Patents

Literature

198 results about "Excimer laser annealing" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Method of fabricating poly-crystalline silicon thin film and method of fabricating transistor using the same

InactiveUS7563659B2Refined grain sizeHigh energyTransistorSemiconductor/solid-state device manufacturingInductively coupled plasmaSilicon thin film

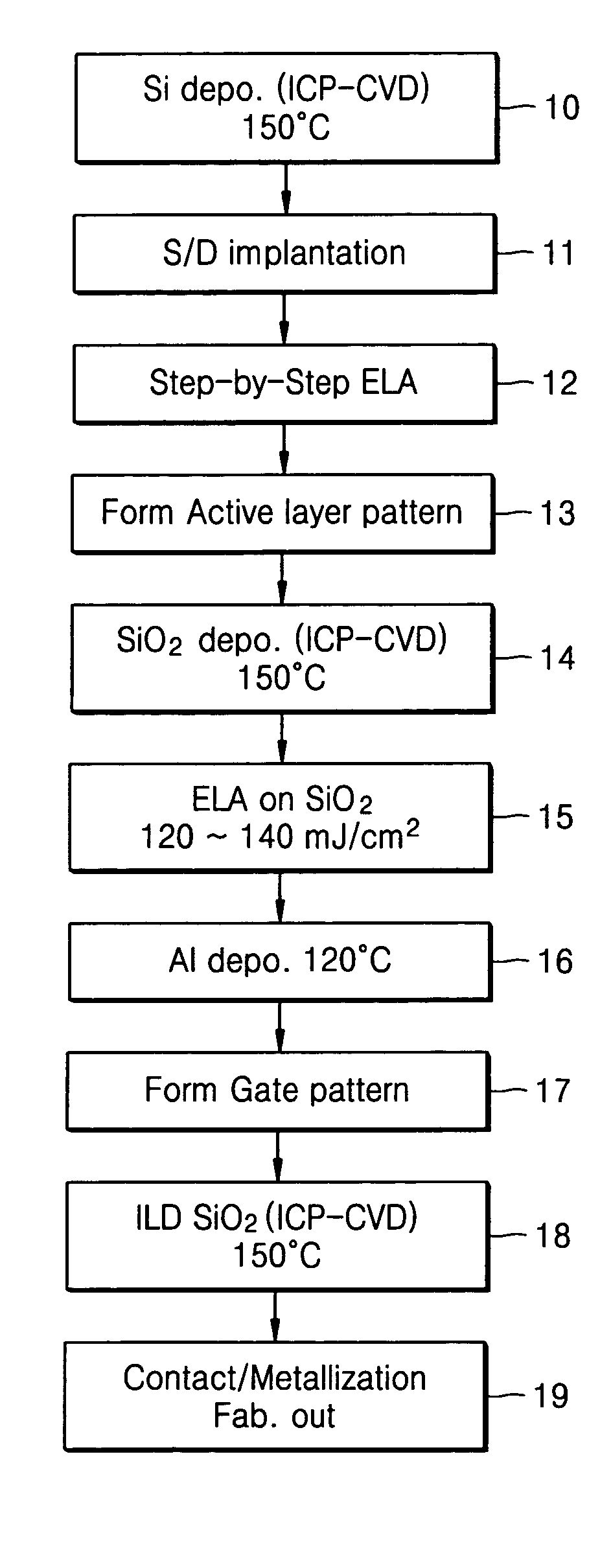

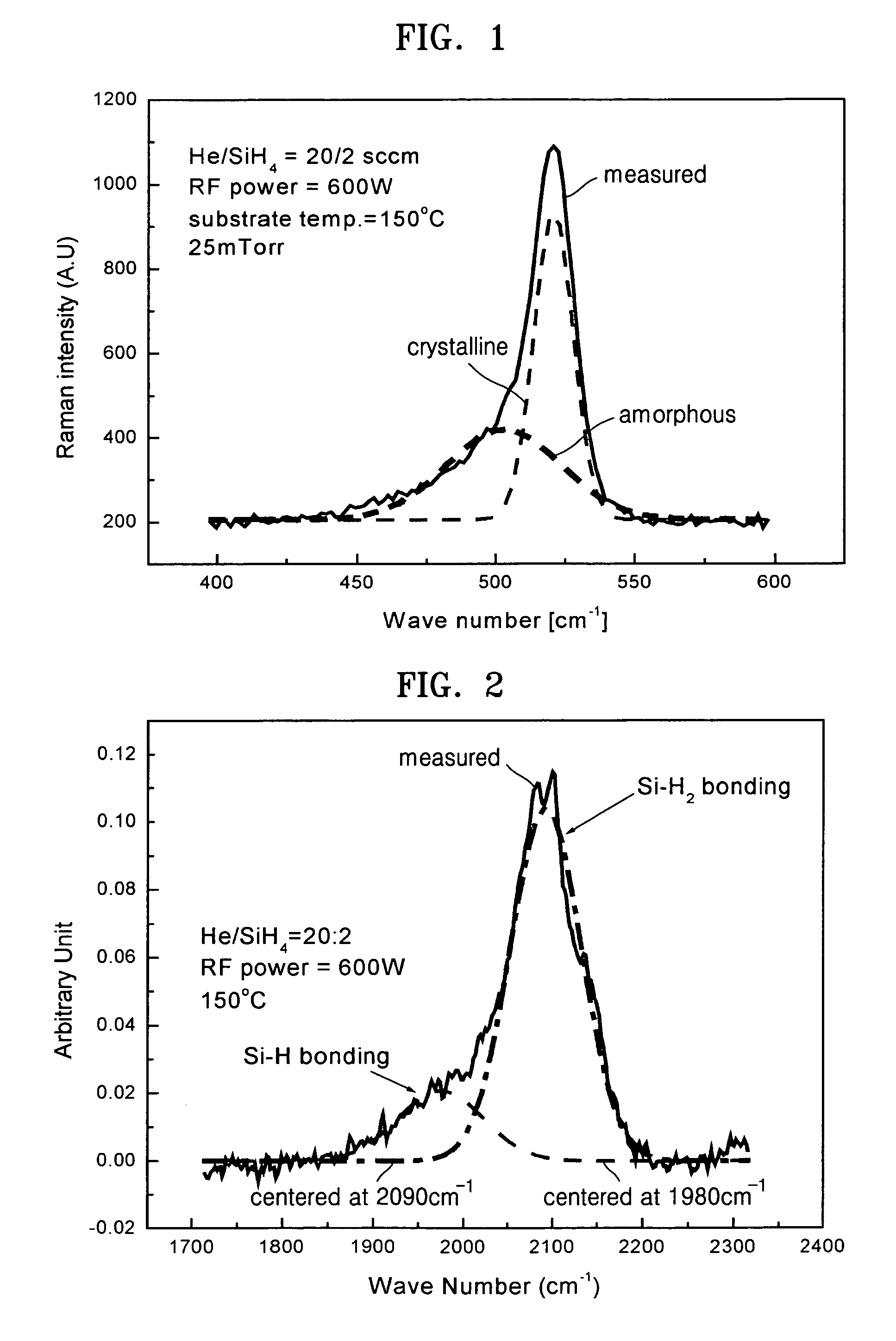

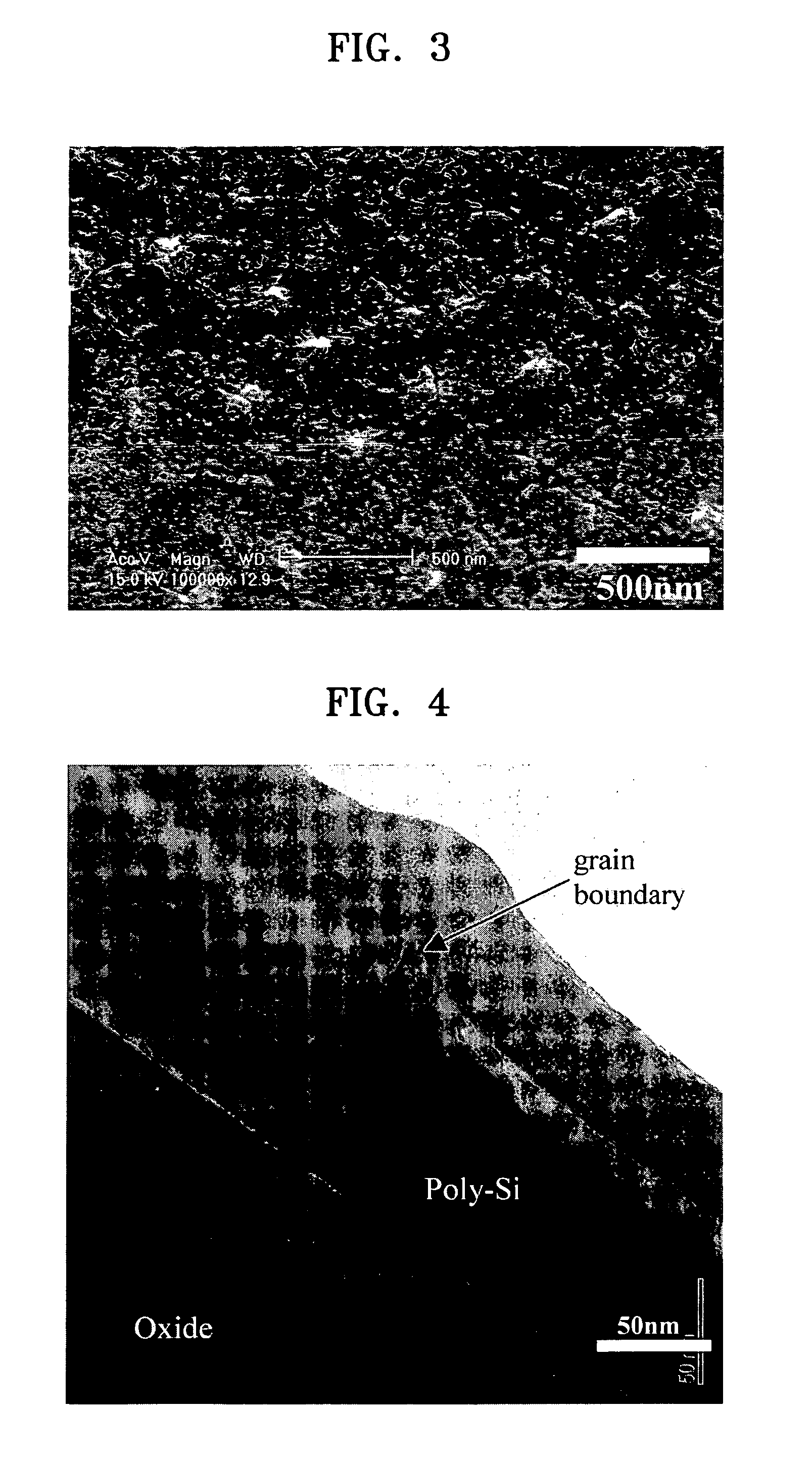

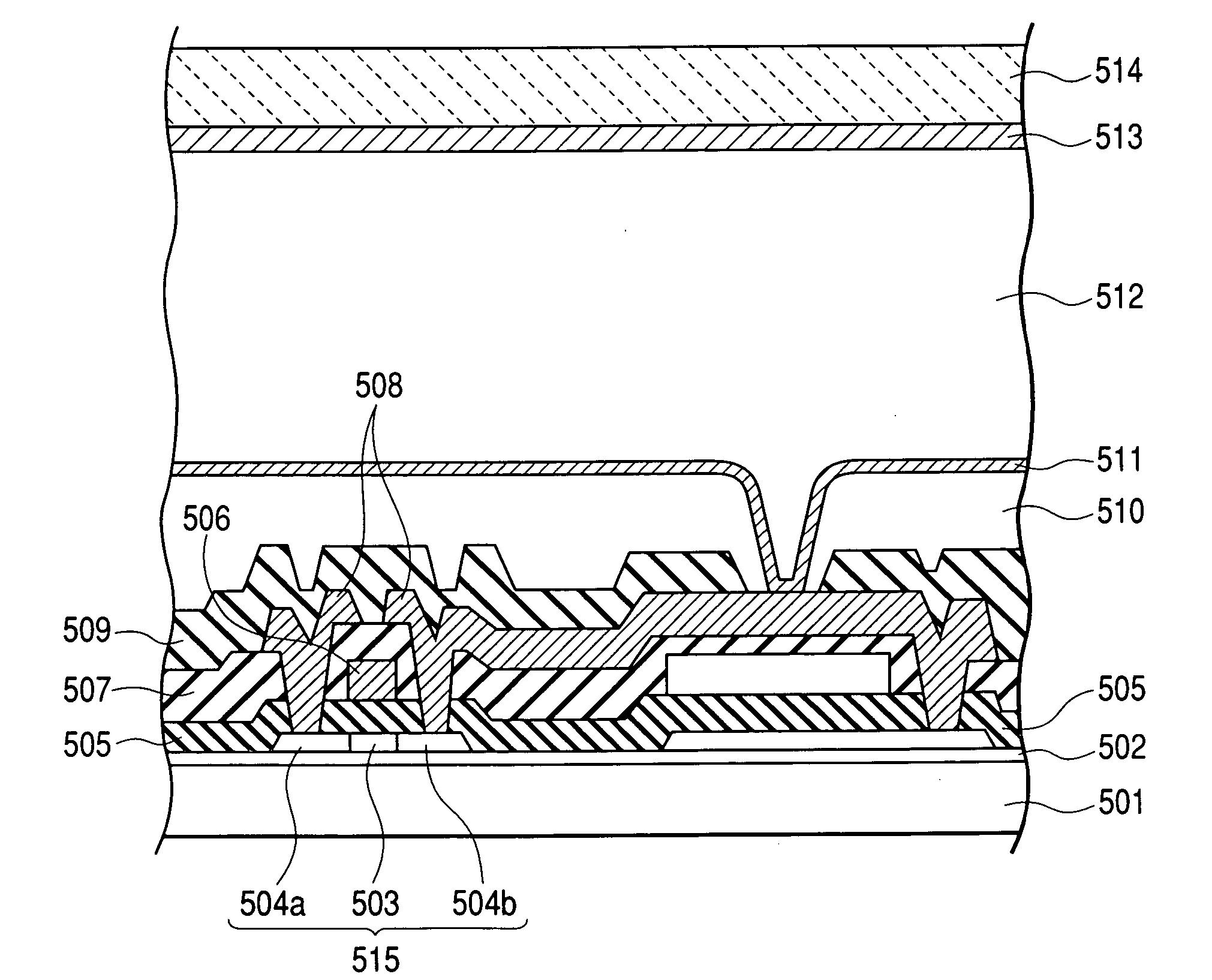

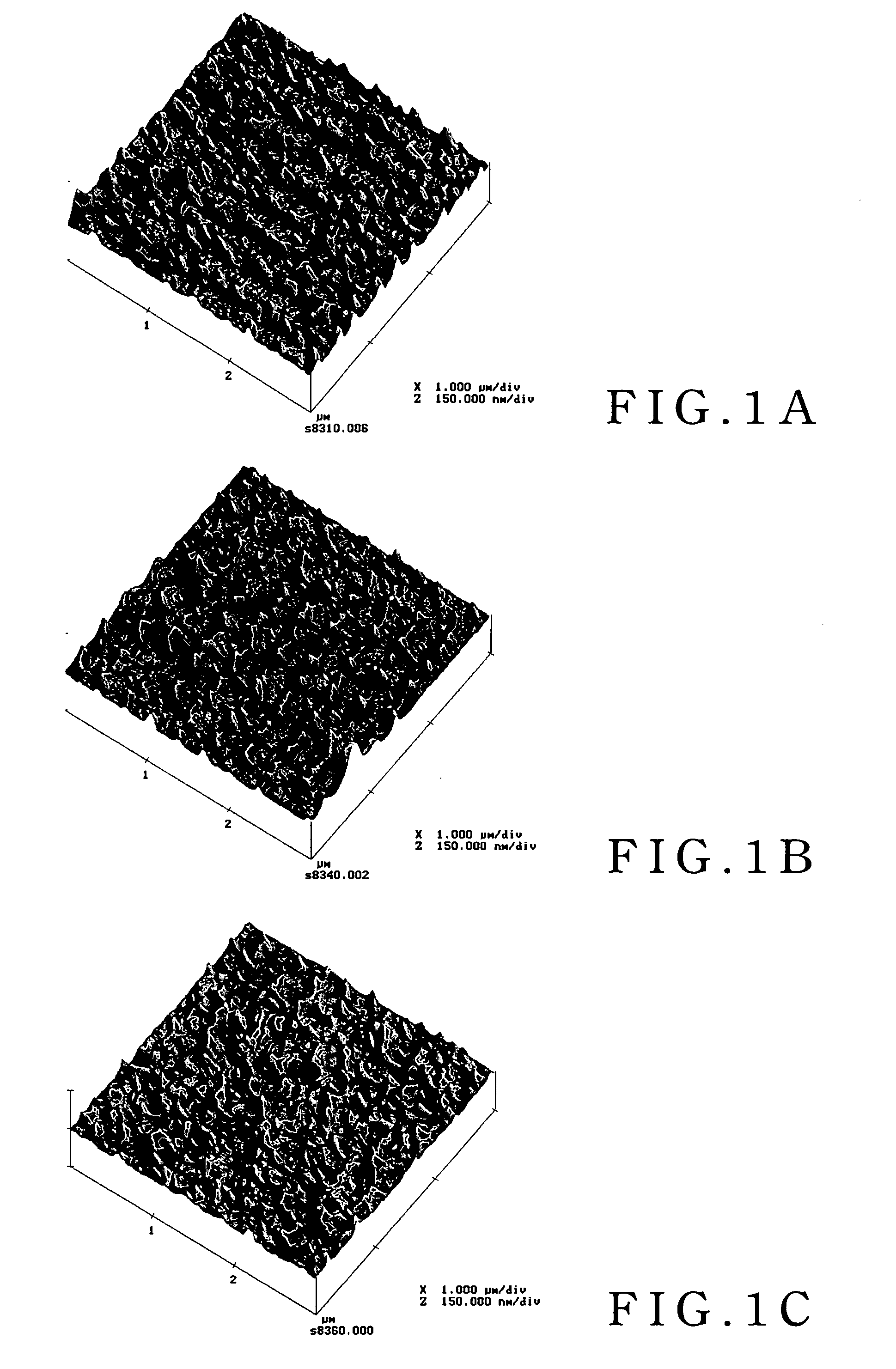

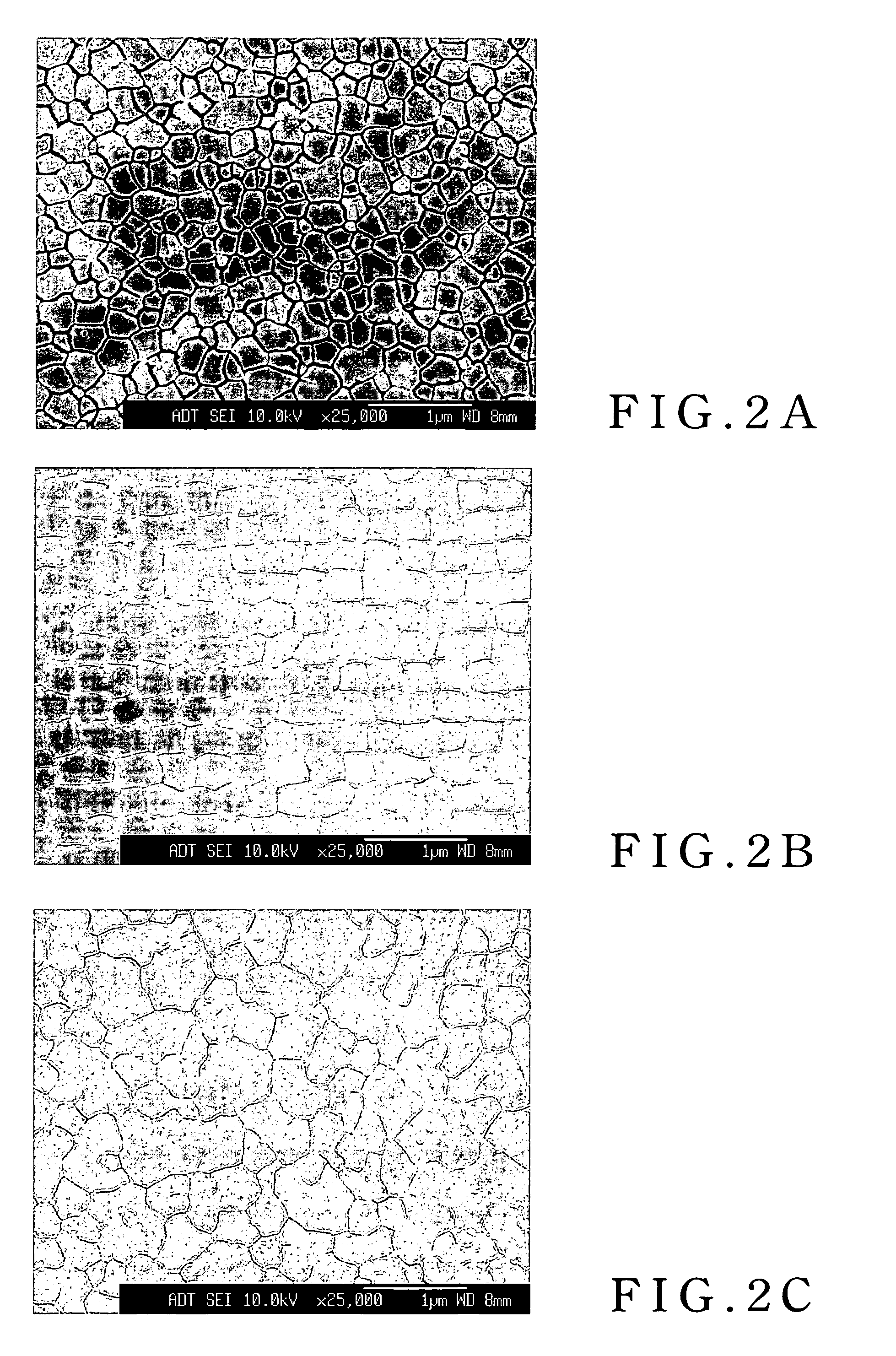

A method of fabricating a poly-Si thin film and a method of fabricating a poly-Si TFT using the same are provided. The poly-Si thin film is formed at a low temperature using inductively coupled plasma chemical vapor deposition (ICP-CVD). After the ICP-CVD, excimer laser annealing (ELA) is performed while increasing energy by predetermined steps. A poly-Si active layer and a SiO2 gate insulating layer are deposited at a temperature of about 150° C. using ICP-CVD. The poly-Si has a large grain size of about 3000 Å or more. An interface trap density of the SiO2 can be as high as 1011 / cm2. A transistor having good electrical characteristics can be fabricated at a low temperature and thus can be formed on a heat tolerant plastic substrate.

