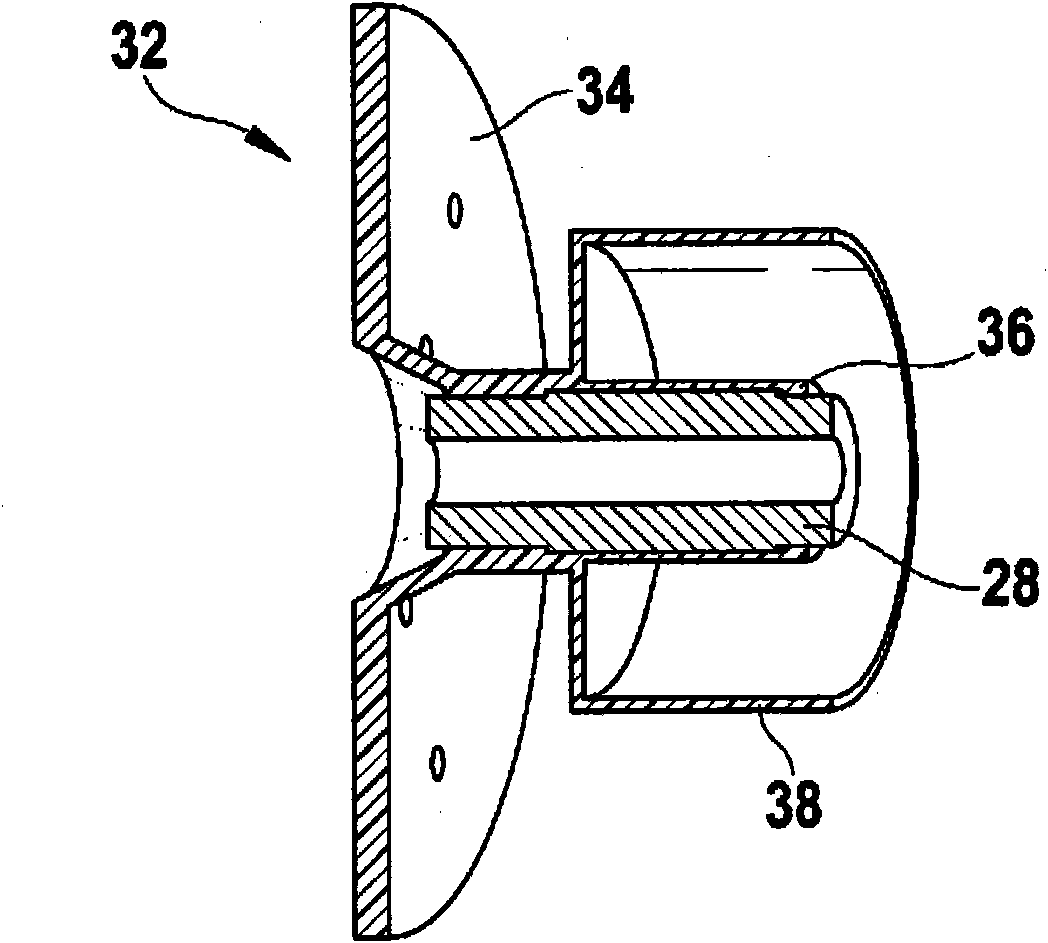

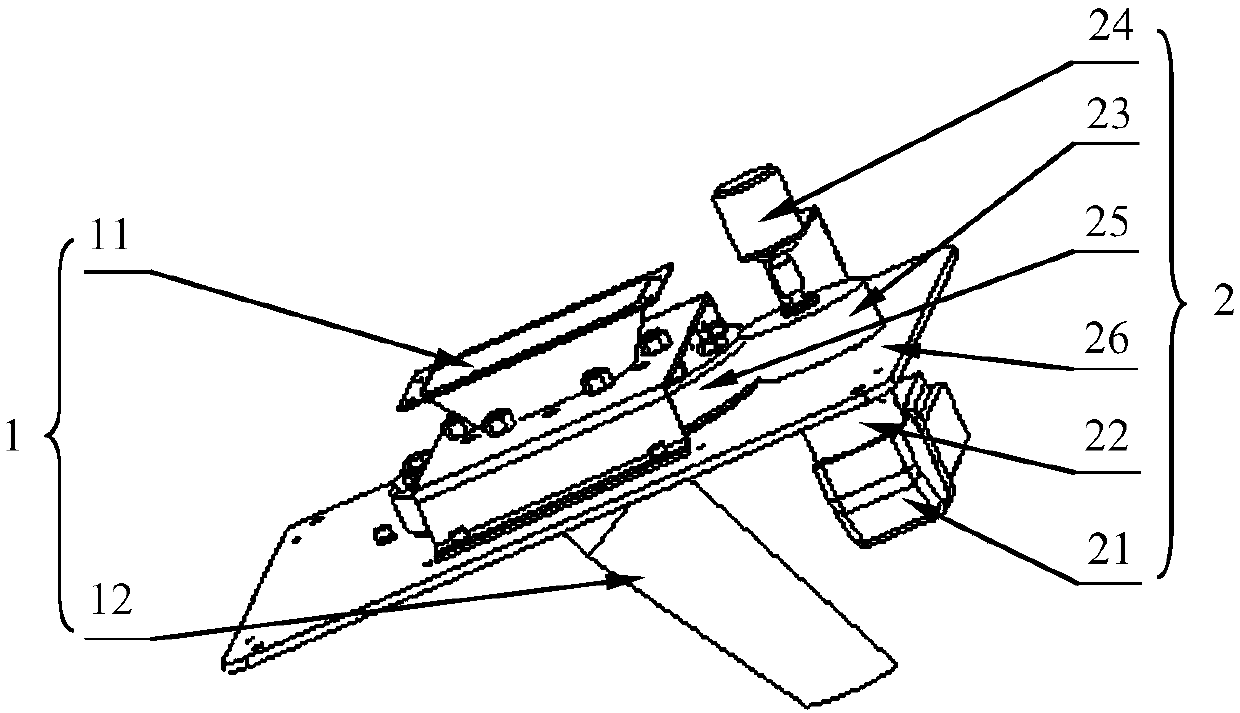

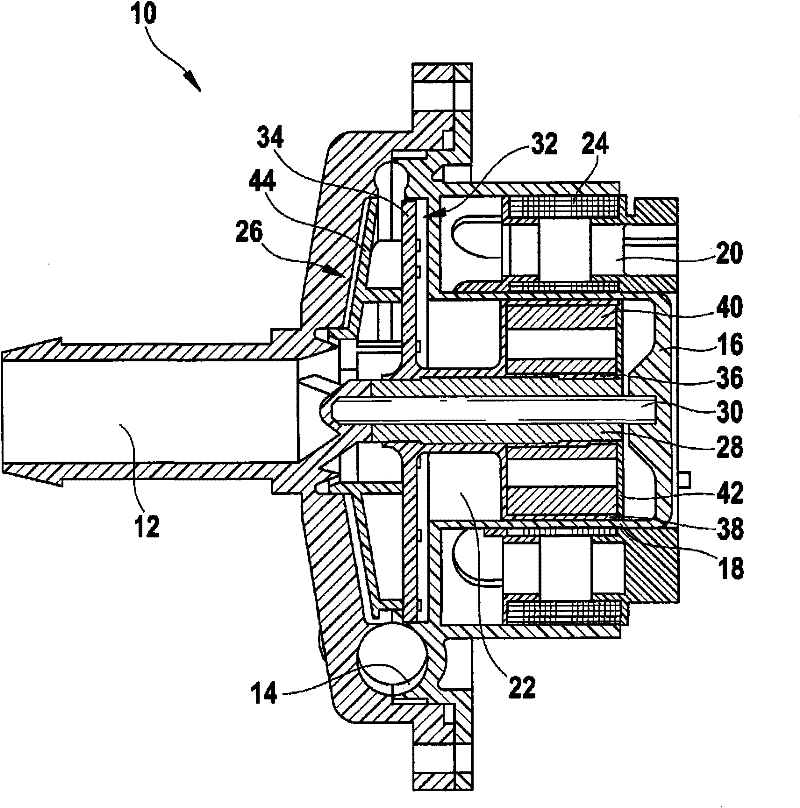

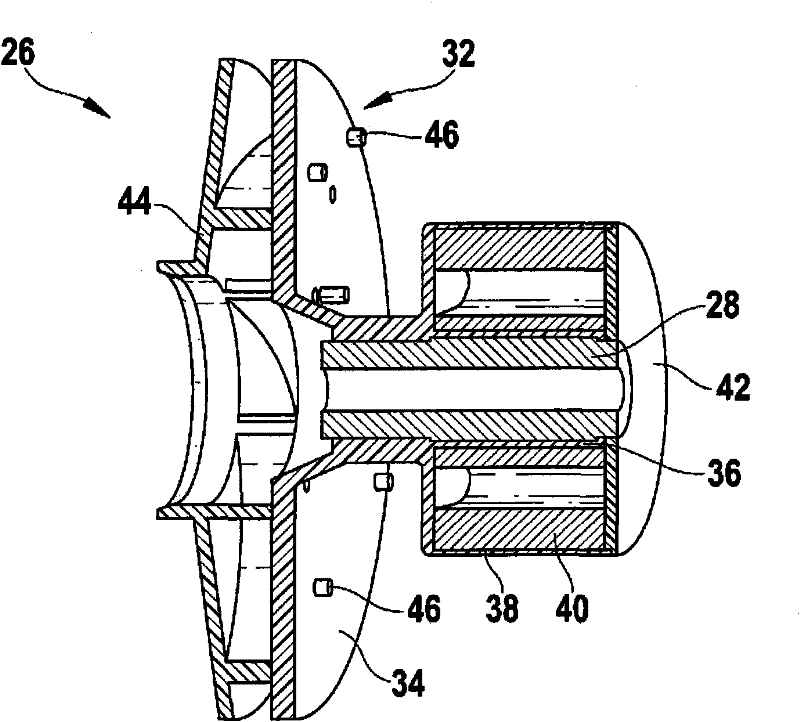

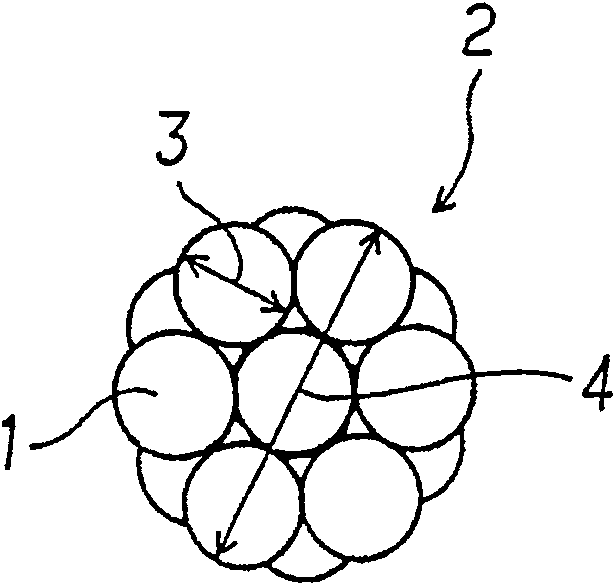

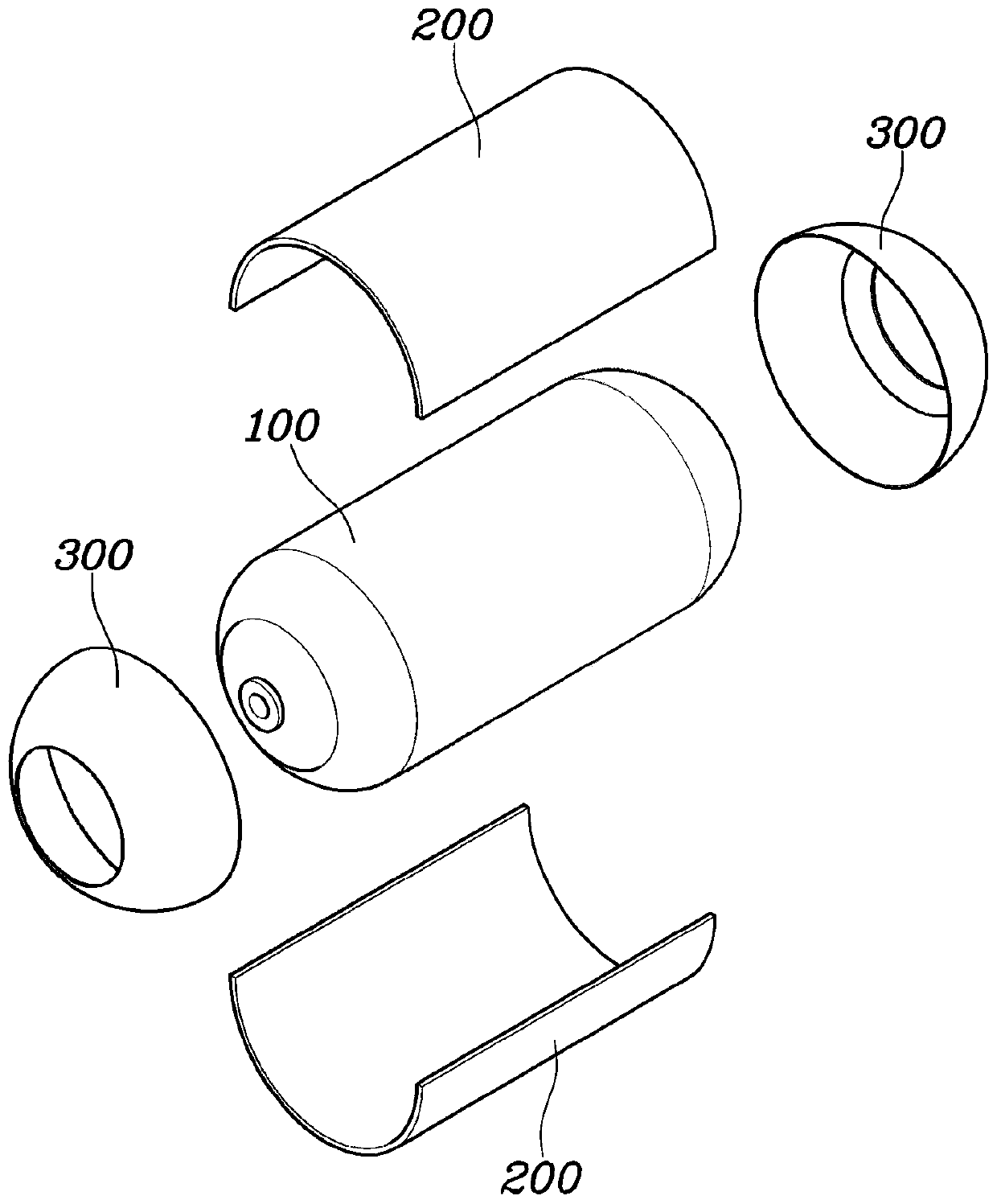

Pump rotor for a canned motor pump

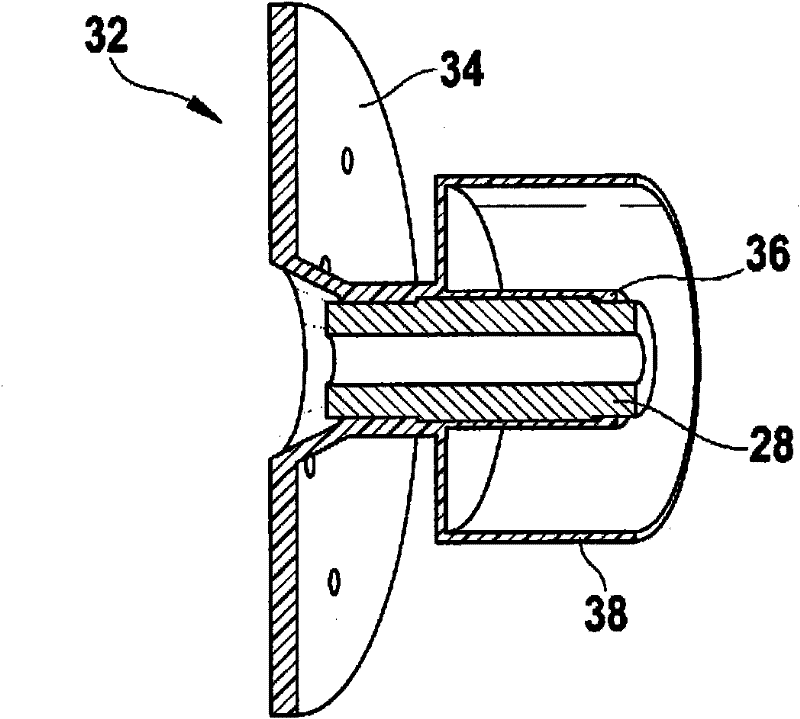

InactiveCN101802411ASmall imbalanceSmall quality deviationPump componentsPump installationsImpellerRotor magnets

The invention relates to a pump rotor (26) for a canned motor pump. The pump rotor (26) comprises a base body (32) designed in one piece, with an impeller base disk (34) and a rotor holder bushing (36) and a rotor unit (40) with rotor magnets that are arranged on the rotor holder bushing (36).

Owner:ROBERT BOSCH GMBH

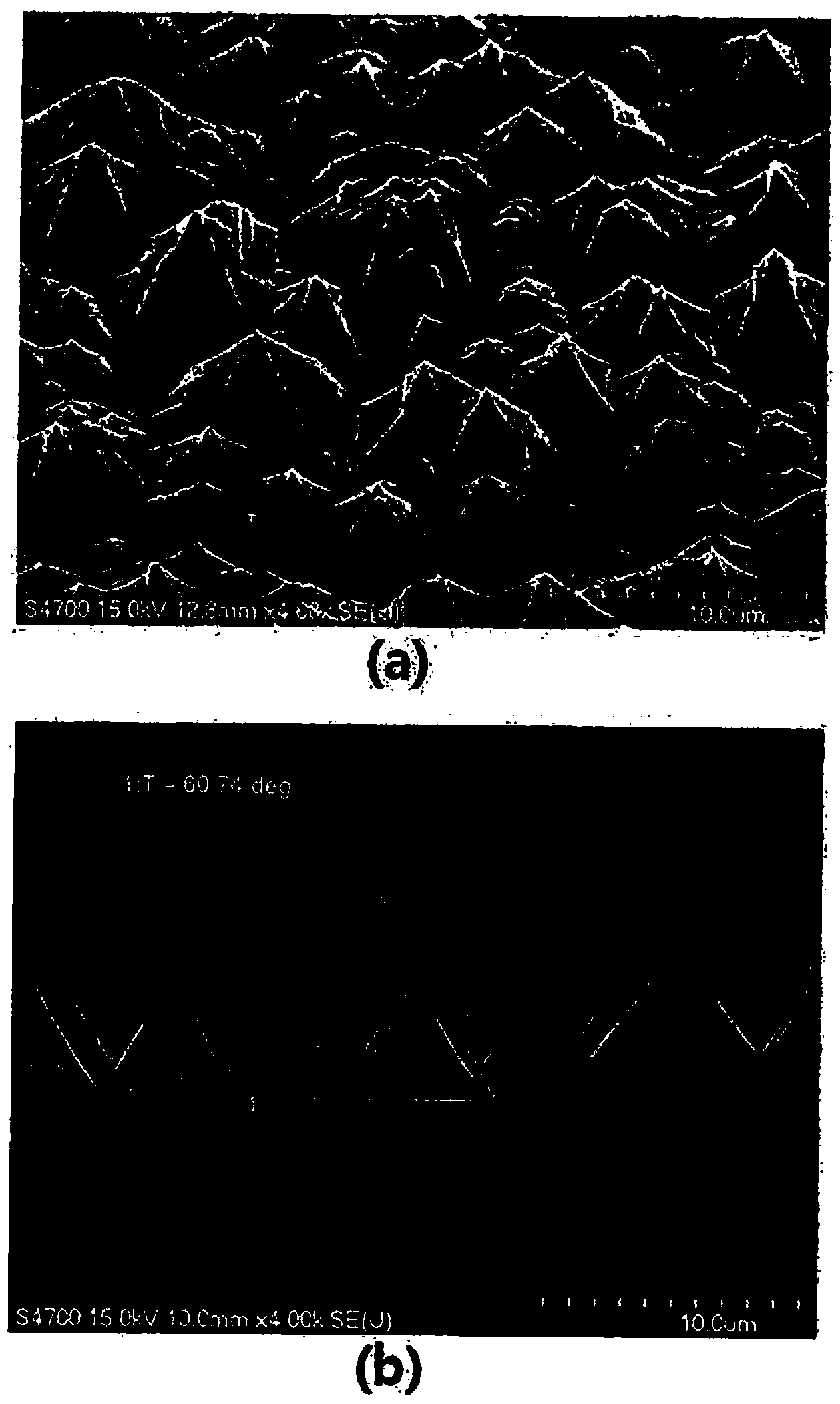

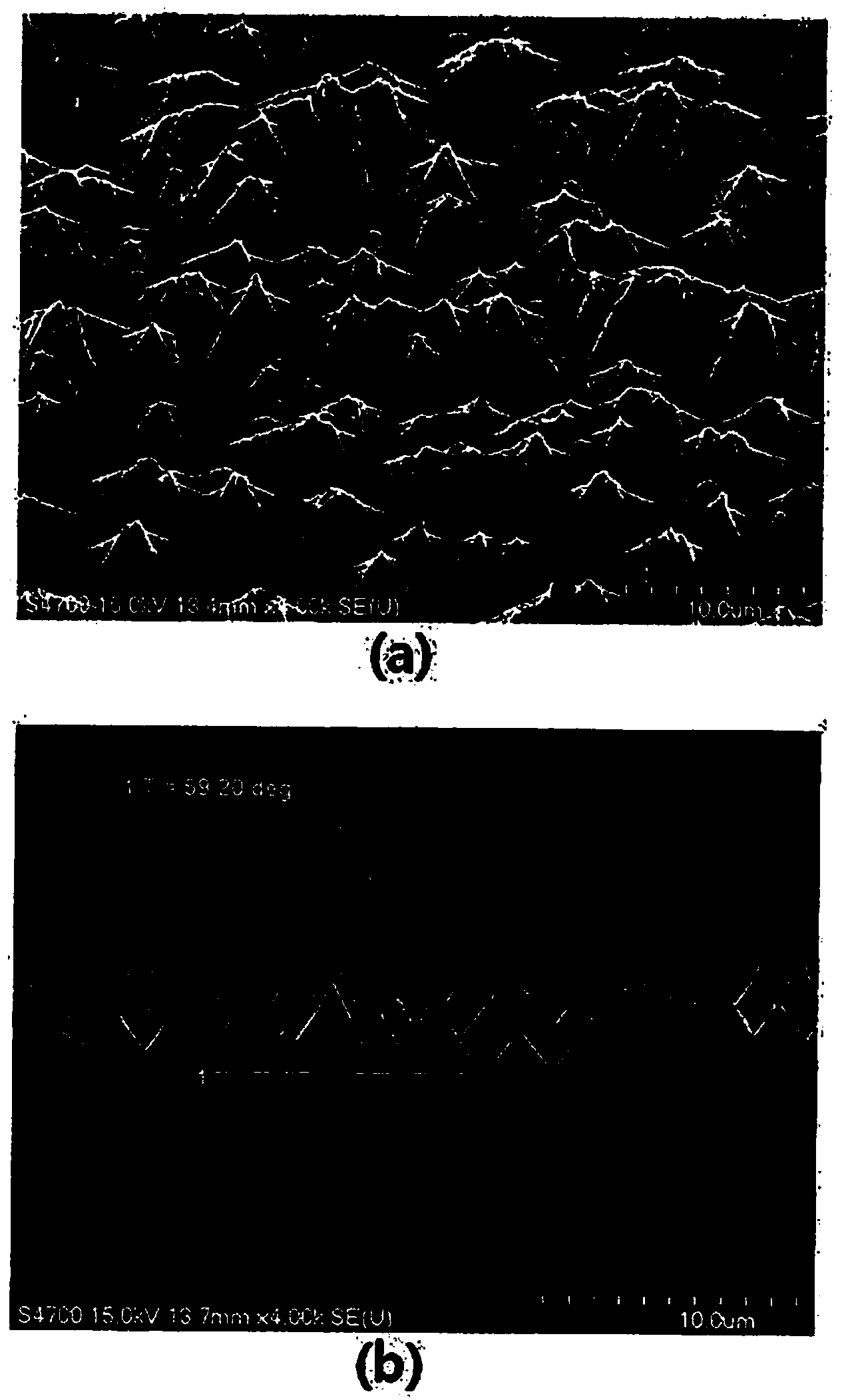

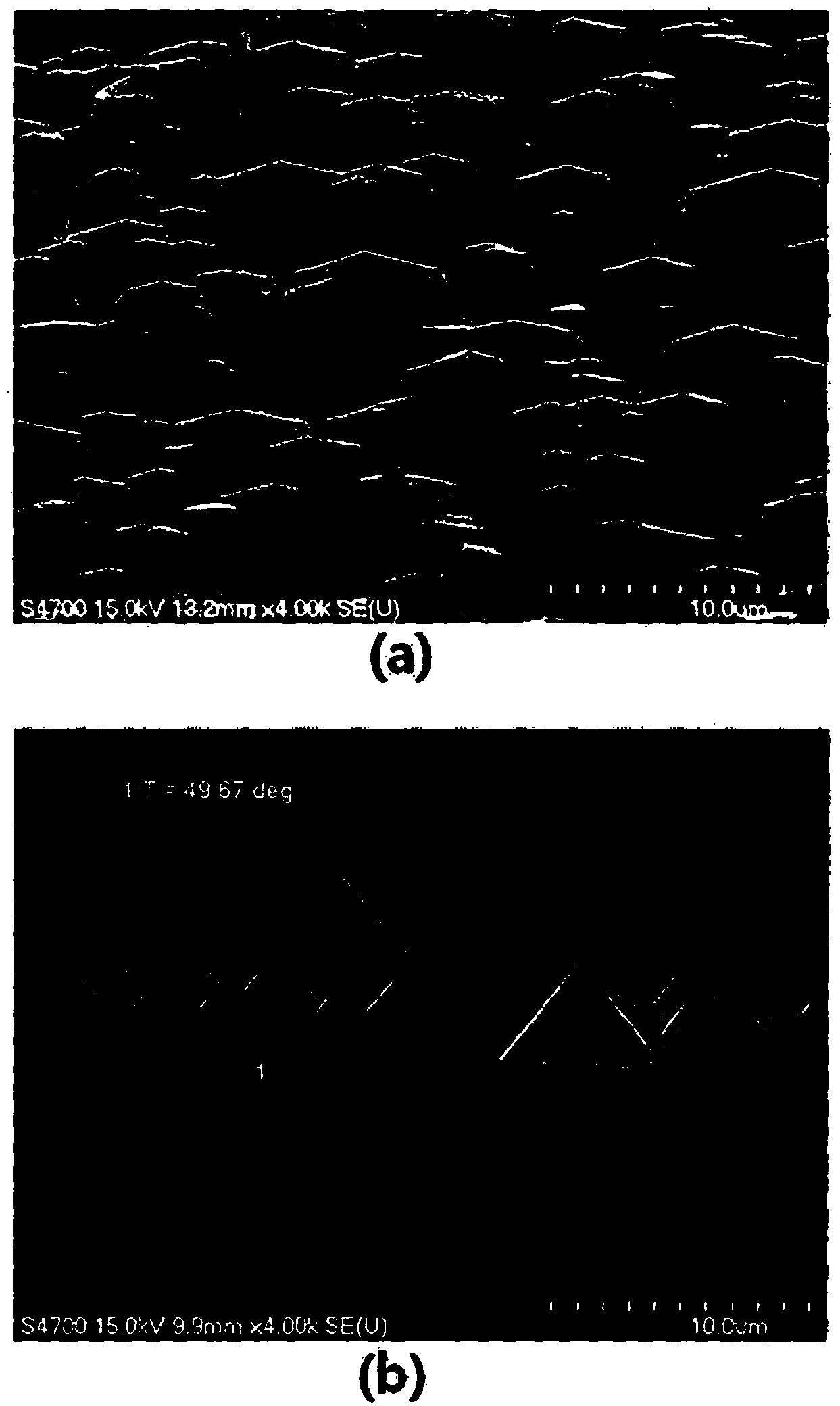

Texture etching solution composition and texture etching method of crystalline silicon wafers

