A hobbing dry cutting processing method based on analysis and optimization of small sample multivariate process parameters

A technology of process parameters and processing methods, applied in electrical digital data processing, special data processing applications, instruments, etc., can solve the problems of difficult to use differential evolution algorithm, less research on process parameter optimization, and lack of optimized process parameter library, etc. Achieve the effect of eliminating attribute redundancy, solving poor optimization effects, and improving processing quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

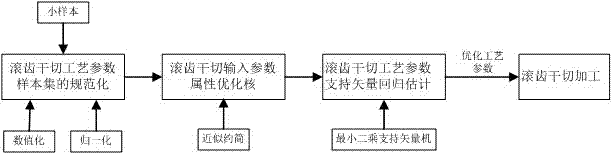

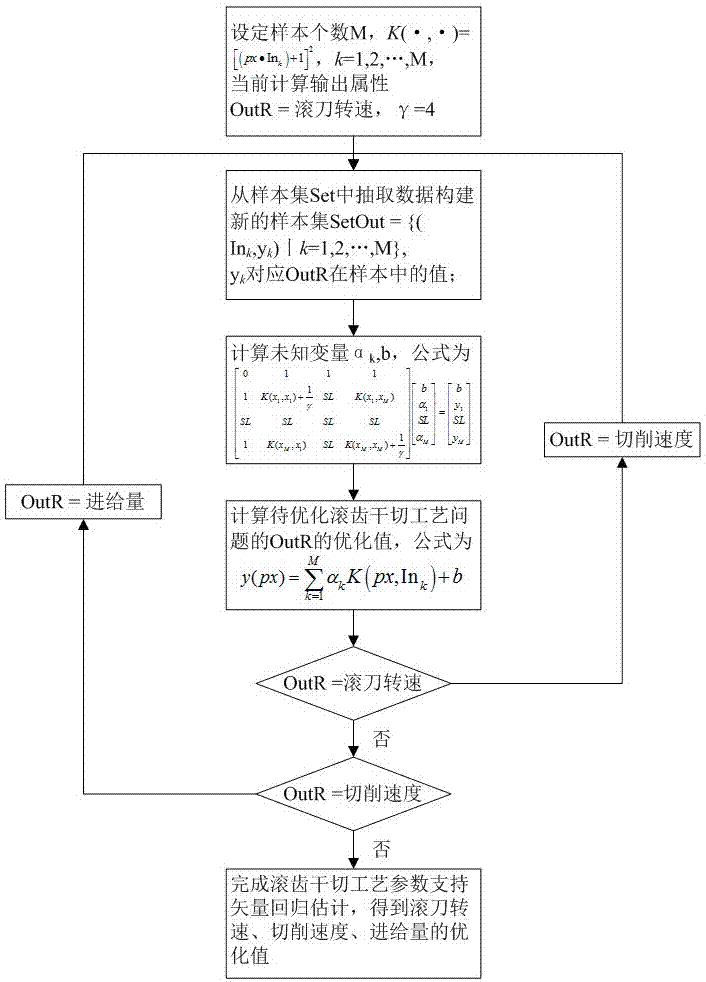

[0034] The idea of the present invention is to standardize the sample set of hobbing dry cutting process parameters, realize digitization and normalization, and with the support of attribute approximation reduction, redundantly eliminate the input parameter attributes to obtain hobbing dry cutting input parameter attributes Optimizing the core, using least squares support vector machine regression algorithm to achieve the optimization of process parameters; using the optimized process parameters for dry cutting.

[0035] The present invention will be further explained below in conjunction with the drawings and implementation cases.

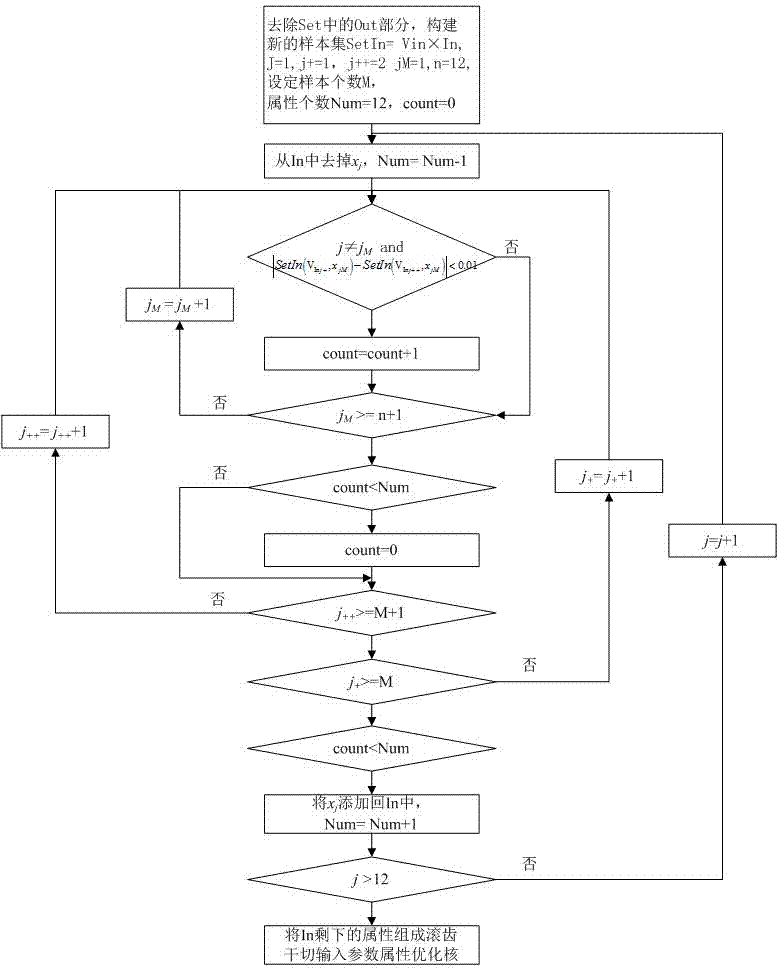

[0036] The specific steps of the present invention are as follows, refer to Figure 1-3 understanding:

[0037] (1) Realize the standardization of the sample set of hobbing dry cutting process parameters; input parameter attributes include workpiece modulus, pressure angle, number of teeth, helix angle, tooth width, material, Brinell hardness, accurac...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com