Owner:SAMSUNG ELECTRONICS CO LTD

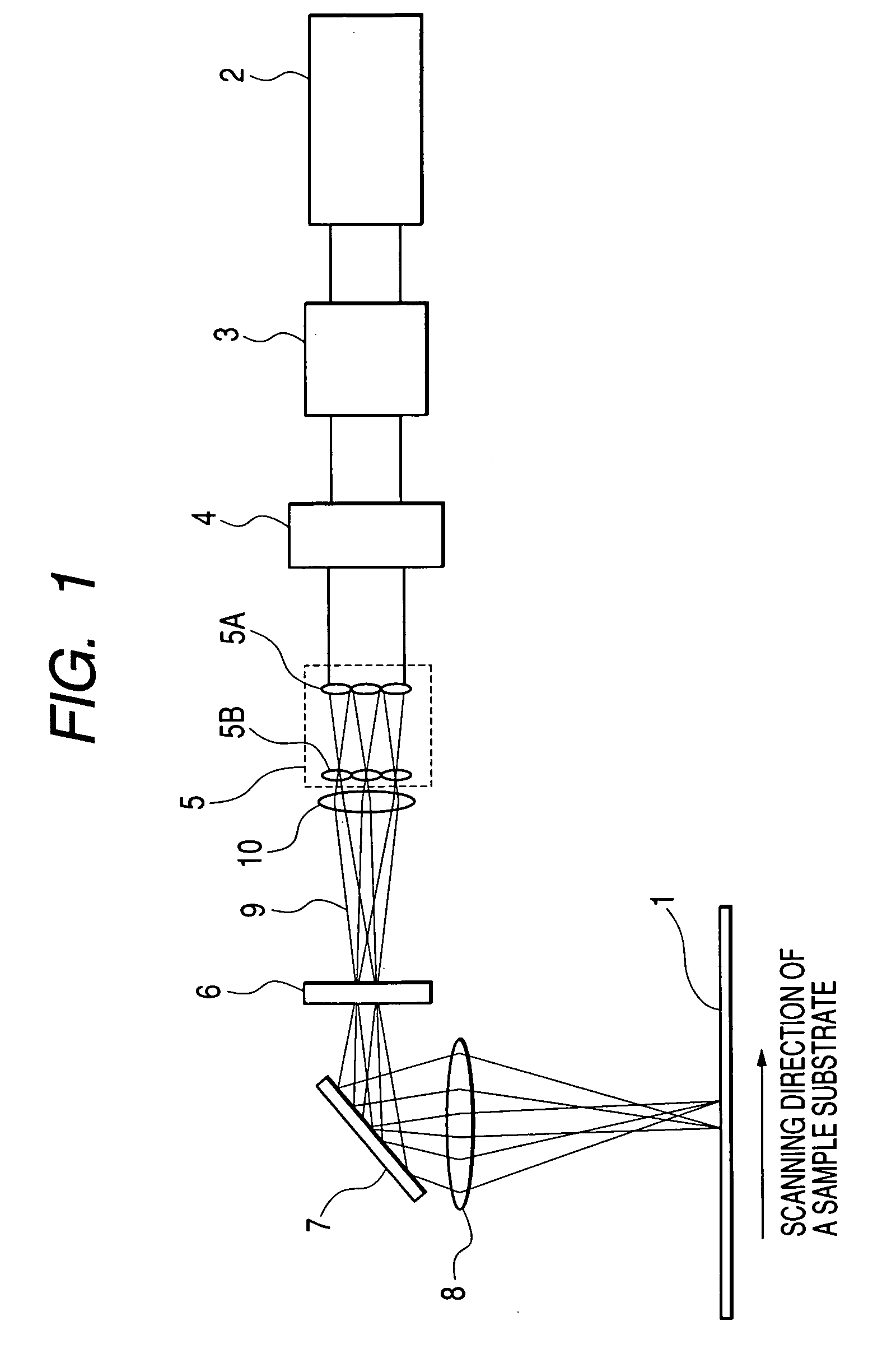

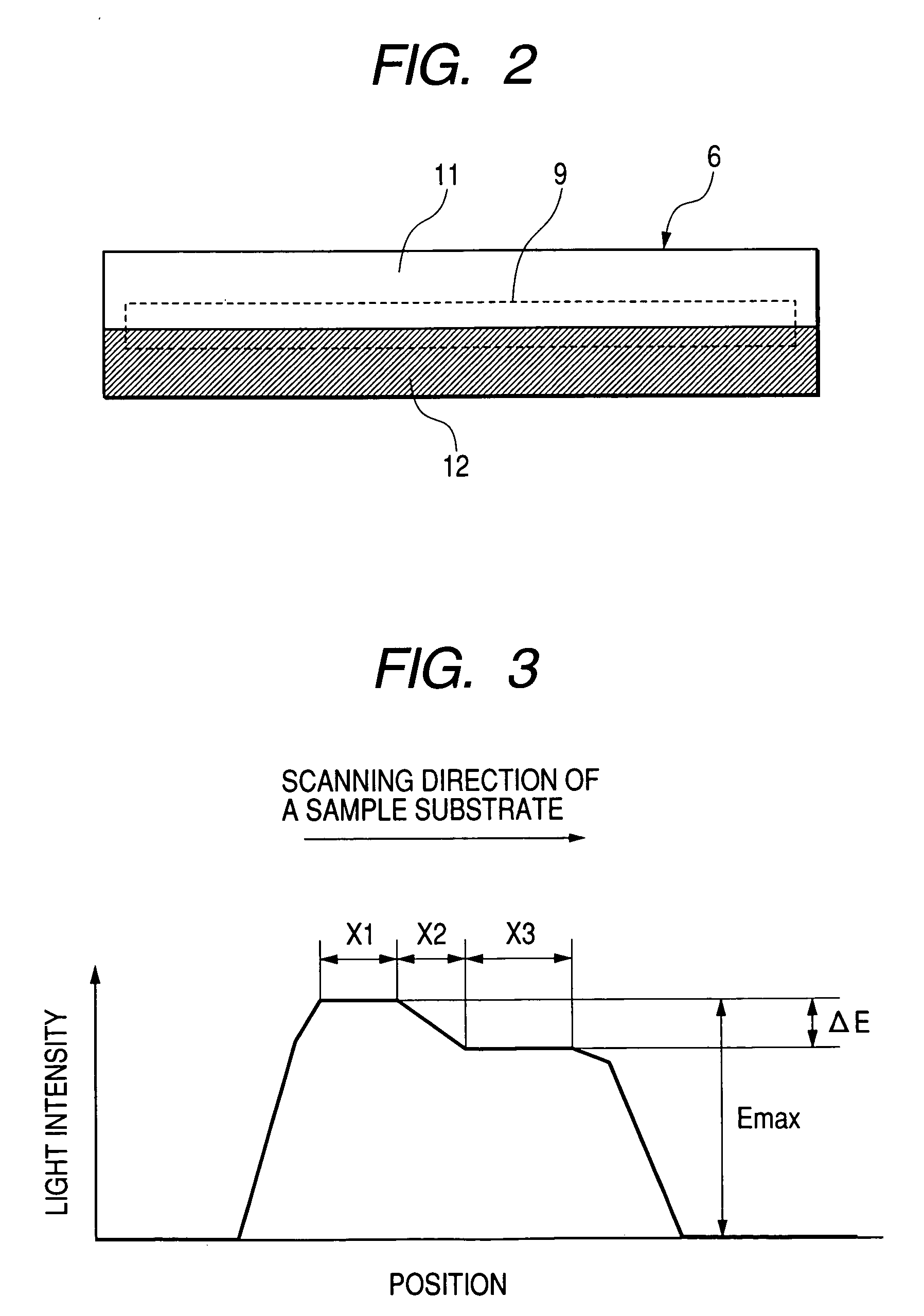

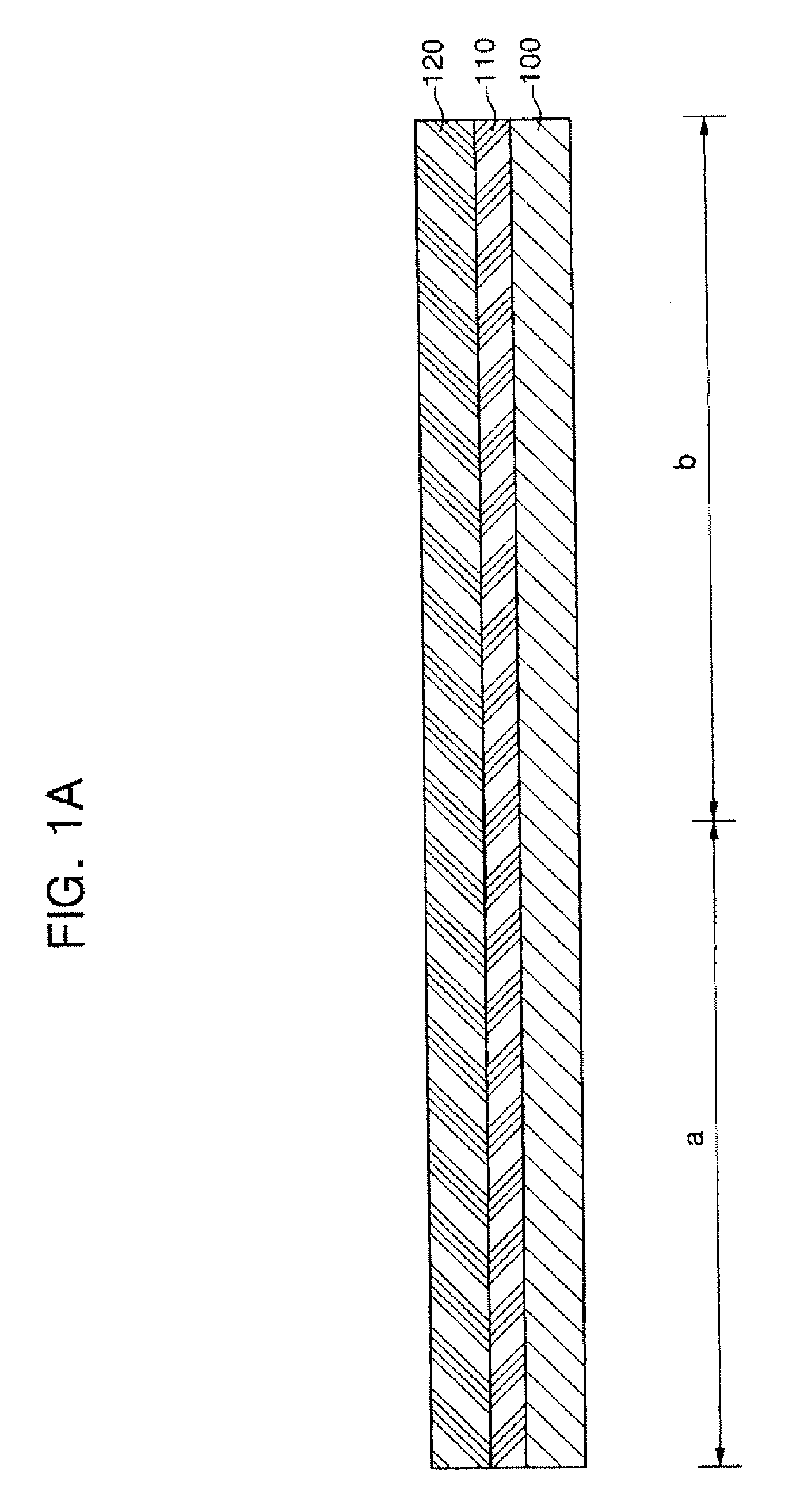

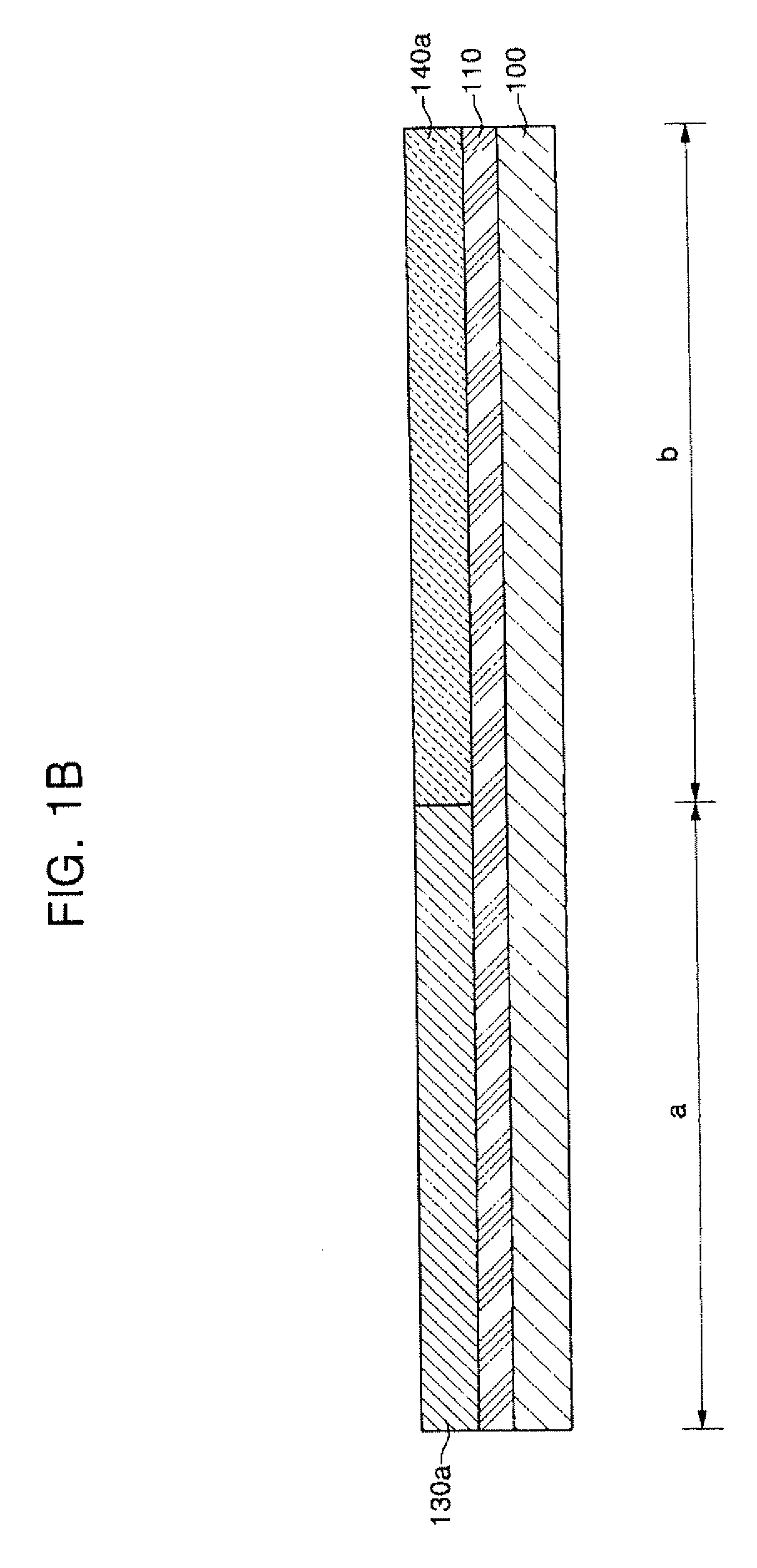

Semiconductor thin film decomposing method, decomposed semiconductor thin film, decomposed semiconductor thin film evaluation method, thin film transistor made of decomposed semiconductor thin film, and image display device having circuit constituted of thin film transistors

InactiveUS20050139830A1Reduce decreaseLong processing timeTransistorSolid-state devicesHigh energySemiconductor thin films

A surface roughness of a polycrystalline semiconductor film to be formed by a laser annealing method is reduced. A transmittance distribution filter is disposed at the optical system of a laser annealing apparatus. The transmittance distribution filter controls an irradiation light intensity distribution along a scanning direction of a substrate formed with an amorphous silicon semiconductor thin film to have a distribution having an energy part equal to or higher than a fine crystal threshold on a high energy light intensity side and an energy part for melting and combining only a surface layer. This transmittance distribution filter is applied to an excimer laser annealing method, a phase shift stripe method or an SLS method respectively using a general line beam to thereby reduce the height of protrusions on a polycrystalline surface.