InactiveCN103890139ASmall quality deviationImprove uniformityFinal product manufactureSurface treatment compositionsCrystallographyEtching

Disclosed are a texture etching solution composition for a crystalline silicon wafer, and a texture etching method using the same. The texture etching solution composition for a crystalline silicon wafer includes a polymer formed by polymerizing a monomer that is substituted with a cyclic compound having 4 to 10 carbon atoms as well as at least one nitrogen atom. The texture etching solution composition and the texture etching method are capable of forming pyramids with a specific structure which can minimize a quality deviation of a texture within a region in formation of a micro-pyramid structure on the surface of the crystalline silicon wafer to increase luminous efficiency while reducing a reflectivity.

Owner:DONGWOO FINE CHEM CO LTD

Rice flour cakes and process for producing the same

InactiveCN1665399AMade to look greatGreat tasteConfectionerySweetmeatsAdditive ingredientWheat flour

Provided are: a rice flour composition that is free from wheat flour and any wheat-derived ingredient and can be produced by a process similar to a conventional process and can produce a confection excellent in appearance, internal phase, taste, and keeping quality; a dough product and a confection product each produced with the composition; and a method of producing the confection product. The rice flour composition for use in confectionery comprises rice flour as a main ingredient and is free from wheat flour and any wheat-derived ingredient. The dough product and the confection product are each produced with the rice flour composition. The method of producing the confection mainly made from rice flour includes the steps of: adding a liquid to the rice flour composition and mixing them to make dough; and shaping the dough and cooking the shaped dough by baking, frying, steam-boiling, microwave-heating, or pressurizing and heating it.

Owner:SHITOGI JAPAN

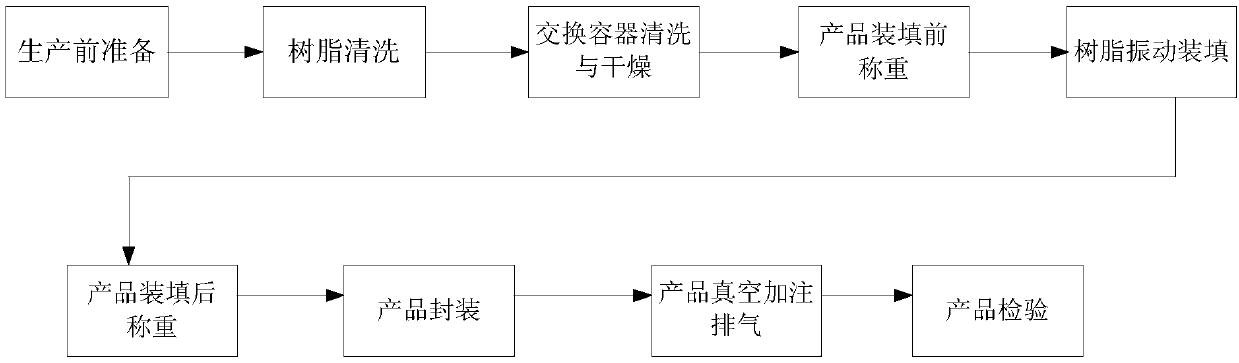

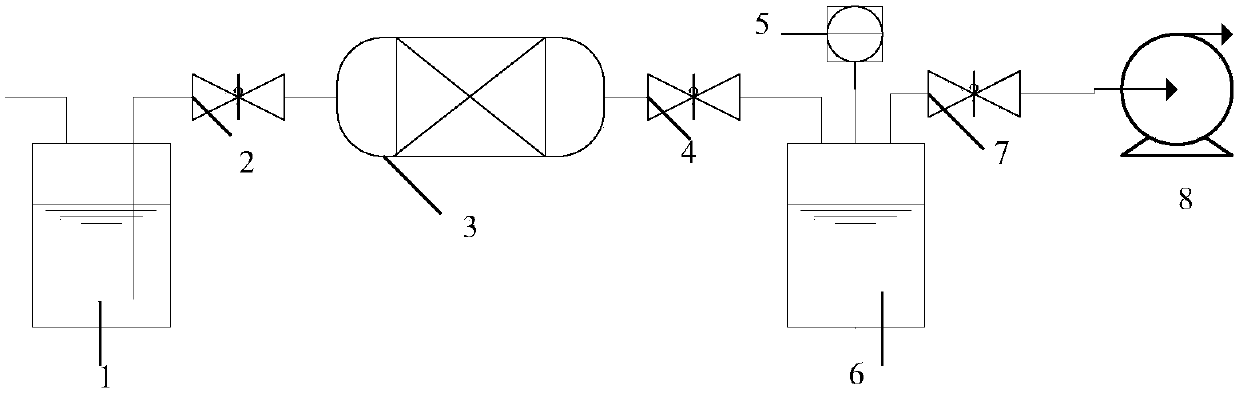

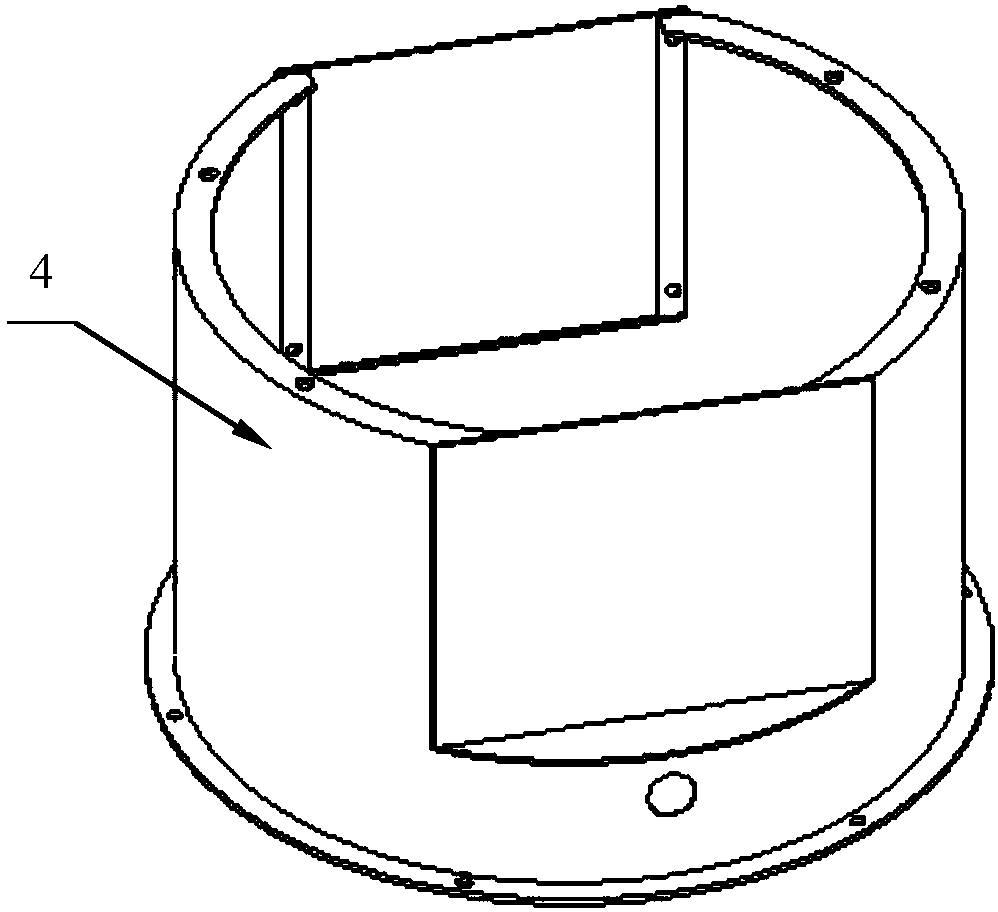

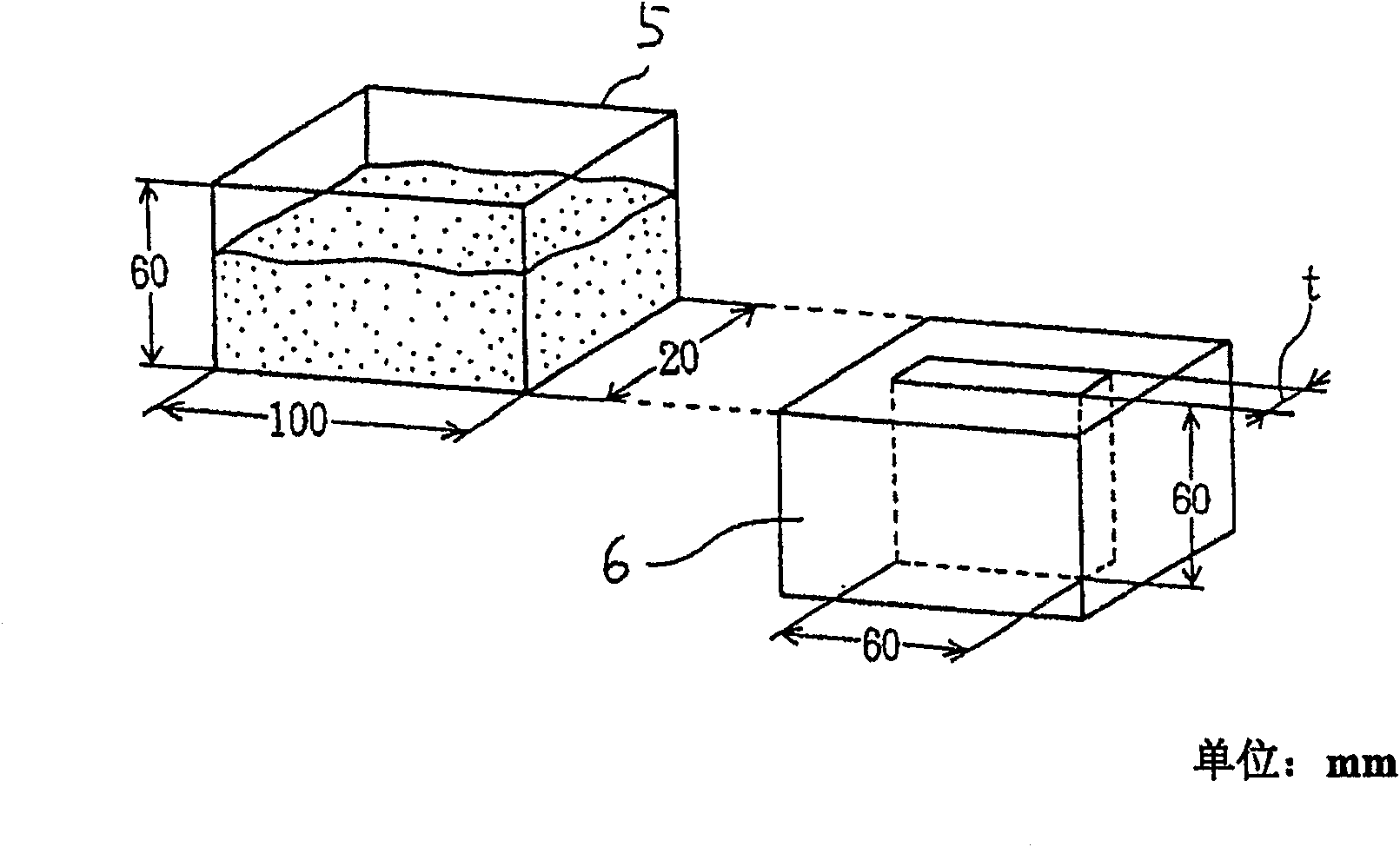

Ion exchange resin filling method for space product

InactiveCN107601621ADigitizeReduce the effect of exchange efficiencyWater/sewage treatment by ion-exchangeIon exchangePhysical chemistry

The invention discloses an ion exchange resin filling method for a space product. The ion exchange resin filling method comprises the following steps: 1, implementing preparation before production; 2,cleaning ion exchange resin; 3, cleaning and drying an ion exchanger; 4, putting the ion exchange resin into the ion exchanger, and placing the ion exchange on a power frequency vibration platform soas to obtain an ion exchanger filled with the ion exchange resin in a vibration manner; 5, performing sealed packaging on the ion exchanger; 6, performing vacuum exhausting on the ion exchange so asto obtain a filled ion exchange; 7, testing the filled ion exchange, thereby obtaining a qualified ion exchange. By adopting a filling method of vibration filling+vacuum injection exhausting, the amount of filled ion exchange resin is numeralized, the filling density of the ion exchange resin is maximized, the air among resin granules is effectively discharged, the influence of the air to the exchange efficiency of the ion exchange resin is reduced, and the service life of the whole ion exchange is prolonged.

Owner:BEIJING MECHANICAL EQUIP INST

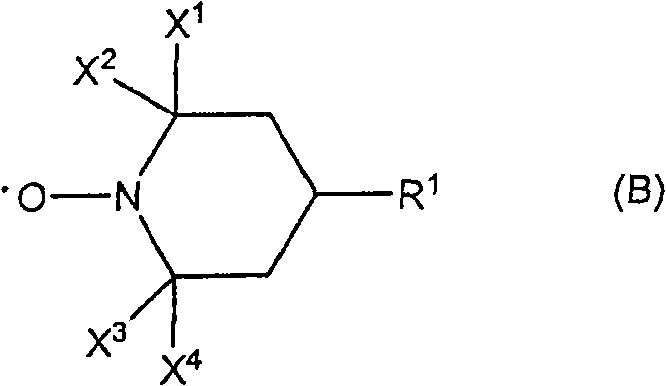

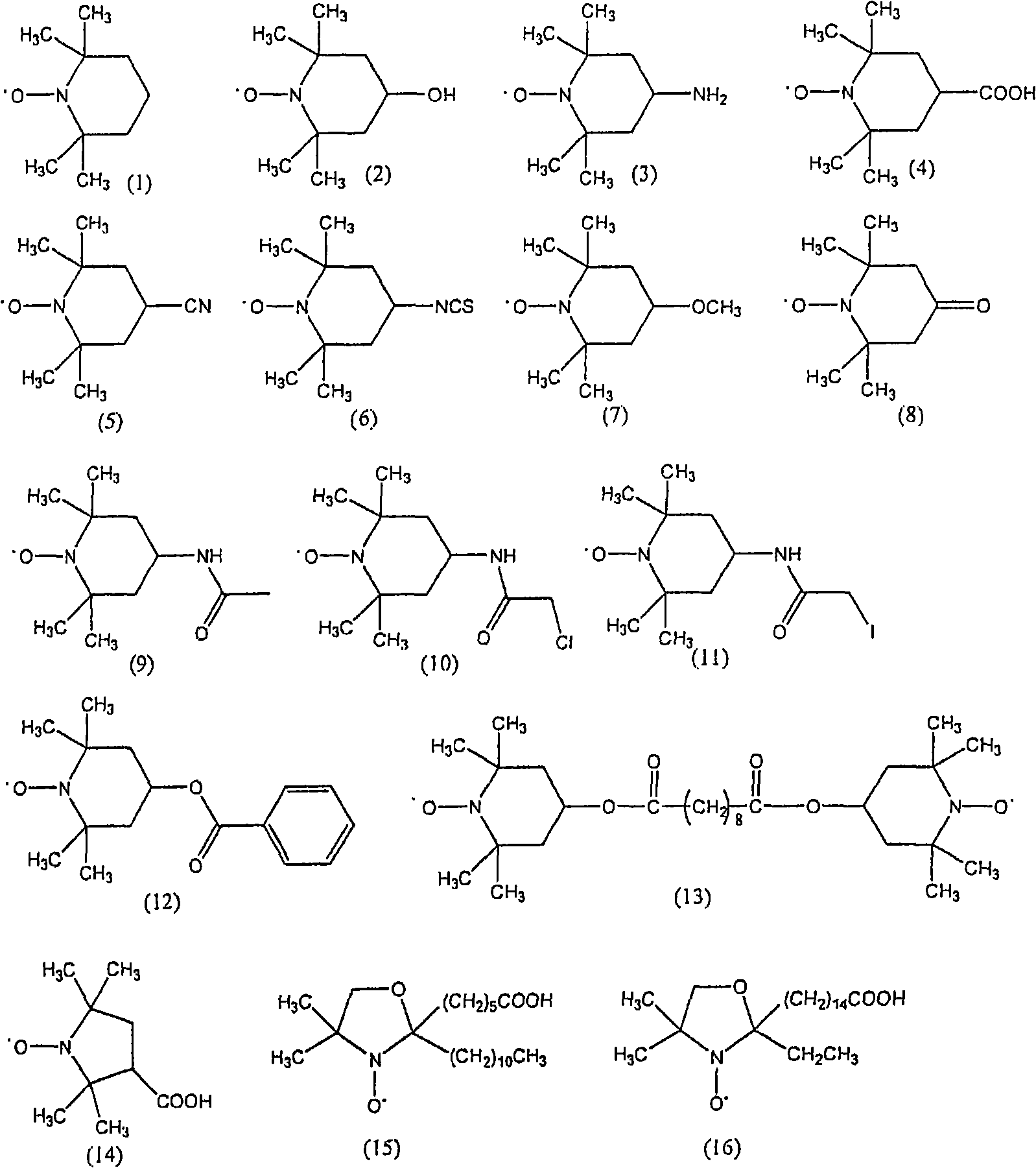

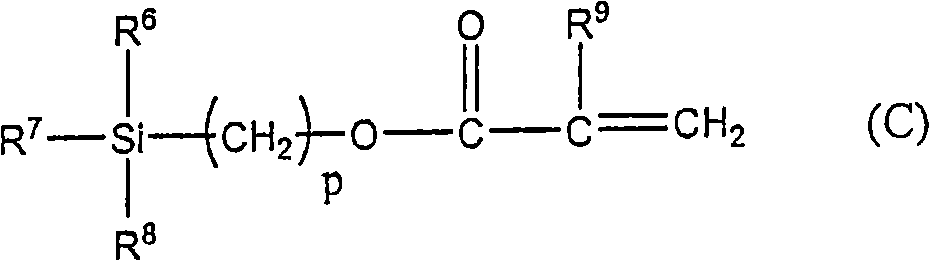

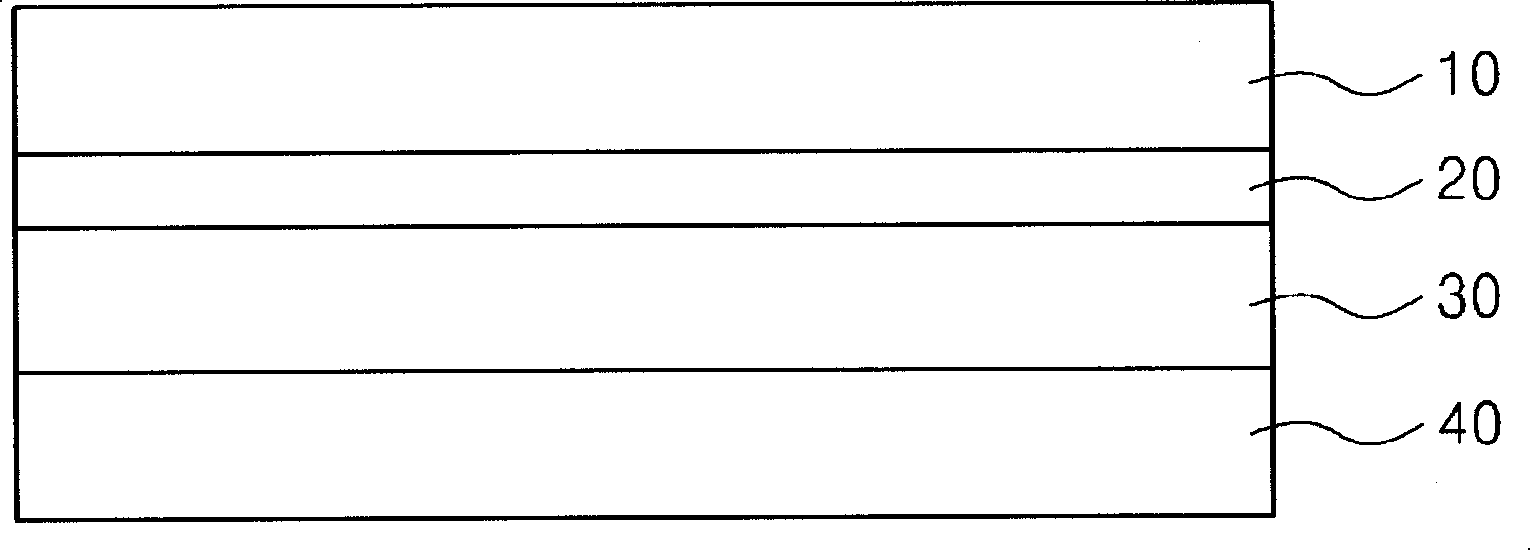

Adhesive composition, circuit connecting material, connection structure of circuit connenctors, and semiconductor devices

InactiveCN101292006AAvoid damageExtend the process time domainPrinted circuit assemblingNon-insulated conductorsSemiconductorSemiconductor device

An adhesive composition which contains an adhesive component comprising a thermoplastic resin, a radical-polymerizable compound, and a radical polymerization initiator, wherein the adhesive component exhibits a signal in the ESR measurement at 25 DEG C.

