Plastic reference material and manufacturing method thereof

A standard material and plastic technology, applied in the field of standard material, can solve problems such as stamping and complicated operation, and achieve the effect of small deviation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

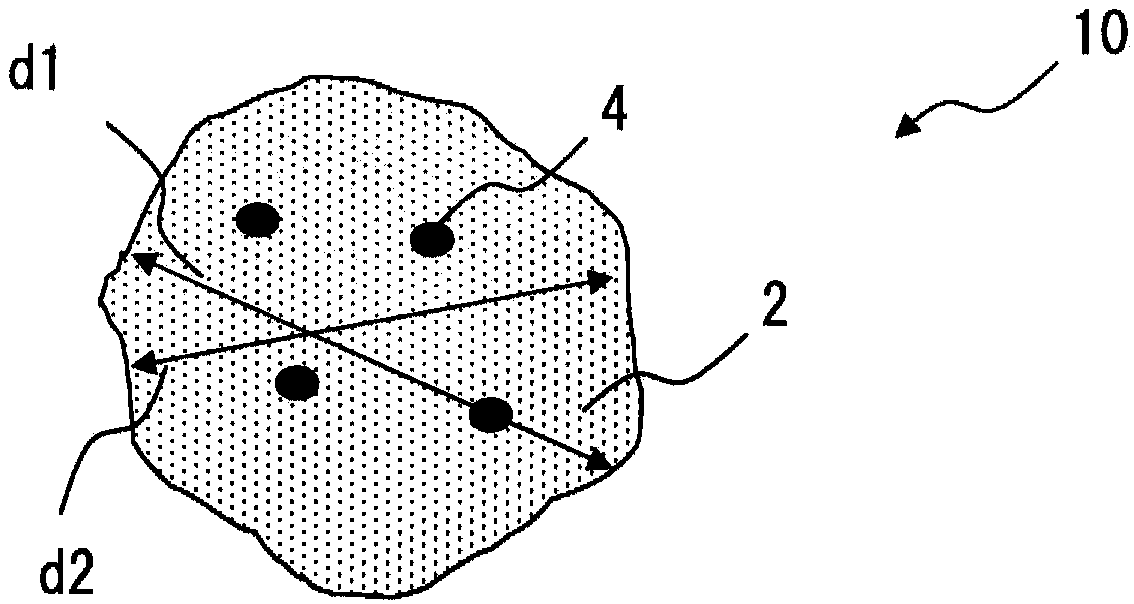

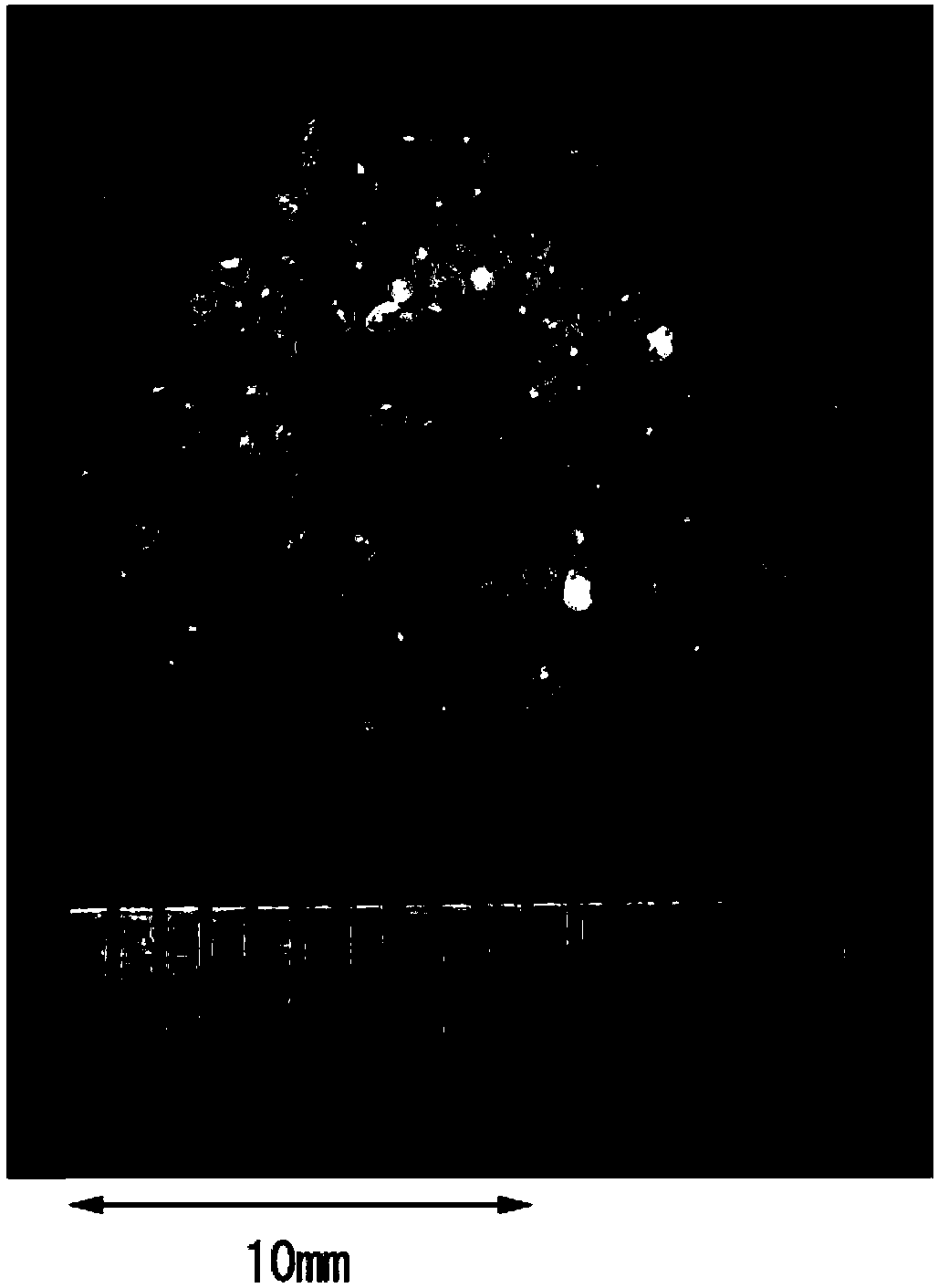

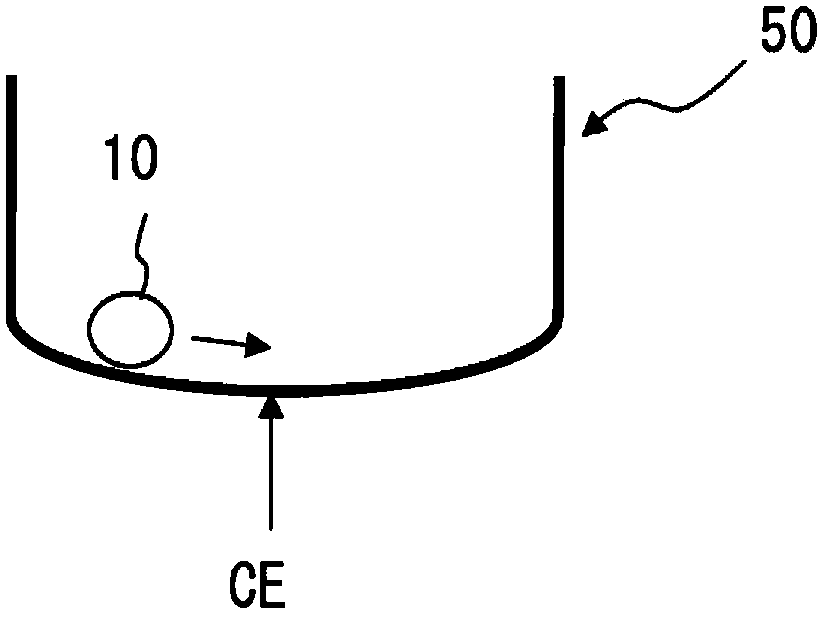

Image

Examples

Embodiment 1

[0072] (complex formation)

[0073] A composite was formed using acrylonitrile-butadiene-styrene copolymer resin (ABS resin) as a plastic substrate and using diisobutyl phthalate (DIBP) as a chemical substance. First, put about 1.5 kg of ABS resin pellets into a plastic bag, add about 1.6 g of DIBP and mix them, then knead the compound in an extrusion kneader, and then use the extrusion kneader to knead the compound. The composite was extruded into a water tank, cooled, and cut into pieces of predetermined size (about 3 mm in diameter and about 3 mm in length) by cutting.

[0074] The process of introducing the obtained chips into the extrusion kneader again and kneading them to form the same chips was repeated three times. In addition, since the initial compound extruded from the extrusion kneader may not be sufficiently mixed, it is discarded. The final fragment-like composite obtained was about 1 kg.

[0075] (granulation)

[0076] Import the resulting fragmented comple...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com