Owner:PANASONIC LIQUID CRYSTAL DISPLAY CO LTD +1

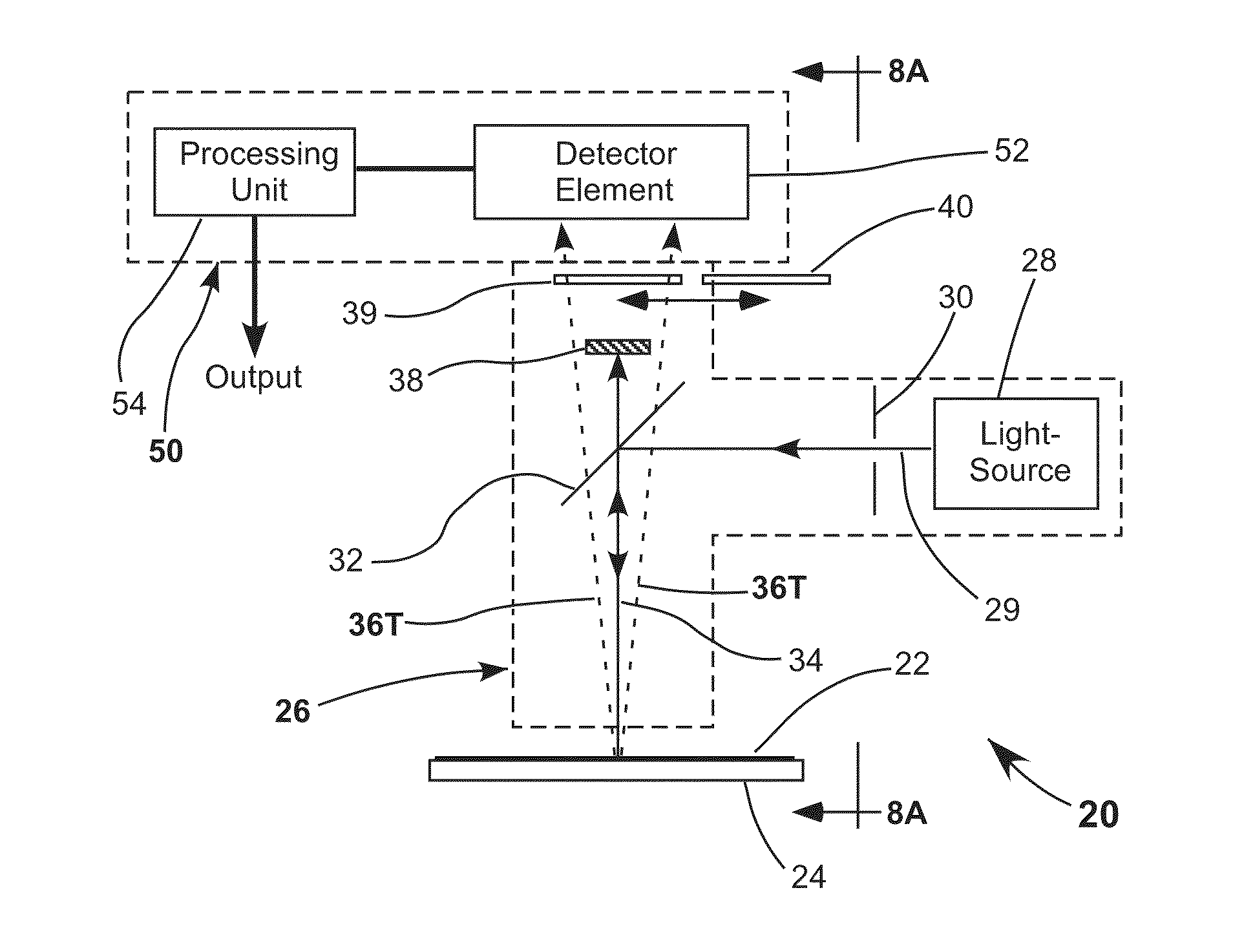

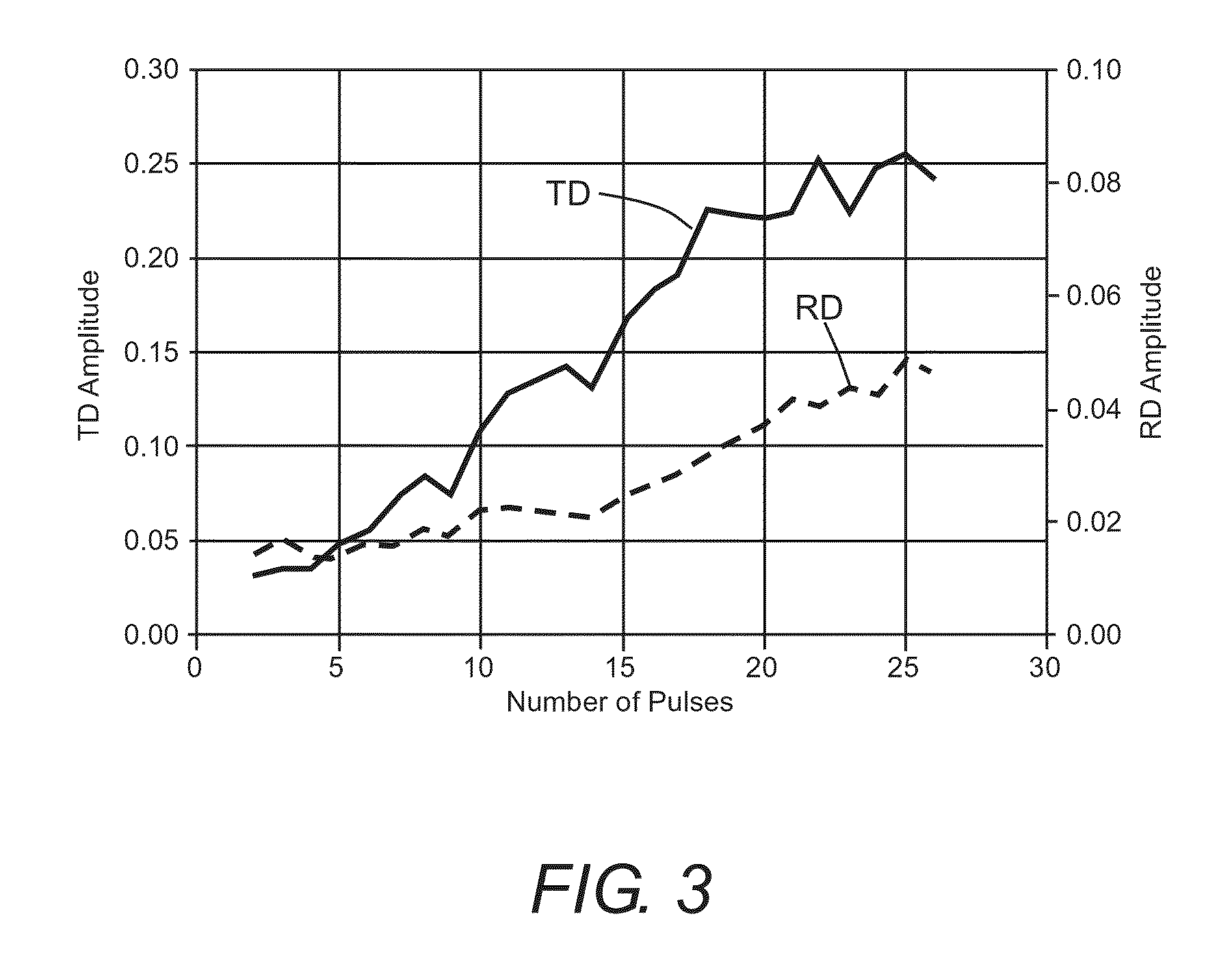

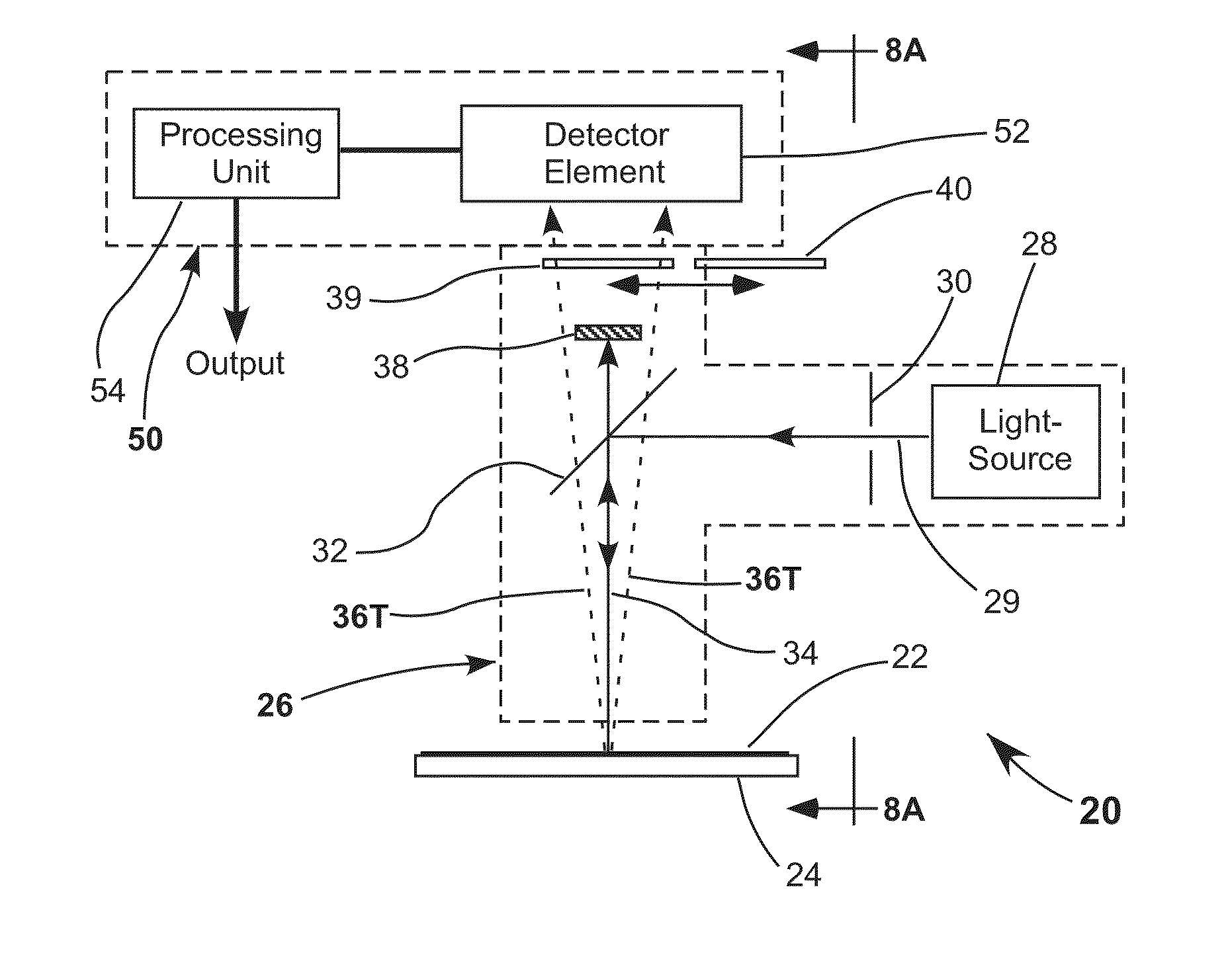

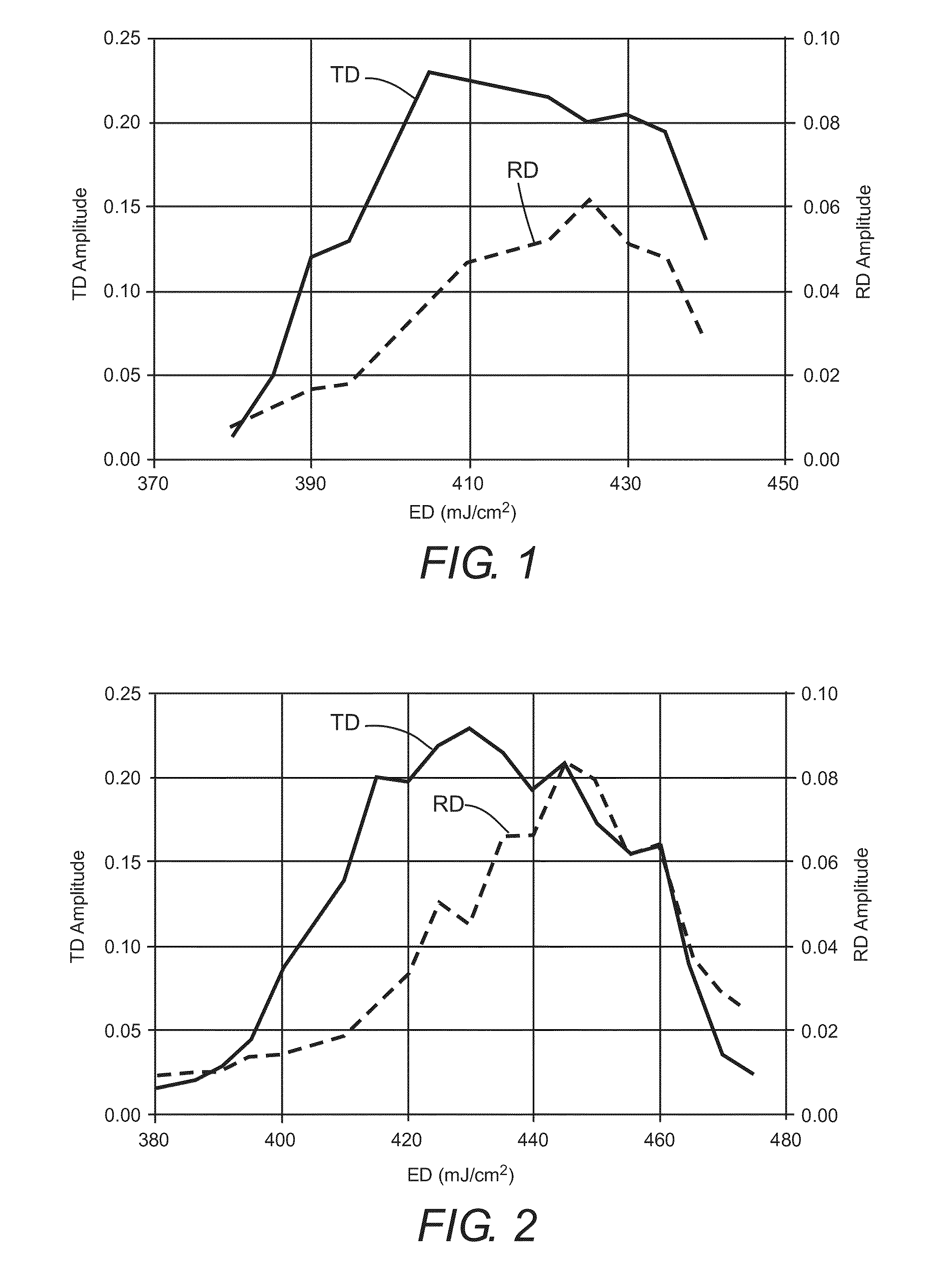

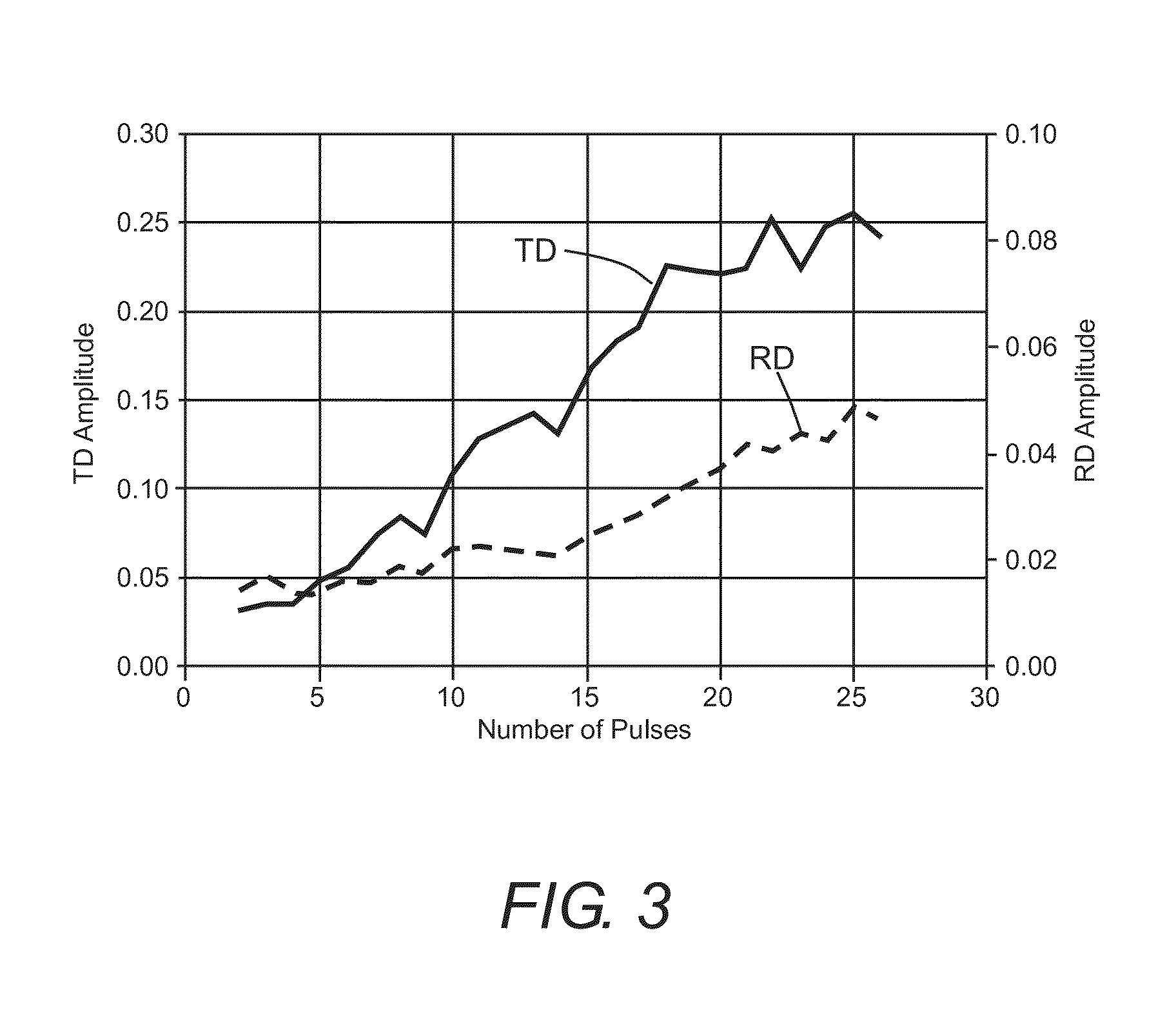

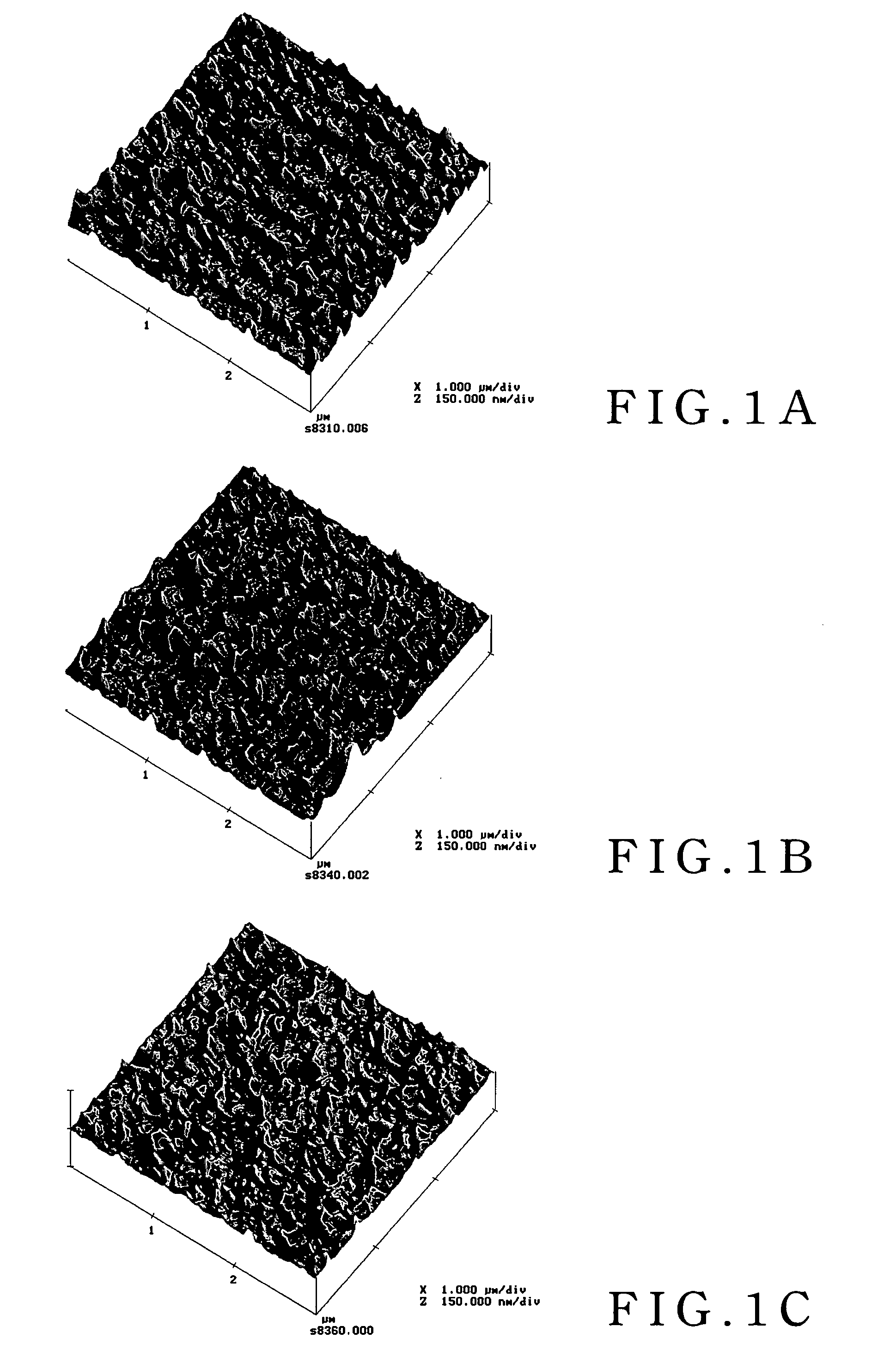

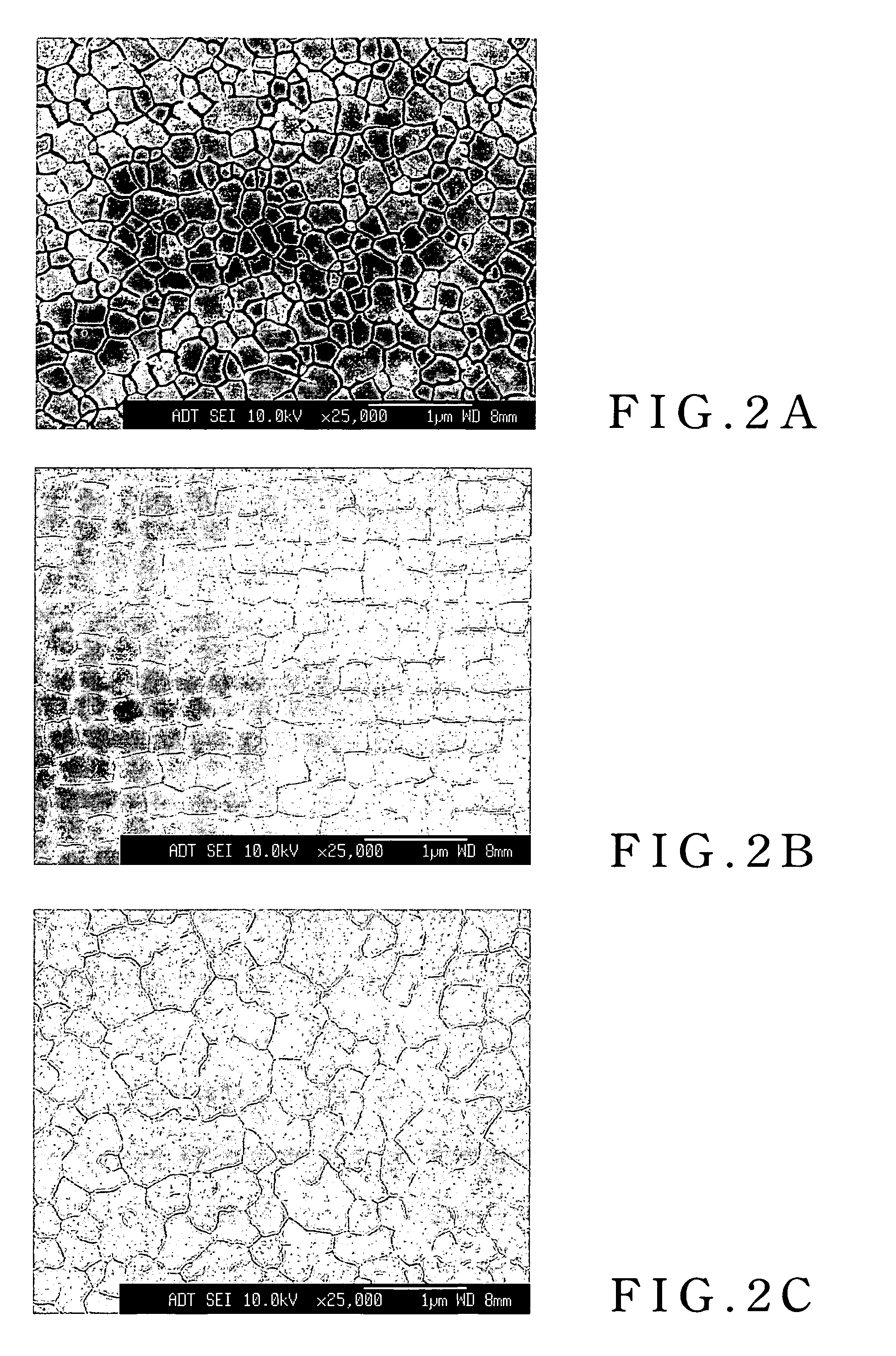

Monitoring method and apparatus for excimer laser annealing process

InactiveUS20130341310A1Investigating semiconductor impuritiesPolycrystalline material growthIrradiationMonitoring methods

A method is disclosed evaluating a silicon layer crystallized by irradiation with pulses form an excimer-laser. The crystallization produces periodic features on the crystalized layer dependent on the number of and energy density in the pulses to which the layer has been exposed. An area of the layer is illuminated with light. A detector is arranged to detect light diffracted from the illuminated area and to determine from the detected diffracted light the energy density in the pulses to which the layer has been exposed.

Owner:COHERENT LASERSYST

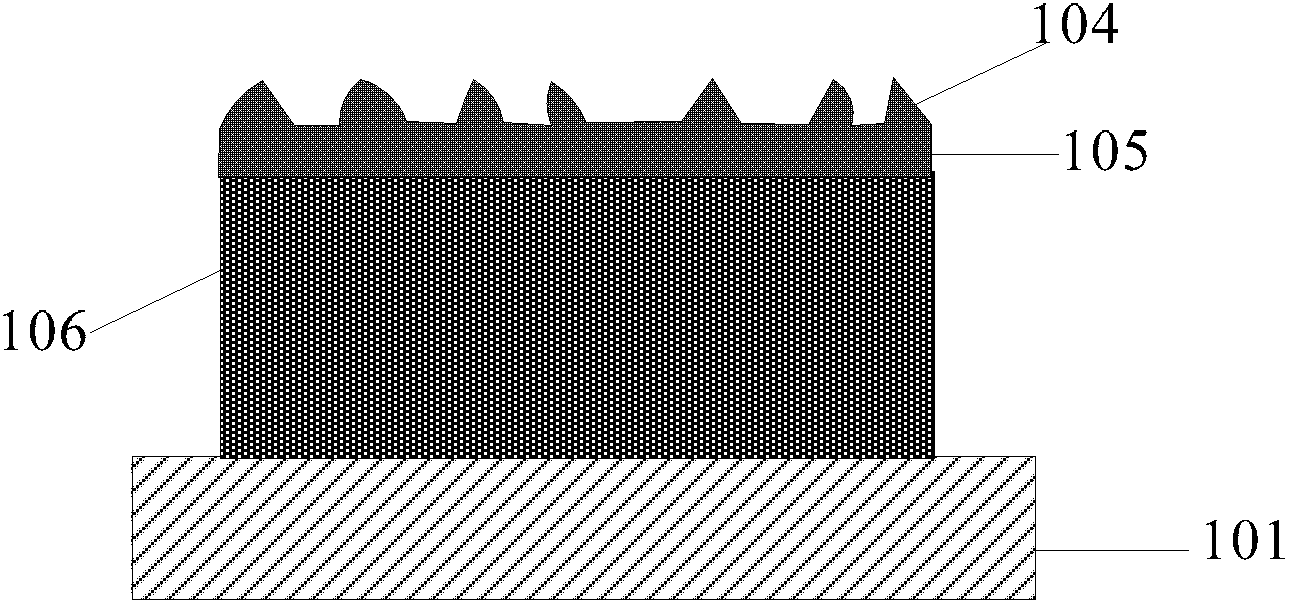

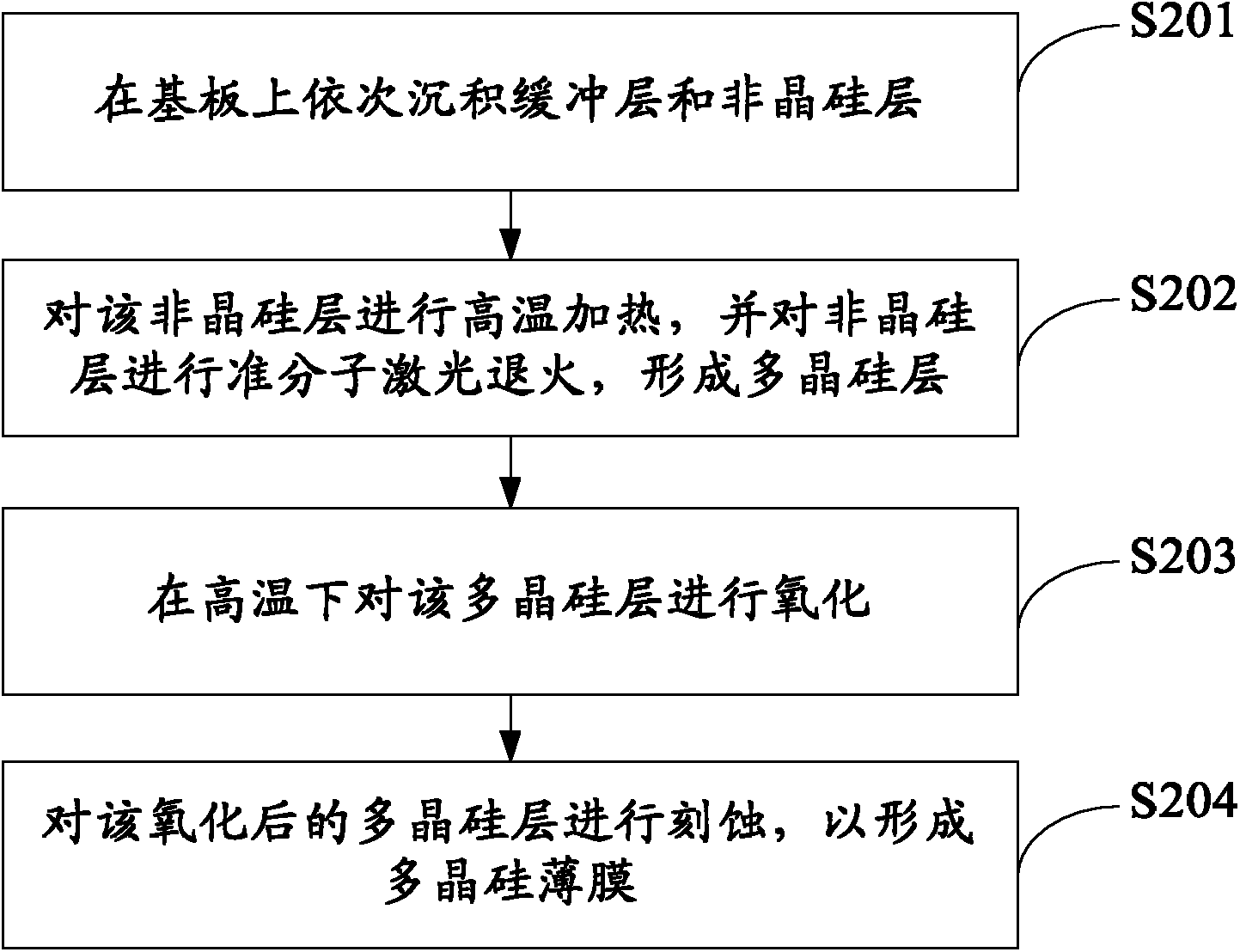

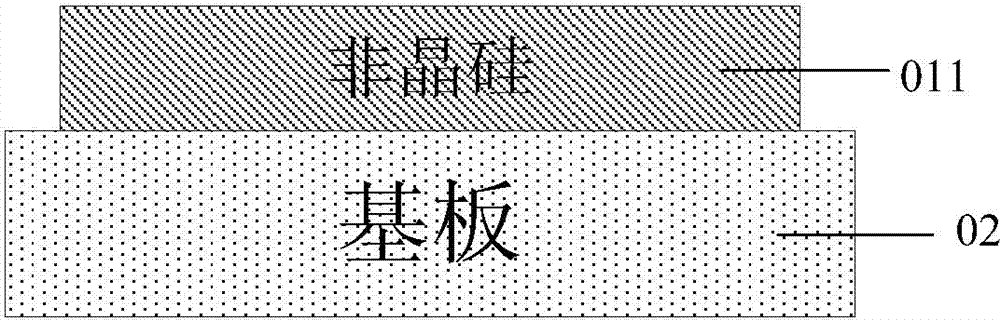

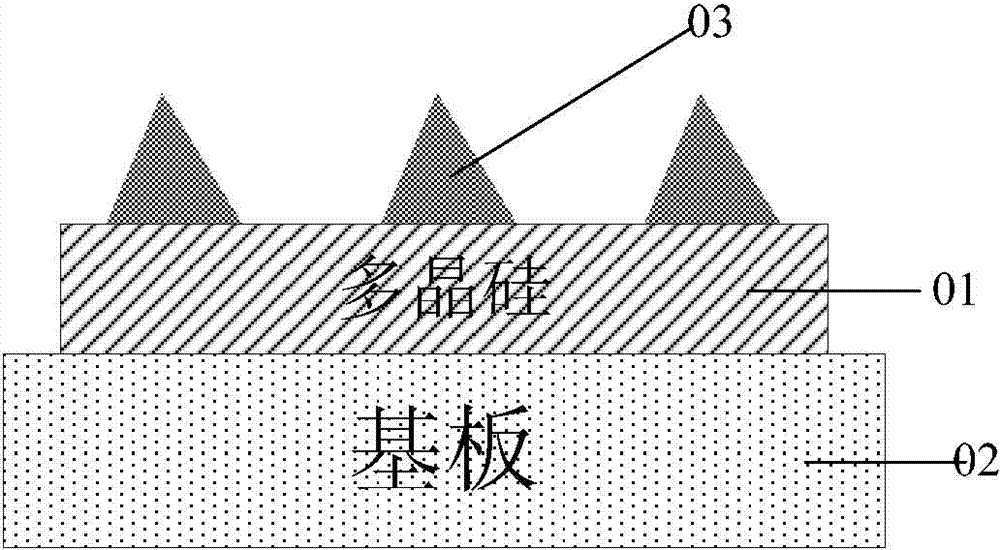

Production method for low-temperature polycrystalline silicon thin film

InactiveCN102655089AReduce leakage currentImprove product qualitySolid-state devicesSemiconductor/solid-state device manufacturingMetallurgyExcimer laser annealing

The embodiment of the invention provides a production method for a low-temperature polycrystalline silicon thin film, relating to the field of manufacturing for a liquid crystal panel, and used for reducing the leakage current generated by the polycrystalline silicon thin film during a use process, and thus improving product quality. The production method for a low-temperature polycrystalline silicon thin film comprises the following steps of: sequentially depositing a buffering layer and an amorphous silicon layer on a substrate; performing high-temperature heating on the amorphous silicon layer, and performing excimer laser annealing on the amorphous silicon layer to form a polycrystalline silicon layer; oxidizing the polycrystalline silicon layer at a high temperature; and etching the oxidized polycrystalline silicon layer to form the polycrystalline silicon thin film. The production method provided by the embodiment of the invention is used for manufacturing a thin-film transistor.