Owner:HITACHI CHEM CO LTD

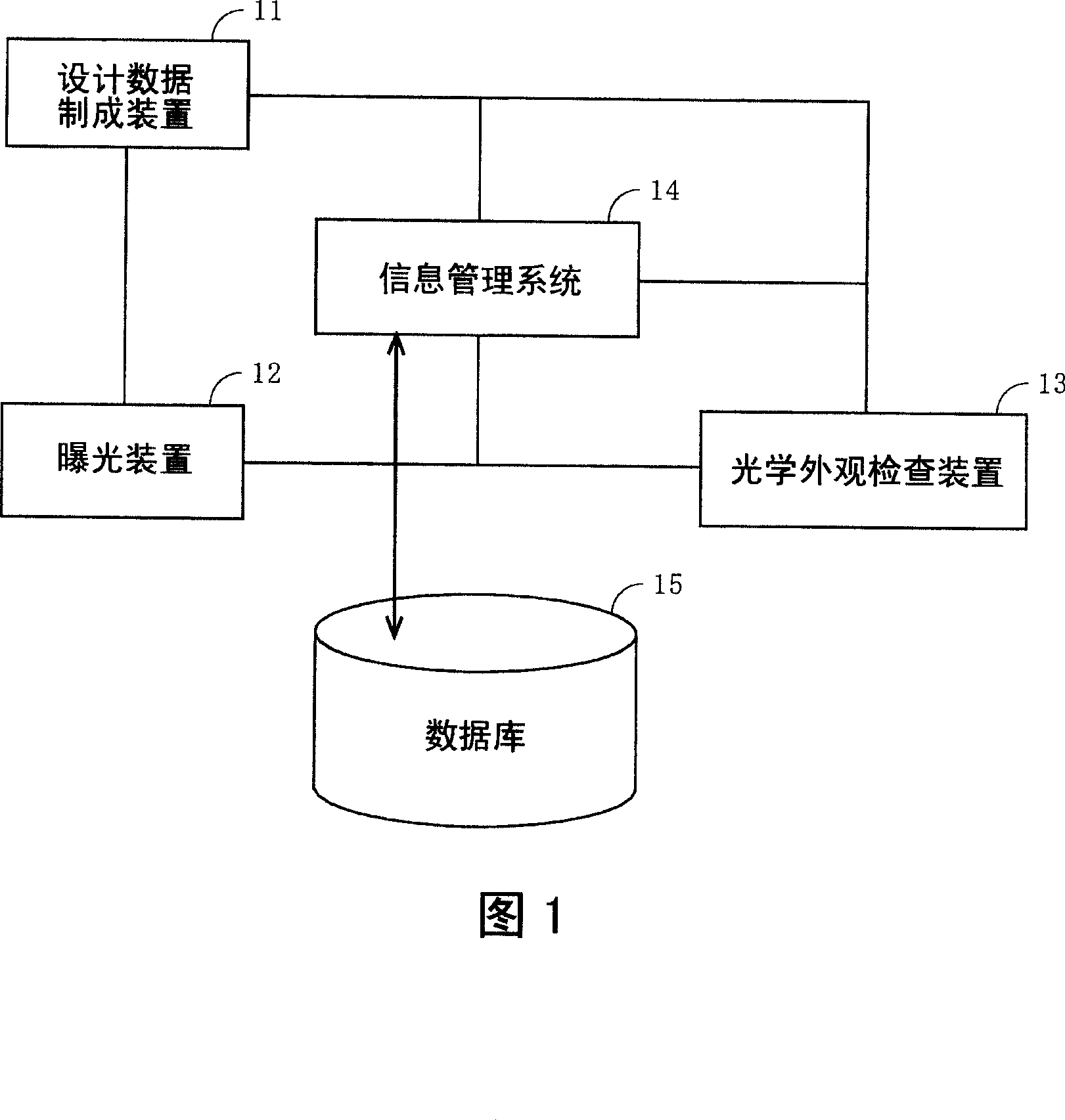

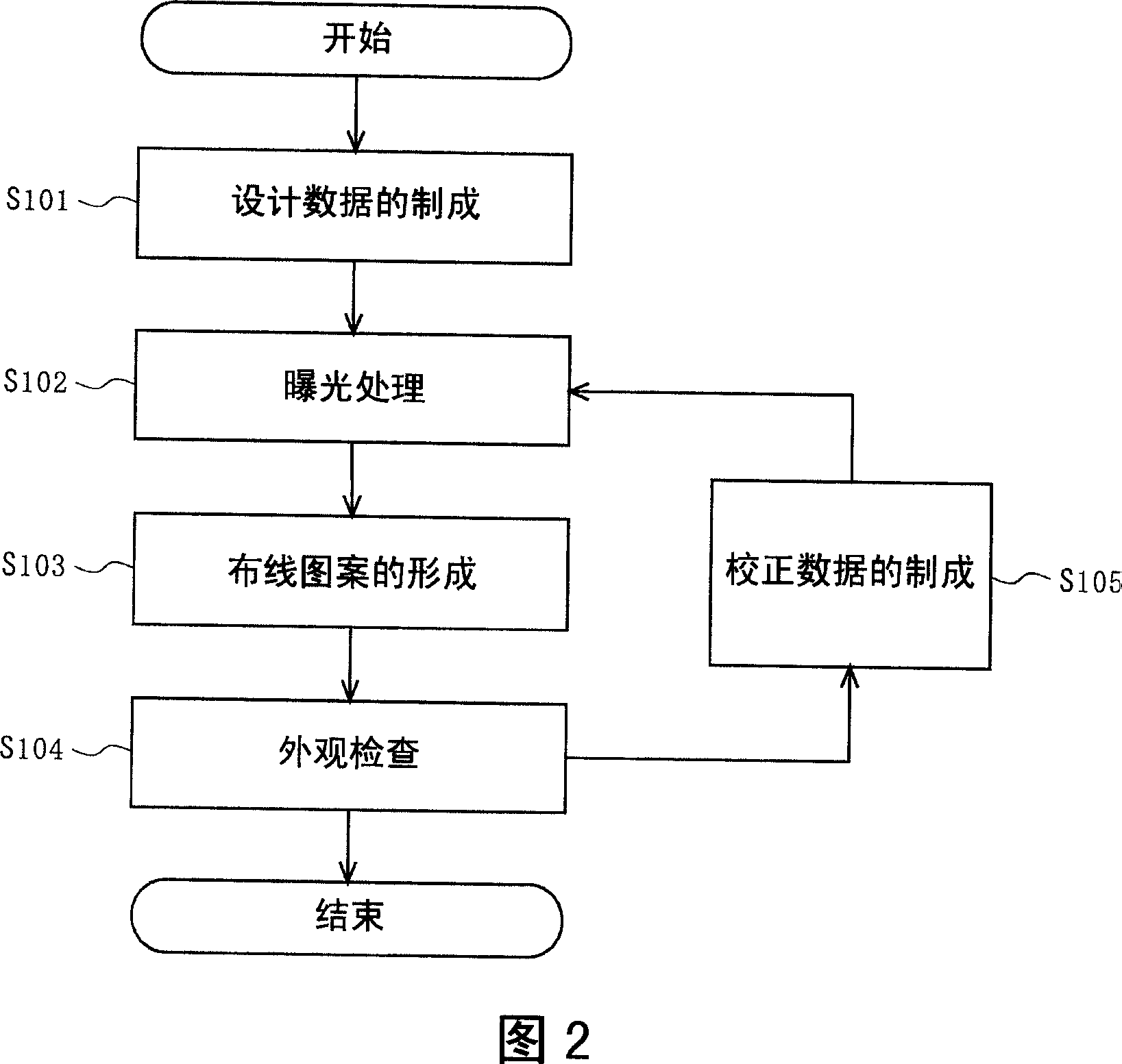

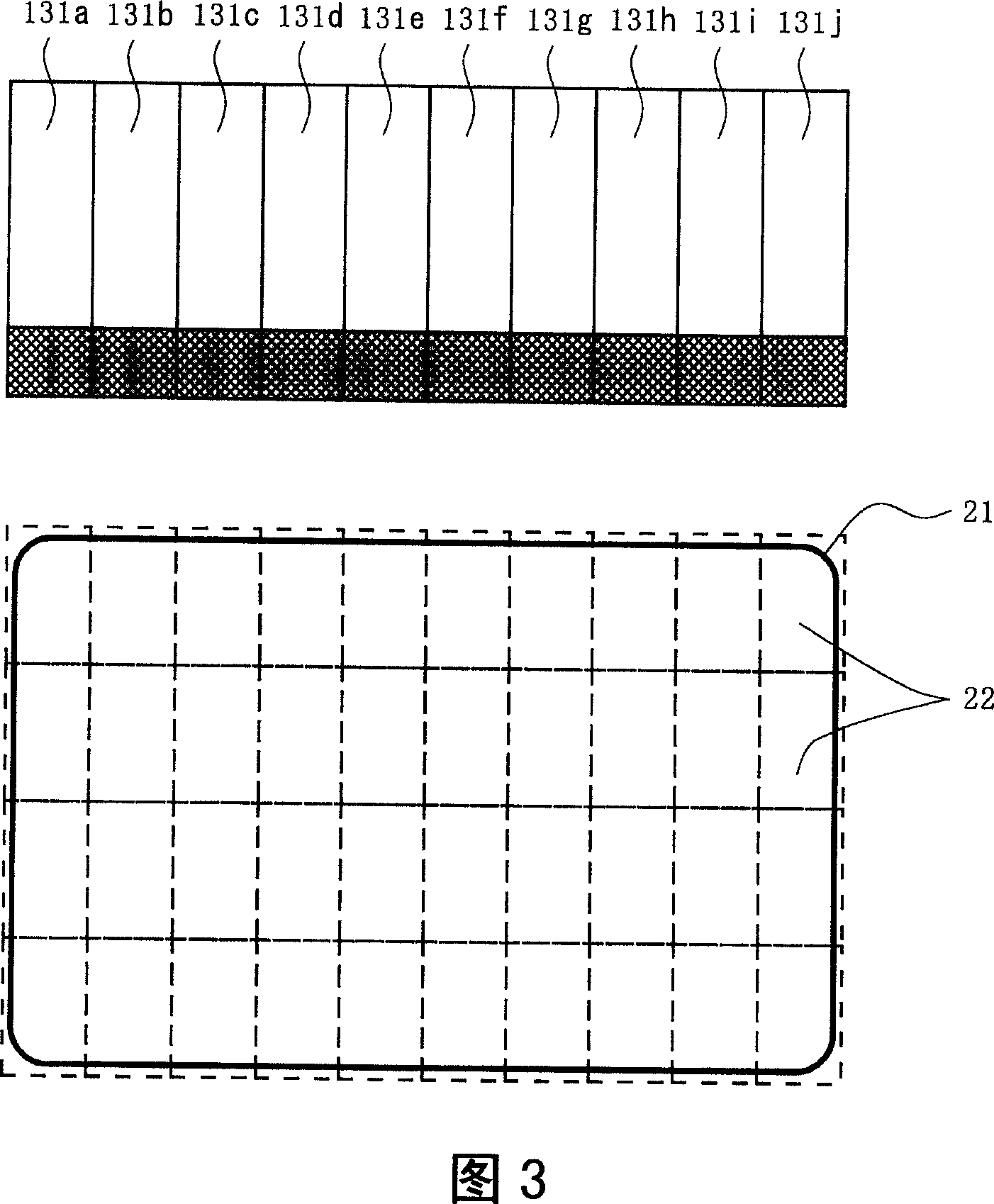

Wiring forming system and method

InactiveCN1933700AIncrease production capacityQuality improvementPhotomechanical exposure apparatusMicrolithography exposure apparatusLine widthPrinted circuit board

PROBLEM TO BE SOLVED: To improve the productivity of printed circuit boards by each performing highly accurate compensation on various defects generated in an actual manufacturing. ŽSOLUTION: An optical appearance inspection device 13 measures the line width of a wiring pattern using a line width measurement algorithm over the entire region of a printed circuit board after the wiring pattern is formed. Then, the optical appearance inspection device 13 prepares a line width histogram in the unit of a region 22 and further prepares a line width distribution by comparing the prepared line width histogram with the line width histogram of a master image data in the same region 22. Information management system 14 prepares a compensated data based on an average of the line width distribution prepared in a predetermined number of printed circuit boards. A stepper 12 performs a thickening or thinning compensation the line width of a wiring pattern on a design data or an image data for exposure in the unit of the region 22 based on the compensated data. Ž

Owner:DAINIPPON SCREEN MTG CO LTD

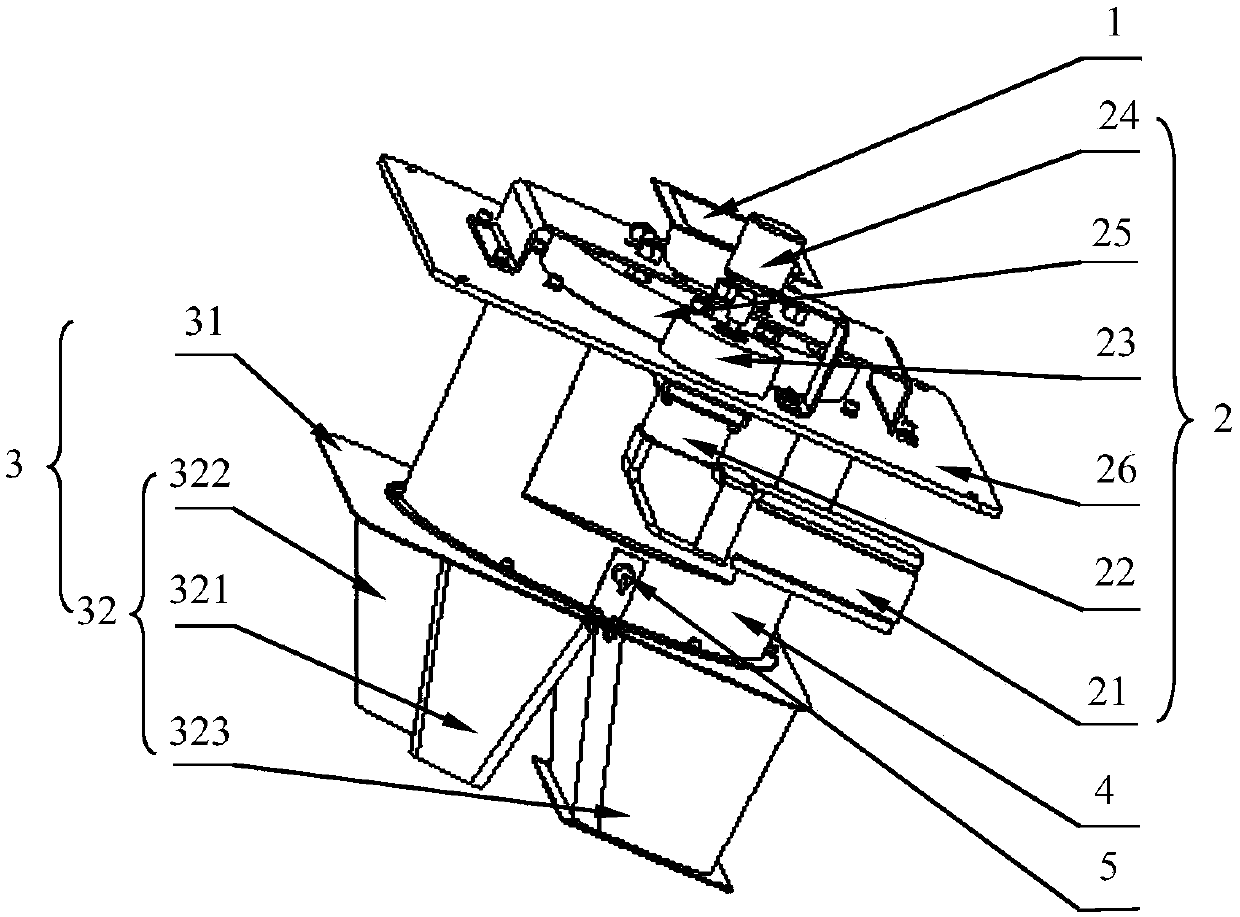

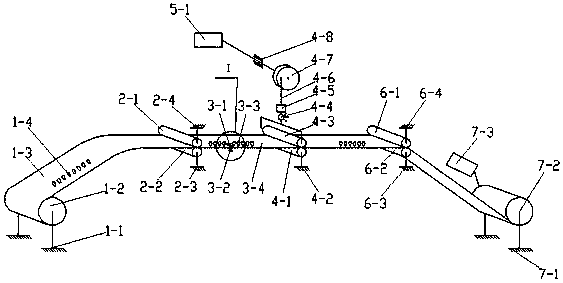

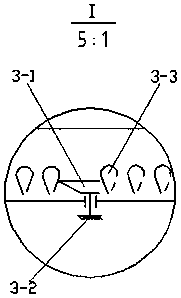

Rotary chute type division device and coal sample preparation device

ActiveCN107796677ASmall quality deviationSmall sampling biasPreparing sample for investigationTime ratioCoal

The application discloses a rotary chute type division device, which comprises a chute component in which a coal flow is flowed, a driving control device, and a slotting discharging hopper; the driving control device is connected with the chute component and used for driving and controlling the chute component to perform rotary movement, and the slotting discharging hopper is located at the tail end of the chute component and used for cutting the coal flow from the chute component; the slotting discharging hopper is provided with a discharging hopper with different sampling angles. For the uniform coal flow passes through the upper part of the slotting discharging hopper by exact time ratio, several parts of coal samples with different masses and fixed quality are acquired from the slotting discharging hopper; the rotary chute type division device is good for improving the division precision. The application further discloses a coal sampling preparation device; for the coal sample canbe acquired at fixed quality, the rotary chute type division device is good for improving the preparation efficiency of the coal sample.

Owner:长沙开元仪器有限公司

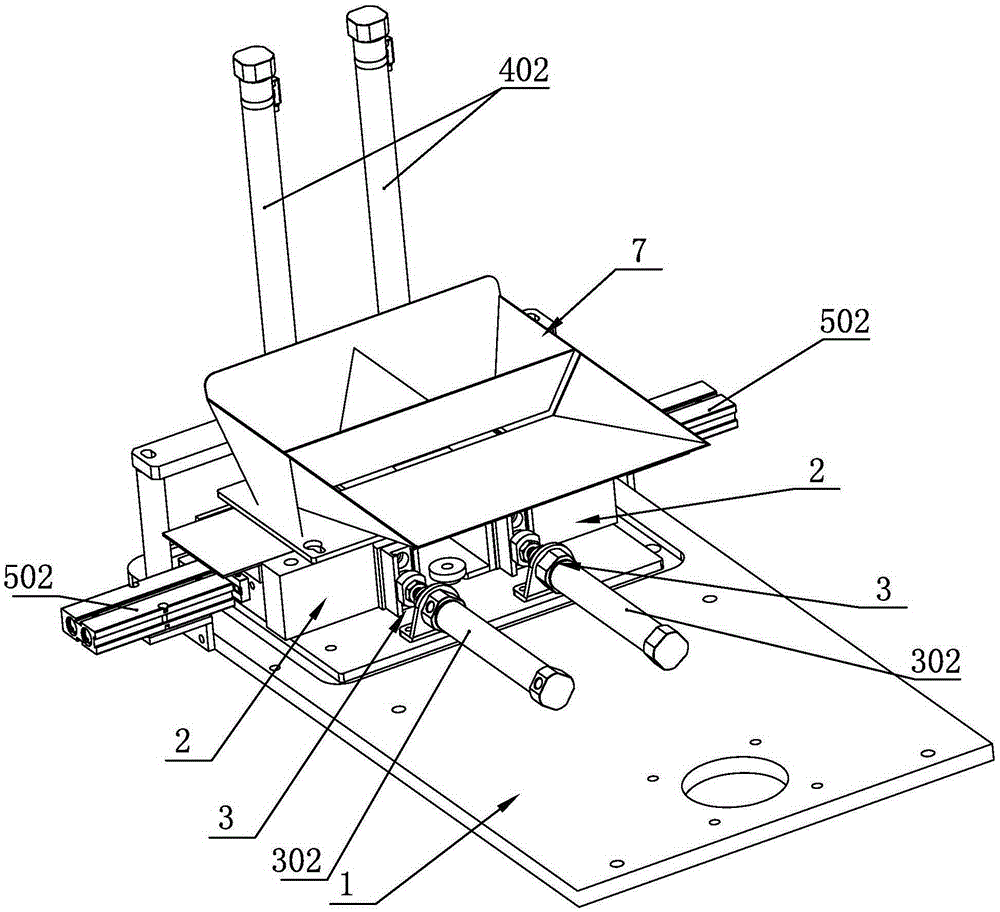

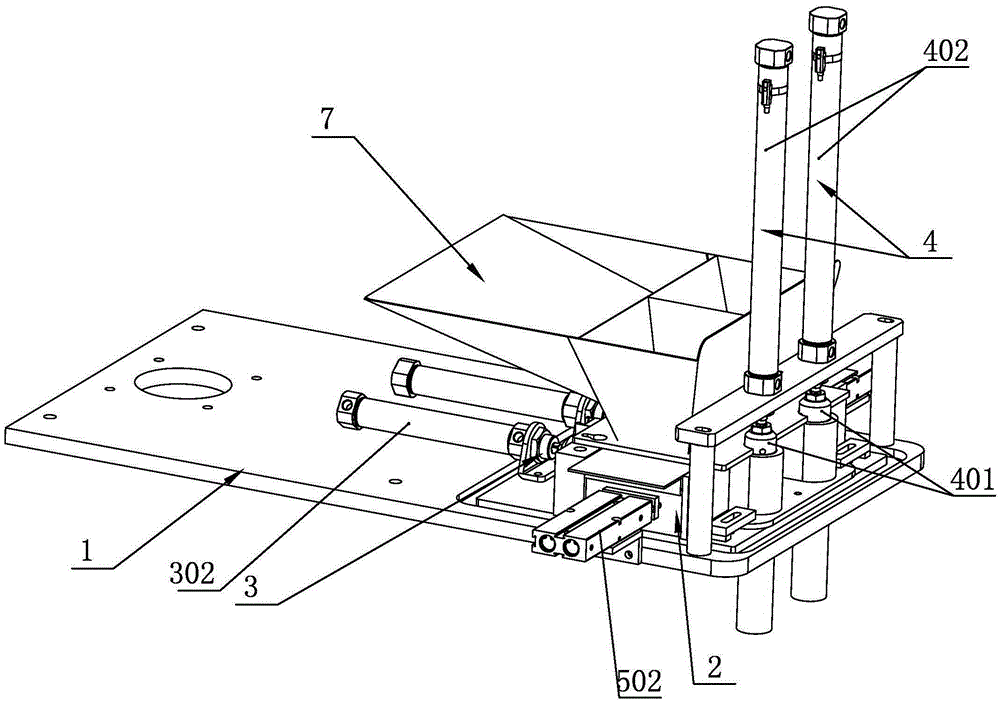

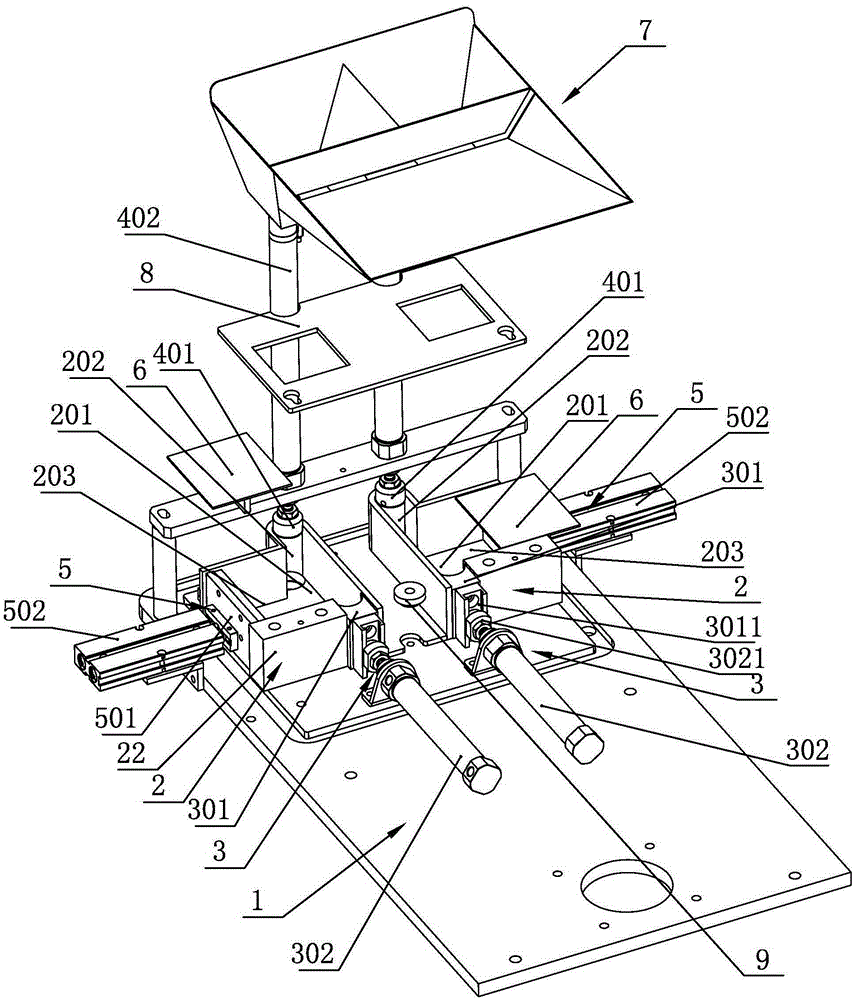

Multi-station charging equipment of packaging machine

PendingCN105253395ASmall quality deviationImprove processing efficiencyPackagingEngineeringExtrusion

The invention relates to multi-station charging equipment of a packaging machine. The multi-station charging equipment comprises a bottom plate and at least two feeding devices arranged on the bottom plate. Each feeding device comprises a shell with a material containing cavity, a first extrusion mechanism and a discharging mechanism. An opening is formed in the top of each shell, a first extrusion groove is formed in each material containing cavity, a discharging channel is formed in one end of each first extrusion groove, and each first extrusion mechanism comprises a first extrusion push block and a first extrusion driving unit. Each discharging mechanism comprises a discharging push block and a discharging driving unit. Second extrusion mechanisms are further included. A second extrusion groove communicated with the corresponding first extrusion groove is further formed in each shell. Each second extrusion mechanism comprises a second extrusion push block and a second extrusion driving unit. Each second extrusion push block is provided with a striker plate. The striker plates move along with the second extrusion push blocks to open or close the openings in the tops of the shells. According to the technical scheme, the technical effects of increasing the extrusion rate and reducing the mass deviation of packaged materials are achieved.

