Quantitative Judgment Method and Feedback System of Ela Inhomogeneity

A technology of uniformity and average value, which is applied in the field of quantitative judgment method and feedback system of laser crystallization process (ELA) inhomogeneity, which can solve problems such as inability to achieve real-time detection, inability to rework, and yield loss. Achieve the effect of eliminating subjectivity, reducing product quality deviation, and improving yield

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031] The quantitative judgment method and feedback system of the present invention will be further described in detail below in conjunction with the accompanying drawings and the embodiments of the present invention.

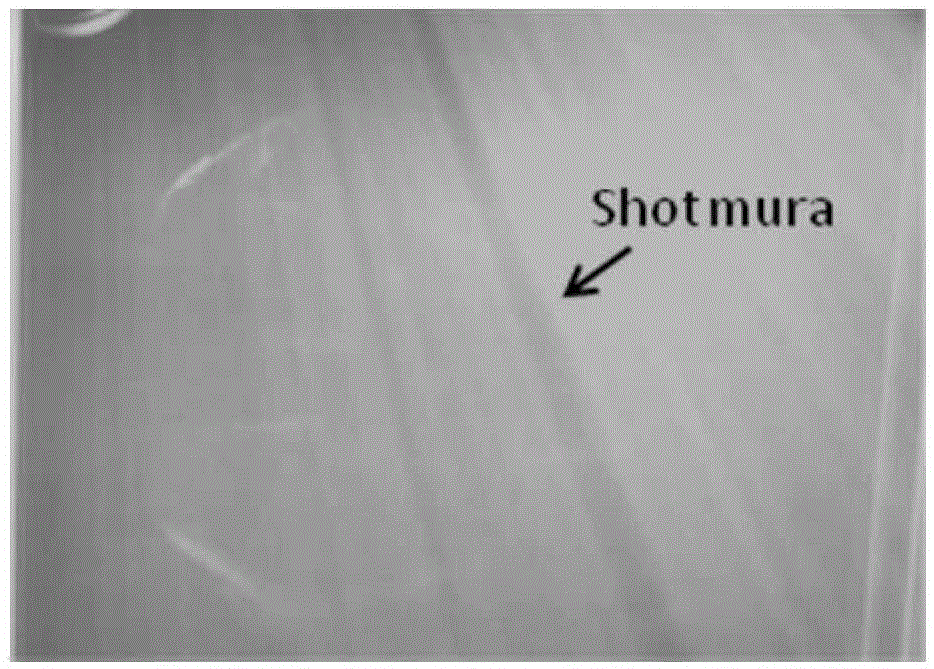

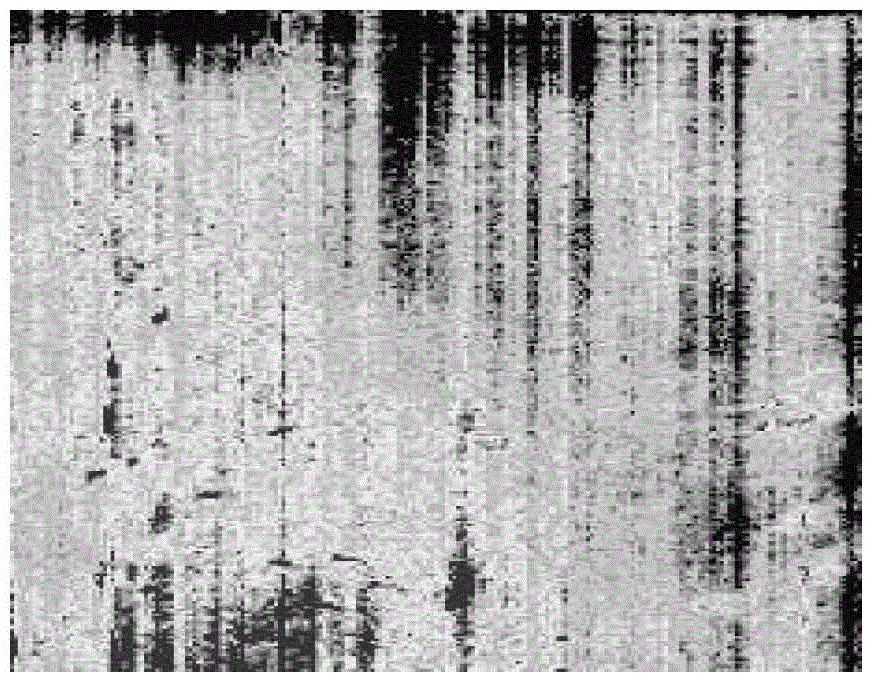

[0032] The method for quantifying and judging the inhomogeneity of the laser crystallization process (ELA) and its feedback system of the present invention can quantify and judge the inhomogeneity of polysilicon, and feed back the detection and judgment results to the process equipment through the feedback system for timely adjustment .

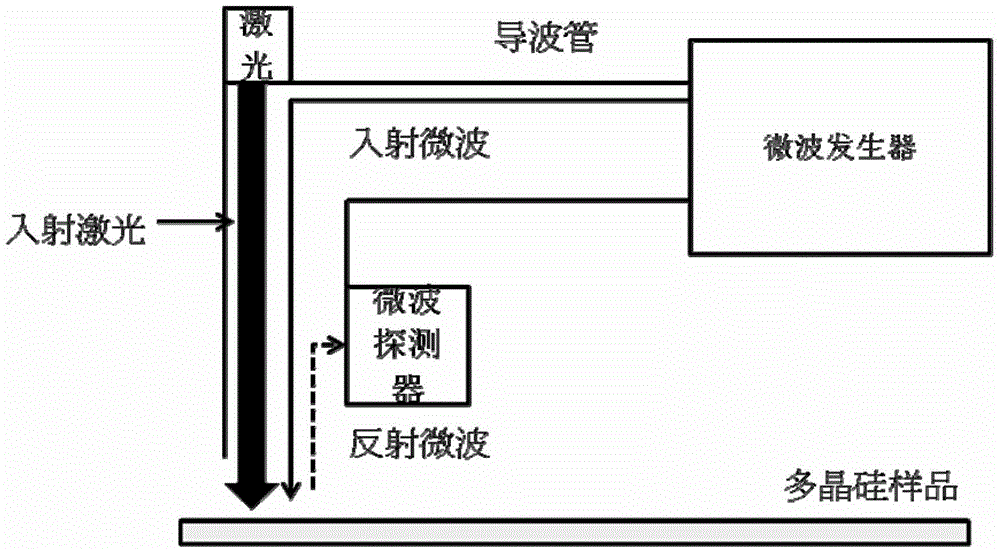

[0033] Figure 7 It is a schematic diagram of the composition of the quantitative feedback system of the present invention. like Figure 7 As shown, the quantitative feedback system includes laser crystallization equipment, and also includes a detection device, a calculation rating module and a feedback adjustment module. in:

[0034] The detection device is used to detect polysilicon minority carrier lifetime;

[0035] ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com