Owner:BOE TECH GRP CO LTD

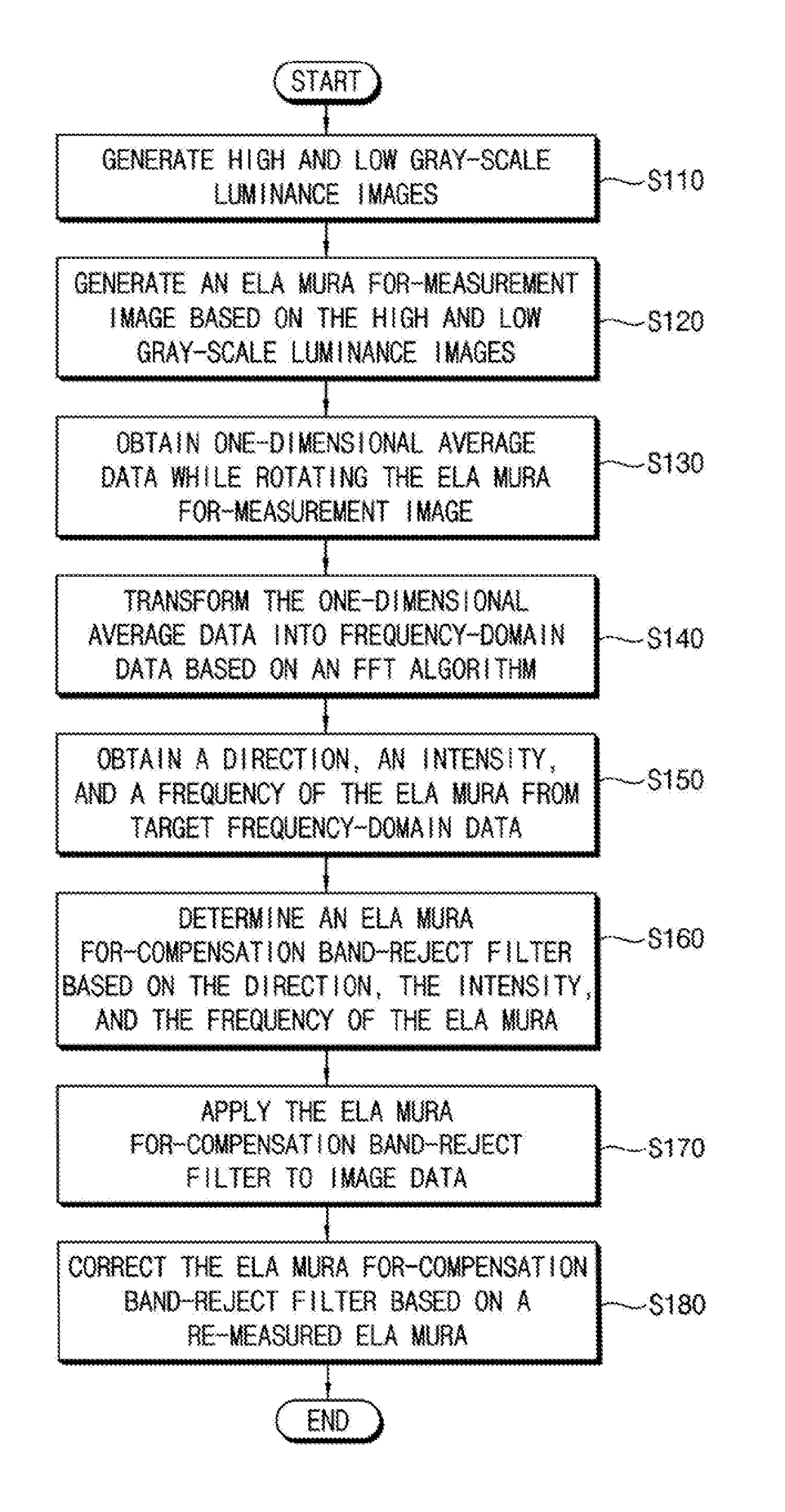

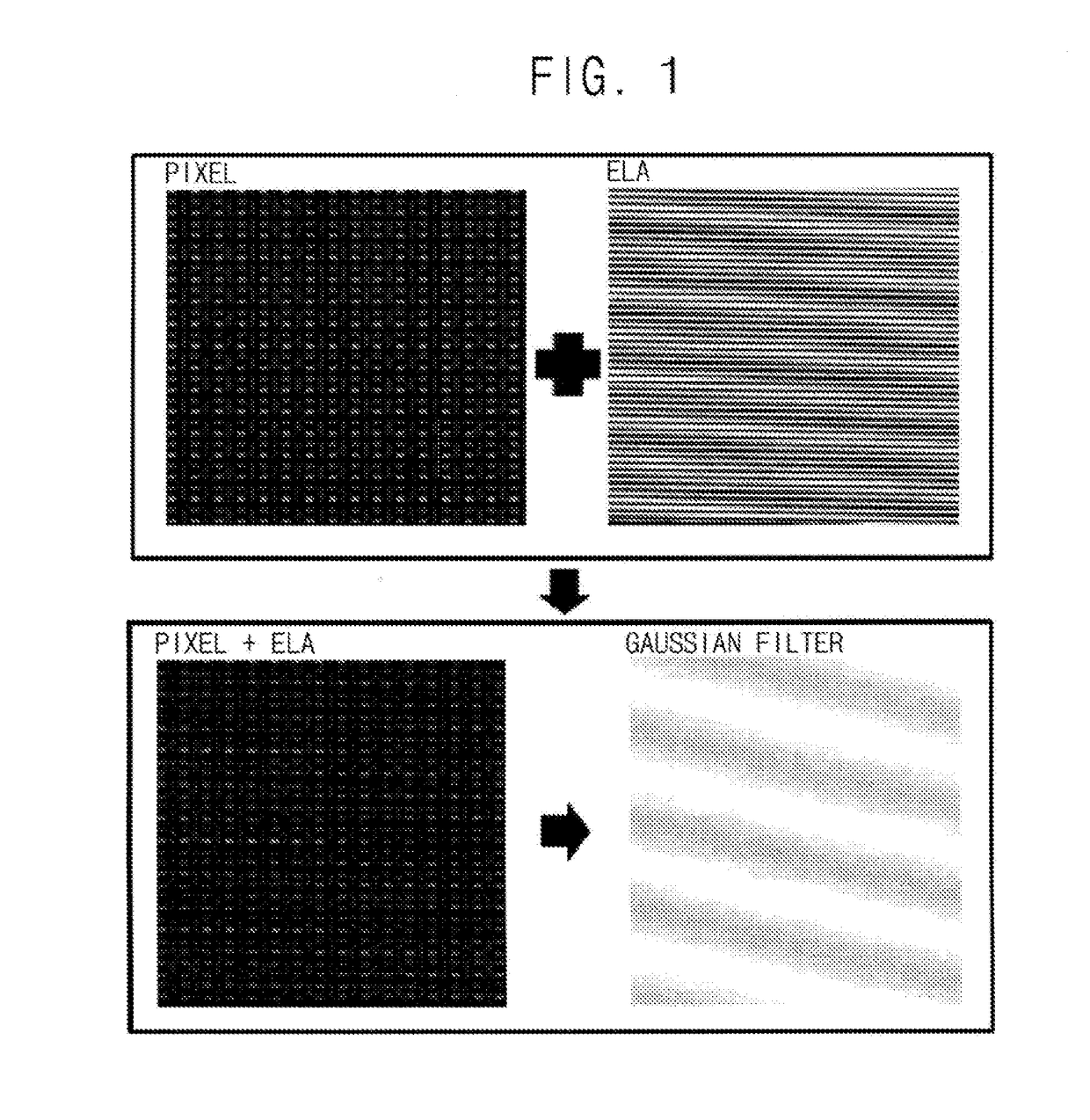

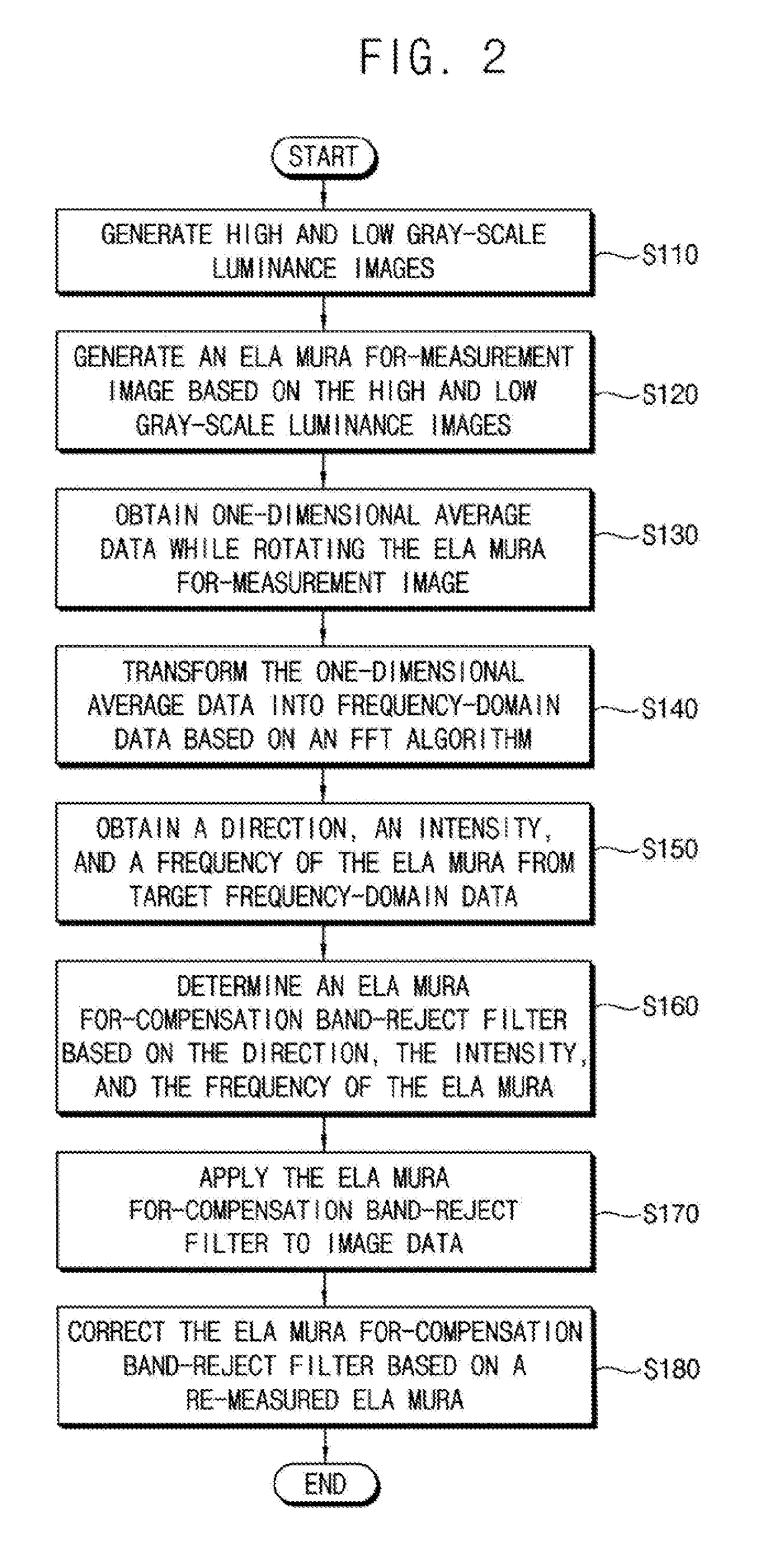

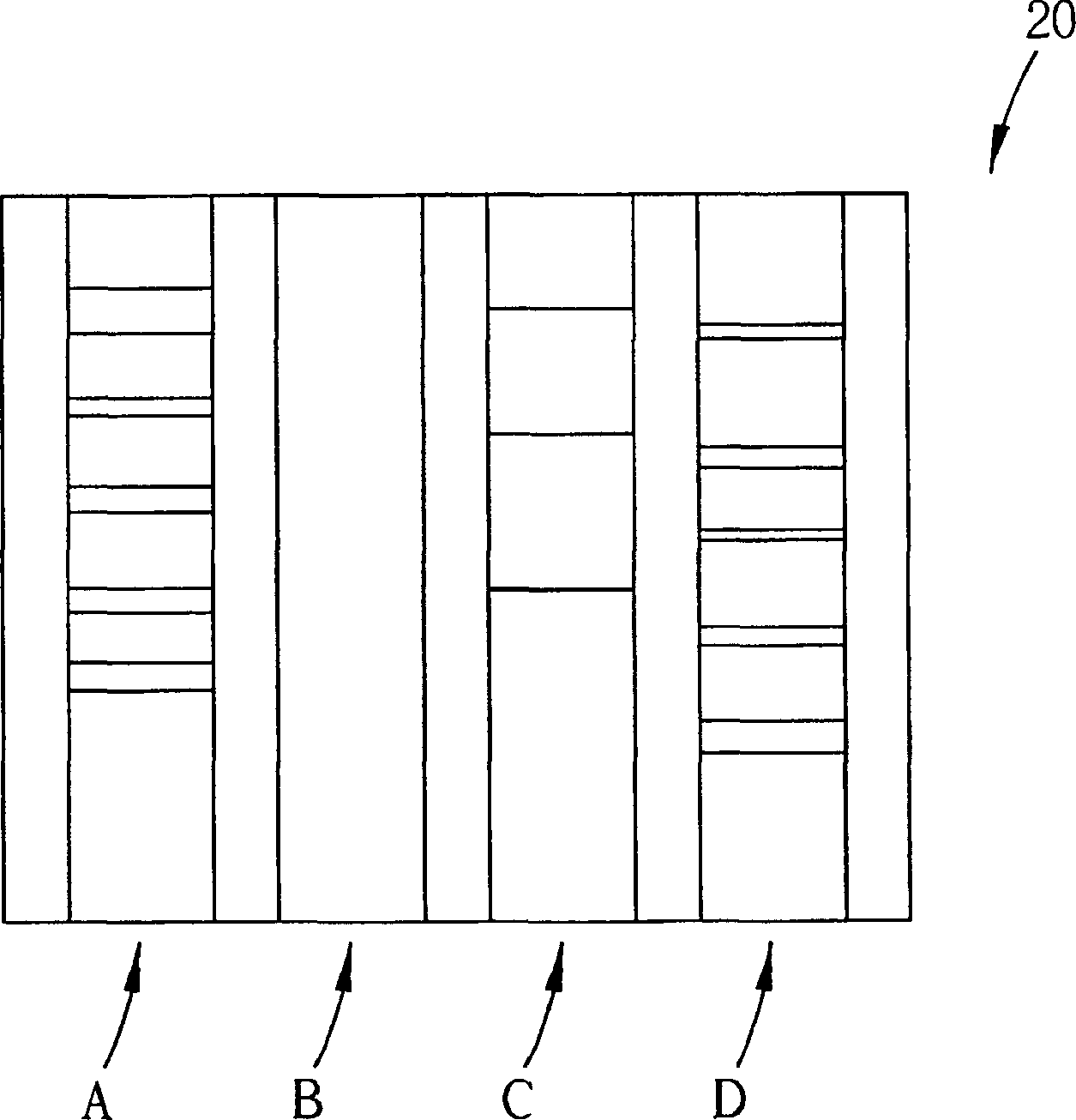

Method of compensating for an excimer laser annealing mura and display device employing the same

A method of compensating for Mura in a display panel includes displaying a high gray-scale image and a low gray-scale image on a display panel. The displayed images are photographed to generate a high gray-scale luminance image and a low gray-scale luminance image. An ELA Mura for-measurement image having moiré-removed luminance values is generated by dividing luminance values of the low gray-scale luminance image by luminance values of the high gray-scale luminance image. One-dimensional average data is obtained from the ELA Mura for-measurement image. The one-dimensional average data is transformed into frequency-domain data. Target frequency-domain data having a maximum peak value is identified from the frequency-domain data. A direction, an intensity, and a frequency of the ELA Mura are obtained from the target frequency-domain data. A filter is determined based on the obtained information. The filter is applied to image data.

Owner:SAMSUNG DISPLAY CO LTD

Inspection method and apparatus of laser crystallized silicons

ActiveUS20050002016A1The method is simple and fastSemiconductor/solid-state device manufacturingOptically investigating flaws/contaminationExcimer laser annealingPolycrystalline silicon

An inspection method and apparatus of laser crystallized silicons in the low-temperature poly Si (LTPS) process. The crystalline quality is inspected by using a visible light source to irradiate the surface of the poly Si and examining the variations of the reflected light caused by the protrusion arrangement at the surface of the poly Si. This method can be adopted on the poly Si samples prepared by the line scanning of the excimer laser annealing (ELA) technology.