Owner:RUIAN CITY KAIHONG PACKING MACHINERY

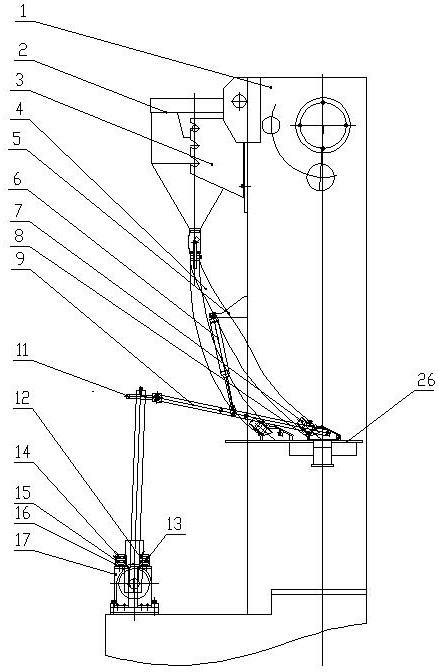

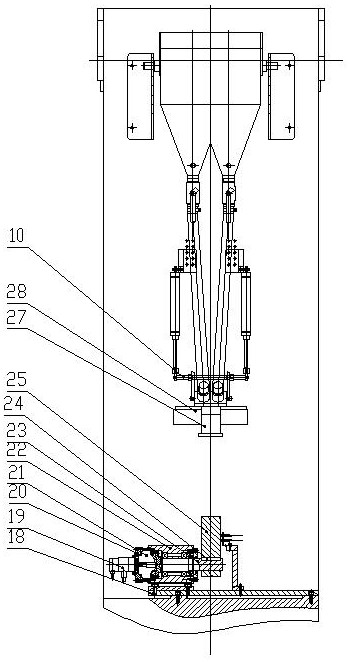

Forming machine servo feeding mechanism with controllable feeding process

PendingCN112707186AImprove molding qualitySmall quality deviationImpedence networksLoading/unloadingMolding machineReducer

The invention relates to a forming machine servo feeding mechanism with a controllable feeding process. The forming machine servo feeding mechanism with the controllable feeding process comprises a machine tool body, a speed reducer is arranged at the lower part of the machine tool body, a servo motor is connected to the speed reducer, a swing rod is connected to an output shaft of the speed reducer in a sleeving mode, a connecting plate is hinged to the upper end of the swing rod, a material boot is hinged to the front end of the connecting plate, a feeding panel is arranged on a female die plate of a machine tool body die frame, the material boot moves back and forth on the feeding panel, a tensioning air cylinder hinged to the machine tool body is arranged above the feeding panel, the lower end of the tensioning air cylinder is hinged to the middle part of the connecting plate, a lower punch is arranged below a female die cavity of the female die plate, a hopper is arranged outside the upper part of the machine tool body, and a rubber hose is arranged at the lower end of the hopper and connected with the material boot.

Owner:YANGZHOU HAILI PRECISION MACHINERY MFG

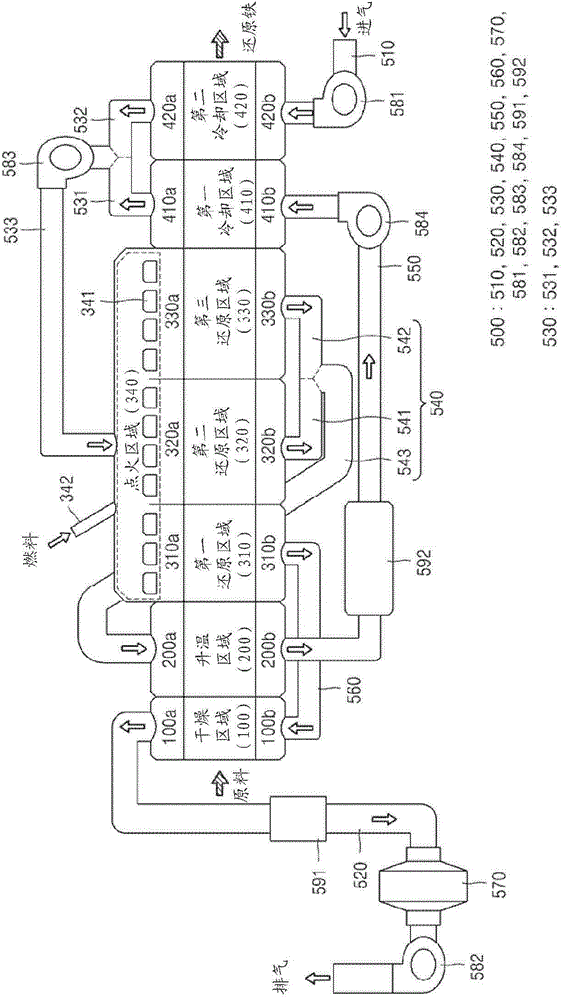

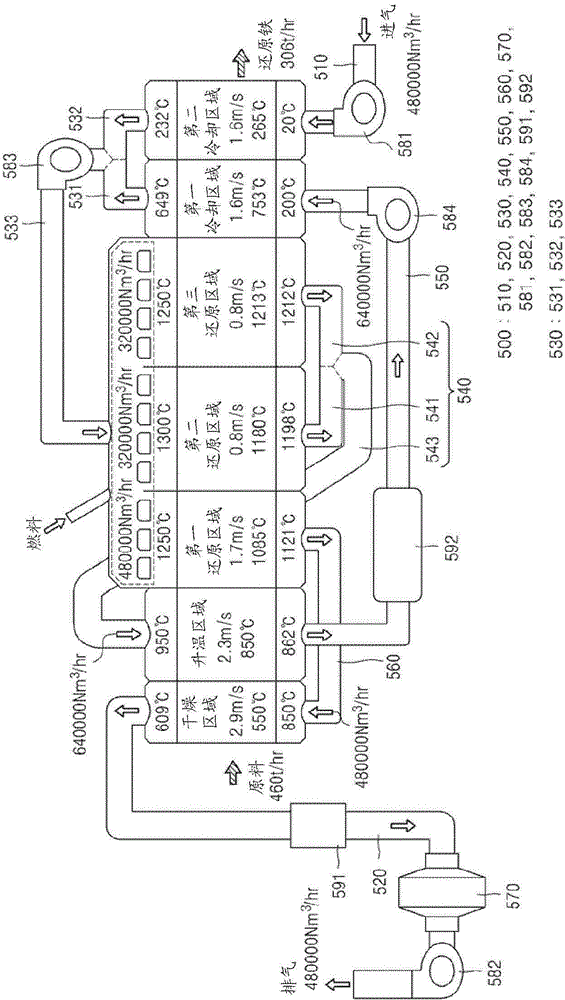

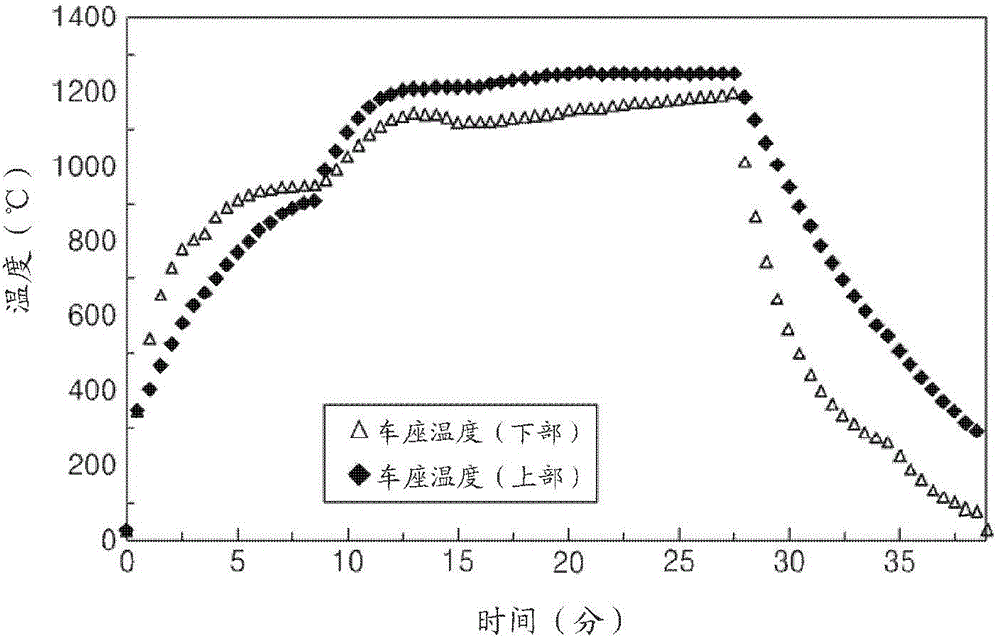

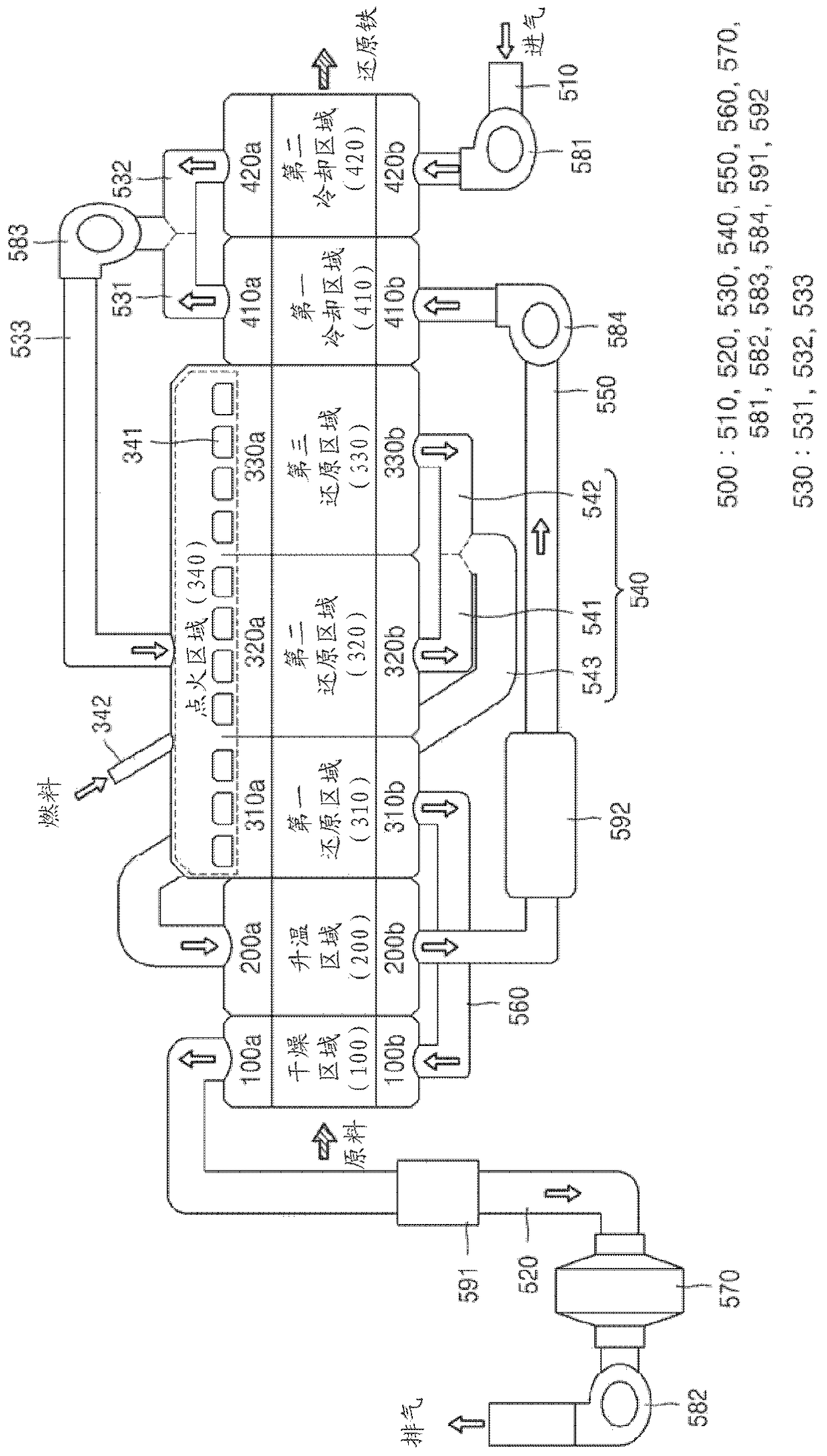

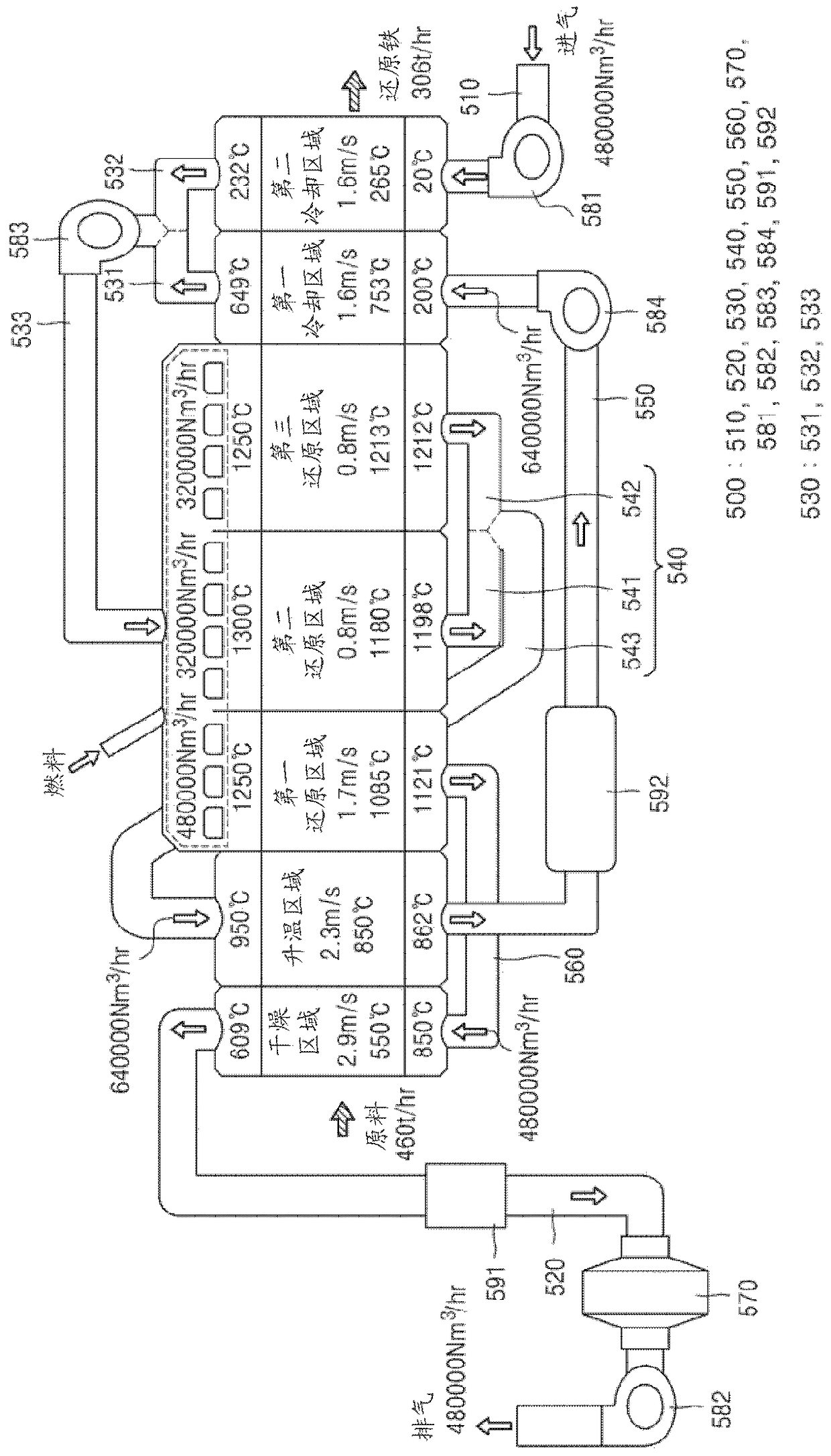

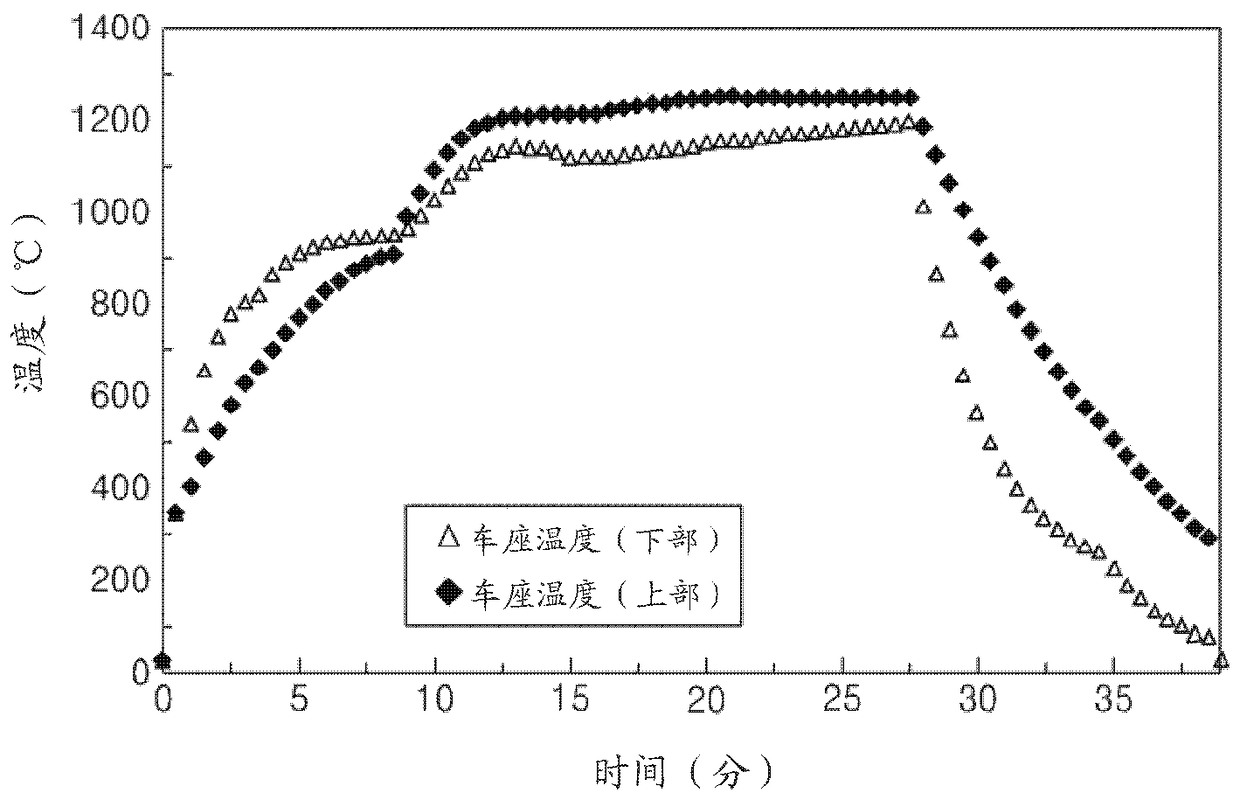

Burning apparatus and manufacturing method of reduced iron

ActiveCN105274323AImprove energy efficiencyReduce manufacturing costFurnace typesControl devices for furnacesProcess engineeringOxygen

The invention provides a burning apparatus and a manufacturing method of reduced iron. The burning apparatus comprises a burning furnace provided with a feed stock processing space, and a gas supply unit. The feed stock processing space is successively divided into a drying region, a heating region, a reduction region and a cooling region along the movement direction of feed stocks. The gas supply unit is used for connecting mutually different regions in the feed stock processing space. During the step of forming the interior atmosphere of the feed stock processing space by means of the gas supply unit, the exhaust gas in the reduction region is respectively supplied to the drying region and the heating region. At the same time, the exhaust gas in the heating region is supplied to the cooling region and the exhaust gas in the cooling region is supplied to the reduction region. Therefore, the temperature of the atmosphere and the concentration of oxygen in the feed stock processing space are controlled, so that the metallization rate of reduced iron in the burning furnace is improved.

