Glass-made performing piece set, manufacture method for the same, and production method for optical element

A technology for preforms and manufacturing methods, which is applied in glass manufacturing equipment, glass molding, glass pressing, etc., and can solve the problems of preform volume deviation and preform volume management that may not be sufficient

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 example

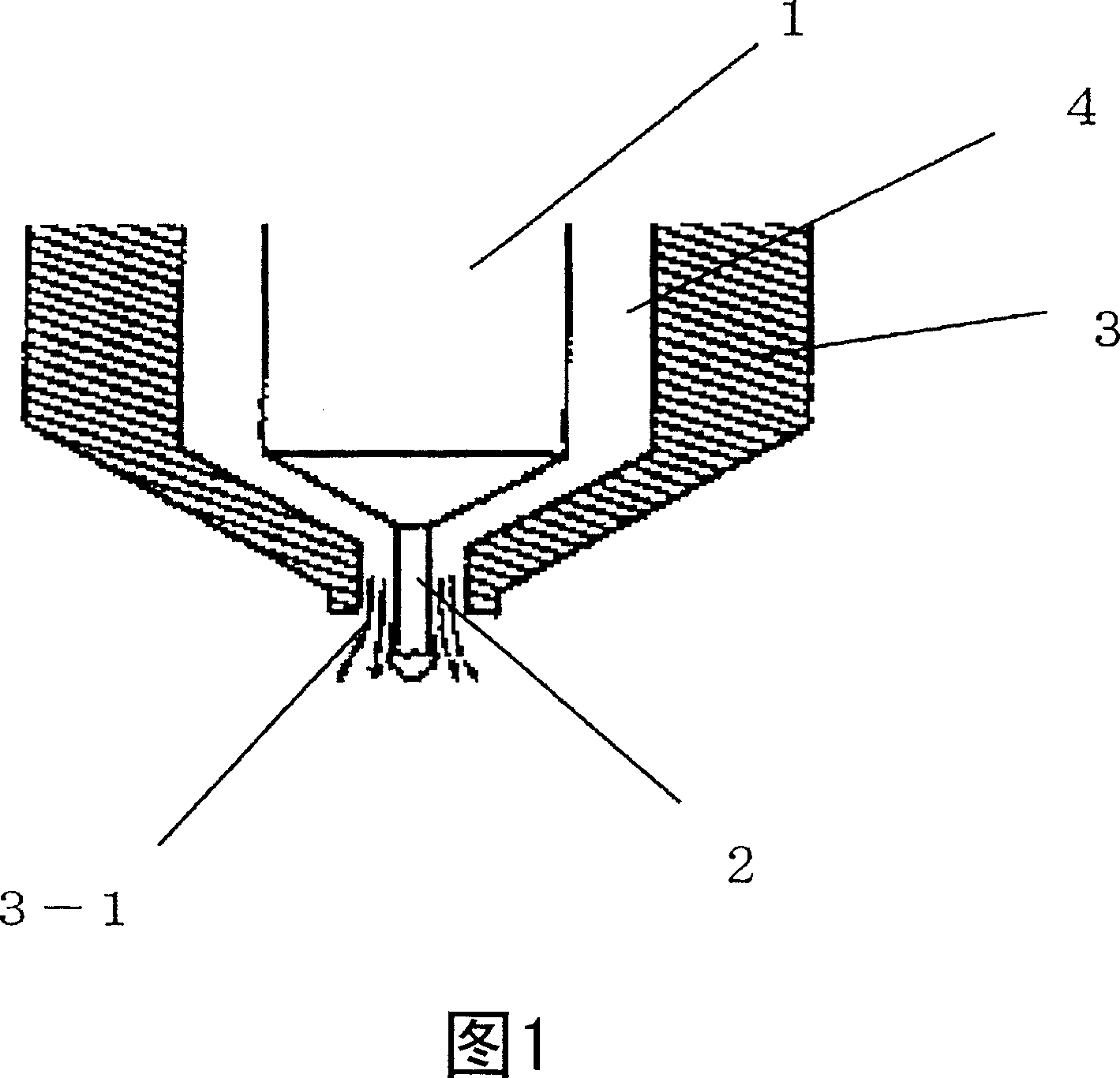

[0099] First, to obtain the SiO shown in Table 1. 2 Optical glasses A and B with an amount of 20% by mass or less are weighed and mixed with glass raw materials, fully stirred, and introduced into the melting vessel, heated, melted, clarified, and stirred to obtain uniform molten glass. The apparatus shown in FIG. 1 was used to produce glass preforms from molten glass droplets of molten glass.

[0100] The pipe 1 connected to the bottom of the melting vessel is opened, and the molten glass flows out from the nozzle 2 installed at the lower end of the pipe at a constant flow rate. The temperature of the nozzle, the tube, and the melting vessel are controlled so that the glass does not lose transparency and has a viscosity that can obtain the desired flow rate.