Owner:AU OPTRONICS CORP

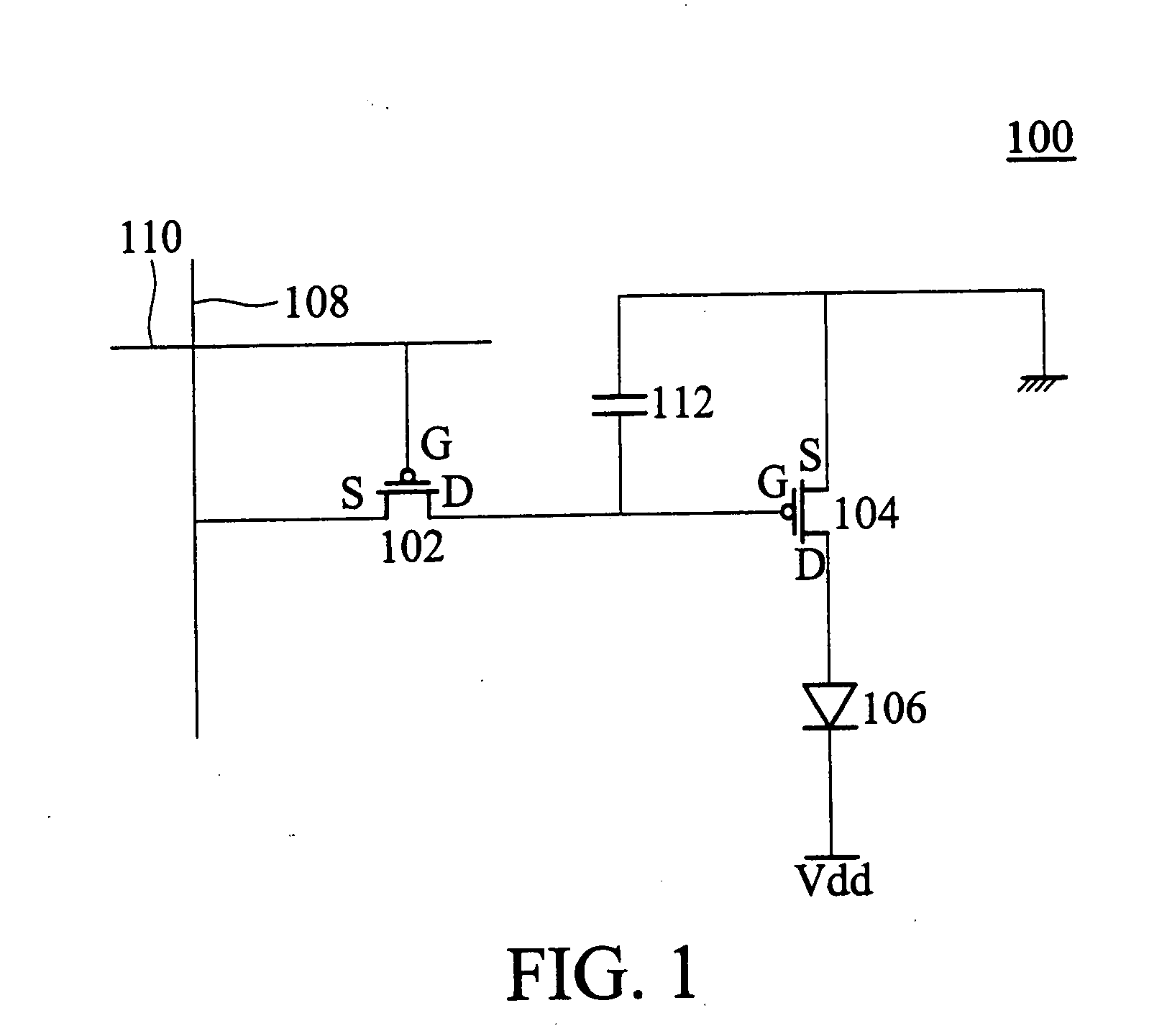

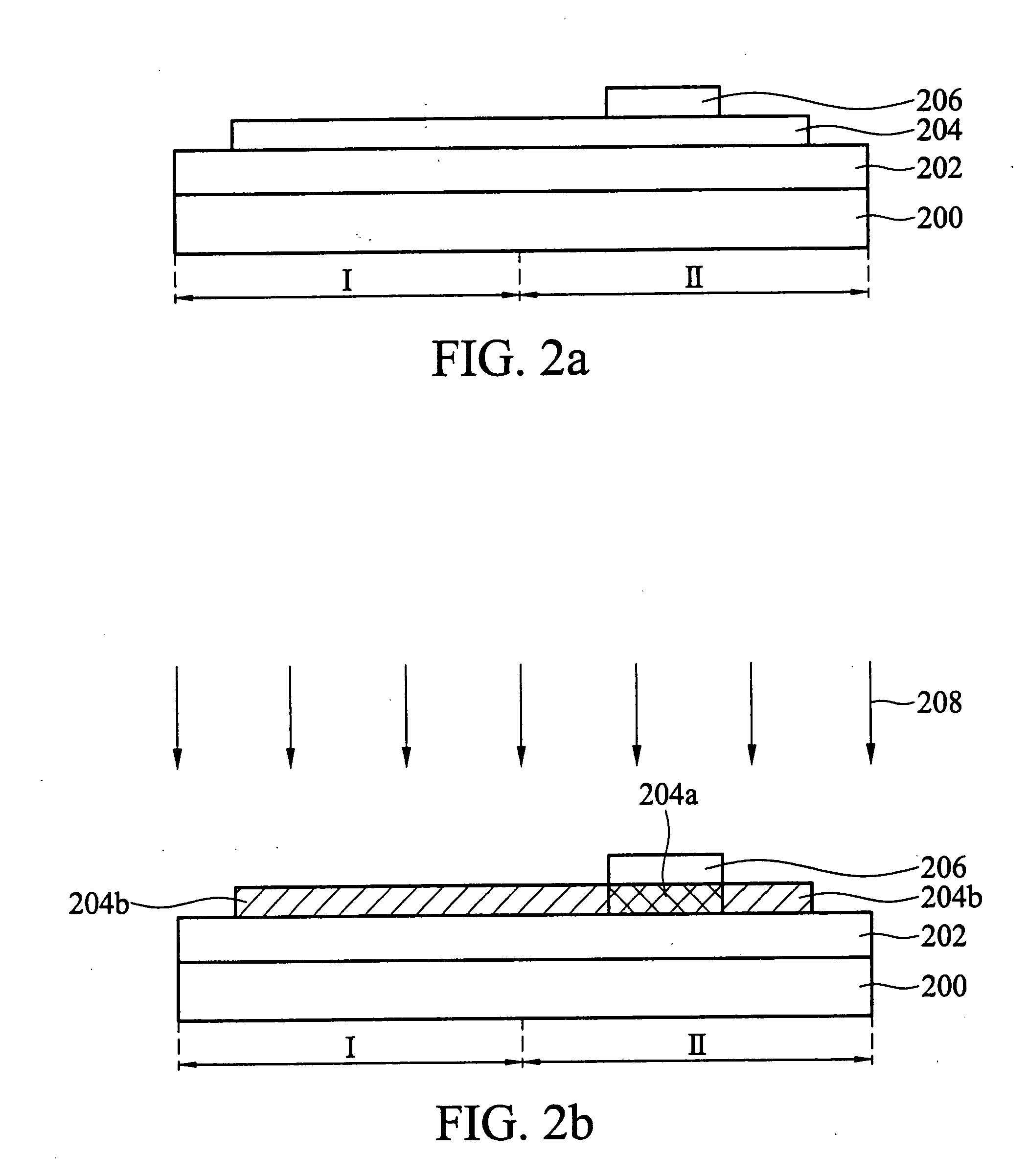

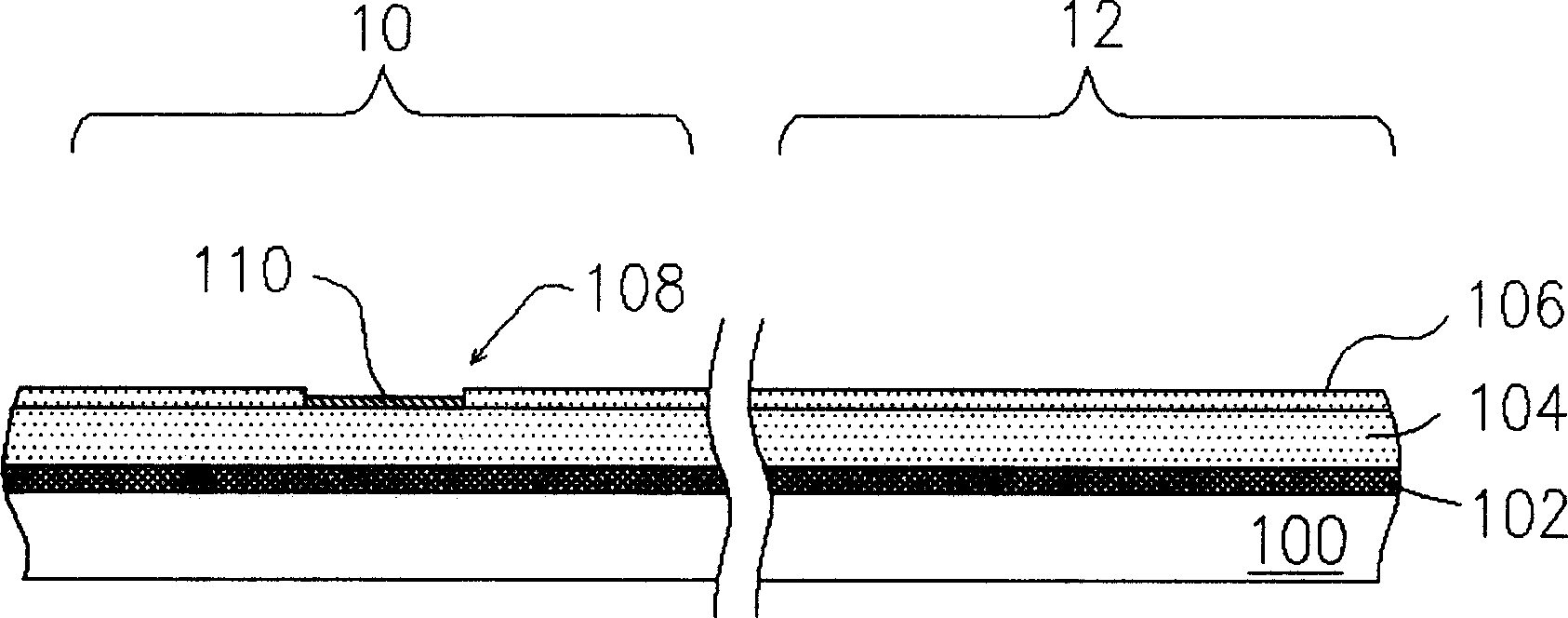

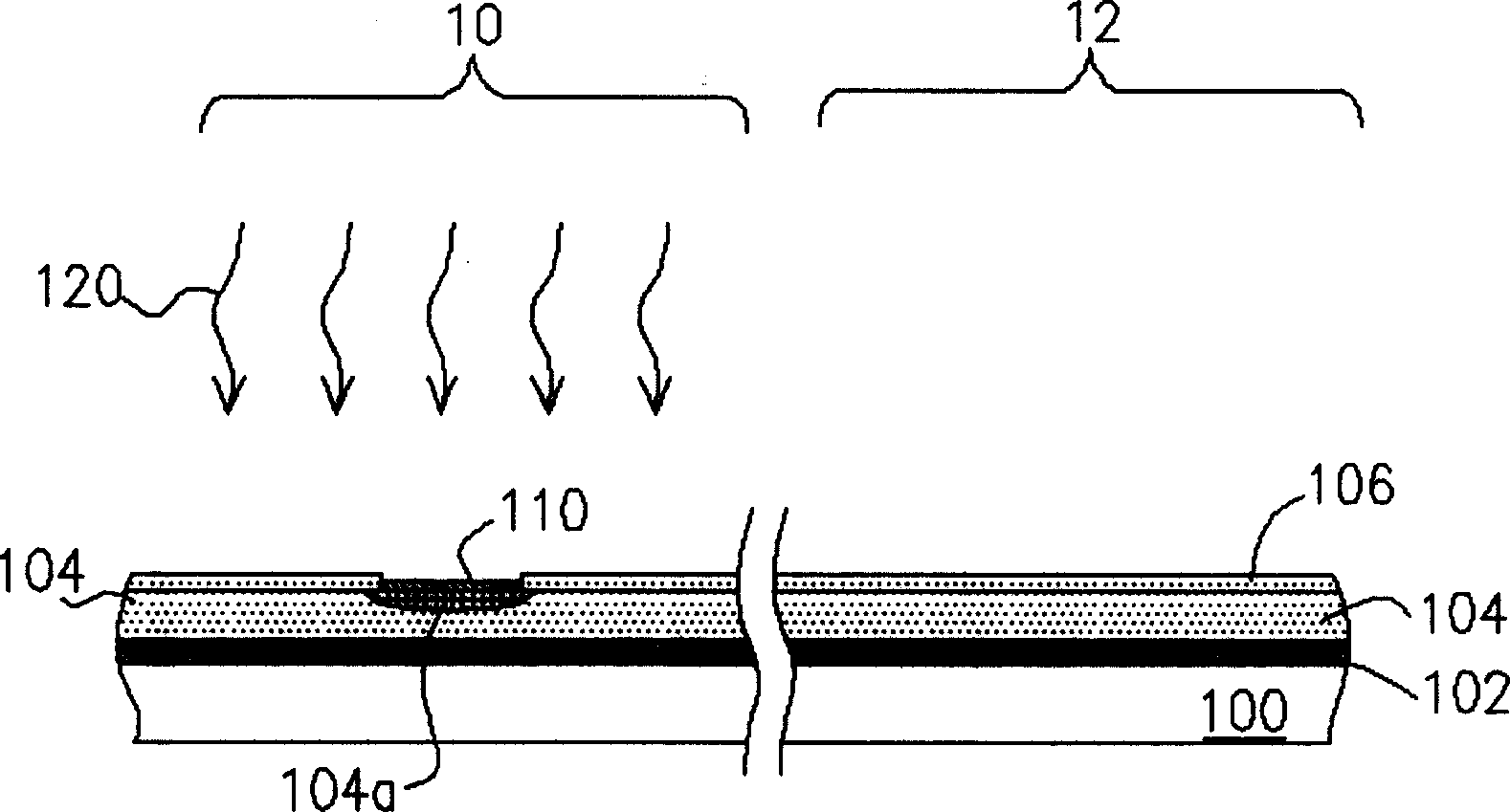

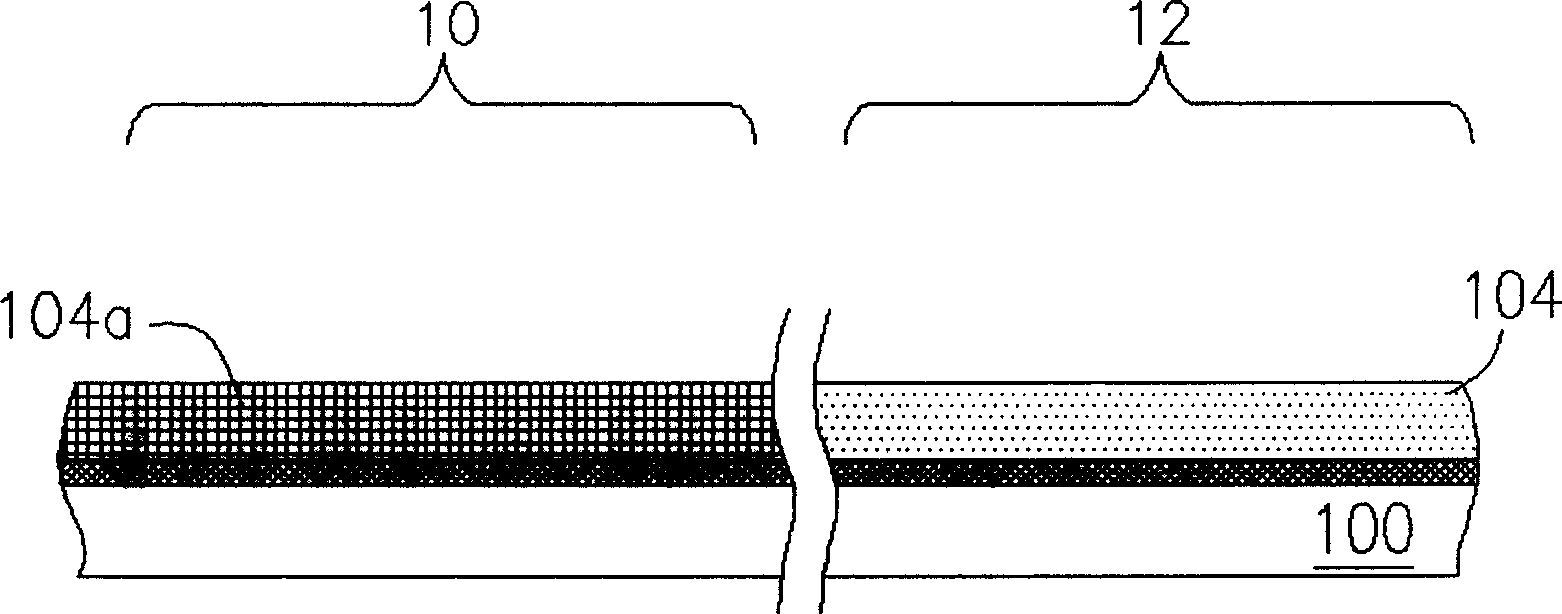

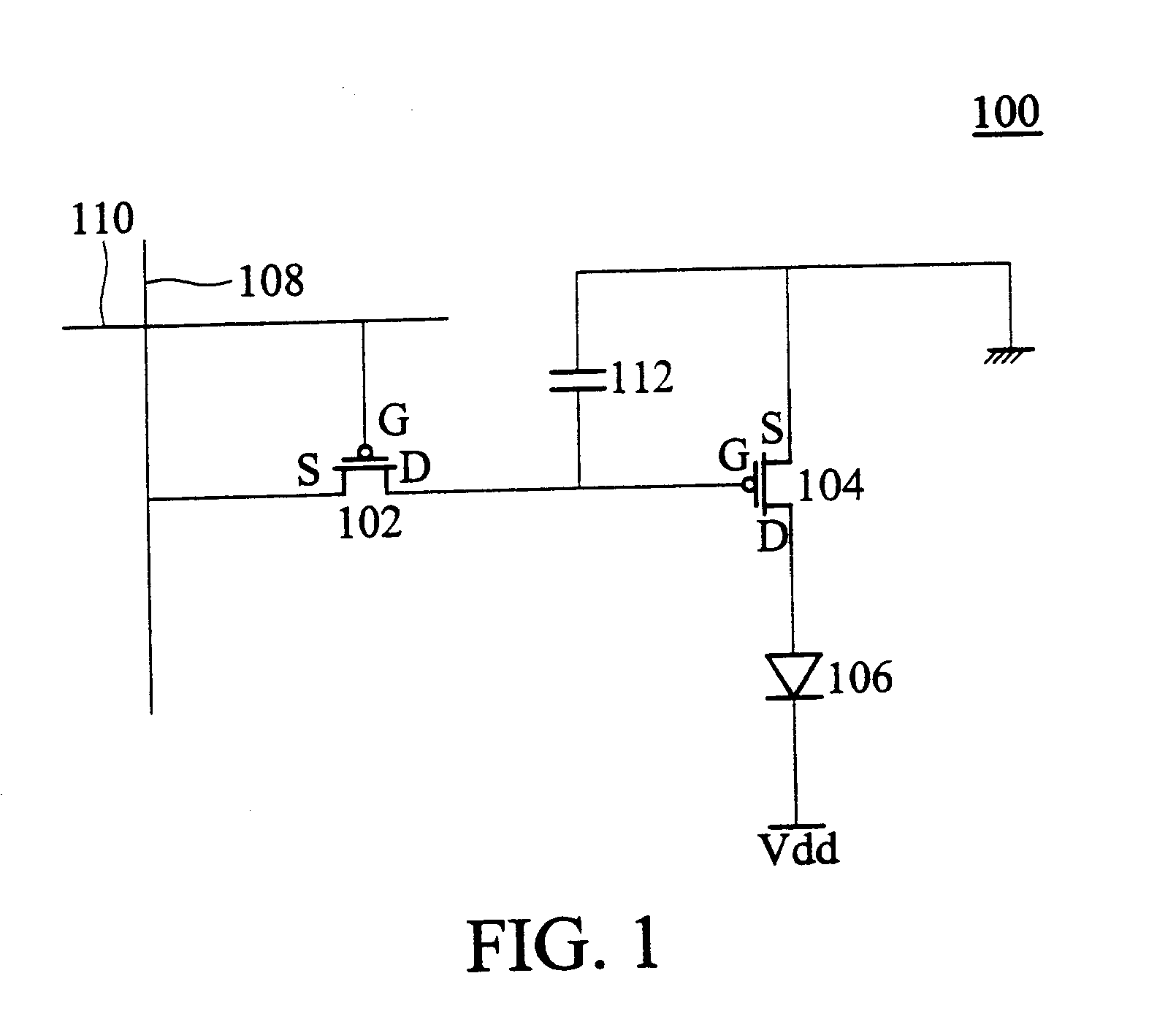

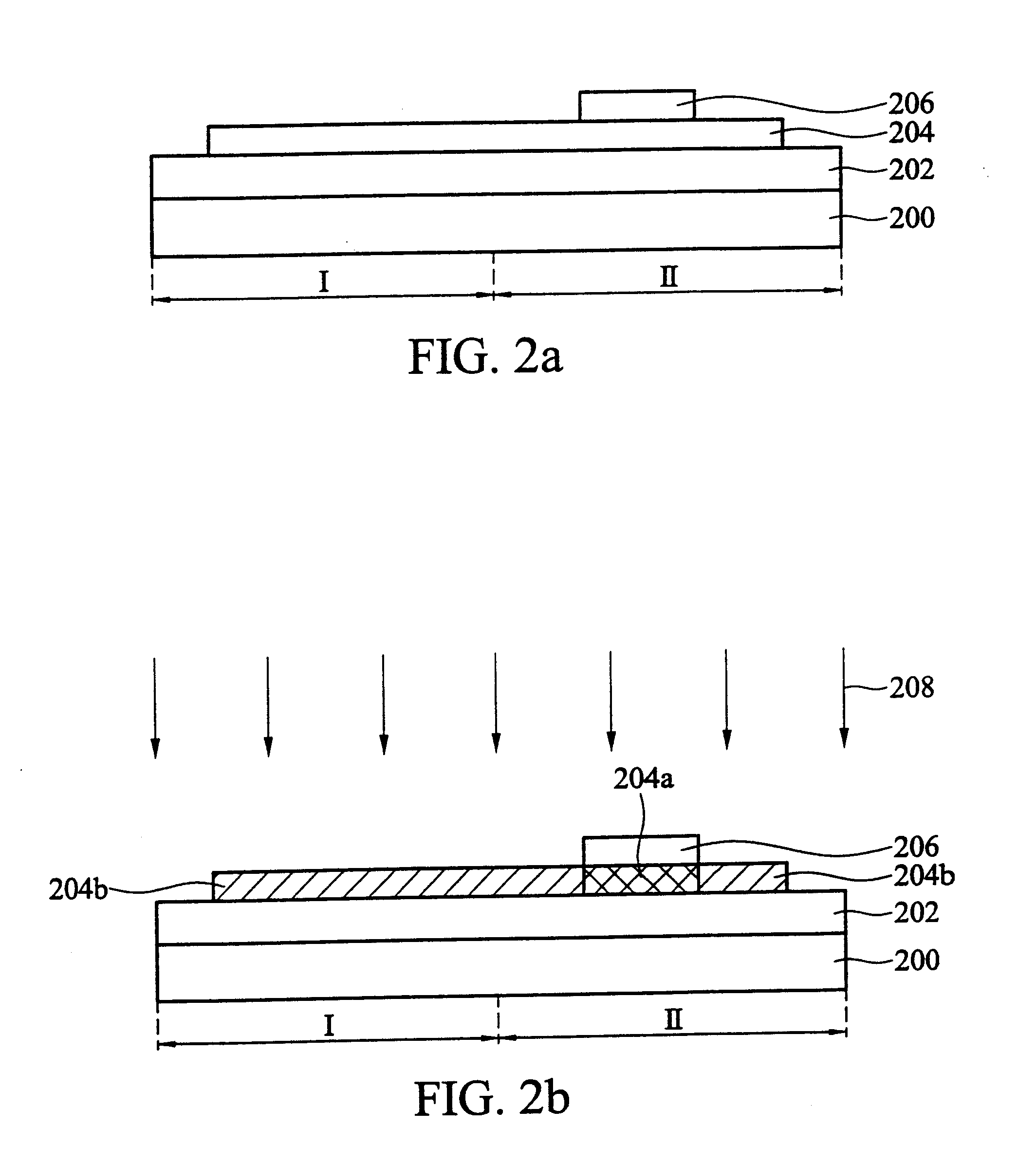

Method of fabricating an organic electroluminescent device and system of displaying images

InactiveUS20080087889A1Decrease difference of electric propertyIncrease the apertureSolid-state devicesSemiconductor/solid-state device manufacturingOptoelectronicsOrganic electroluminescence

A method for fabricating organic electroluminescent devices is disclosed. The method comprises providing a substrate divided into first and second regions, forming an amorphous silicon layer on the substrate, forming a protection film on the amorphous silicon layer within the second region, performing an excimer laser annealing process on the amorphous silicon layer for converting it to a polysilicon layer, removing the protection film, patterning the polysilicon layer, thus a first patterned polysilicon layer in the first region and a second patterned polysilicon layer in the second region are formed. A resultant organic electroluminescent device is obtained. Specifically, the grain size of the first patterned polysilicon layer is large than that of the second patterned polysilicon layer.

Owner:INNOLUX CORP

Manufacturing method of low-temperature polycrystalline silicon (poly-Si) thin film transistor (TFT)

ActiveCN102629558ALarge grainImprove mobilitySemiconductor/solid-state device manufacturingHydrogenOptoelectronics

The invention discloses a manufacturing method of a low-temperature polycrystalline silicon (poly-Si) thin film transistor (TFT). The method is characterized by: forming an amorphous silicon (a-Si) layer on a substrate; carrying out hydrogen relief treatment on the a-Si layer so that the a-Si layer becomes a microgranular; then, forming the a-Si layer which does not be performed with grain refining on the a-Si layer of the microgranular; and then carrying out the hydrogen relief treatment on the a-Si layer so that the a-Si layer becomes the microgranular; and continuously repeating so as to form the a-Si layer and carrying out the hydrogen relief treatment so as to form the a-Si layer with multilayer micromeritics; finally, carrying out excimer laser annealing (ELA) so that the a-Si layer with the multilayer micromeritics crystallizes into a poly-Si layer. After the poly-Si layer becomes the a-Si layer of the multilayer micromeritic through pretreatment, the ELA is performed so that the crystalline grain of the poly-Si layer becomes larger and a carrier mobility is high.

Owner:CENTURY DISPLAY (SHENZHEN) CO LTD

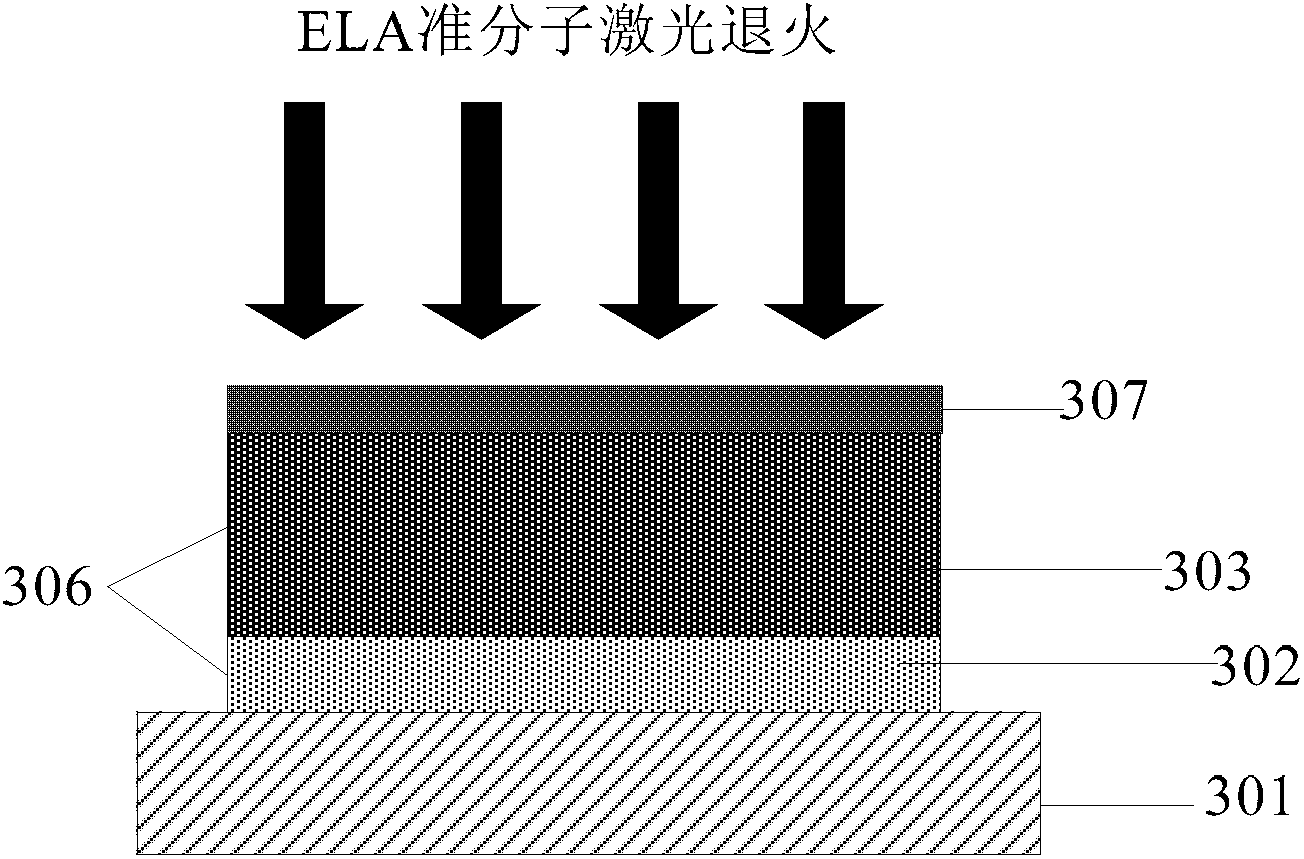

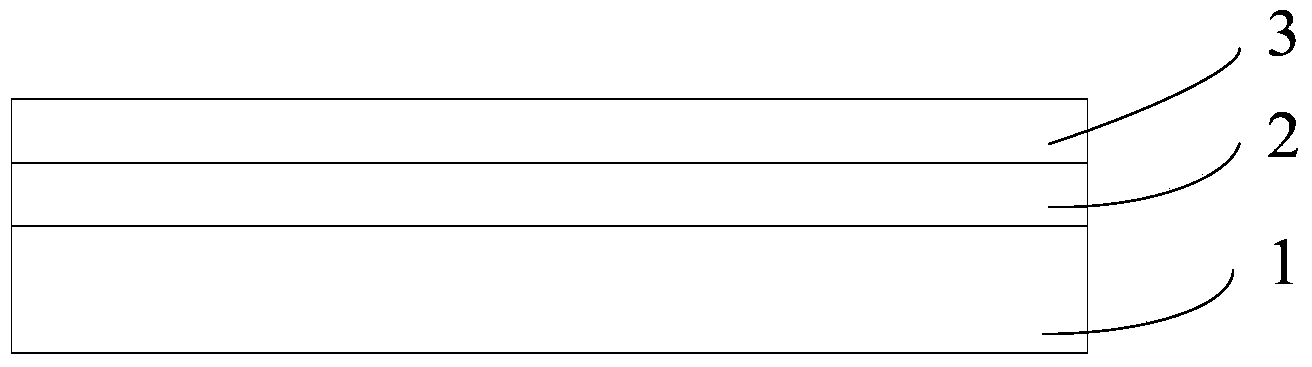

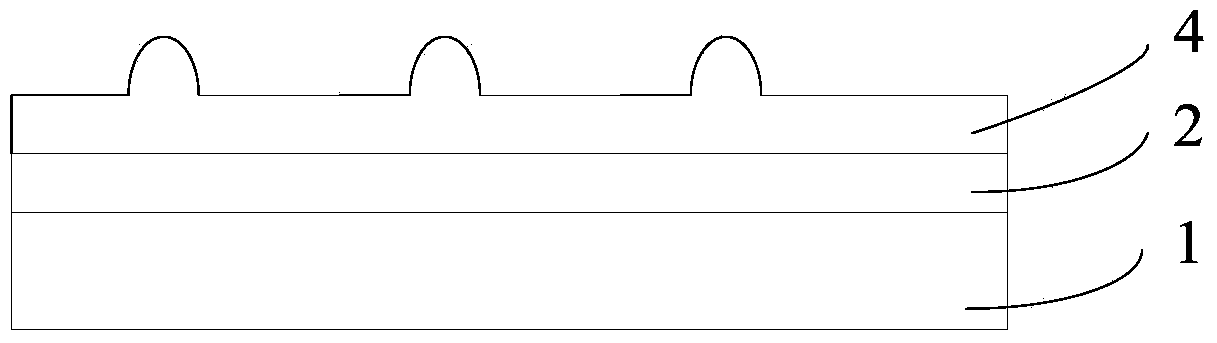

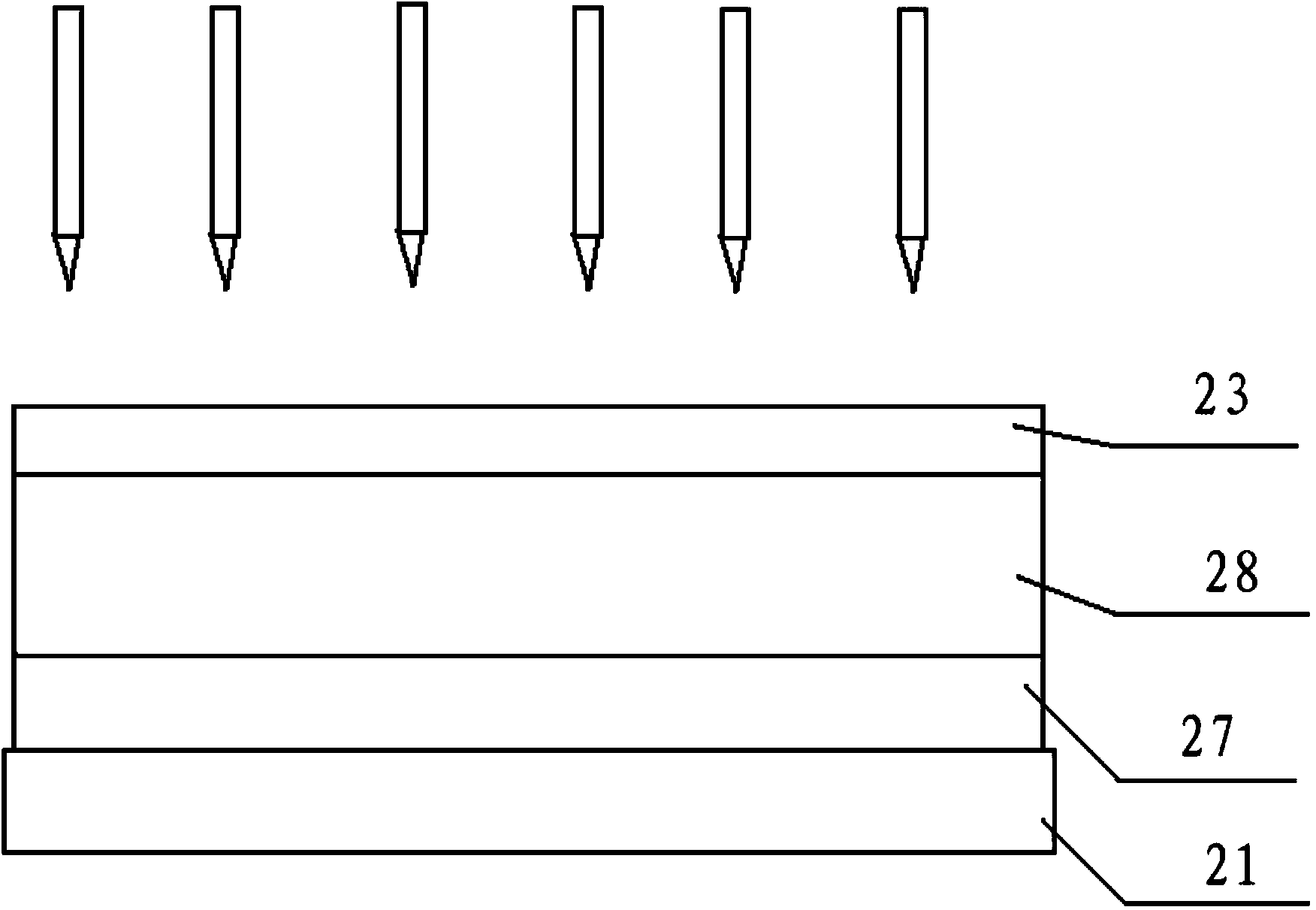

Low-temperature poly-silicon manufacturing method, method for manufacturing TFT substrate by utilization of low-temperature poly-silicon manufacturing method, and TFT substrate structure