Owner:浦项股份有限公司

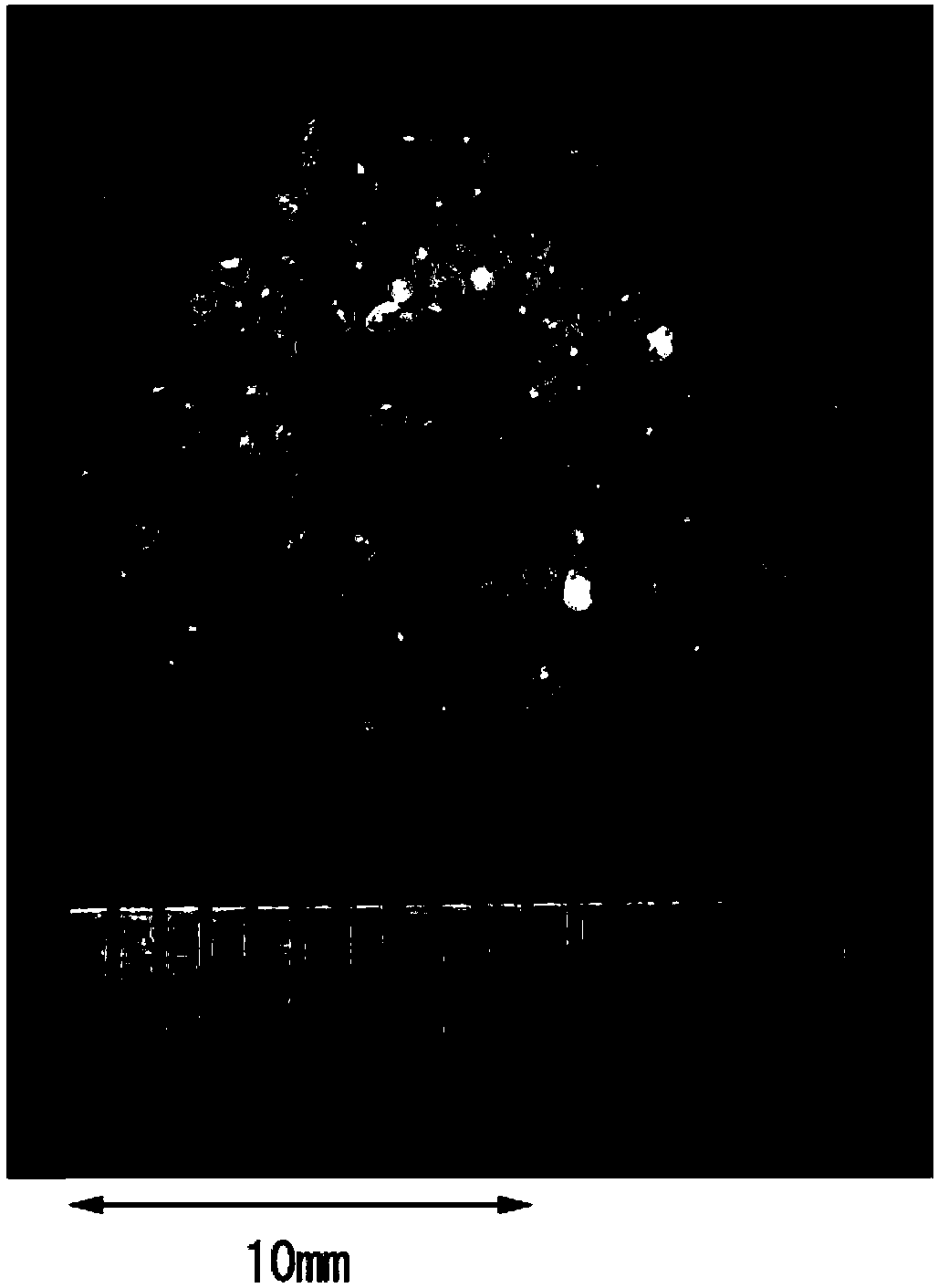

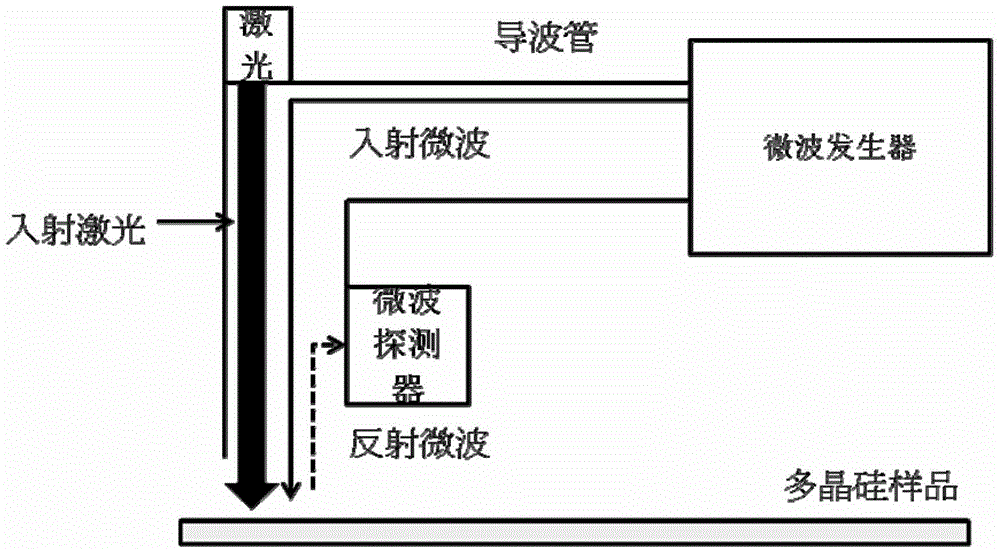

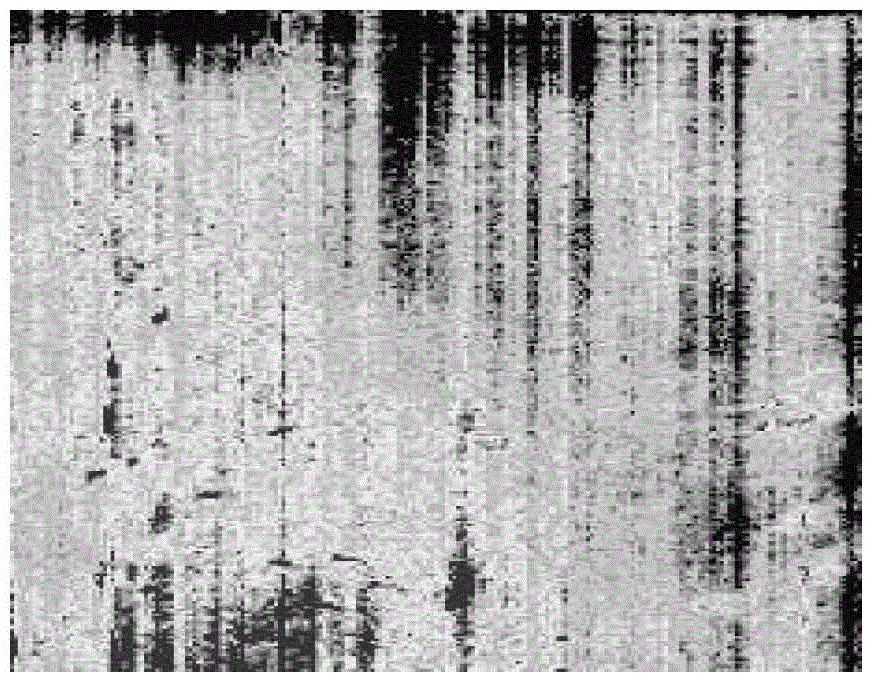

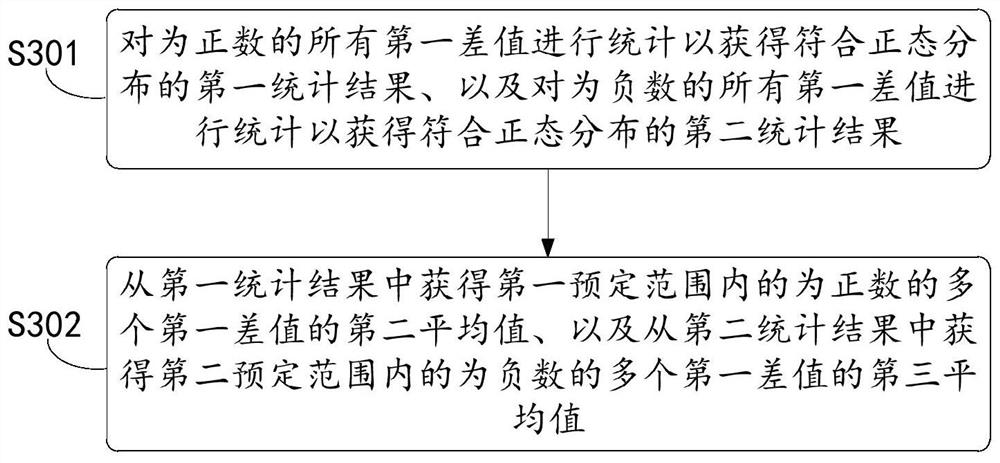

Mura quantification method based on excimer laser annealing

ActiveCN111127415AQuality is conducive to strict controlQuality science and objectivityImage enhancementImage analysisGrey levelMaterials science

The invention discloses a Mura quantification method based on excimer laser annealing, and the method comprises the following steps: S1, obtaining Mura images of different regions of the same substrate after excimer laser annealing under the conditions of the same illumination and the same exposure time; s2, performing image processing on the obtained Mura image; and S3, analyzing the image subjected to the image processing into a gray scale intensity standard deviation to perform Mura quantization. In the present invention, the gray scale strength standard deviation is creatively used for carrying out quantitative evaluation on the Mura; the quality of the polycrystalline silicon after the excimer laser annealing process can be quantitatively judged; the defect of subjective feeling evaluation of human eyes is overcome; the judgment of the Mura has a unified standard and a quantifiable index, the product quality deviation caused by artificial subjective factors is reduced, the strictcontrol of the product quality is facilitated, the quality parameters of the polycrystalline silicon after the excimer laser annealing process can be more scientifically and objectively judged, and the method has important application significance.

Owner:信利(仁寿)高端显示科技有限公司

Pump rotor for a canned motor pump

InactiveCN101802411BSmall imbalanceSmall quality deviationPump componentsPump installationsImpellerRotor magnets

The invention relates to a pump rotor (26) for a canned motor pump. The pump rotor (26) comprises a base body (32) designed in one piece, with an impeller base disk (34) and a rotor holder bushing (36) and a rotor unit (40) with rotor magnets that are arranged on the rotor holder bushing (36).

Owner:ROBERT BOSCH GMBH

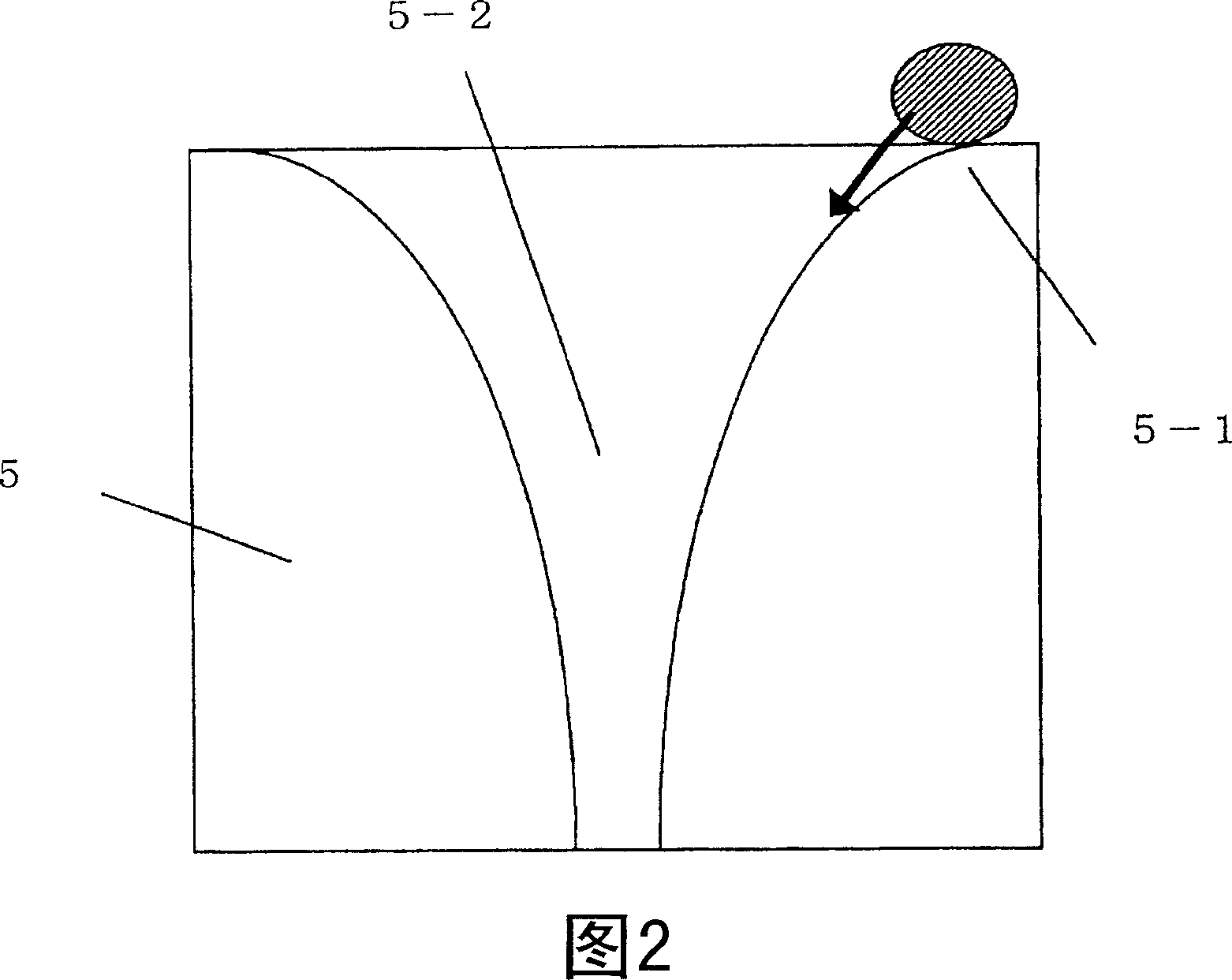

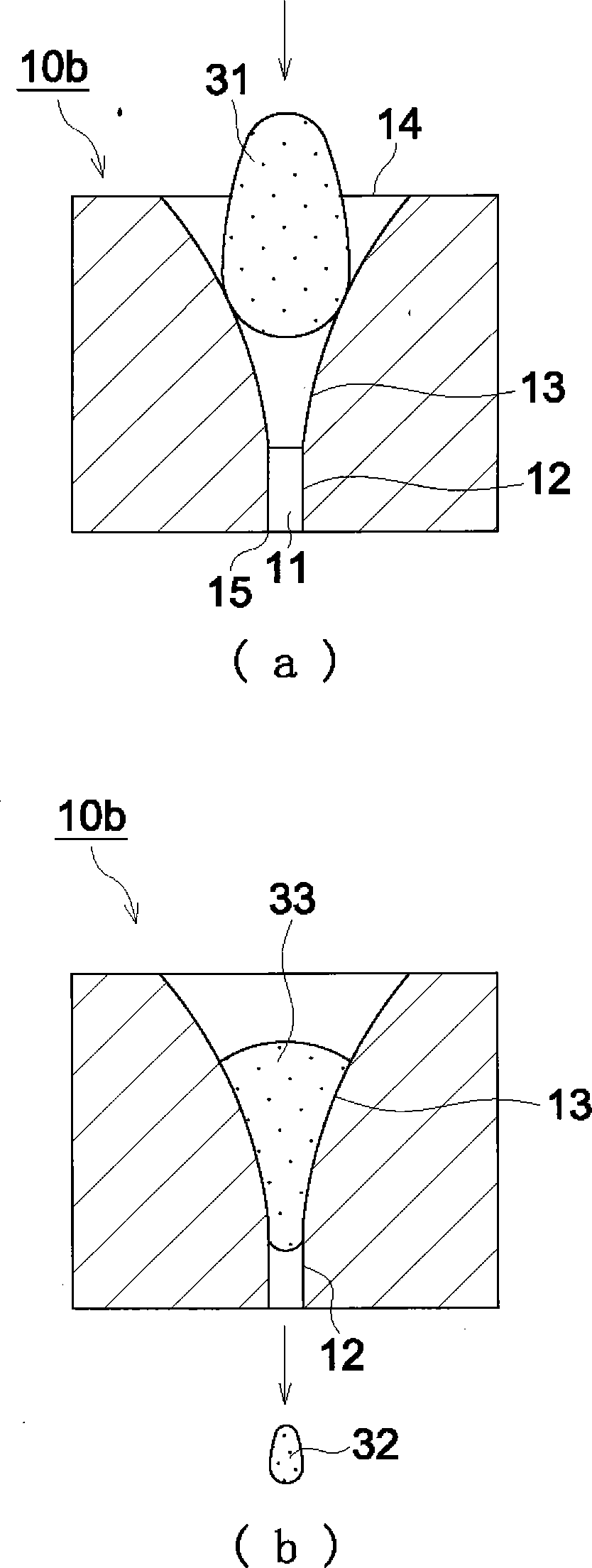

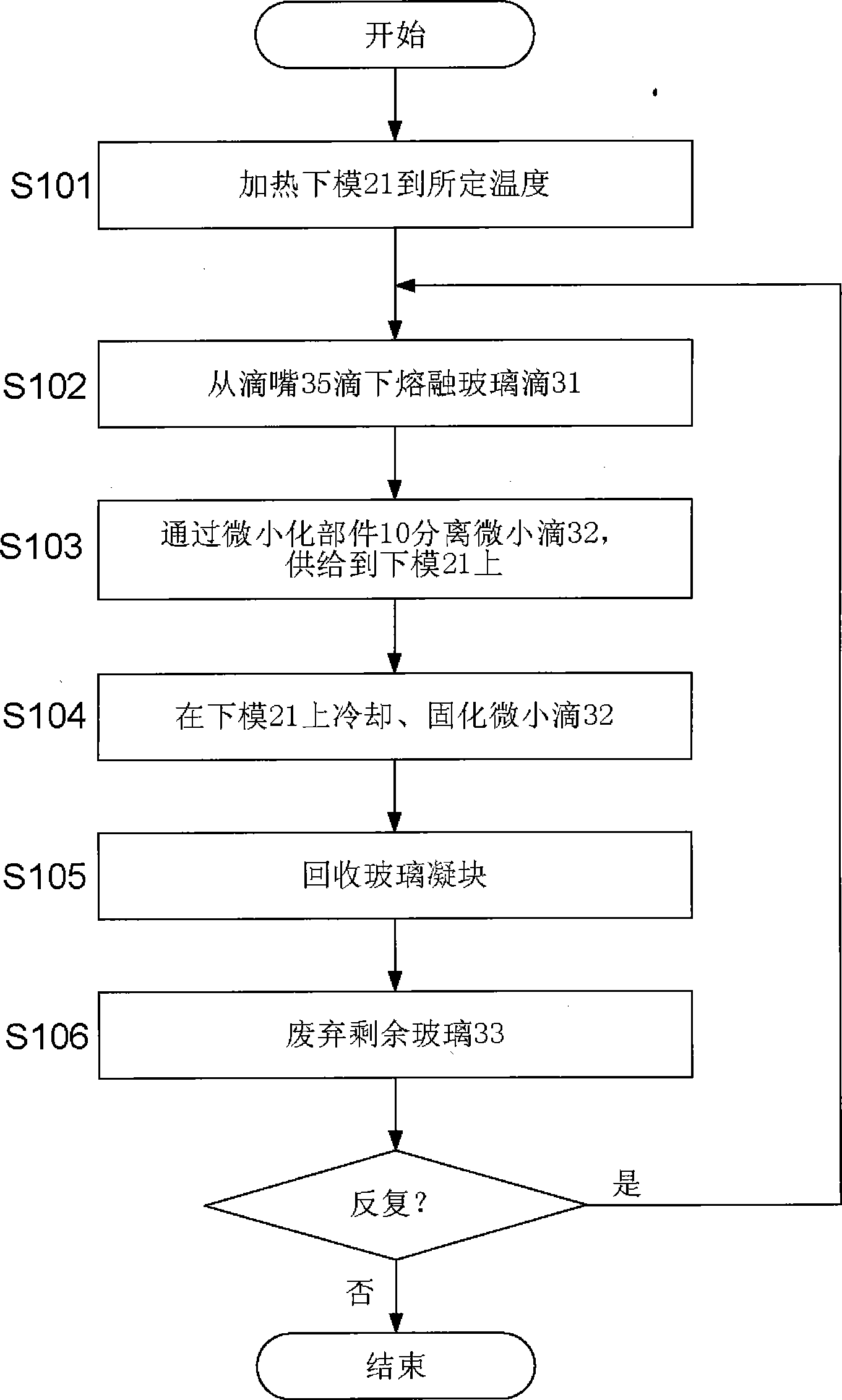

Glass-made performing piece set, manufacture method for the same, and production method for optical element

ActiveCN1958493ASmall quality deviationReduce weightGlass pressing apparatusVolume variationComposite material

The object of this invention is to provide a glass preform lot or molded body (base material) lot in which the volume variation between respective preforms or molded bodies is highly controlled. The glass preform lot or preform base material lot is composed of a spherical preform or preform base material comprising glass whose SiO2 content is regulated within the range of 0 to 20 mass% and in which an average mass is <=200 mg and the ratio of mass tolerance to the mass is within +-0.3%. The method for production of the glass preform lot or glass molded body lot comprising the plurality of glass preforms or molded bodies comprises dropping the glass drip having a prescribed mass from the outflow port of an outflow nozzle, performing the precision press-molding of the obtained glass drop, and repeating the above process. An optical element is produced by heating the glass preform taken out from its lot and performing the precision press molding using the mold for press molding.

Owner:HOYA CORP

Iron based powder for powder metallurgy

Iron based mixed powder for powder metallurgy is provided. The powder at least adds graphite powder and a dissociated lubricant in iron based powder composed of pulverization iron powder which is attached by partly alloying copper powder on surfaces, and preferable pulverization pure iron powder, the graphite powder and powder for improving cutability are fixed on surfaces of the iron based powder by using an adhesive, the iron based powder has following particle size distribution, relatively to total weight of the iron based powder, particles with a particle diameter less than 45 mu m are less than 18.5% by weight; articles with a particle diameter more than 75 mu m and less than 150 mu m are more than 46% by weight; articles with a particle diameter more than 150 mu m and less than 180 mu m are less than 10% by weight; and articles with a particle diameter more than 180 mu m are less than 0.5% by weight; With the powder, the iron based mixed powder for powder metallurgy having good compression performance and filling performance can be obtained.

Owner:JFE STEEL CORP

Adhesive resin composition containing an amine-based accelerator, and a decorative film including same

ActiveCN103298900ASmall quality deviationGuaranteed stabilityNon-macromolecular adhesive additivesFilm/foil adhesivesHydrogenReaction rate

The present invention relates to an adhesive resin composition for a decorative film, and to a decorative film including same. In the present invention, an amine-based (including N) accelerator having a functional group which can react with active hydrogen is used for increasing the reaction rate of an adhesive resin which is required for the preparation of a decorative film having a metallic effect, thereby ensuring coating stability and increasing the reaction rate. Thus, according to the present invention, an adhesive resin which has little deviation in quality (boil resistance) between and within rolls can be provided in a short time.