[0101] A cover 3 for forming a gas flow path is provided on the lower end of the tube 1 and the outer periphery of the nozzle 2 as shown in FIG. 1, and a gas flow path for flowing gas is provided in the space between the co...

no. 2 example

[0112] The spherical preform base material was mass produced using the same method as in the first embodiment. The glass used, the number of base materials obtained, the average quality, the ratio of the quality tolerance to the average quality, the quality tolerance, and the diameter are shown in Table 1. After tempering the group consisting of the base materials of these preforms to reduce the distortion, grinding is performed to obtain a group of preforms having the same value as the ratio of the mass tolerance to the average mass of the base material of the preforms.

no. 3 example

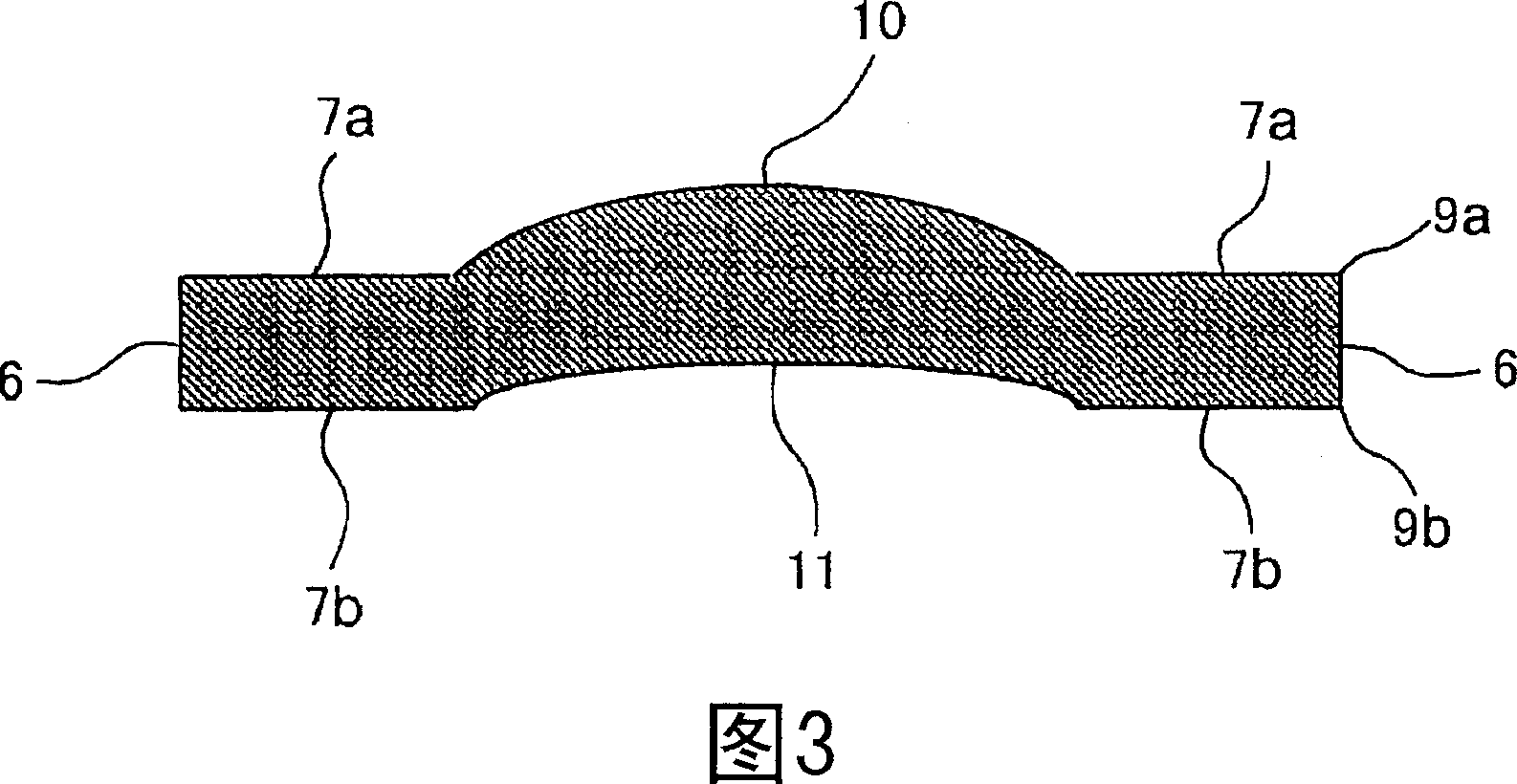

[0114] Using each of the preform groups obtained in the first and second examples, a small aspheric lens having the schematic cross-sectional shape shown in FIG. 3 was obtained by precision extrusion molding. No lens breakage can be seen, and it has sufficient optical performance as a lens. In addition, the edge 6 and the flange-like flat portion 7 of each lens replicate the molding surface of the extrusion mold, and the edge where the edge and the flange-like flat portion intersect is a rounded free surface. Therefore, it can be confirmed that no forming burr occurs.

[0115] These aspheric lenses function as a lens constituting an imaging optical system of an imaging device built in a mobile phone. By assembling the lens obtained in this way and a lens having an edge and a flange-like flat portion as a positioning reference surface that is made by exactly the same method except for the shape, into the lens holder, the positioning reference surface is in a state where the holder ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| mass | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com