Plasma treatment device and substrate surface treatment device

A technology for processing devices and plasmas, applied to plasmas, lighting devices, electrical components, etc., to achieve the effect of small quality deviation and high reliability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

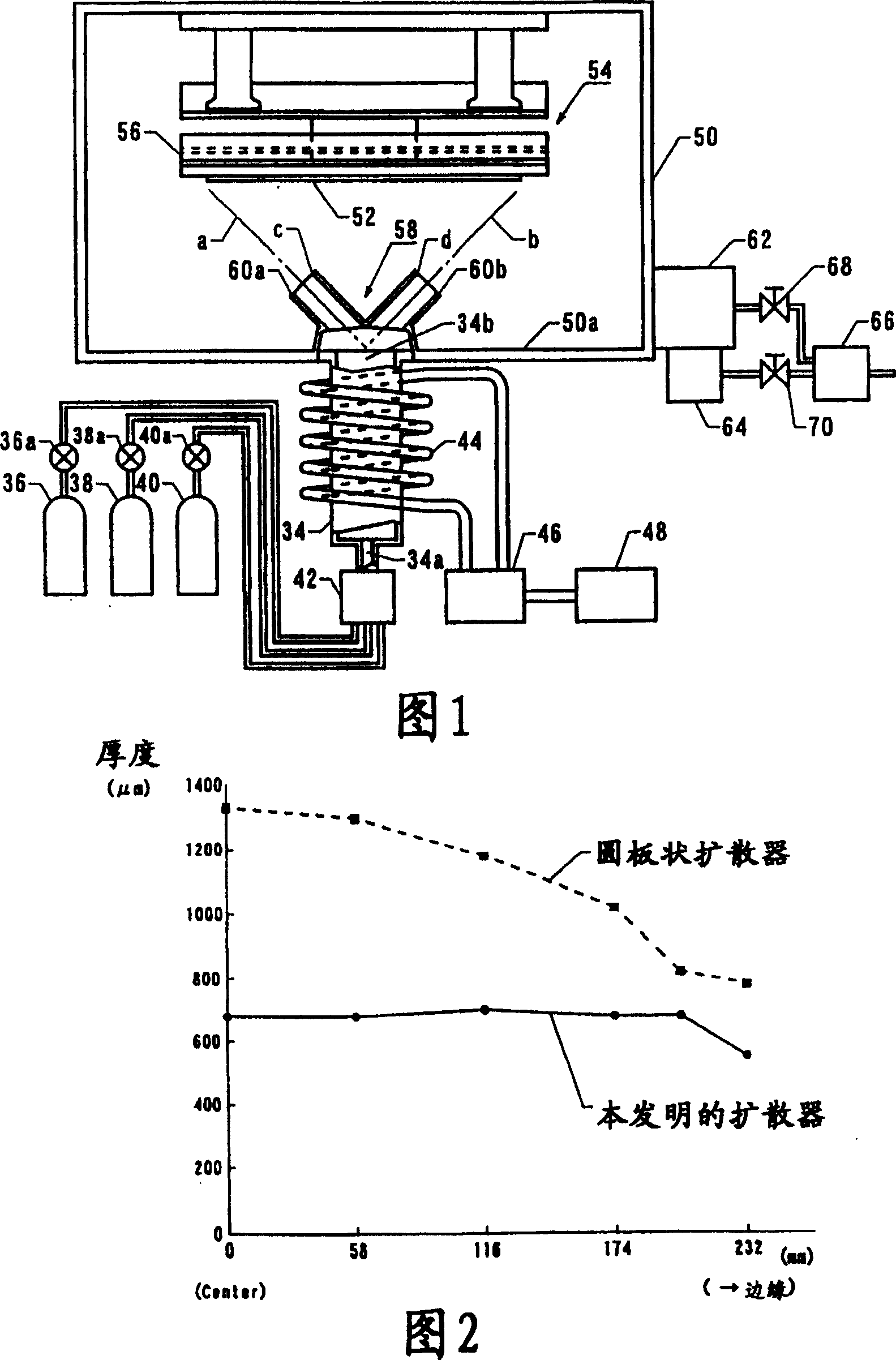

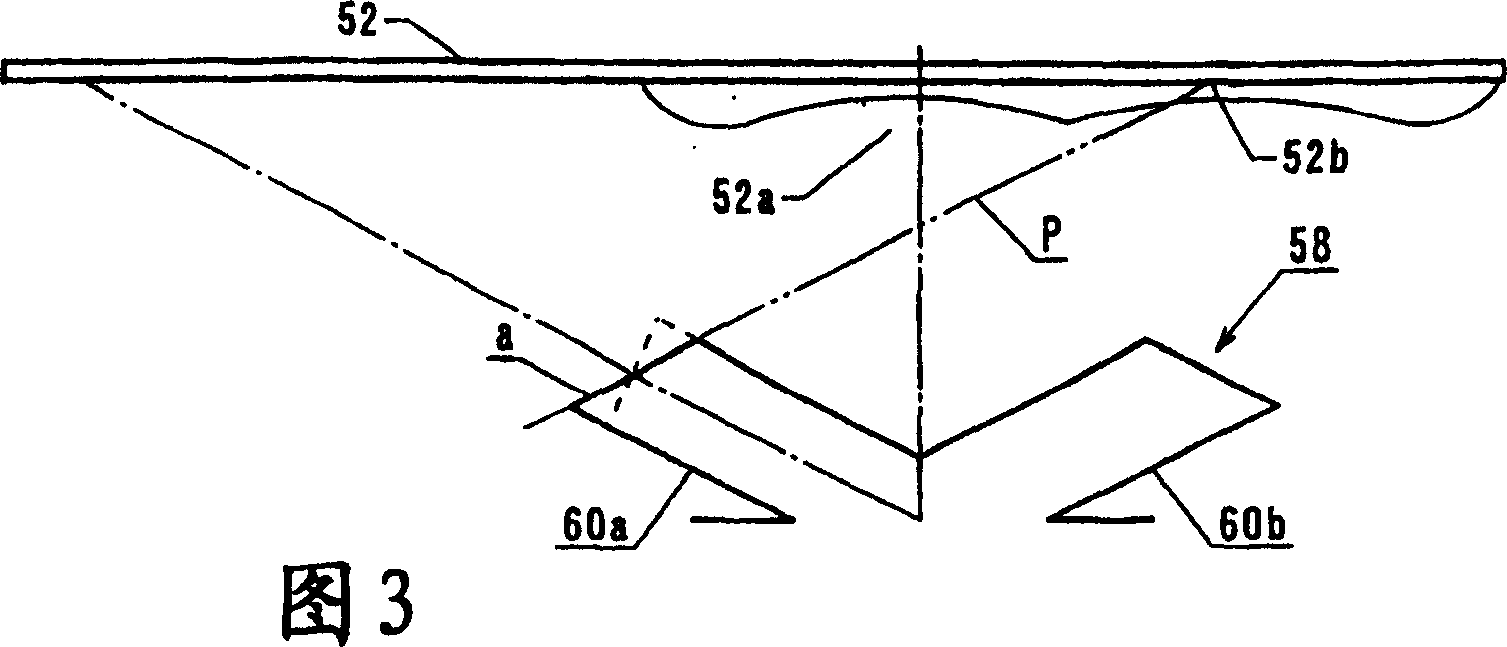

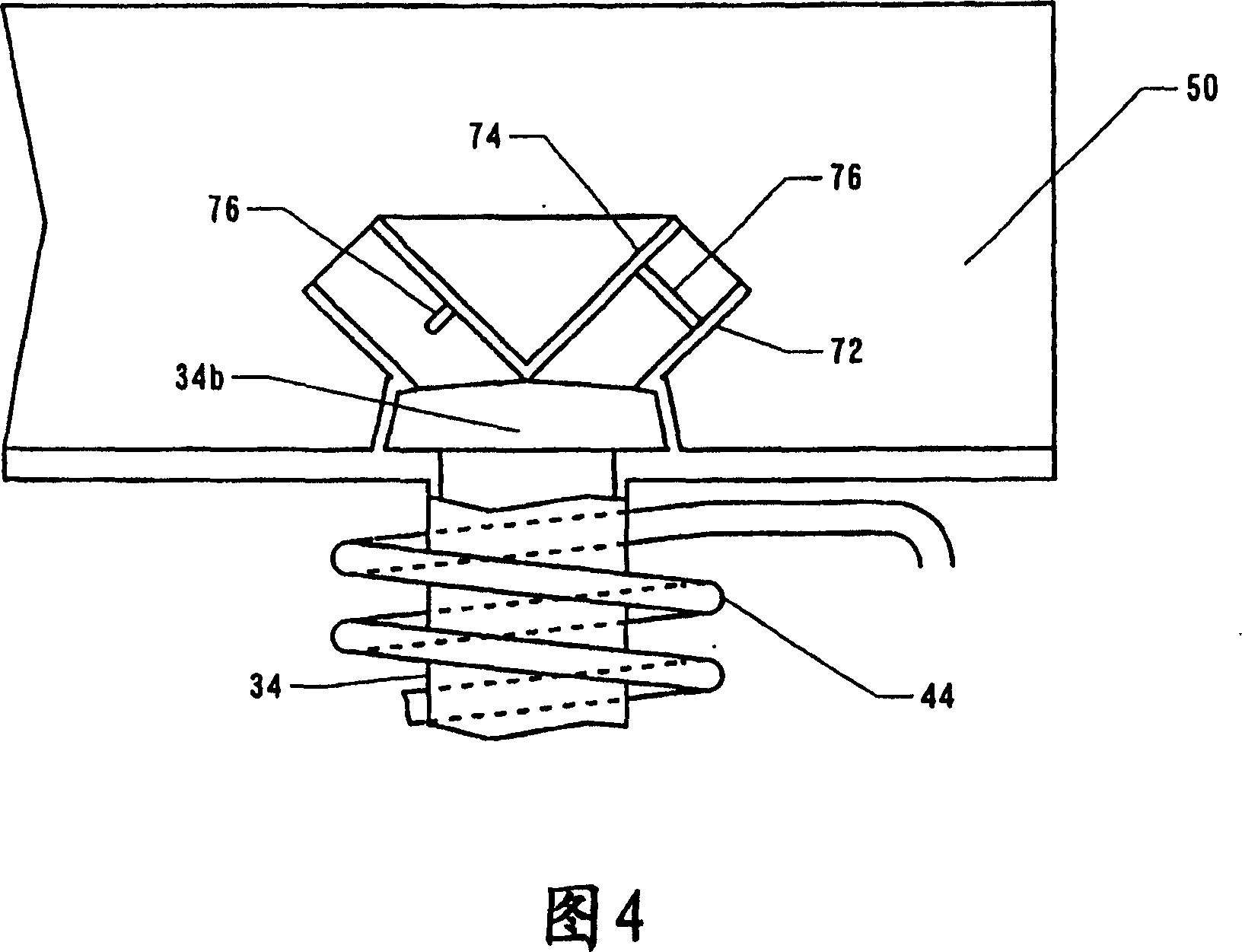

[0035] An embodiment of the present invention will be described below with reference to FIG. 1 . In the figure, 34 is the plasma generation chamber that excites and supplies gas to generate plasma, and a plurality of gas pumps 36, 38 opened and closed by valves 36a, 38a, 40a are connected through a flow regulator 42 in the gas supply port 34a at the lower end of the chamber. , 40. 44 is an induction coil wound on the outer periphery of the plasma generation chamber 34, and is connected to a high frequency oscillator 48 through a distribution circuit 46 to provide high frequency current to stimulate the gas supplied to the plasma generation chamber 34 into a plasma state. 50 is a decompression chamber, and its peripheral surface is provided with an inlet and outlet omitted in the figure. The bottom 50a of this chamber communicates with the plasma generation chamber 34, and plasma gas is supplied from the plasma supply port (plasma introduction part) 34b. 52 is a substrate (plas...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com