Owner:LG HAUSYS LTD

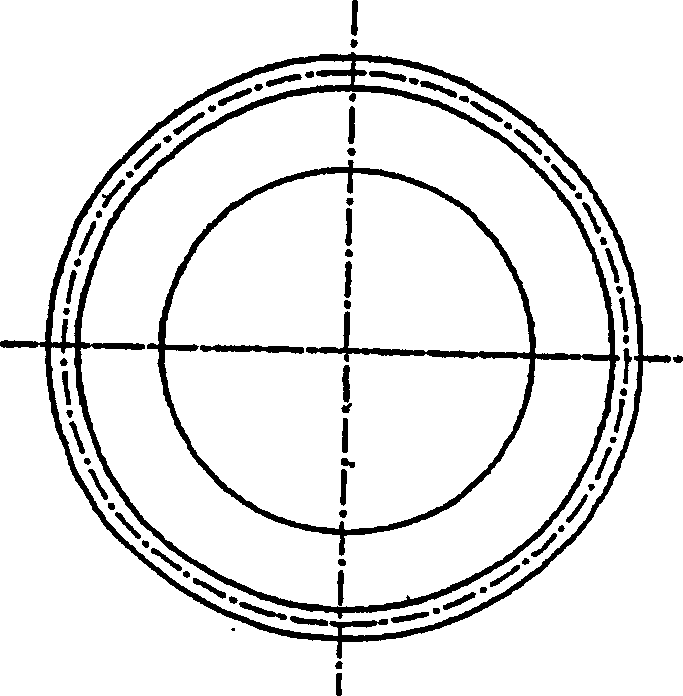

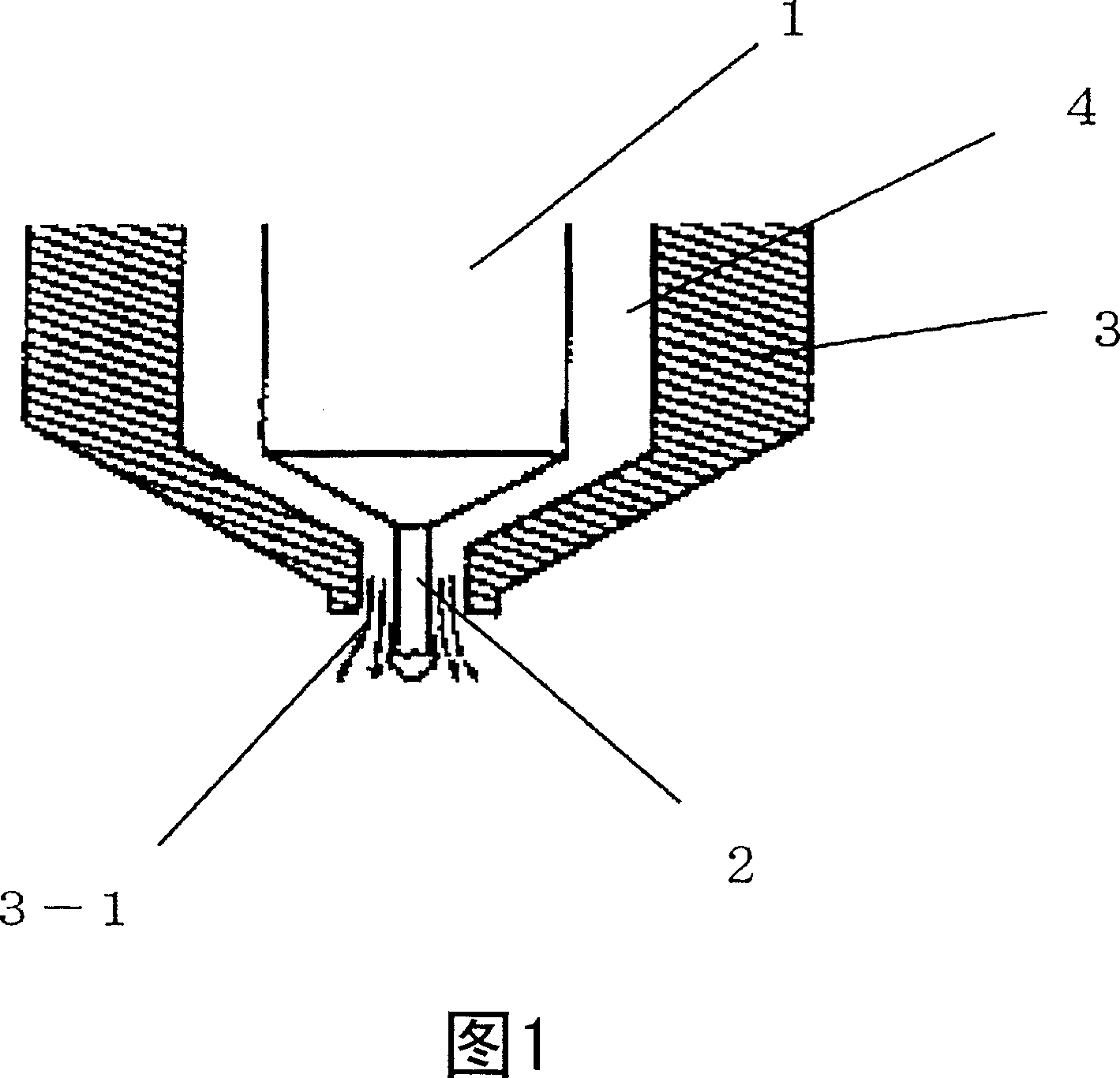

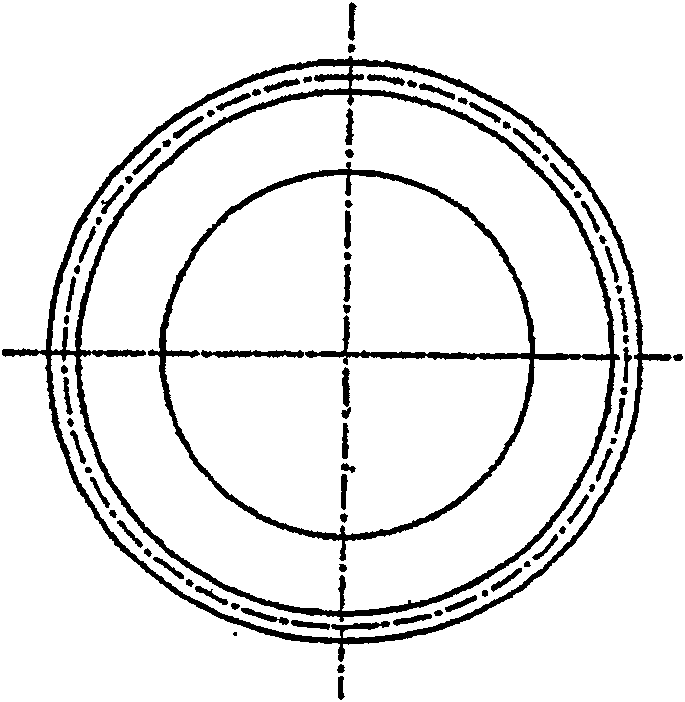

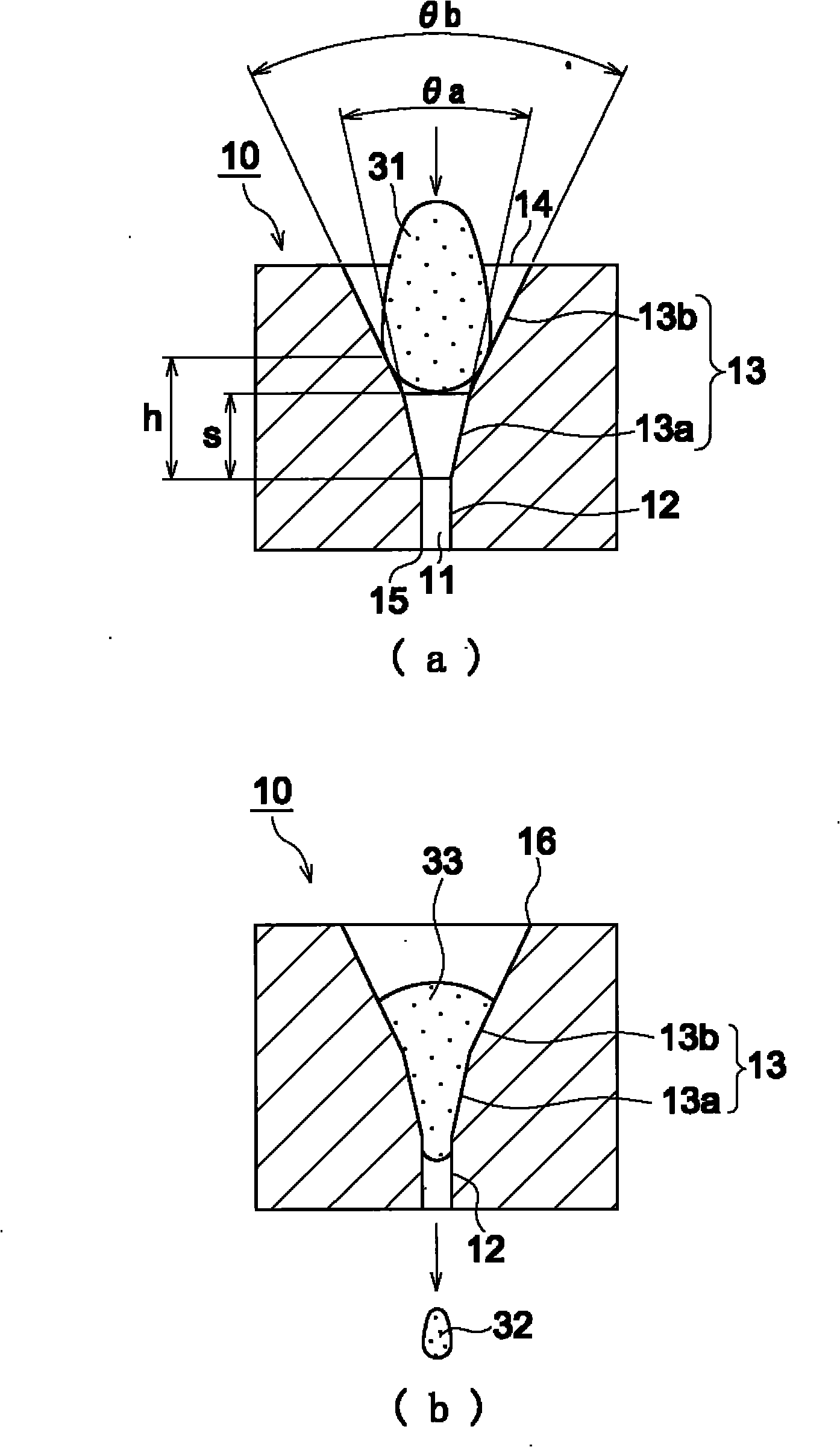

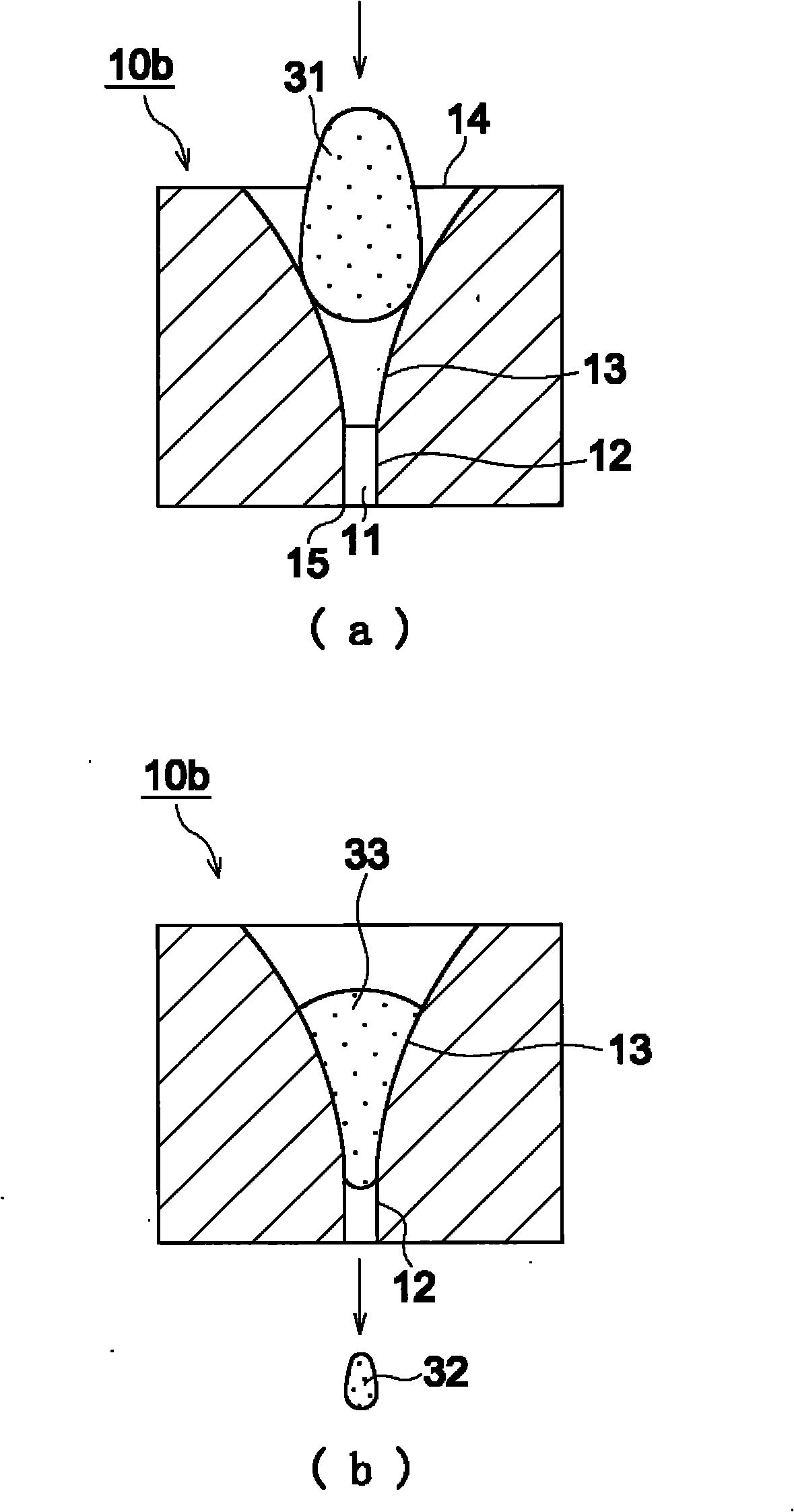

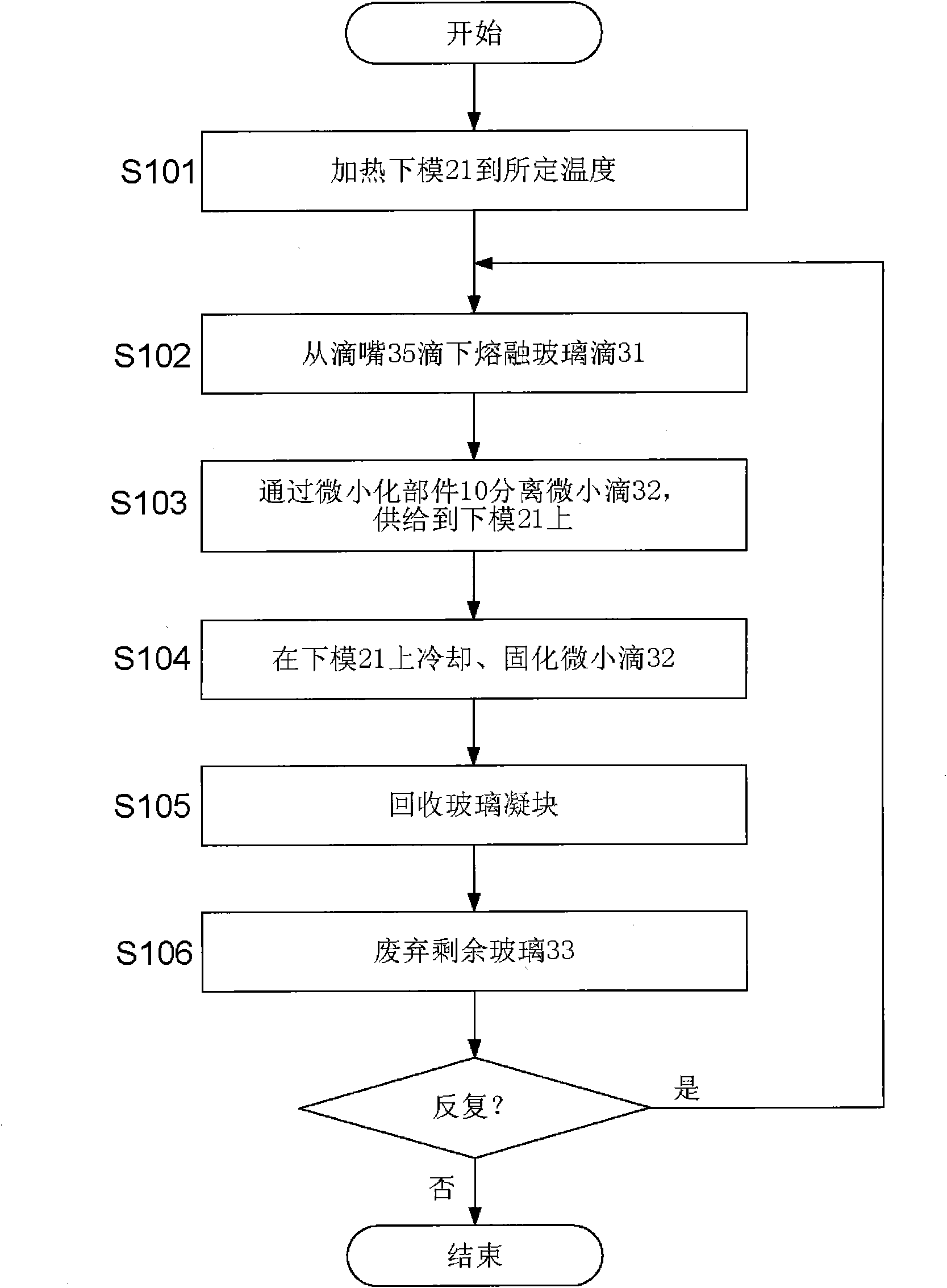

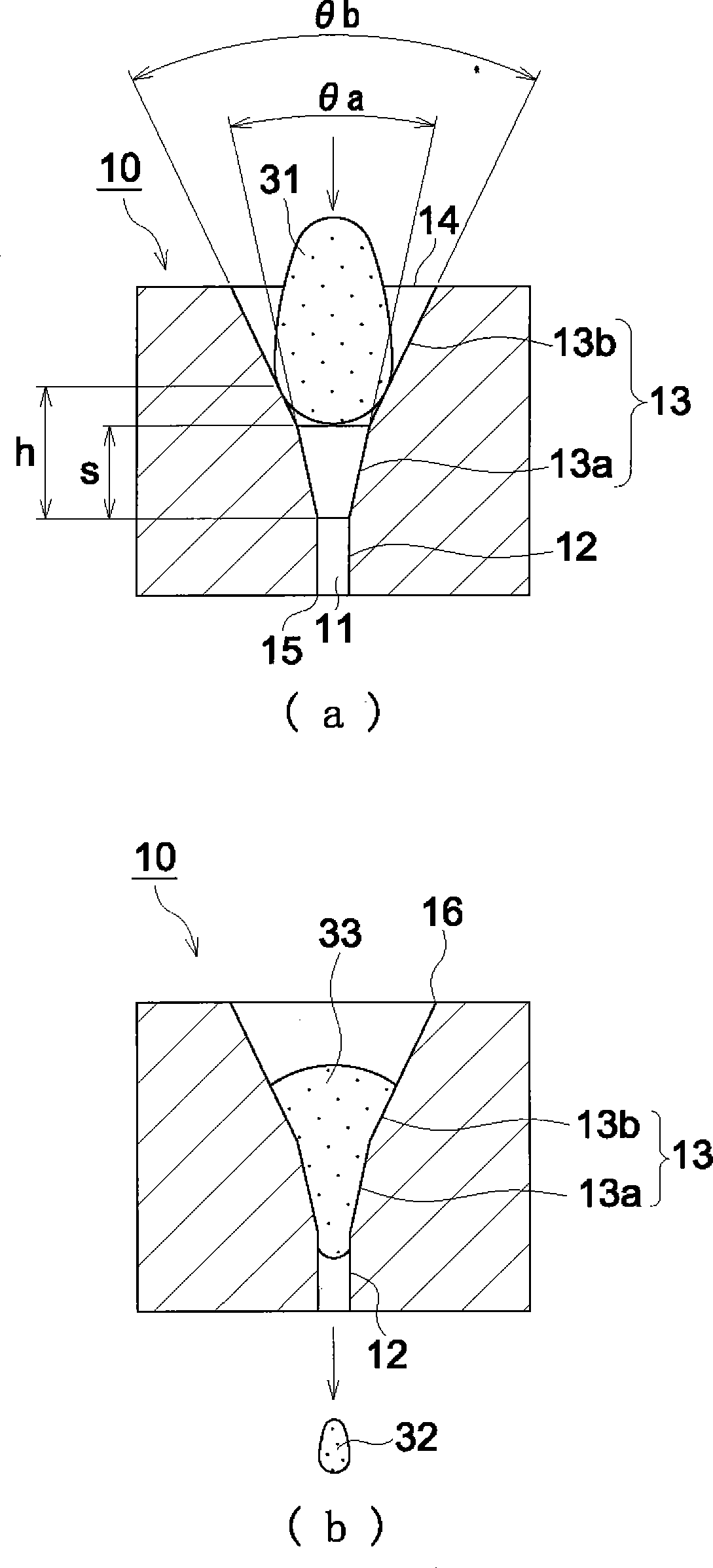

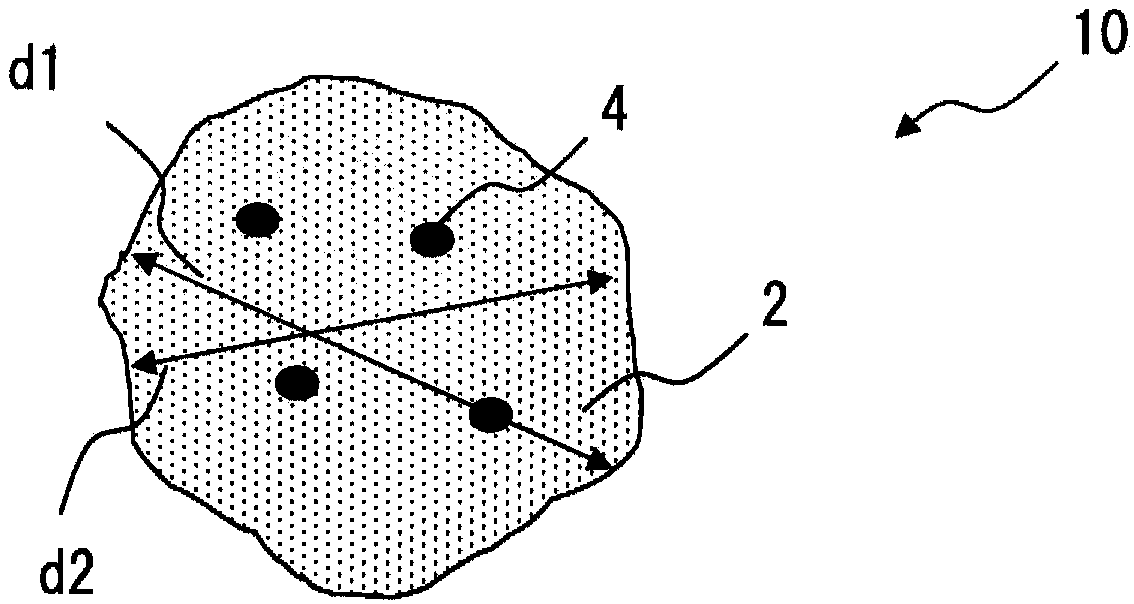

Member for miniaturizing molten glass droplet, method for producing glass gob, method for producing glass molding, and method for producing minute glass droplet

InactiveCN101959811AReduce positional deviationProduct quality is fully stableGlass pressing apparatusHalogen/halogen-acidsMolten glassGlass forming

Inner circumferential surface of a through hole in a member for miniaturizing a molten glass droplet includes a tapered part having a diameter spreading toward an inlet through which a molten glass droplet enters and receiving a molten glass droplet, and a straight part having a substantially constant diameter and passing therethrough a molten glass droplet collided against the tapered part. An area of the tapered part which is in contact with a molten glass droplet (a) consists of a plurality of areas each having a different opening angle of a taper, wherein an area closer to the straight part has a smaller opening angle of a taper. (b) Alternatively, the opening angle of a taper becomes smaller continuously toward the straight part.

Owner:KONICA MINOLTA OPTO

Member for miniaturizing molten glass droplet, method for producing glass gob, method for producing glass molding, and method for producing minute glass droplet

InactiveCN101959811BSmall quality deviationProduct quality is fully stableGlass pressing apparatusHalogen/halogen-acidsMaterials scienceMolten glass

Inner circumferential surface of a through hole in a member for miniaturizing a molten glass droplet includes a tapered part having a diameter spreading toward an inlet through which a molten glass droplet enters and receiving a molten glass droplet, and a straight part having a substantially constant diameter and passing therethrough a molten glass droplet collided against the tapered part. An area of the tapered part which is in contact with a molten glass droplet (a) consists of a plurality of areas each having a different opening angle of a taper, wherein an area closer to the straight part has a smaller opening angle of a taper. (b) Alternatively, the opening angle of a taper becomes smaller continuously toward the straight part.