InactiveCN104064451AImprove insulation effectReduce the number of grain boundariesTransistorSolid-state devicesEngineeringPre treatment

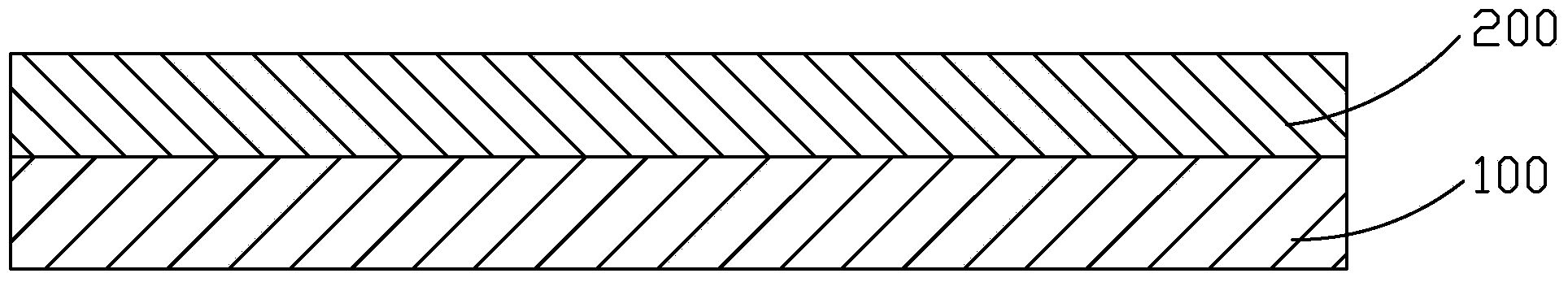

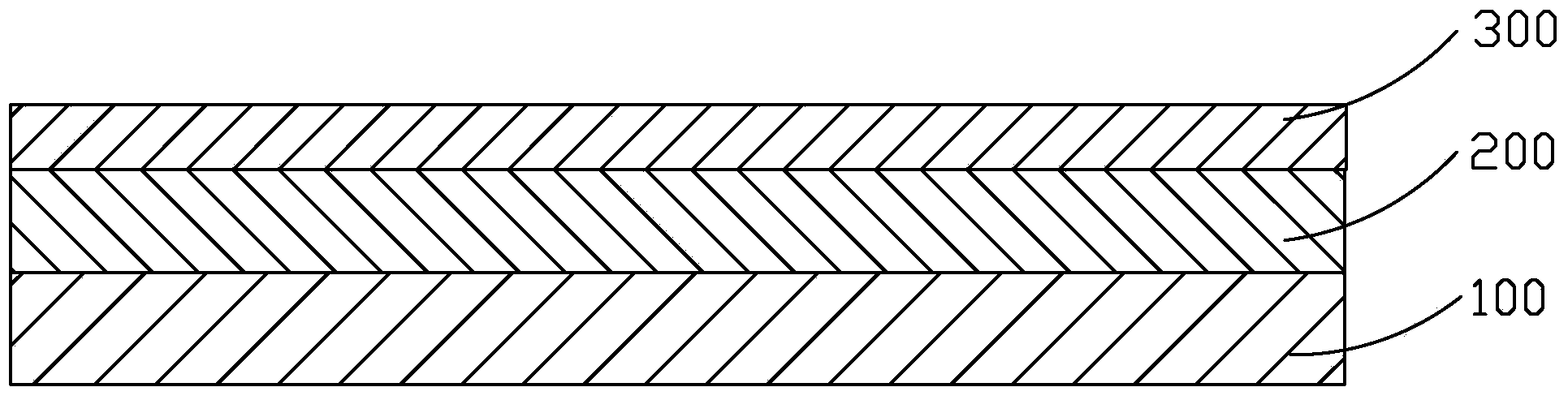

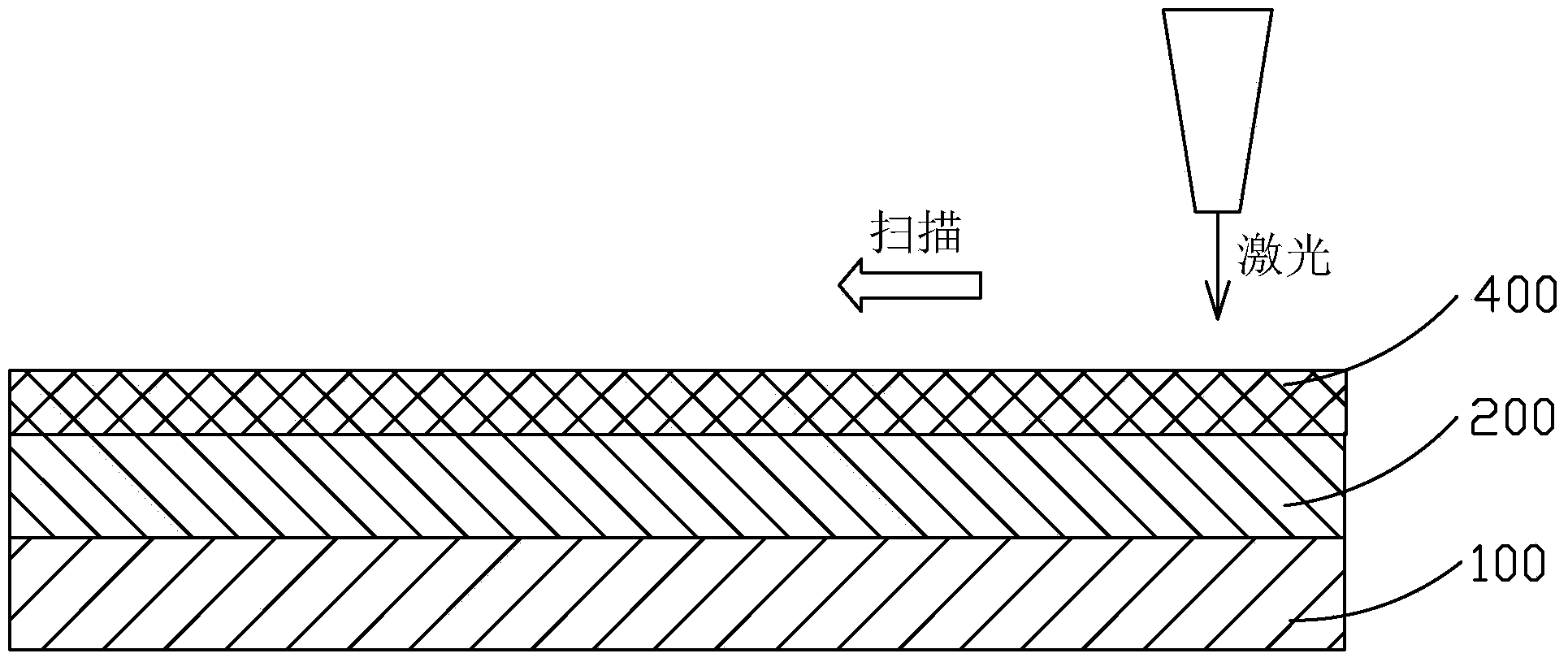

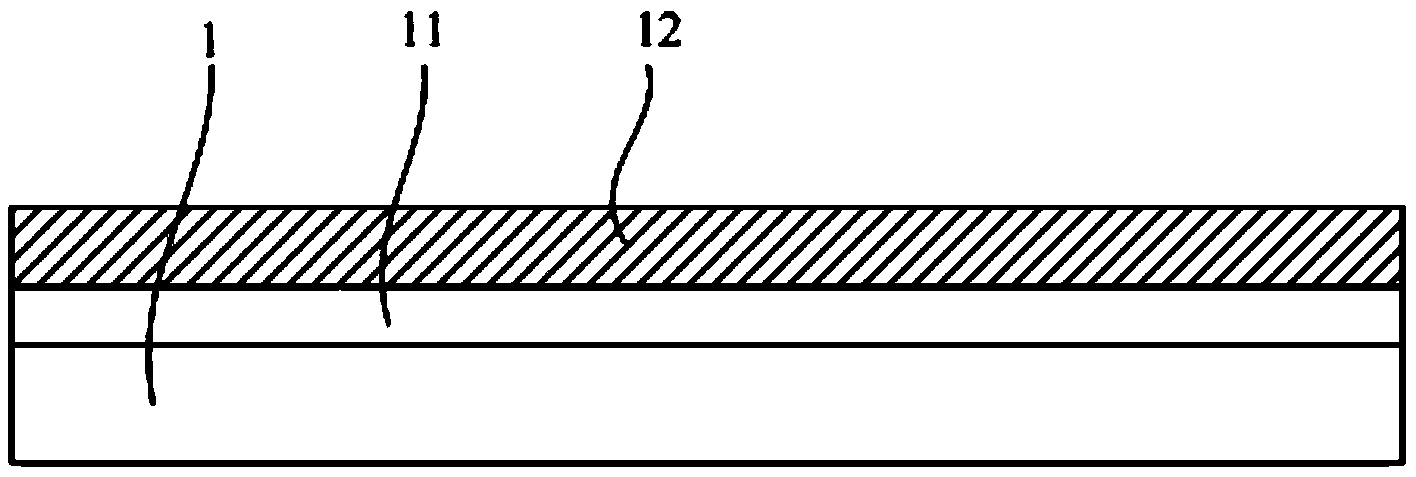

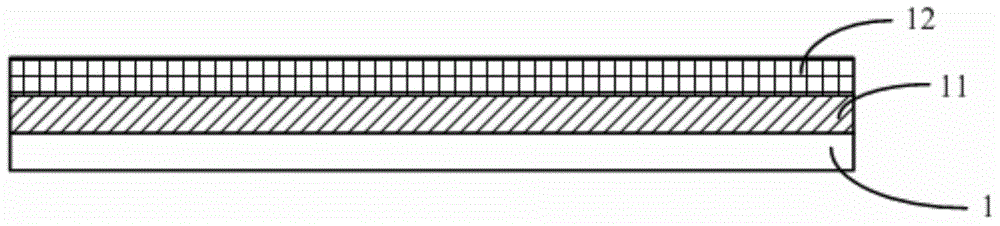

The invention provides a low-temperature poly-silicon manufacturing method, a method for manufacturing a TFT substrate by utilization of the low-temperature poly-silicon manufacturing method, and a TFT substrate structure. The low-temperature poly-silicon manufacturing method comprises the following steps that 1, the substrate (1) is provided; 2, a buffer layer (2) is formed on the substrate (1) in a deposition mode; 3, pattern processing is carried out on the buffer layer (2), and a convex portion (21) and a concave portion (23) which are different in thickness are formed; 4, an amorphous silicon layer (3) is formed on the buffer layer (2) provided with the convex portion (21) and the concave portion (23) in a deposition mode; 5, excimer laser annealing pretreatment is carried out on the amorphous silicon layer (3); 6, excimer laser annealing is carried out on the amorphous silicon layer (3), the whole surface of the amorphous silicon layer (3) is scanned through laser beams, and the amorphous silicon layer (3) is made to melt and is recrystallized to form a poly-silicon layer (4). The method can effectively control the crystallization position and crystallization direction when the amorphous silicon layer is recrystallized.

Owner:TCL CHINA STAR OPTOELECTRONICS TECH CO LTD

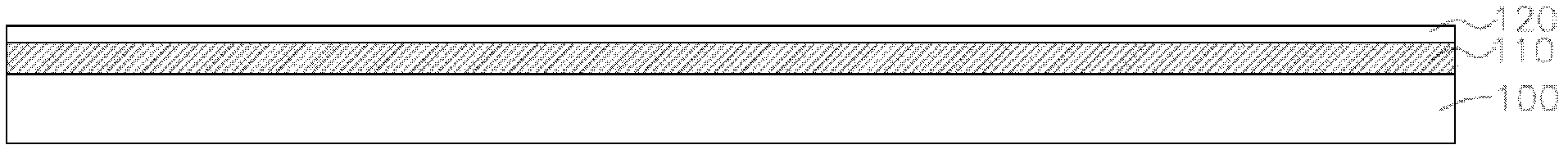

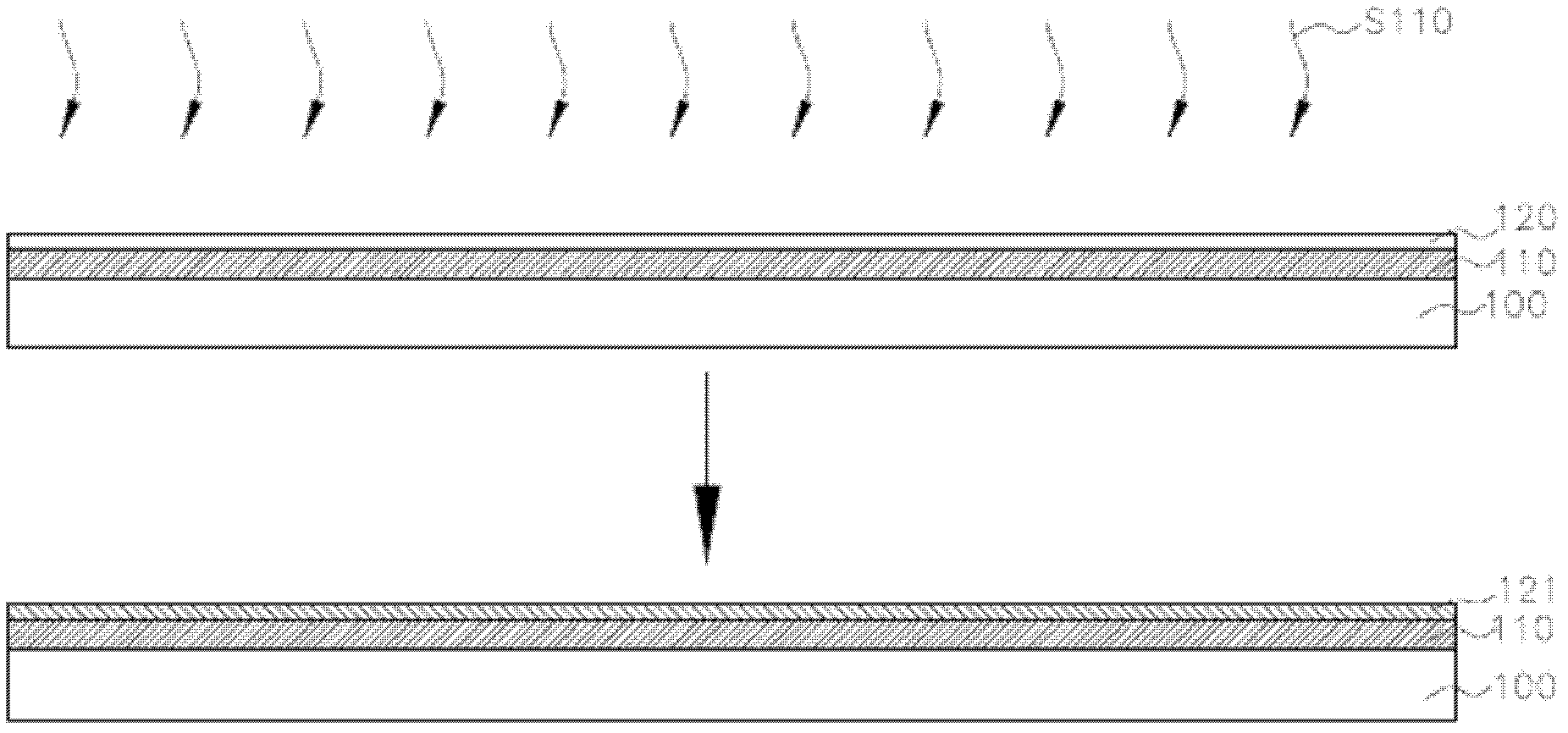

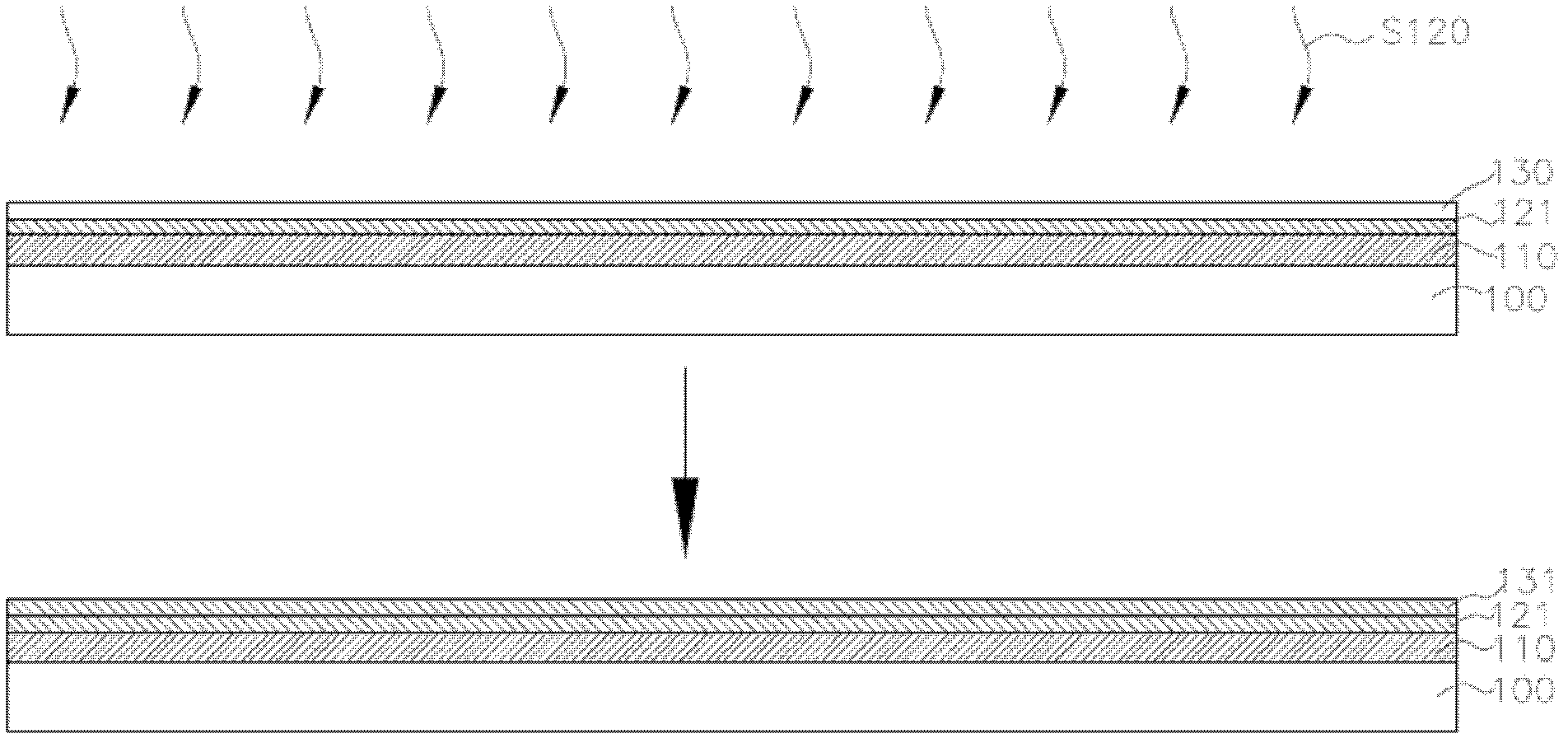

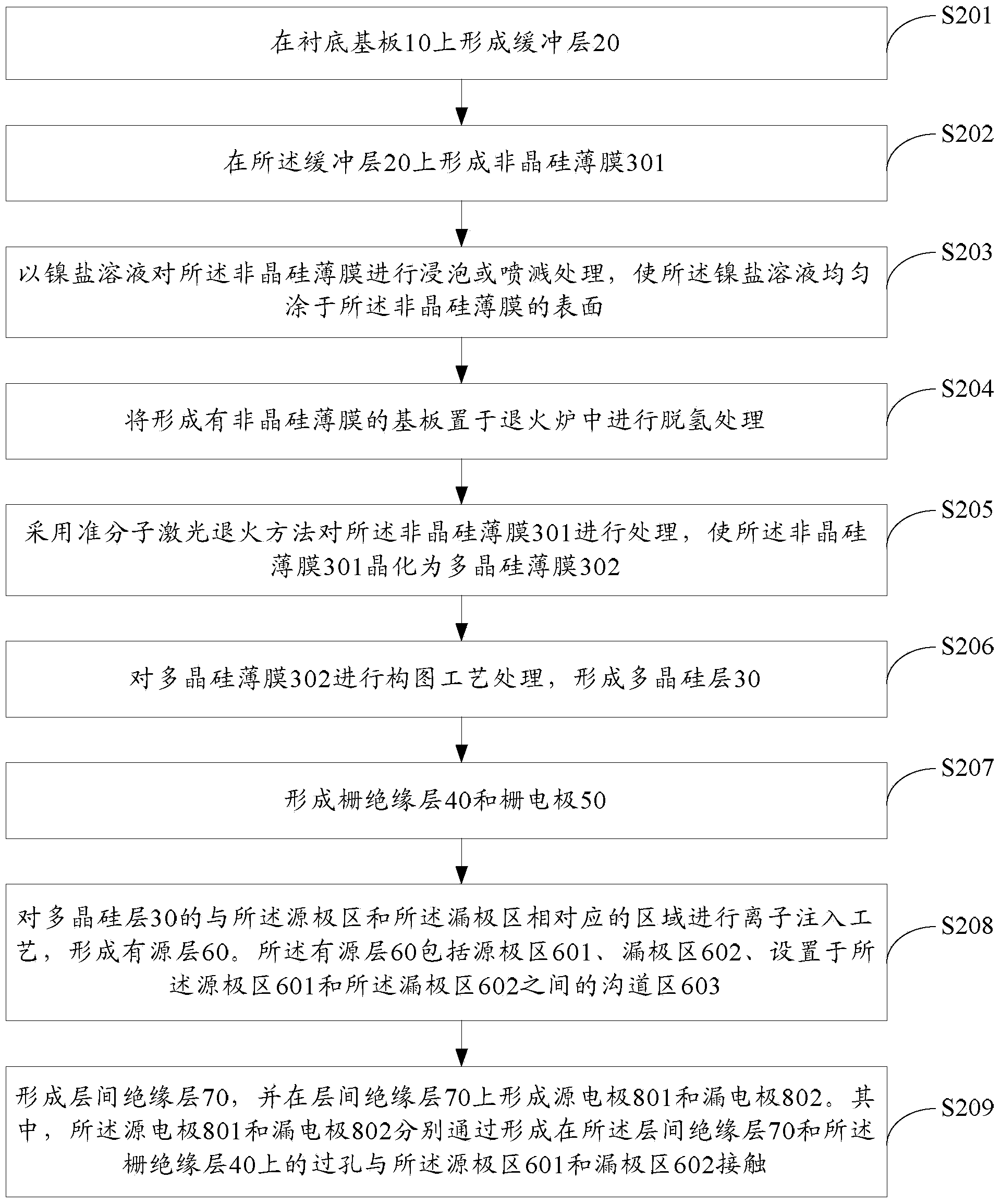

Preparation method of polycrystalline silicon thin film, polycrystalline silicon thin film transistor and array substrate

The embodiment of the invention provides a preparation method of a polycrystalline silicon thin film, a polycrystalline silicon thin film transistor and an array substrate and relates to the technical field of display. By means of the preparation method, polycrystalline silicon crystals are uniform, the grain size is increased, crystal quality is improved, and therefore the electrical properties of the thin film transistor are improved. The preparation method of the polycrystalline silicon thin film comprises the steps that an amorphous silicon thin film is formed on a substrate; the amorphous silicon thin film is treated through an excimer laser annealing method, so that the amorphous silicon thin film is crystallized into the polycrystalline silicon thin film. Furthermore, after the amorphous silicon thin film is formed and before the amorphous silicon thin film is treated though the excimer laser annealing method, the preparation method further comprises the steps that the surface of the amorphous silicon thin film is subjected to nickel salt solution treatment, so that a nickel salt solution is uniformly smeared on the surface of the amorphous silicon thin film. The method is used for preparation of the polycrystalline silicon thin film, the low-temperature polycrystalline silicon thin film transistor and the array substrate requiring that the uniformity of the polycrystalline silicon crystals is improved, the grain size is increased, and crystal quality is improved.

