Ion exchange resin filling method for space product

A technology of ion exchange resin and ion exchanger, which is applied in the direction of ion exchange water/sewage treatment, etc., can solve the problems such as the inability to determine the filling amount of ion exchange resin, the presence of air between ion exchange resin particles, and the lack of tight filling of ion exchange resin, etc. Achieve the effect of maximizing, reducing porosity and improving service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0052] Preferred embodiments of the present invention will be described in detail below in conjunction with the accompanying drawings, wherein the accompanying drawings constitute a part of the application and together with the embodiments of the present invention are used to explain the principle of the present invention and are not intended to limit the scope of the present invention.

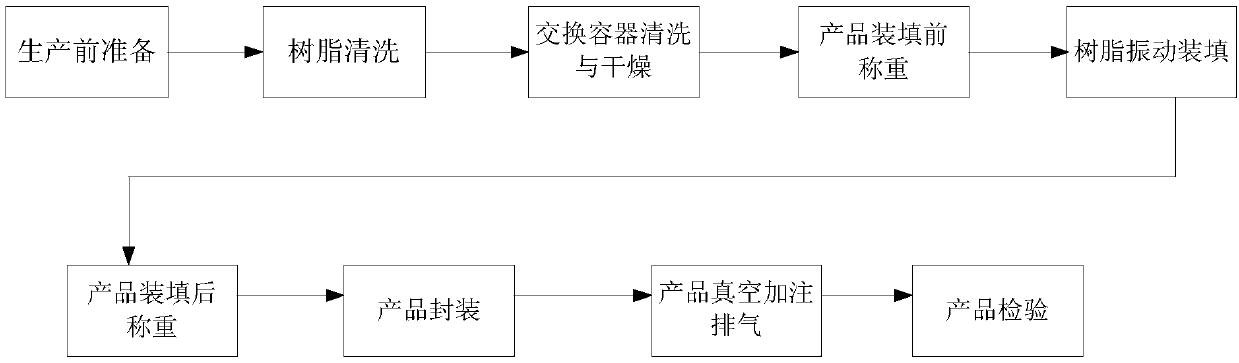

[0053] A specific embodiment of the present invention discloses a method for filling ion exchange resins for space products, such as figure 1 shown, including the following steps:

[0054] Step 1. Pre-production preparation: prepare the ion exchangers required for filling, ion exchange resin filling molds, vibration tooling, vacuum pumps and other equipment, as well as ultrapure water, ion exchange resins and other materials required in the filling process;

[0055] Step 2. Ion exchange resin cleaning: For the ion exchange resin that needs to be filled, soak and clean it with ultrapure water ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com