Owner:KONICA MINOLTA OPTO

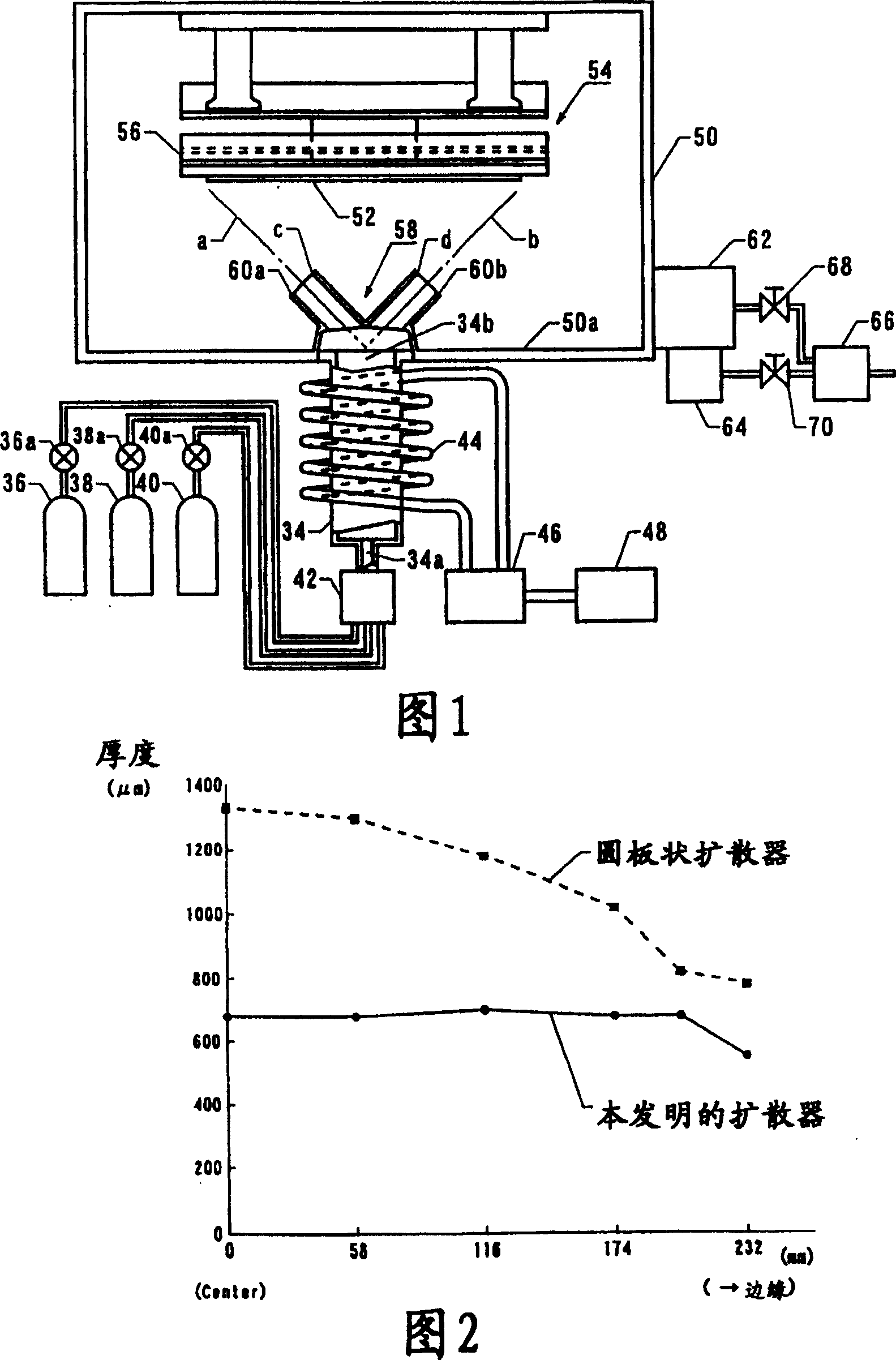

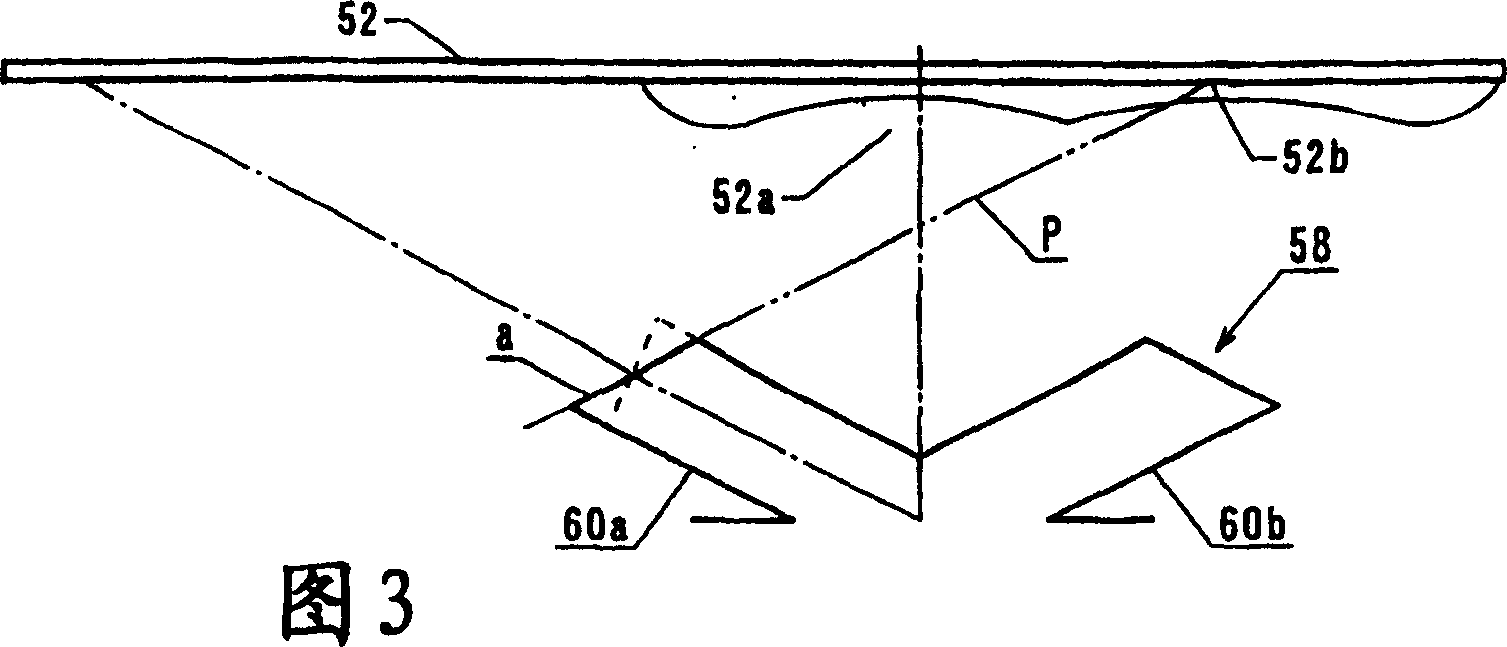

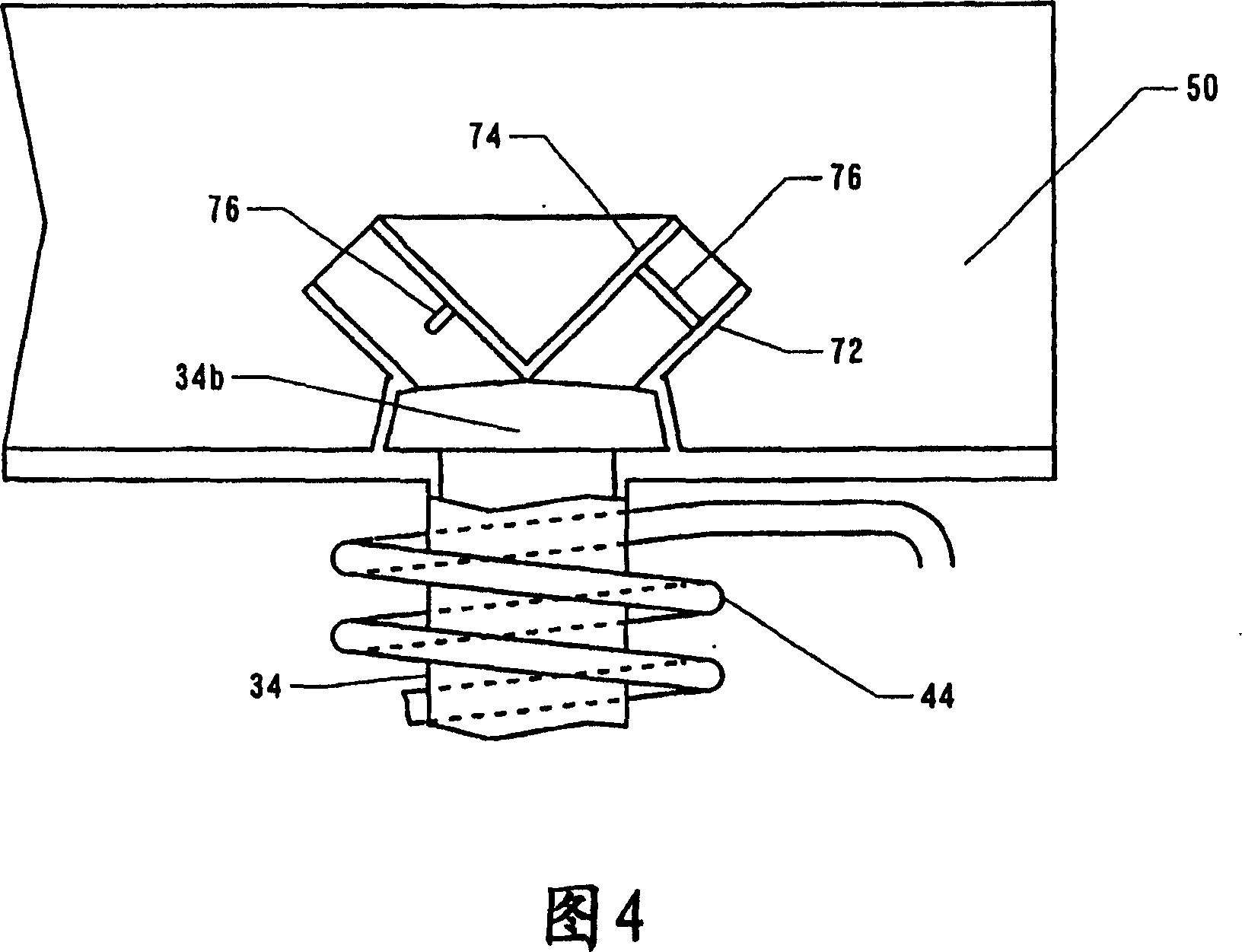

Plasma treatment device and substrate surface treatment device

InactiveCN100348077CQuality improvementSmall quality deviationElectric discharge tubesSemiconductor/solid-state device detailsOrganic filmProduct gas

The invention provides a plasma treatment device by which cleaning operation and organic film forming operation can be continuously conducted by the same equipment, and even when a member to be treated by plasma treatment is a member exposing a conductive thin film to a part of an organic film with which a substrate is coated, the surface of the conductive thin film can be cleaned without damaging coat resin. The plasma treatment device comprises a plasma generation room 34 for generating plasma by activating supplied gas; a pressure reducing chamber 50 connected to the plasma generation room 34 and capable of storing a member 52 to be treated by plasma treatment; and a diffuser 58 capable of guiding plasma to a gas passage in the plasma generation room 34 in an inclination direction, and leading the plasma into the pressure reducing chamber 50 while diffusing the plasma.

Owner:INNOLUX CORP +1

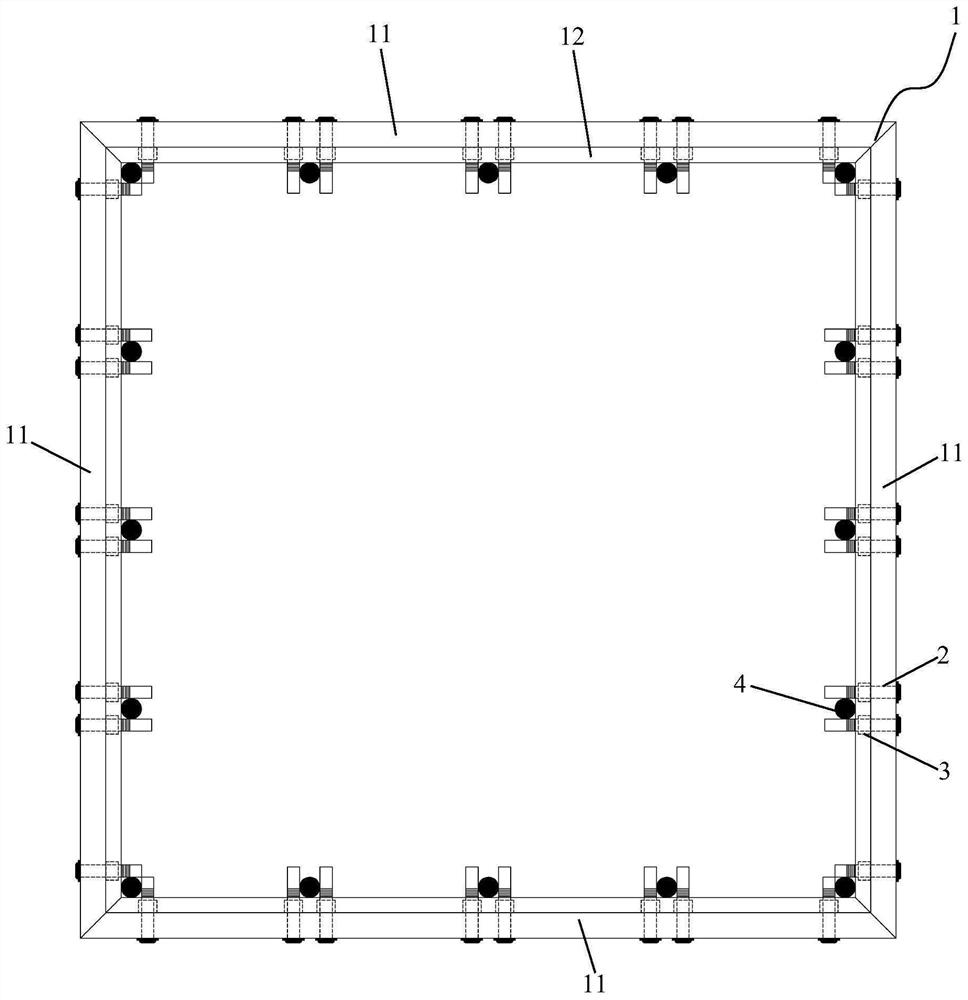

Accurate positioning device for high-turnover frame column main reinforcements

The invention discloses an accurate positioning device for high-turnover frame column main reinforcements. The accurate positioning device is characterized in that a main frame comprises a plurality of square and rectangular pipes; corresponding strip-shaped holes are formed in the inner side walls and the outer side walls of the square and rectangular pipes in the length direction of the square and rectangular pipes; strip-shaped baffles with L-shaped sections are symmetrically fixed to the top edges and the bottom edges of the inner side walls of the square and rectangular pipes, and the two strip-shaped baffles and the inner side walls of the square and rectangular pipes form a limiting cavity; multiple bolt rods are arranged and penetrate through the two strip-shaped holes from the outer side walls of the square and rectangular pipes to enter the main frame; the number of the nuts is the same as that of the bolt rods, and the nuts are arranged in the limiting cavity and are in threaded fastening connection with the bolt rods; and the nuts can slide in the length direction of the limiting cavity. The accurate positioning device for the high-turnover frame column main reinforcements is convenient to operate, light in self weight, capable of being freely adjusted according to different sections, the number of steel bars and the distance and high in turnover rate, and meanwhile, the device can effectively limit the steel bars, so that the steel bars are accurately positioned and have small mass deviation.

Owner:CHINA CONSTR FIFTH ENG DIV CORP LTD

Sintering device and method for producing reduced iron

ActiveCN105274323BIncrease metallization rateSmall quality deviationFurnace typesControl devices for furnacesProcess engineeringOxygen

The invention provides a burning apparatus and a manufacturing method of reduced iron. The burning apparatus comprises a burning furnace provided with a feed stock processing space, and a gas supply unit. The feed stock processing space is successively divided into a drying region, a heating region, a reduction region and a cooling region along the movement direction of feed stocks. The gas supply unit is used for connecting mutually different regions in the feed stock processing space. During the step of forming the interior atmosphere of the feed stock processing space by means of the gas supply unit, the exhaust gas in the reduction region is respectively supplied to the drying region and the heating region. At the same time, the exhaust gas in the heating region is supplied to the cooling region and the exhaust gas in the cooling region is supplied to the reduction region. Therefore, the temperature of the atmosphere and the concentration of oxygen in the feed stock processing space are controlled, so that the metallization rate of reduced iron in the burning furnace is improved.

Owner:浦项股份有限公司

An online peel strength detection device and working method of a hook cutting machine for hook and loop fasteners

ActiveCN106370450BSave human effortSave moneyStructural/machines measurementTraction systemControl system

Owner:WUXI PAIHO TEXTILES CO LTD

Freeze-drying Technology of Cardiopeptide for Injection

ActiveCN108478781BKeep aliveShorten drying timePowder deliveryPeptide/protein ingredientsFreeze-dryingBiomedical engineering

Owner:DALIAN UNIV OF TECH

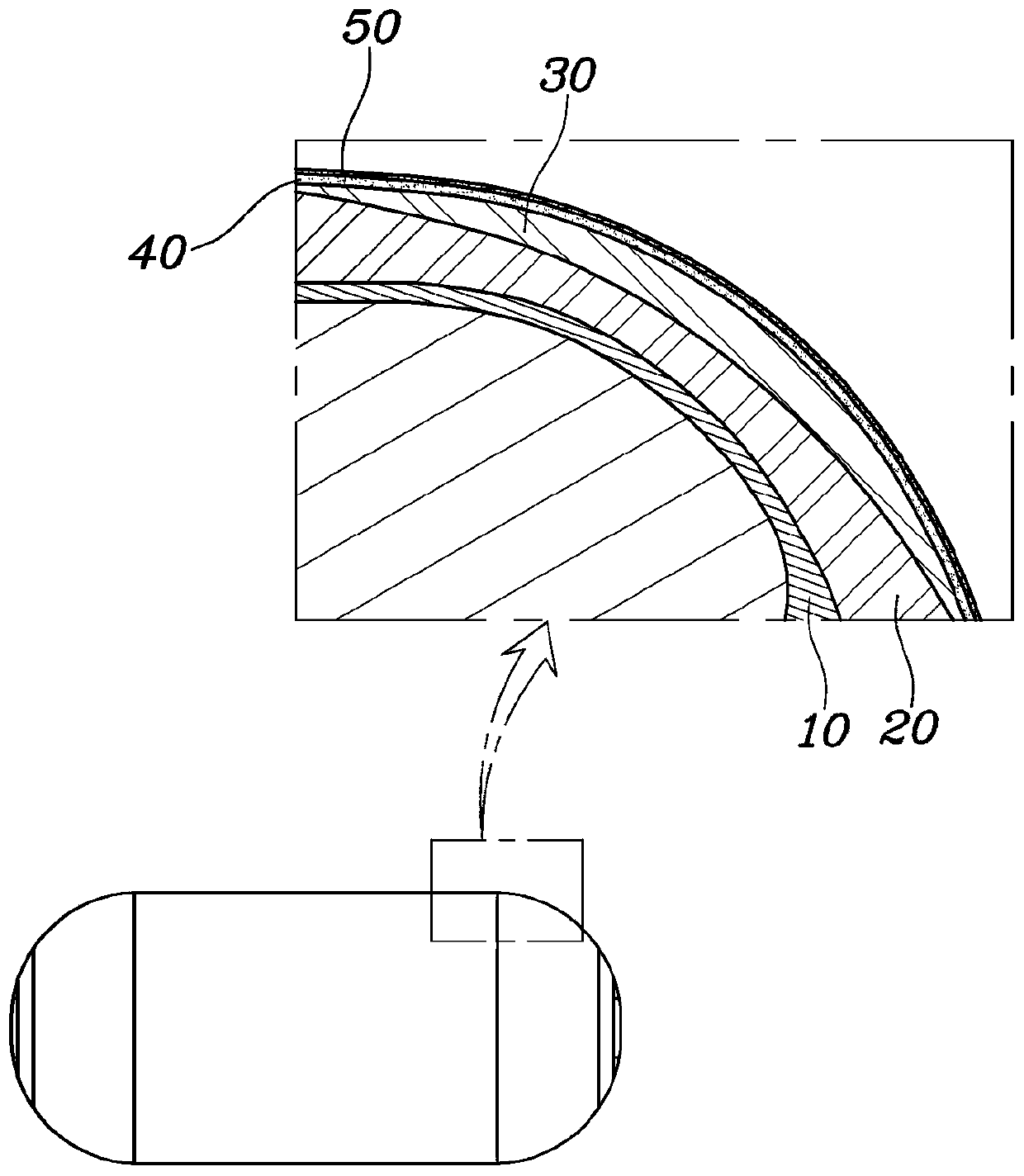

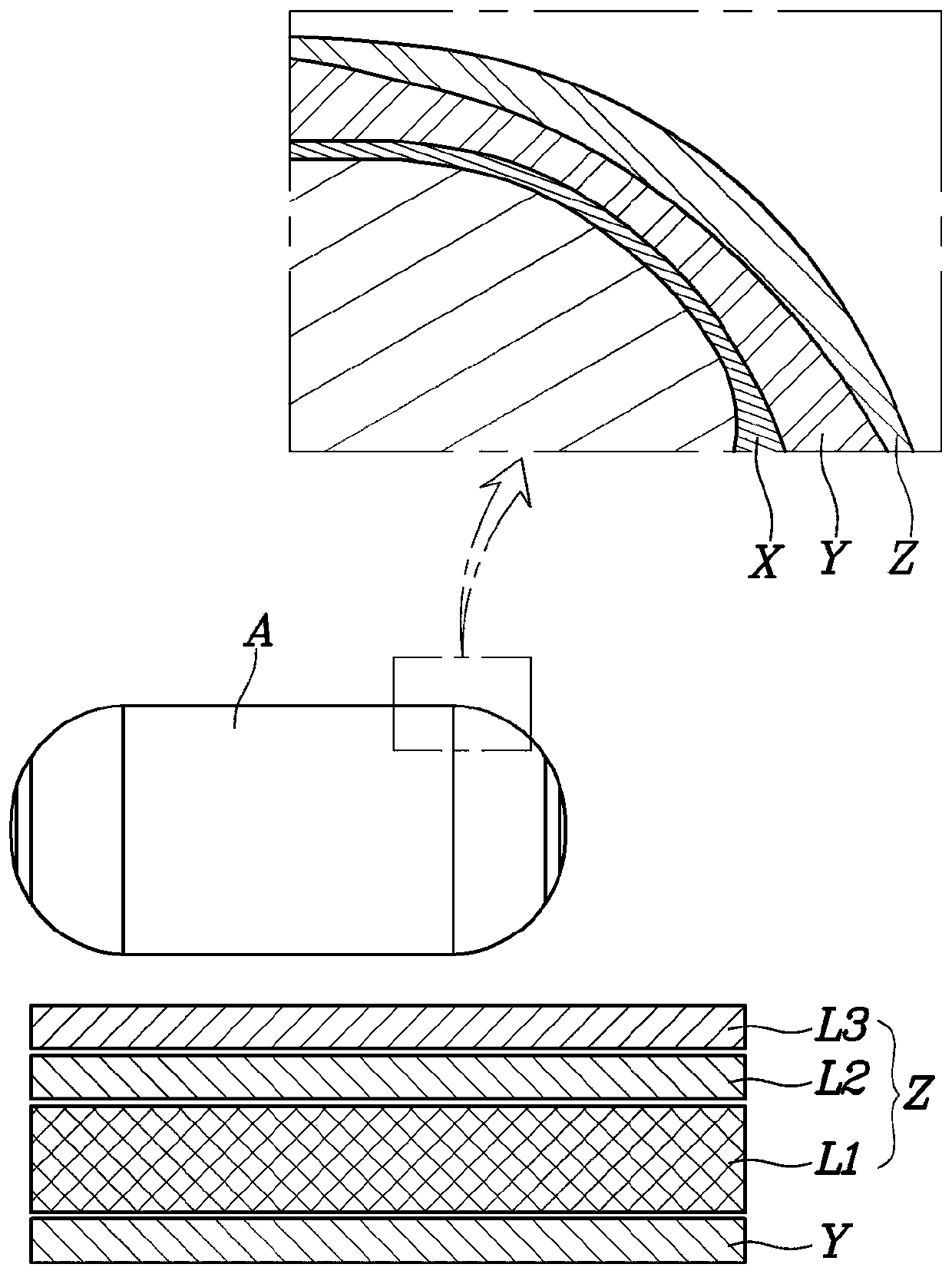

High-pressure vessel and manufacturing method thereof

ActiveCN111094832ASimplify the manufacturing processReduce manufacturing cost and timeVessel manufacturingVessel geometry/arrangement/sizeManufacturing engineeringProtection layer

Proposed are a high-pressure vessel and a manufacturing method thereof, the high-pressure vessel comprising: a liner including a cylinder portion and dome portions disposed at both ends of the cylinder portion, and storing a high-pressure fluid therein, each of the dome portions having a dome shape; a composite material layer surrounding an outer surface of the liner; and a protective layer surrounding an outer surface of the composite material layer and including a shock-absorbing layer, a heat-resistant layer, and a surface protective layer, which are sequentially laminated, wherein the shock-absorbing layer of the protective layer is made of a resin material and formed by an injection method on an inner surface of the heat-resistant layer.