Owner:BOE TECH GRP CO LTD

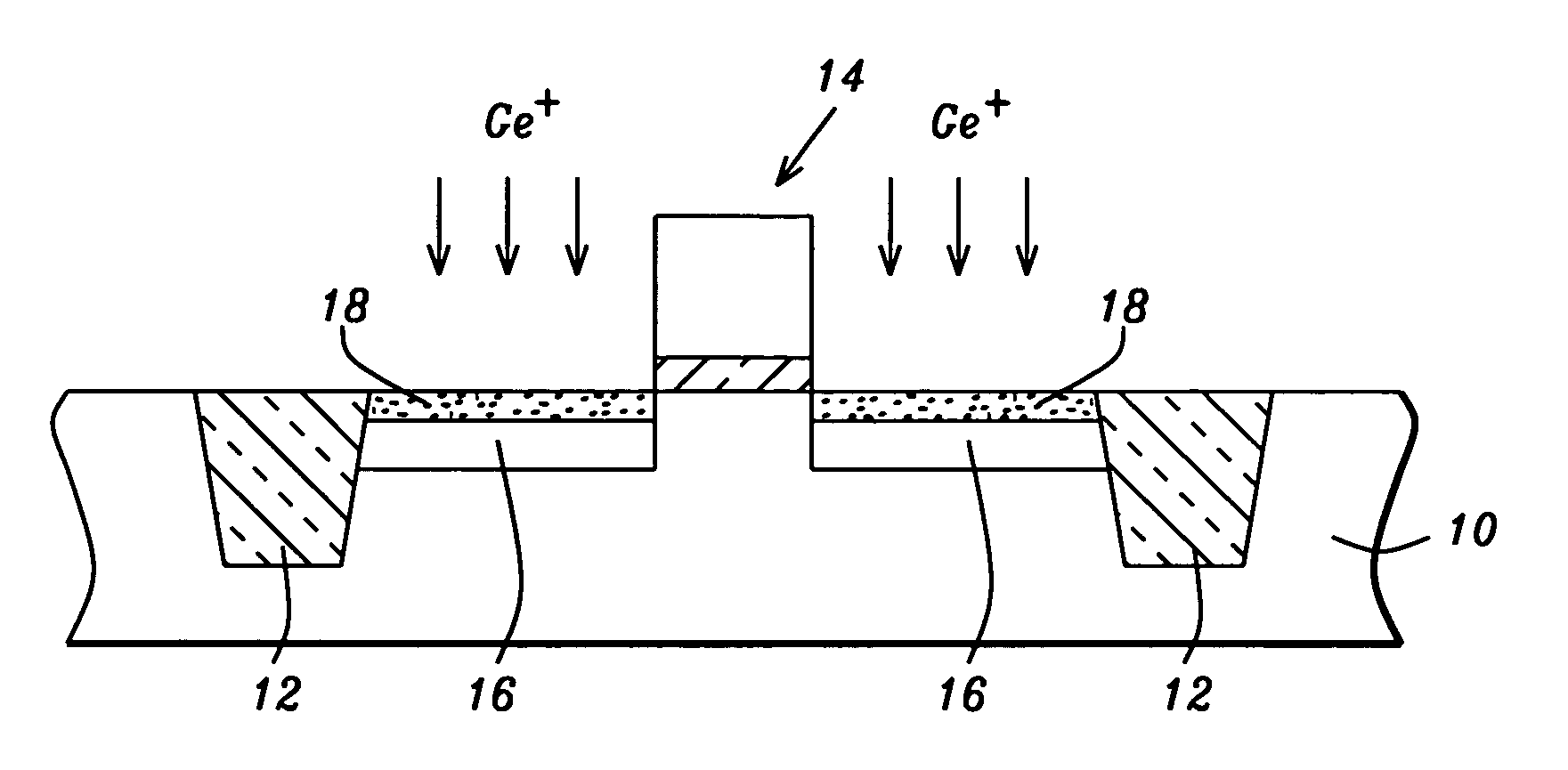

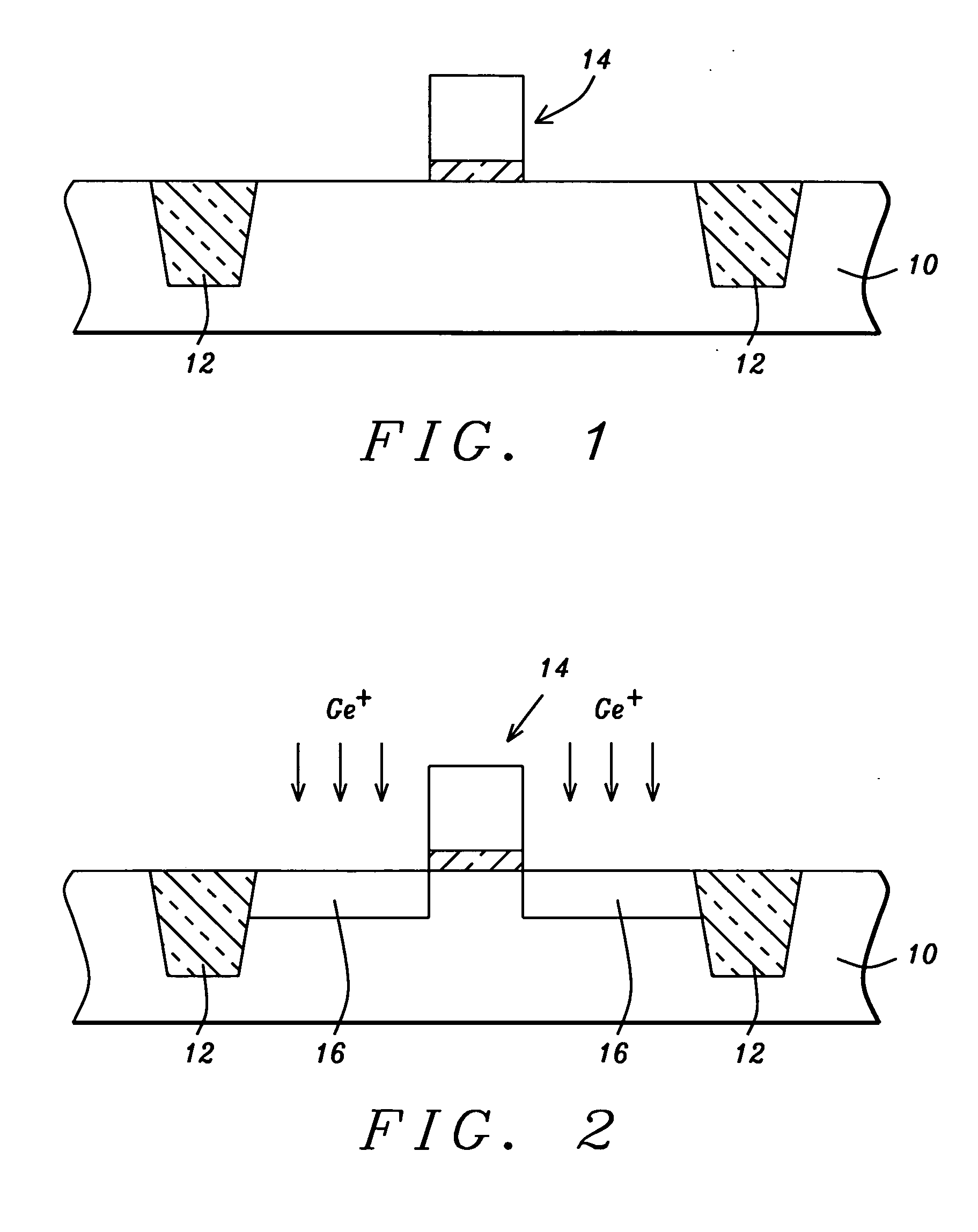

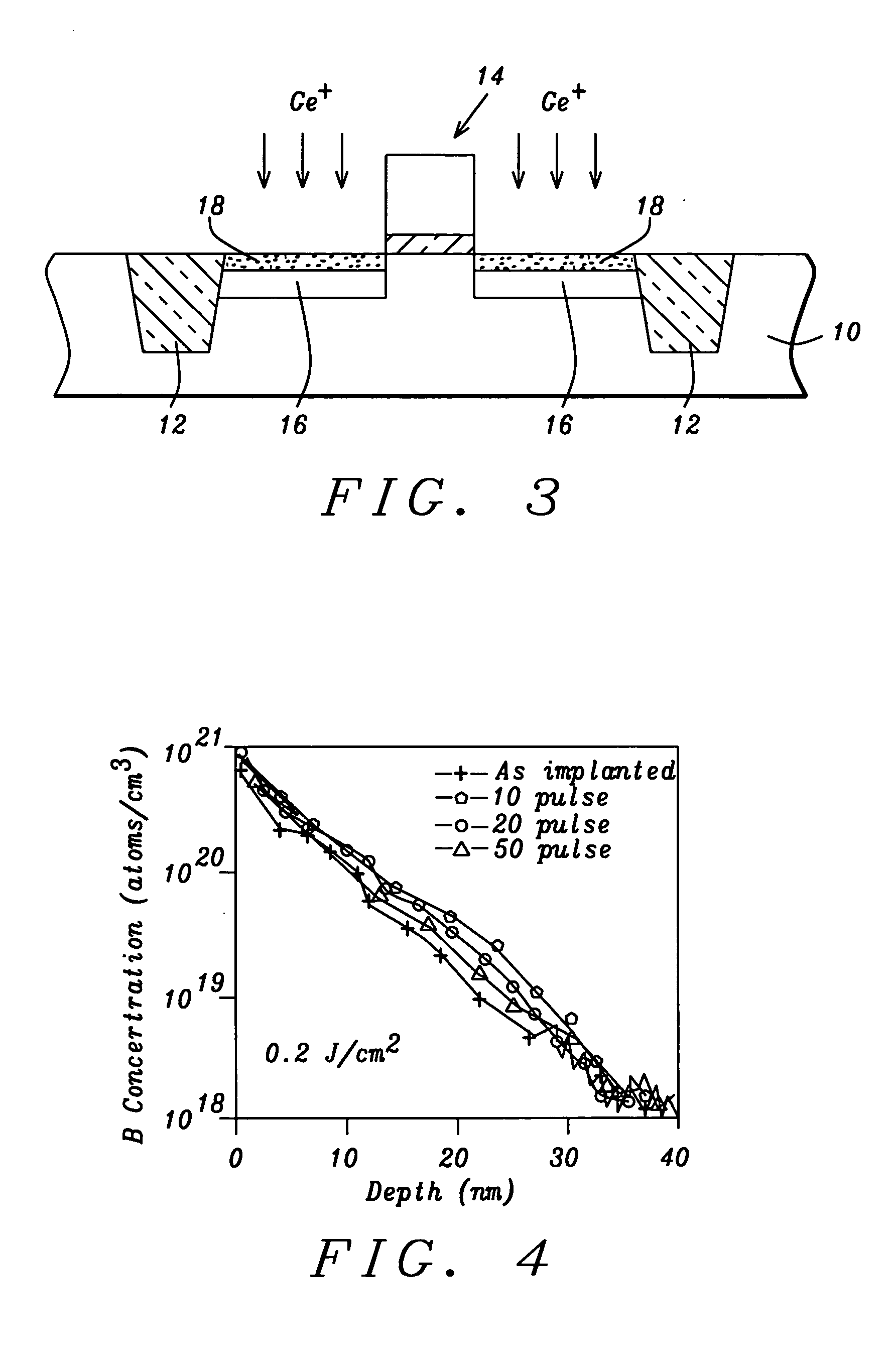

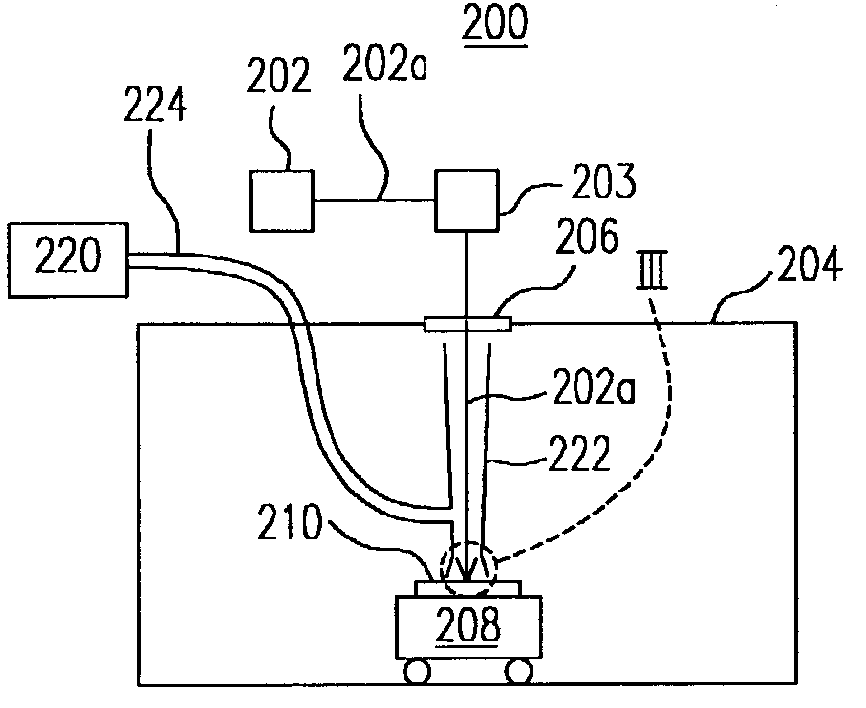

Dual step source/drain extension junction anneal to reduce the junction depth: multiple-pulse low energy laser anneal coupled with rapid thermal anneal

InactiveUS20050158956A1Reduce sheet resistanceShallow junctionSemiconductor/solid-state device manufacturingMOSFETDevice material

A process is described to form a semiconductor device such as MOSFET or CMOS with shallow junctions in the source / drain extension regions. After forming the shallow trench isolations and the gate stack, sidewall dielectric spacers are removed. A pre-amorphizing implant (PAI) is performed with Ge+ or Si+ ions to form a thin PAI layer on the surface of the silicon regions adjacent to the gate stack. B+ ion implantation is then performed to form source / drain extension (SDE) regions. The B+ implant step is then followed by multiple-pulsed 248 nm KrF excimer laser anneal with pulse duration of 23 ns. This step is to reduce the sheet resistance of the junction through the activation of the boron dopant in the SDE junctions. Laser anneal is then followed by rapid thermal anneal (RTA) to repair the residual damage and also to induce out-diffusion of the boron to yield shallower junctions than the just-implanted junctions prior to RTA.

Owner:CHARTERED SEMICONDUCTOR MANUFACTURING

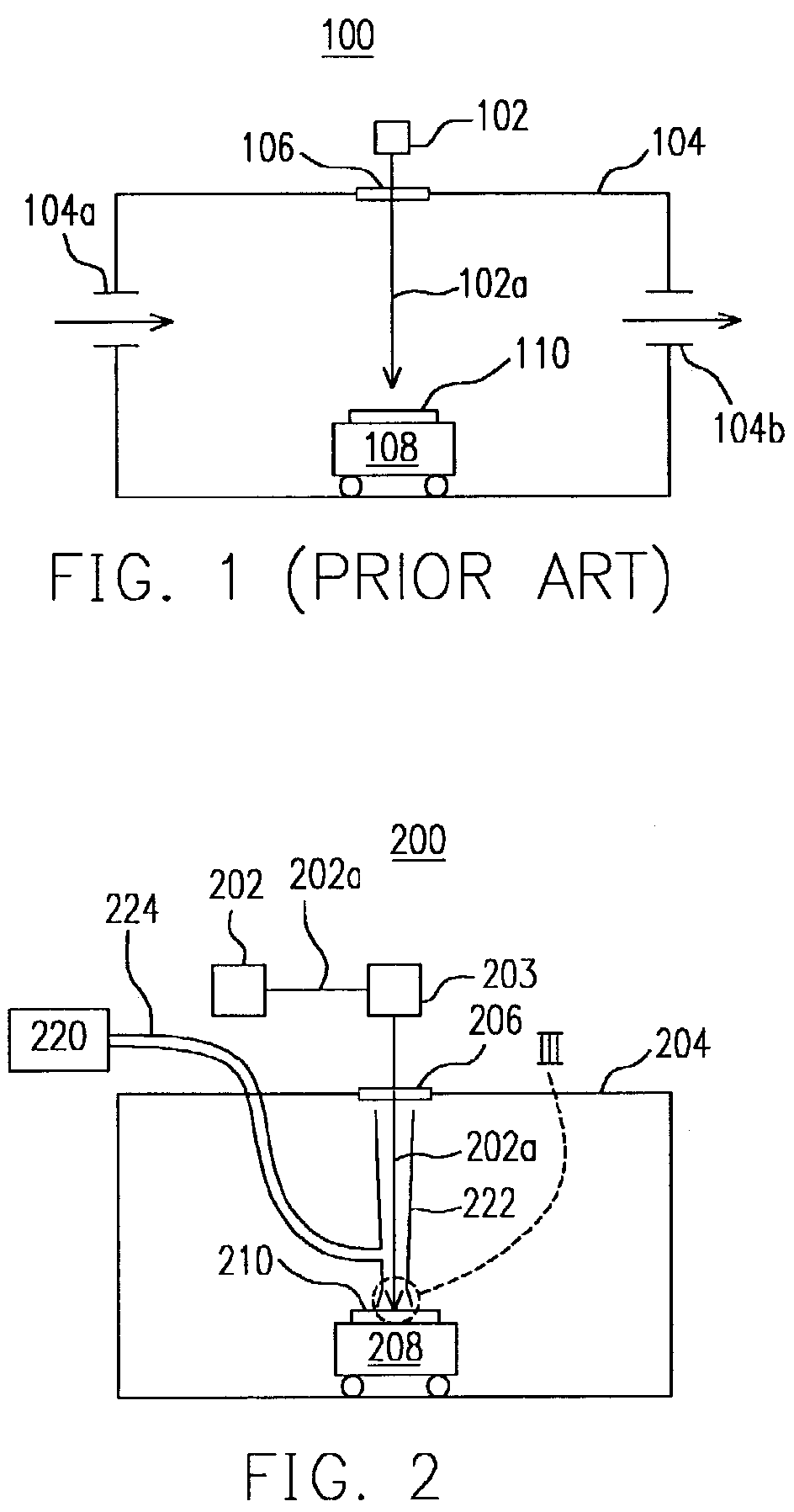

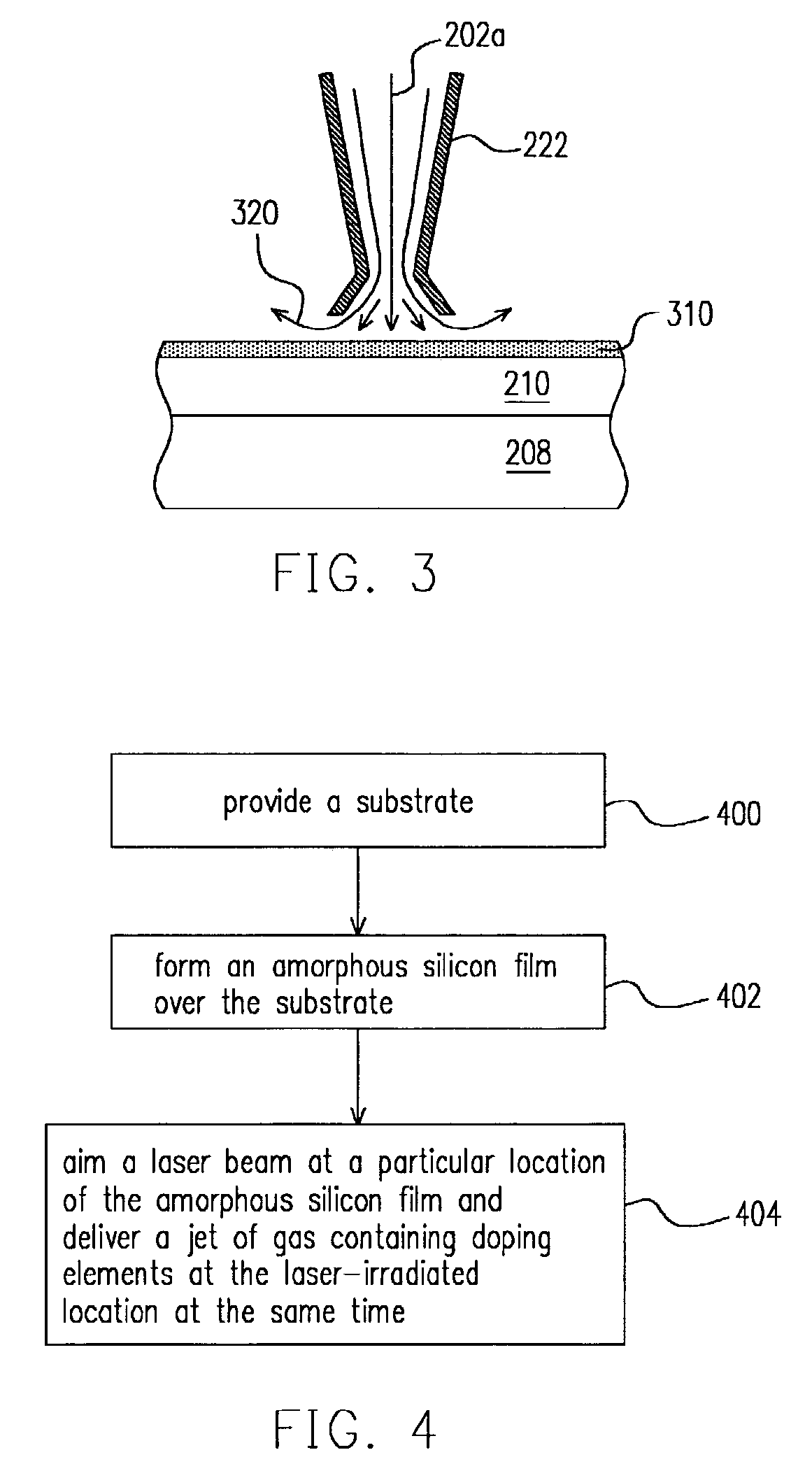

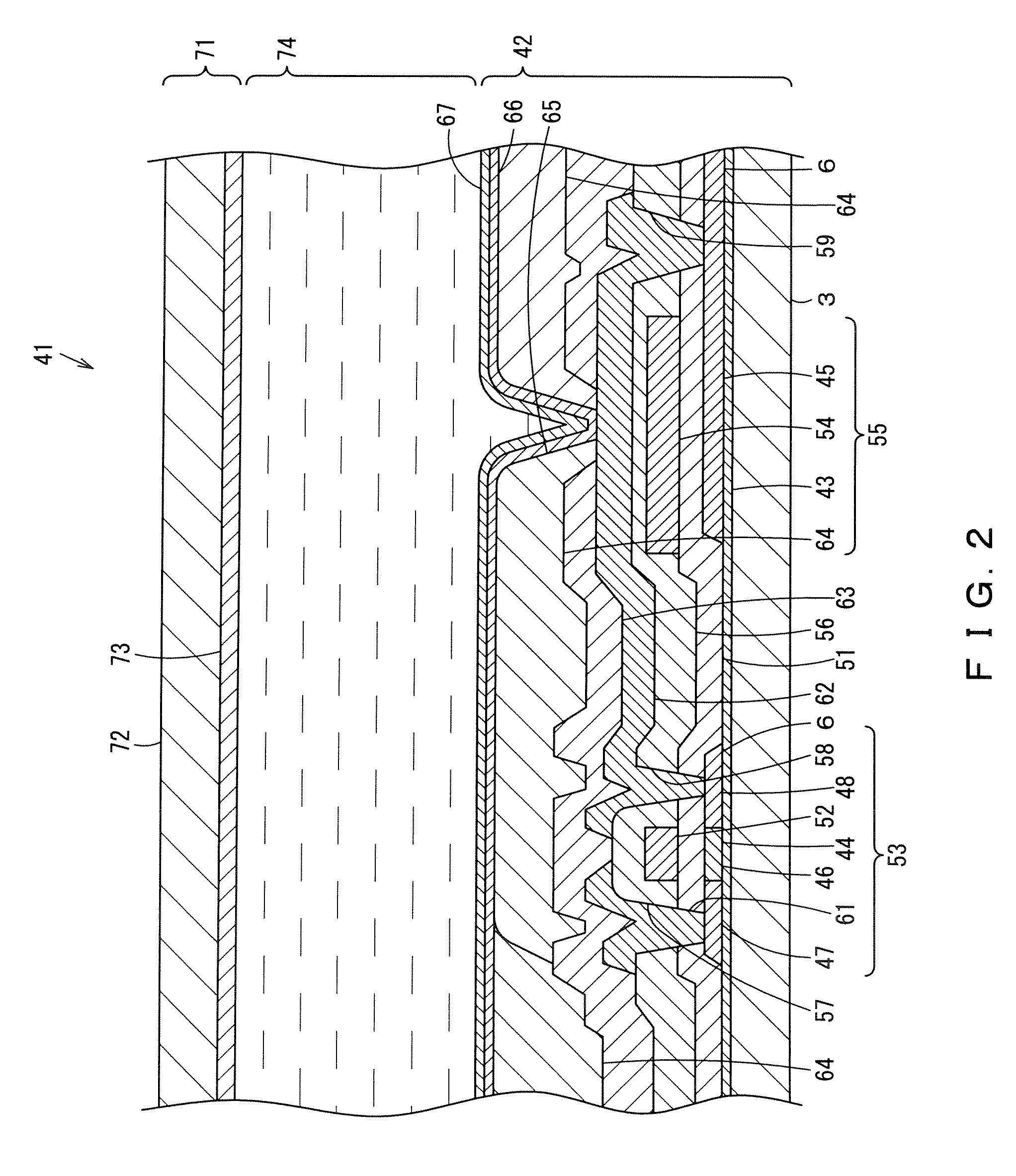

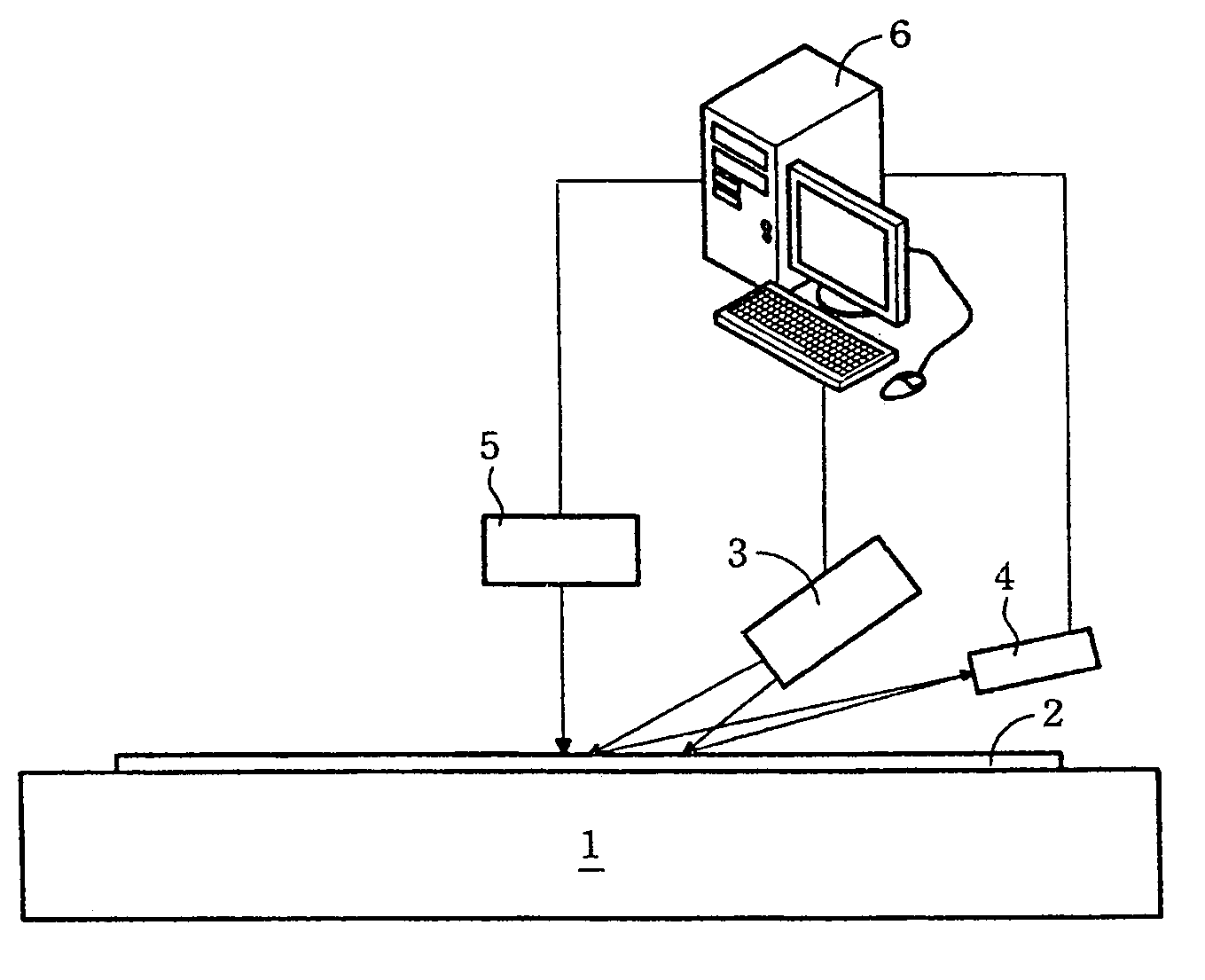

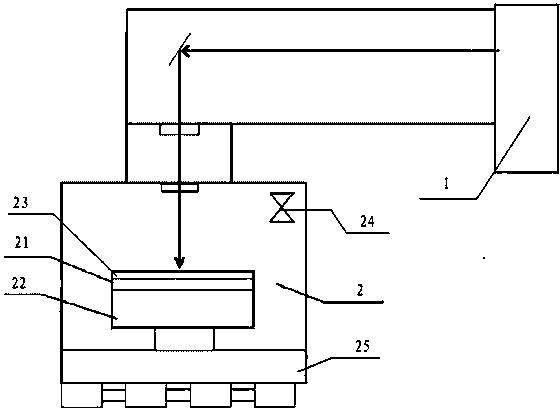

Laser annealing apparatus

ActiveUS7247812B2Minimize changesImprove accuracySemiconductor/solid-state device manufacturingChemical vapor deposition coatingOptoelectronicsGas supply

An excimer laser annealing apparatus and the application of the same for stabilizing the atmosphere surrounding an area irradiated by an excimer laser. The apparatus includes a chamber, a gas diversion nozzle, an excimer laser and a gas supply device. The gas diversion nozzle is positioned inside the chamber. The laser beam produced by the excimer laser passes through the gas diversion nozzle. The gas supply device connects with the gas diversion nozzle for providing a jet of gas to the laser-irradiated area and carrying away any pollutants from the irradiated area.