Owner:DONG HEE IND +1

Plastic reference material and manufacturing method thereof

InactiveCN108627594ASimple and high-precision analysis operationLight in massSamplingComponent separationMaximum diameterAmount of substance

Owner:HITACHI HIGH TECH SCI CORP

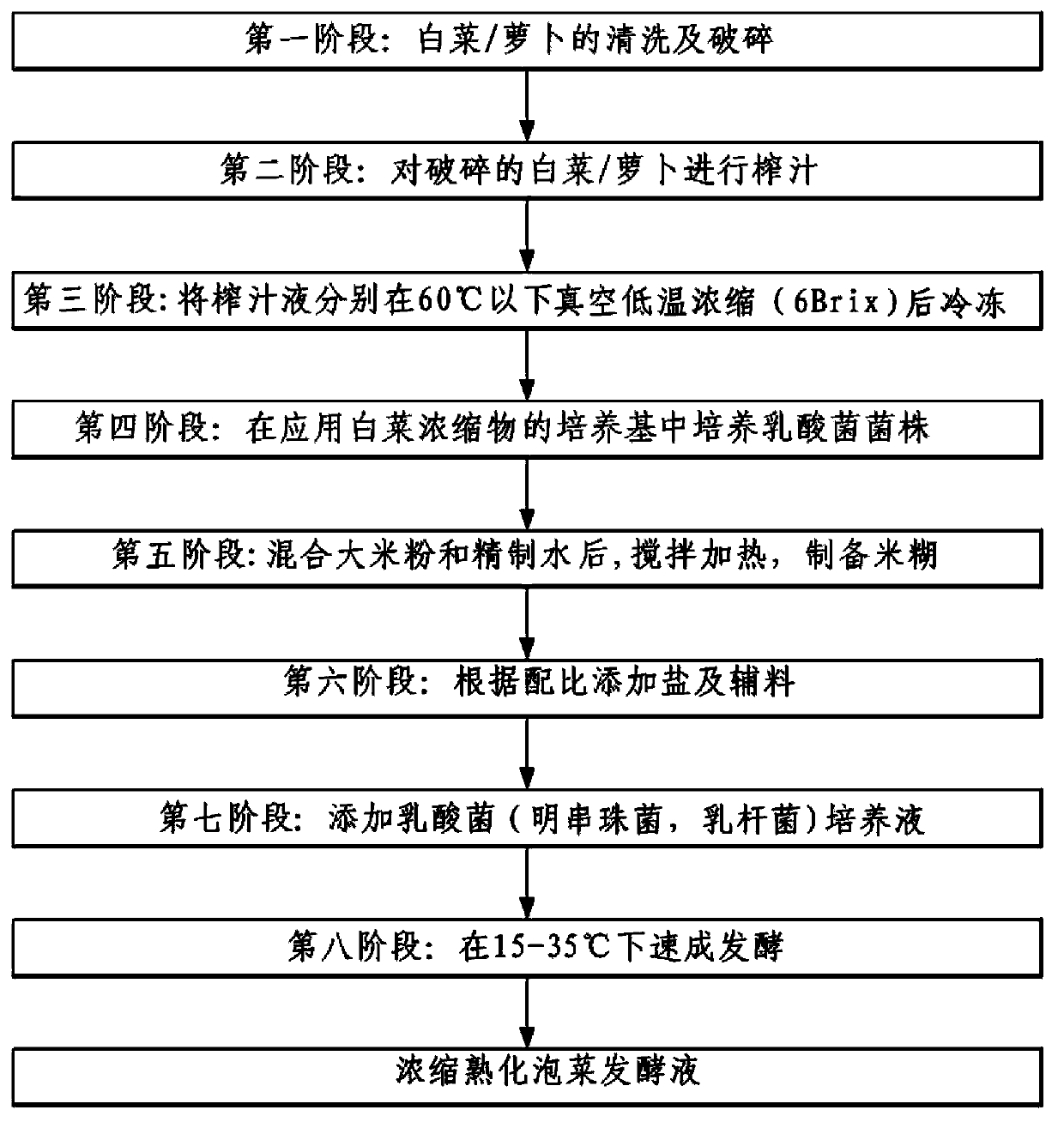

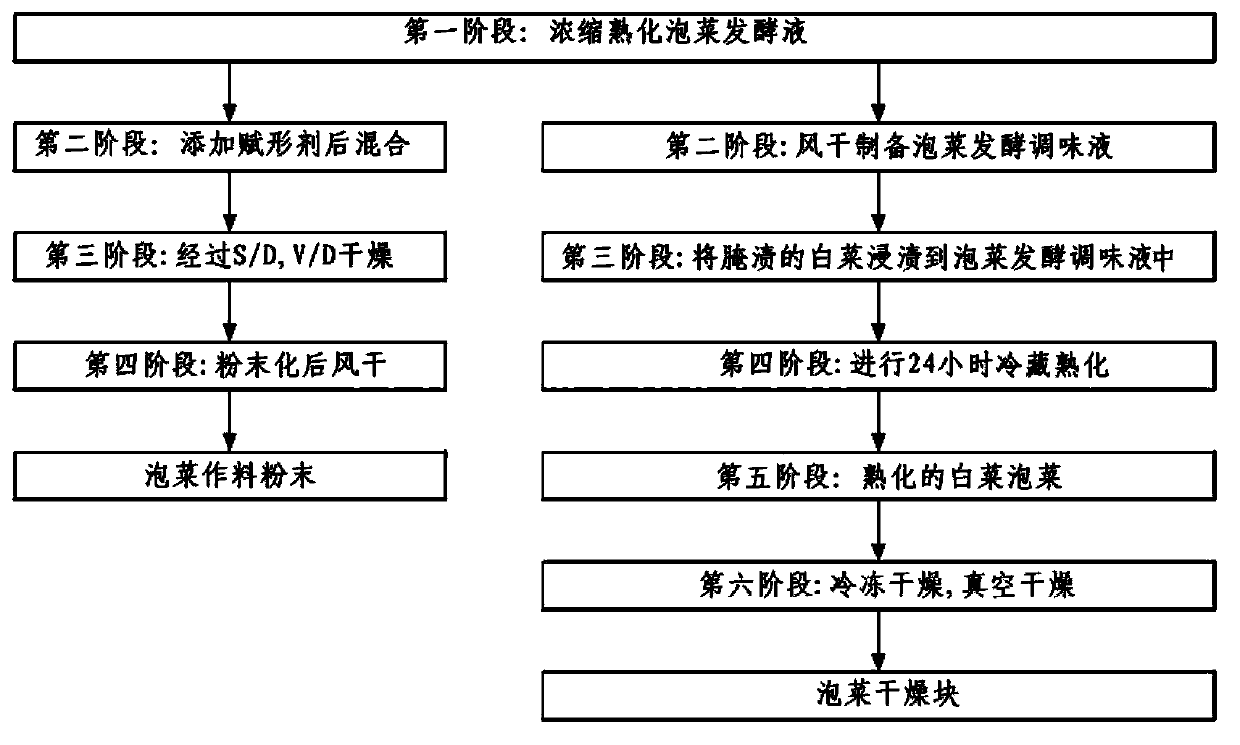

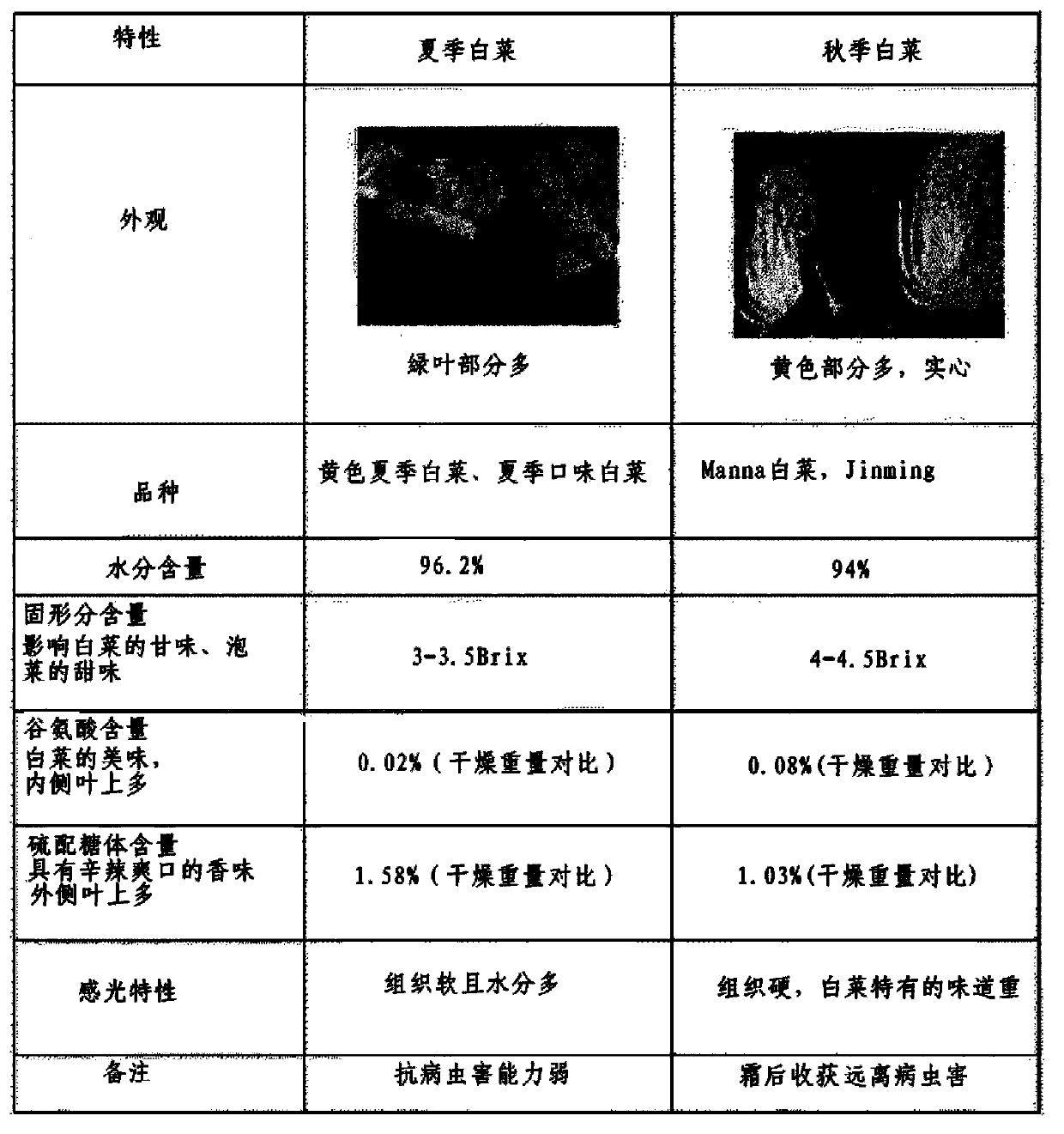

Method to produce concentrated cured kimchi fermentation liquor by using low-temperature evaporated chinese cabbage and radish concentrated liquor

ActiveCN103125898BGreat tasteImprove qualityFruit and vegetables preservationFood preparationBiotechnologyMicrobiology

The invention relates to a method to produce concentrated cured kimchi fermentation liquor by using low-temperature evaporated chinese cabbage and radish concentrated liquor, especially to a method to produce the concentrated cured kimchi fermentation liquor through a speeded-up fermentation method of adding fermentation bacterial strains into the low-temperature concentrated chinese cabbage and radish concentrate at 25 DEG C to 26 DEG C. More specifically, at low temperatures, chinese cabbages and radishes harvested during optimal periods are concentrated to a high concentration level, and the concentrate is fermented at 15 DEG C to 35 DEG C, thereby standardizing raw kimchi materials used throughout the year, shortening the fermentation time, and accordingly producing liquid kimchi with standard quality in a large scale in a industrialized manner. With the adoption of the method, the raw materials with the certain quality can be supplied throughout the year in the form of the concentrate irrespective of the harvest periods of the raw materials, so that the quality of the kimchi can be increased. In addition, through the selective fermentation of the bacterial strains, the kimchi taste deviation brought by producing procedures is minimized, and the fermentation procedure is controlled, thereby producing the concentrated cured kimchi fermentation liquor which is irrespective of seasons and is of a quality maintained at a certain level.

Owner:NONG SHIM

Quantitative Judgment Method and Feedback System of Ela Inhomogeneity

ActiveCN103219229BReduce subjectivityAdjust the status in timeSemiconductor/solid-state device manufacturingProcess equipmentComputer module

Owner:KUNSHAN VISIONOX DISPLAY TECH

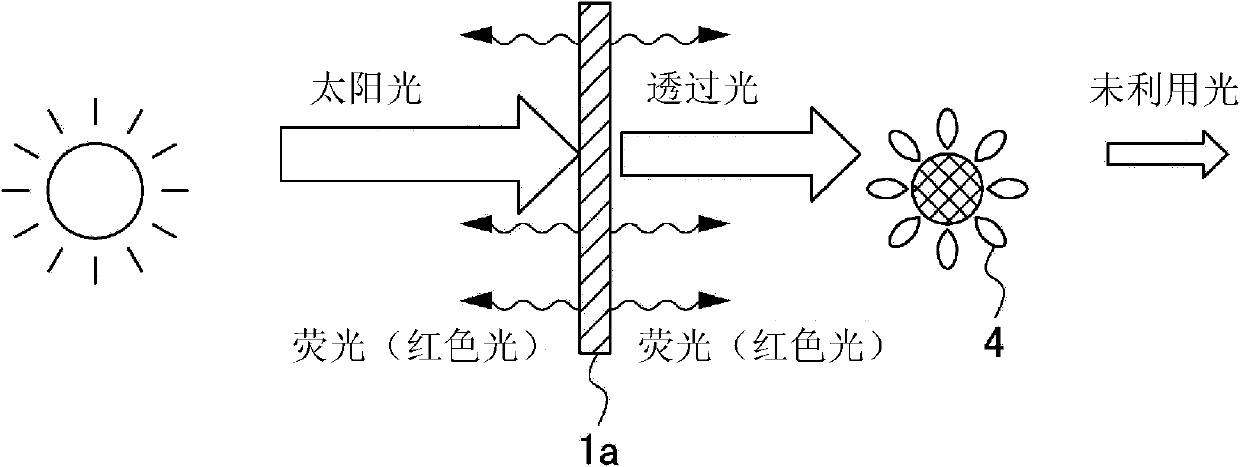

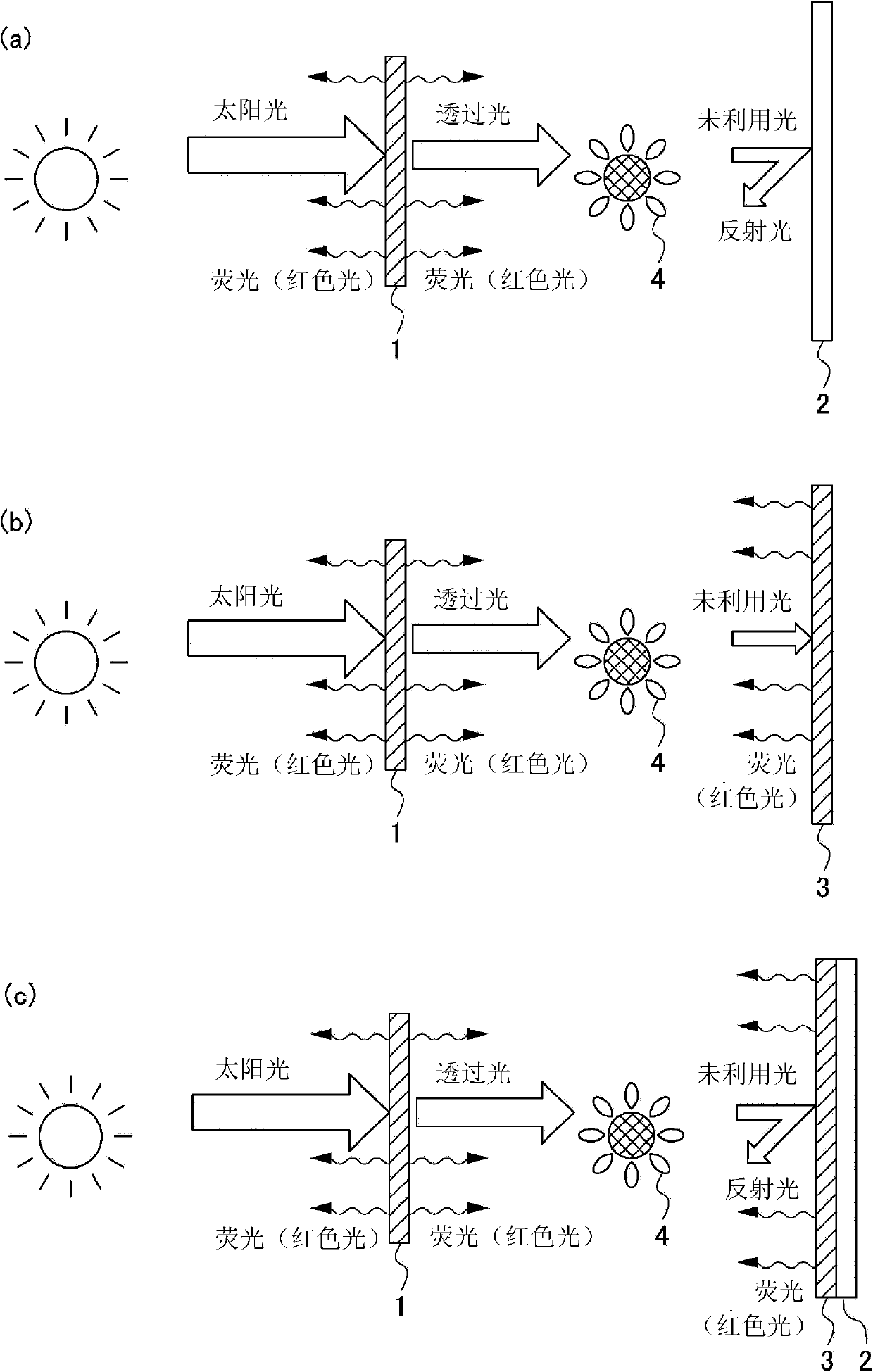

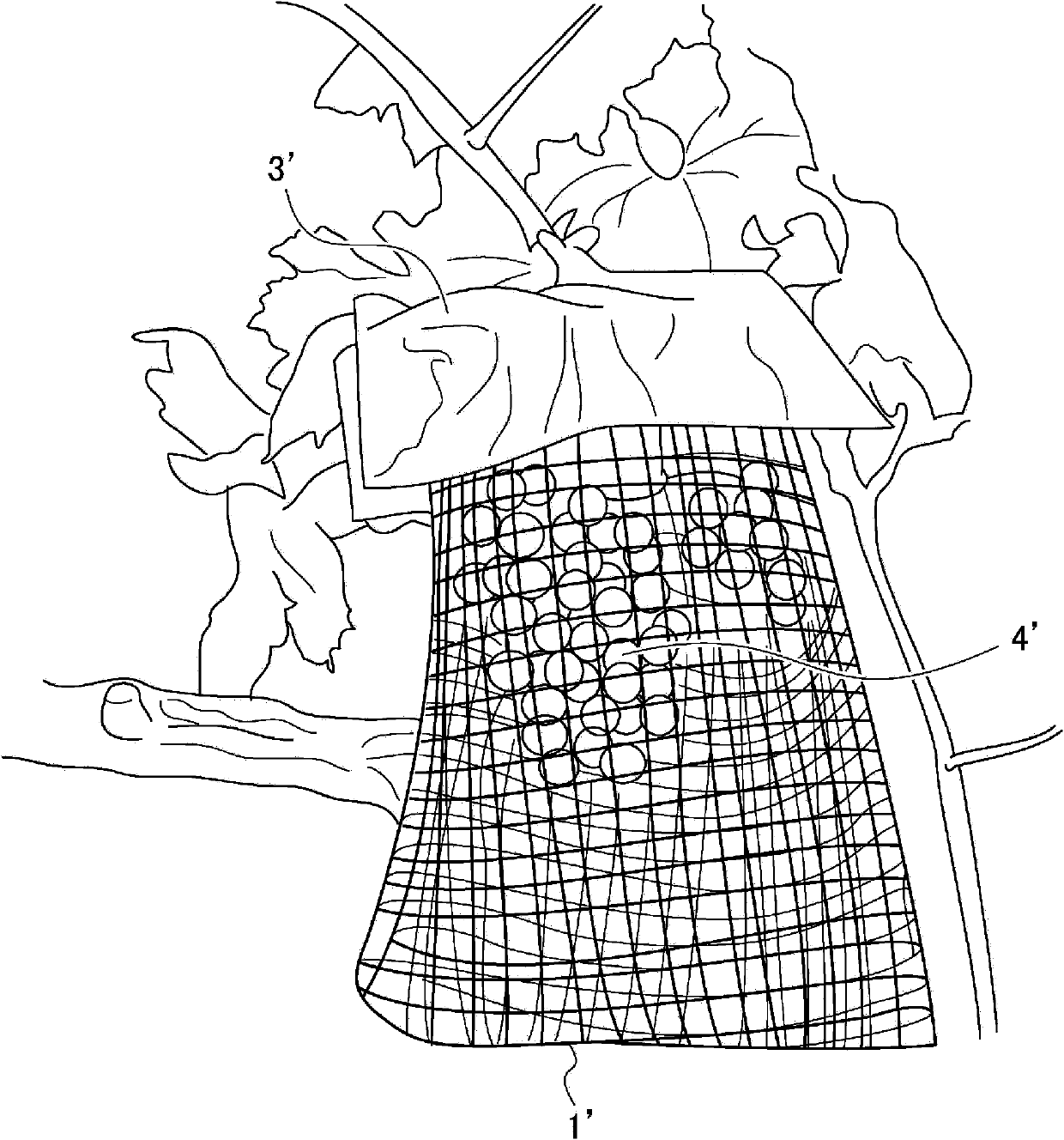

Farm crop cultivation method using fluorescent emitting material and material to be used therein

ActiveCN102149272BWeight increasePromote growthHorticulture methodsPlant protective coveringsAnimal scienceLight irradiation

Owner:TOKYO UNIVERSITY OF SCIENCE +1

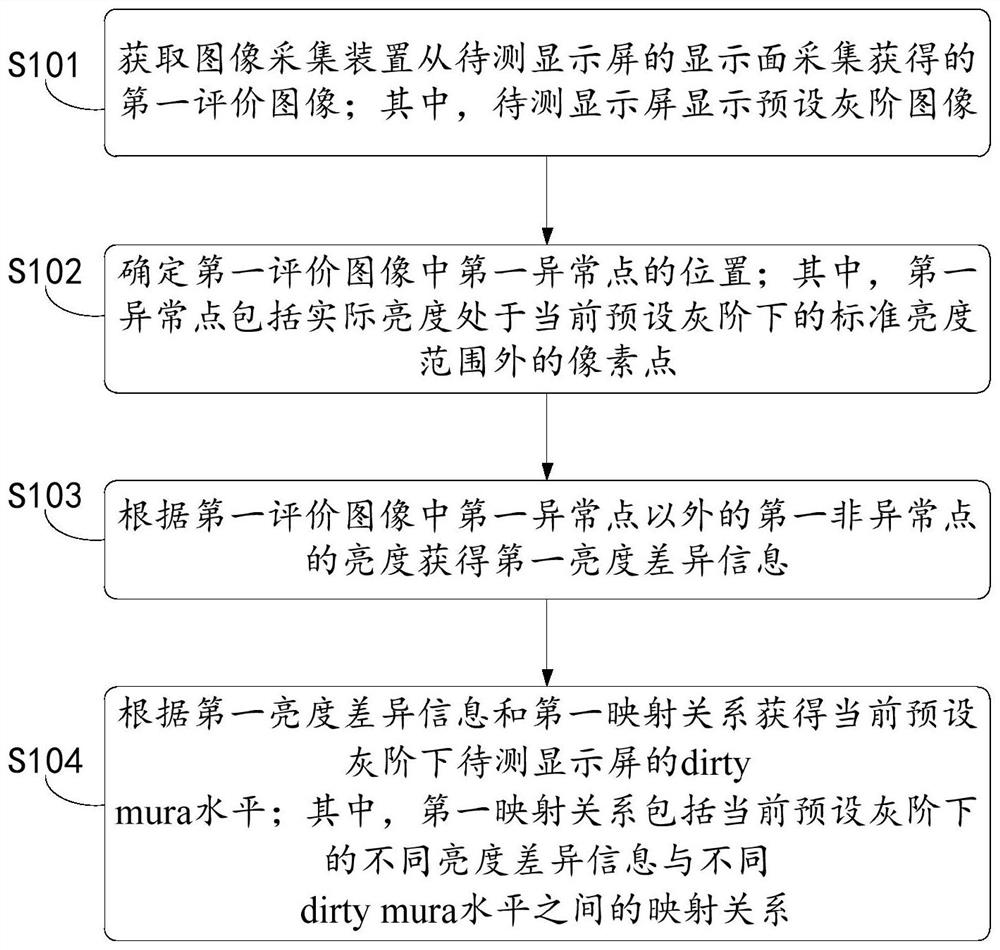

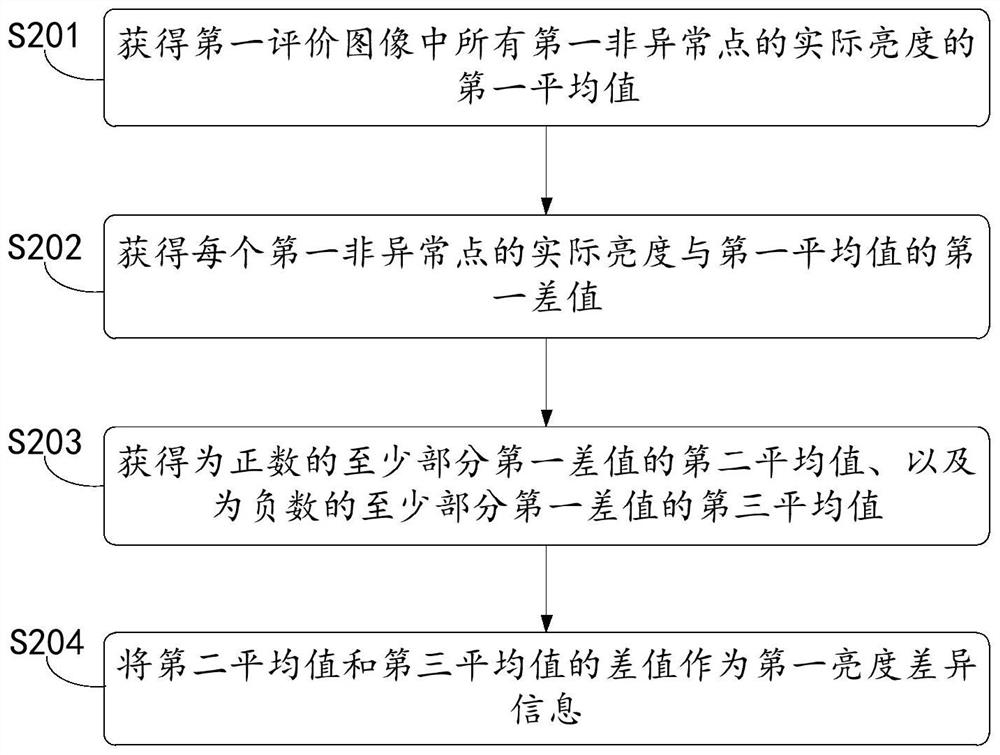

Evaluation method and evaluation system for display effect of display screen and storage device

PendingCN114354133AReduce product quality deviationStrict quality controlTesting optical propertiesComputer graphics (images)Image acquisition

The invention discloses an evaluation method and an evaluation system for a display effect of a display screen and a storage device. The evaluation method comprises the following steps: acquiring a first evaluation image acquired by an image acquisition device from a display surface of a to-be-tested display screen; wherein the display screen to be tested displays a preset gray scale image; determining the position of a first abnormal point in the first evaluation image; obtaining first brightness difference information according to the brightness of a first non-abnormal point except the first abnormal point in the first evaluation image; according to the first brightness difference information and a first mapping relation, obtaining a diverse mura level of the display screen to be tested under the current preset gray scale; wherein the first mapping relation comprises a mapping relation between different brightness difference information and different dirty mura levels under the current preset gray scale. By means of the mode, a mode for quantifying the dirty mura level can be provided, and product quality deviation caused by human subjective factors is reduced.

Owner:HEFEI VISIONOX TECH CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com