Owner:AU OPTRONICS CORP

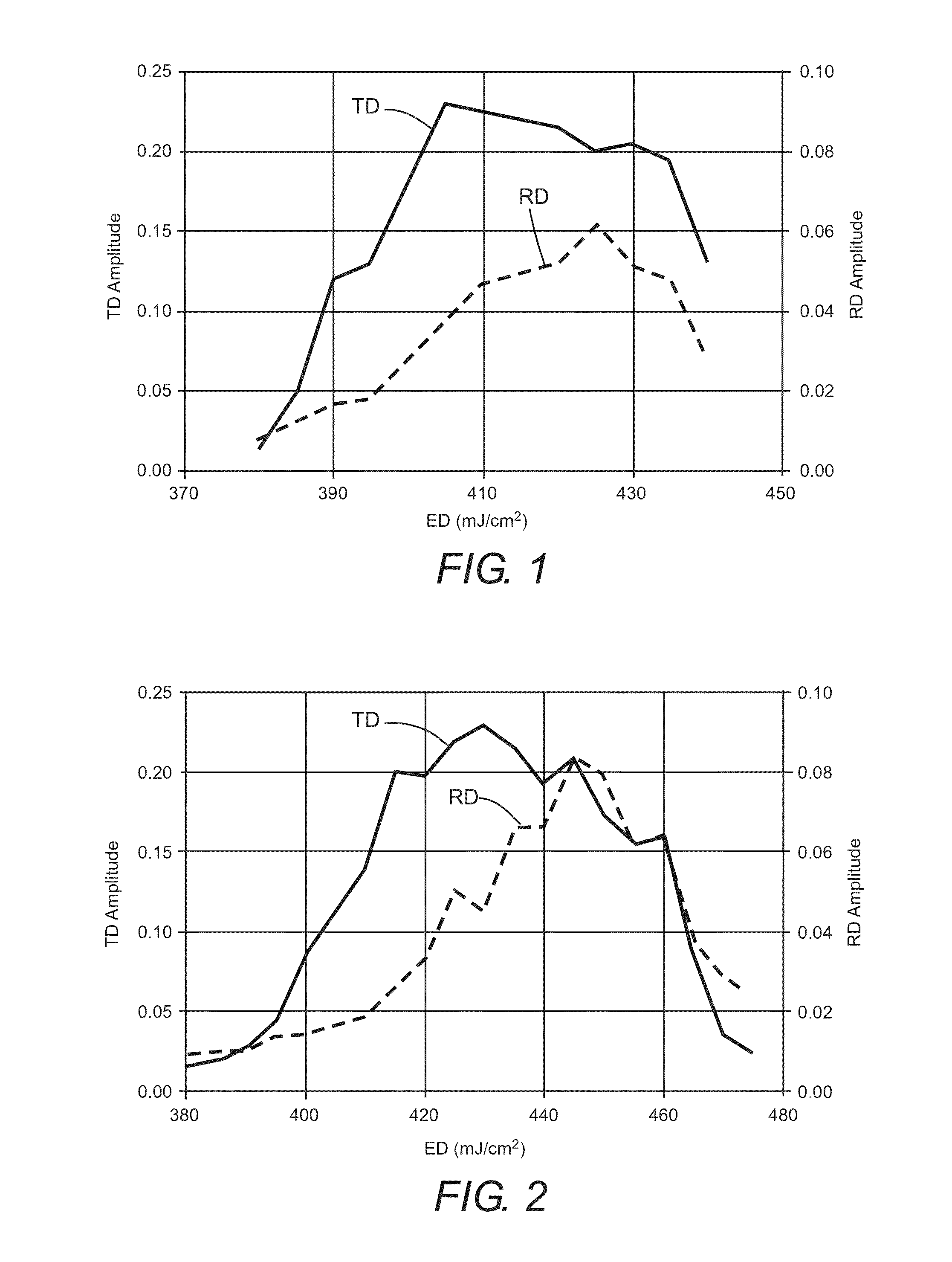

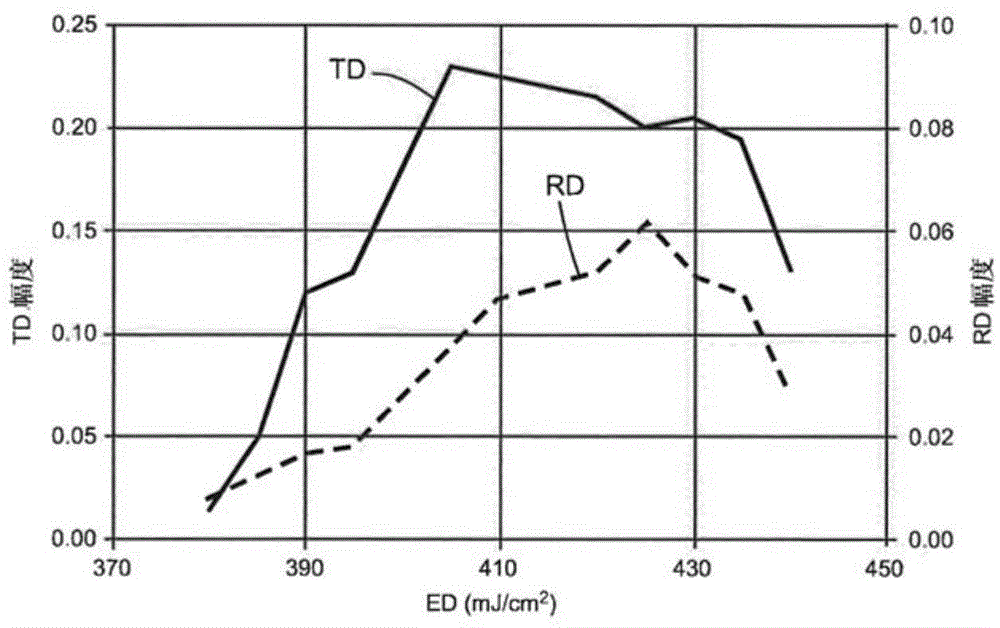

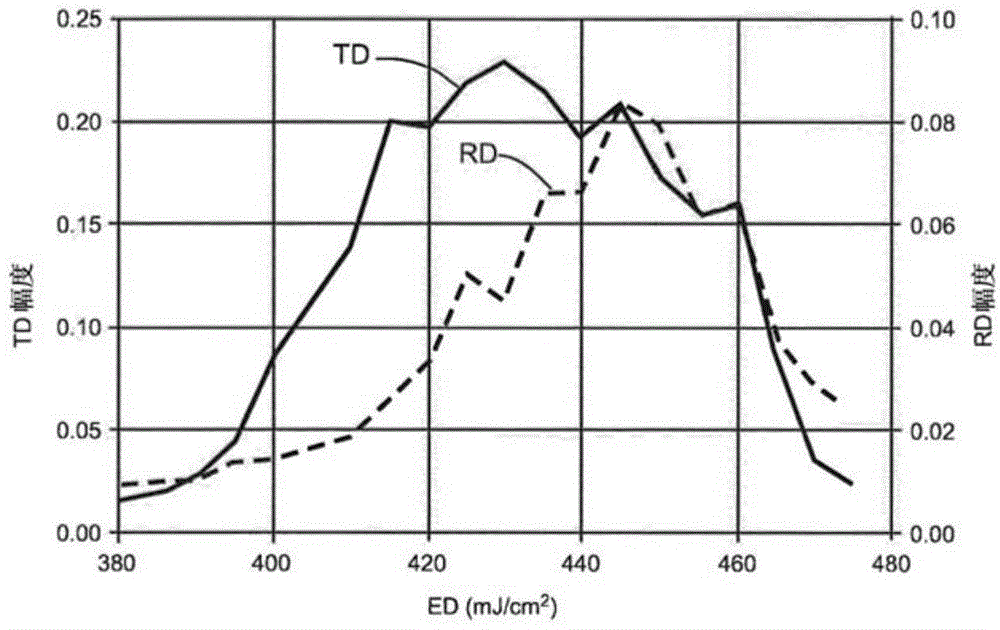

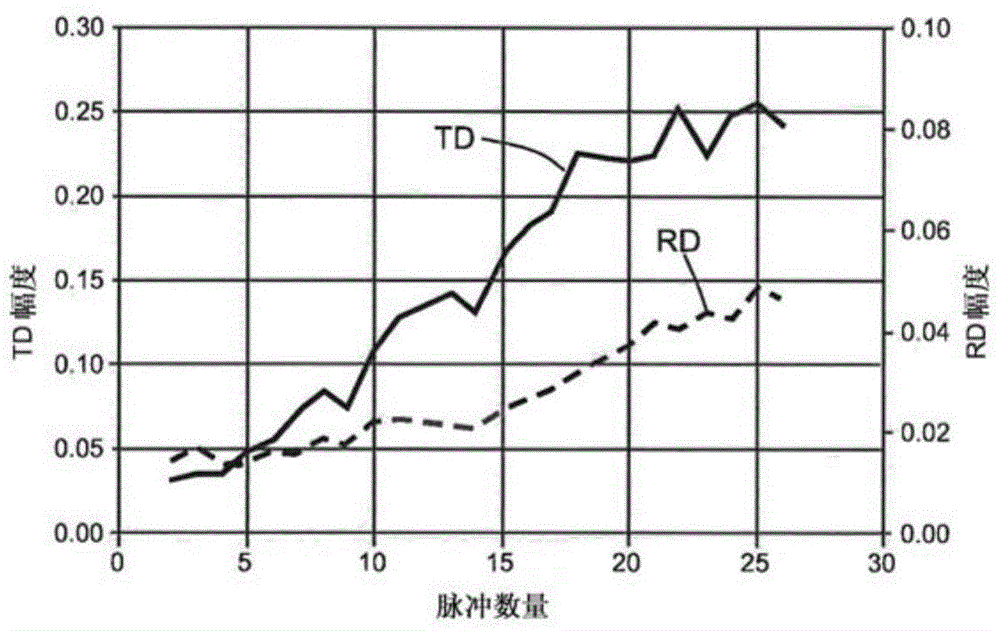

Monitoring method and apparatus for control of excimer laser annealing

ActiveUS20150247808A1Investigating semiconductor impuritiesPolycrystalline material growthIrradiationMonitoring methods

A method is disclosed evaluating a silicon layer crystallized by irradiation with pulses form an excimer-laser. The crystallization produces periodic features on the crystalized layer dependent on the number of and energy density ED in the pulses to which the layer has been exposed. An area of the layer is illuminated with light. A microscope image of the illuminated area is made from light diffracted from the illuminated are by the periodic features. The microscope image includes corresponding periodic features. The ED is determined from a measure of the contrast of the periodic features in the microscope image.

Owner:COHERENT LASERSYST

Low-temp. polycrystalline silicon film transistor and its polycrystalline silicon layer making method

InactiveCN1536620AImprove featuresStatic indicating devicesSemiconductor/solid-state device manufacturingLow leakageHigh electron

The invention provides a low-temperature polycrystalline silicon film transistor and its polycrystalline silicon layer making method. First, form a noncrystalline silicon layer on a panel which including a display region and a peripheral circuit region. Then, form a metal layer on a part of the noncrystalline silicon layer in peripheral circuit region, then crystallize to make the other part form a polycrystalline silicon layer. Successively, make a quasi-molecular laser annealing processing to largen the crystal particles on the polycrystalline silicon layer and make the noncrystalline silicon layer in the display region into a polycrystalline silicon layer. Because the crystal particles of polycrystalline silicon in the peripheral circuit region are larger than those in the other parts, it can meet the demand of high-electron mobility. And because the crystal particles of polycrystalline silicon are smaller, it can meet the demand of low-leakage current.

Owner:AU OPTRONICS CORP

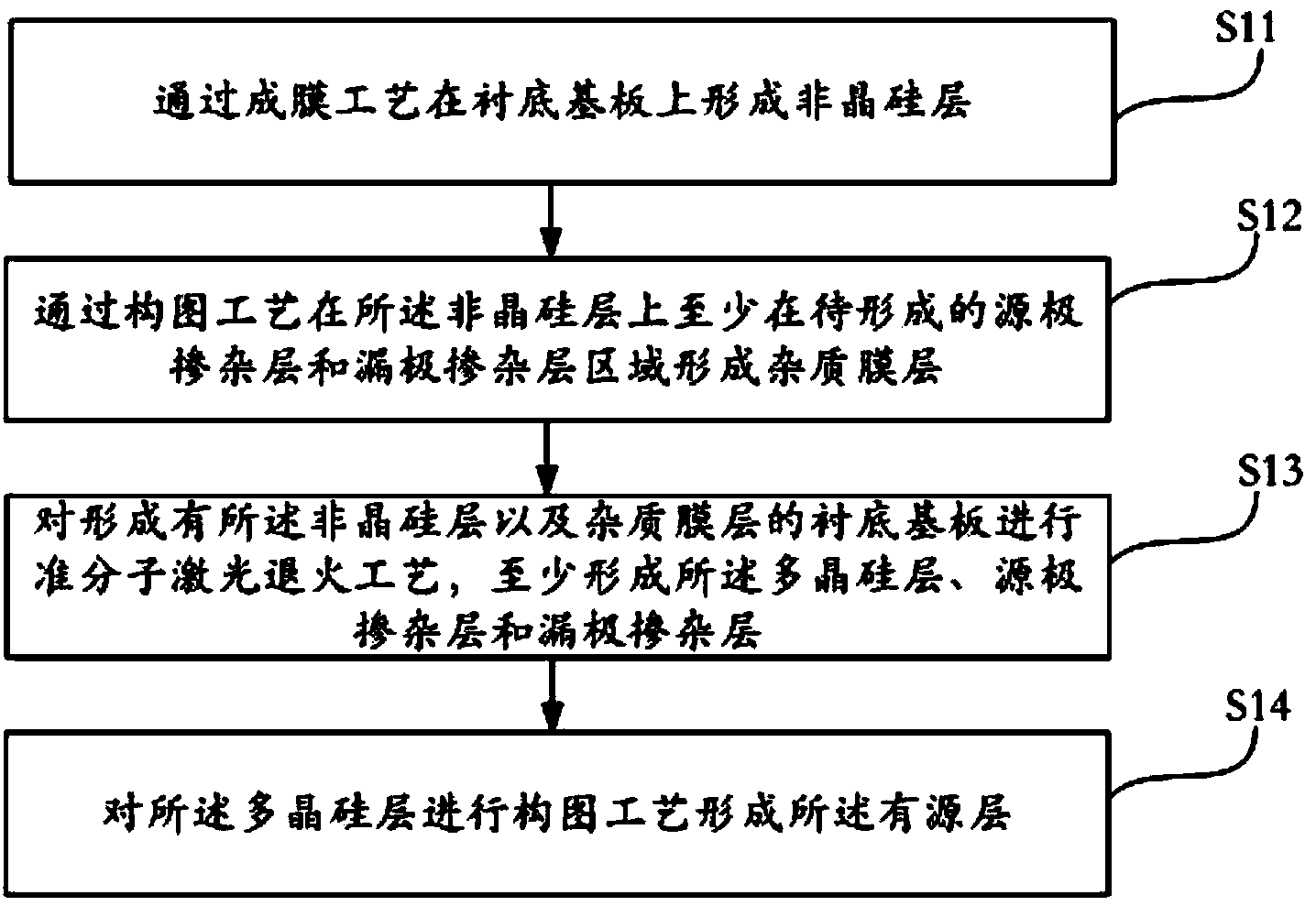

Low-temperature polycrystalline silicon thin film transistor, array substrate and manufacturing method of array substrate

ActiveCN103839826AAvoid defectsImprove performanceTransistorSolid-state devicesComposition processOptoelectronics

The invention discloses a low-temperature polycrystalline silicon thin film transistor, an array substrate and a manufacturing method of the array substrate, so that manufacturing process procedures of the thin film transistor are simplified. The method includes the process that an active layer, a source electrode doping layer and a drain electrode doping layer are formed on a substrate, wherein the process that the active layer, the source electrode doping layer and the drain electrode doping layer are formed on the substrate includes the steps of forming an amorphous silicon layer on the substrate through a film forming technology, forming impurity film layers on at least a source electrode doping layer to be formed and a drain electrode doping layer to be formed on the amorphous silicon layer through a composition process, carrying out the excimer laser annealing process on the substrate provided with the amorphous silicon layer and the impurity film layers to at least form the polycrystalline silicon layer, the source electrode doping layer and the drain electrode doping layer, and the composition process is carried out on the polycrystalline silicon layer to form the active layer.

Owner:BOE TECH GRP CO LTD

Making method for organic EL part and image display system

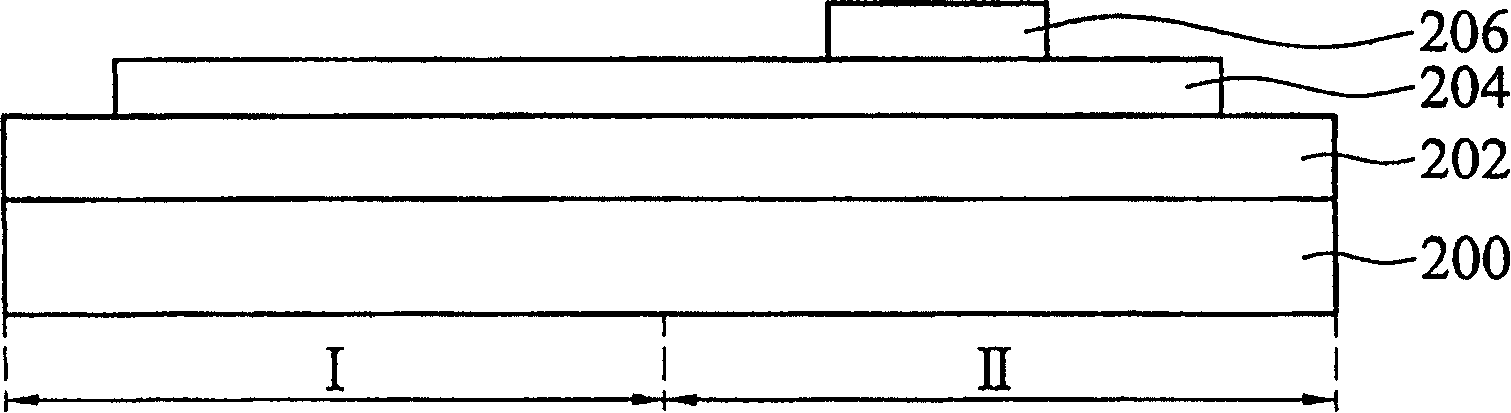

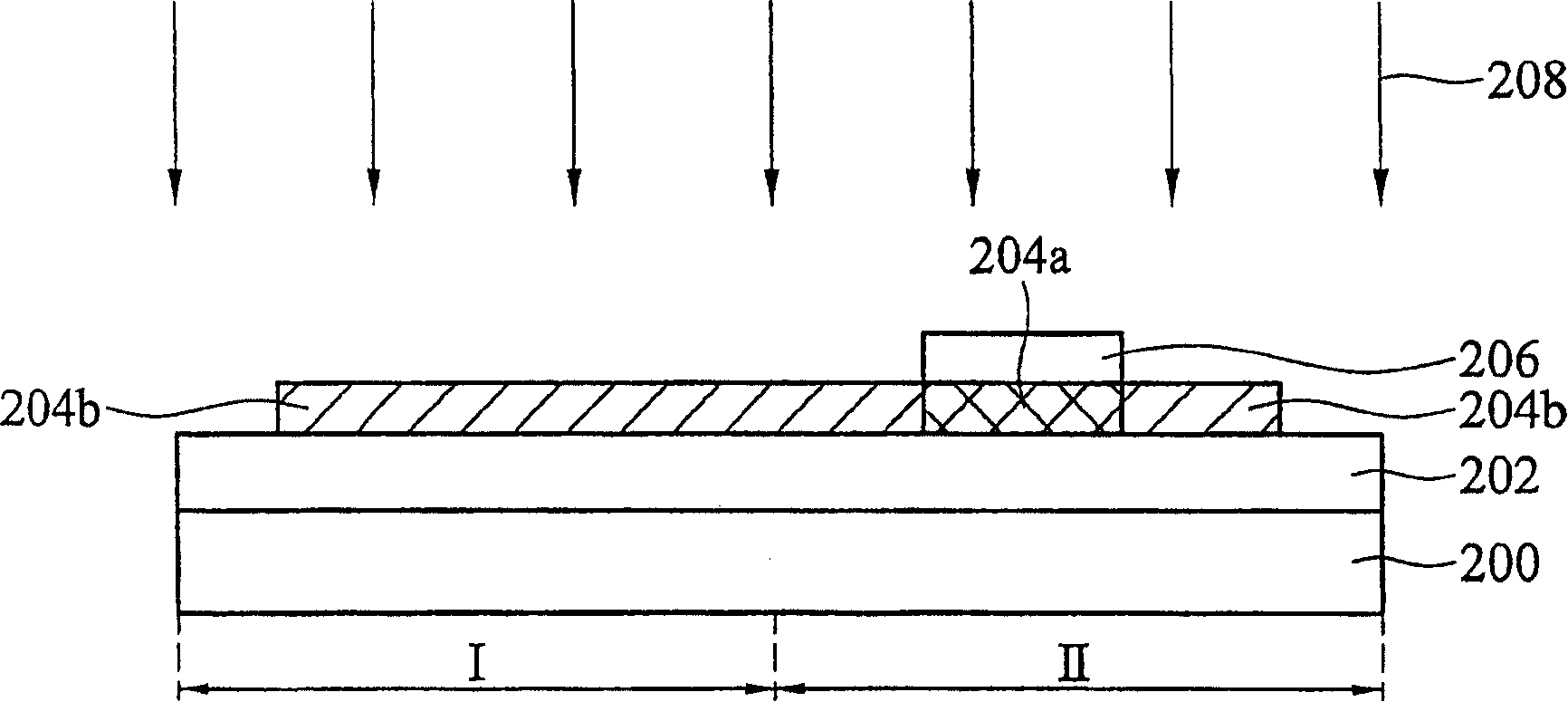

ActiveCN101170076AImprove the problem of excessive electrical differenceIncrease opening ratioSolid-state devicesSemiconductor/solid-state device manufacturingTectorial membraneEffect light

The invention relates to a method of manufacturing an organic electrization lighting component. The invention includes the steps of providing a base plate, including a first component area and a second component area; forming an amorphous silicon layer above the base plate; forming a protection film above the partial amorphous silicon layer in the second component area; performing excimer laser annealing process on the amorphous silicon layer, in order to convert the amorphous layer to a polycrystalline silicon layer; removing the protection film; patterning the amorphous silicon layer to form a first patterning polycrystalline silicon layer in the first component area and a second patterning polycrystalline silicon layer in the second component area, wherein, the grain size of the first patterning polycrystalline silicon layer is greater than the second patterning polycrystalline silicon layer, forming the organic electrization lighting component.

Owner:INNOLUX CORP

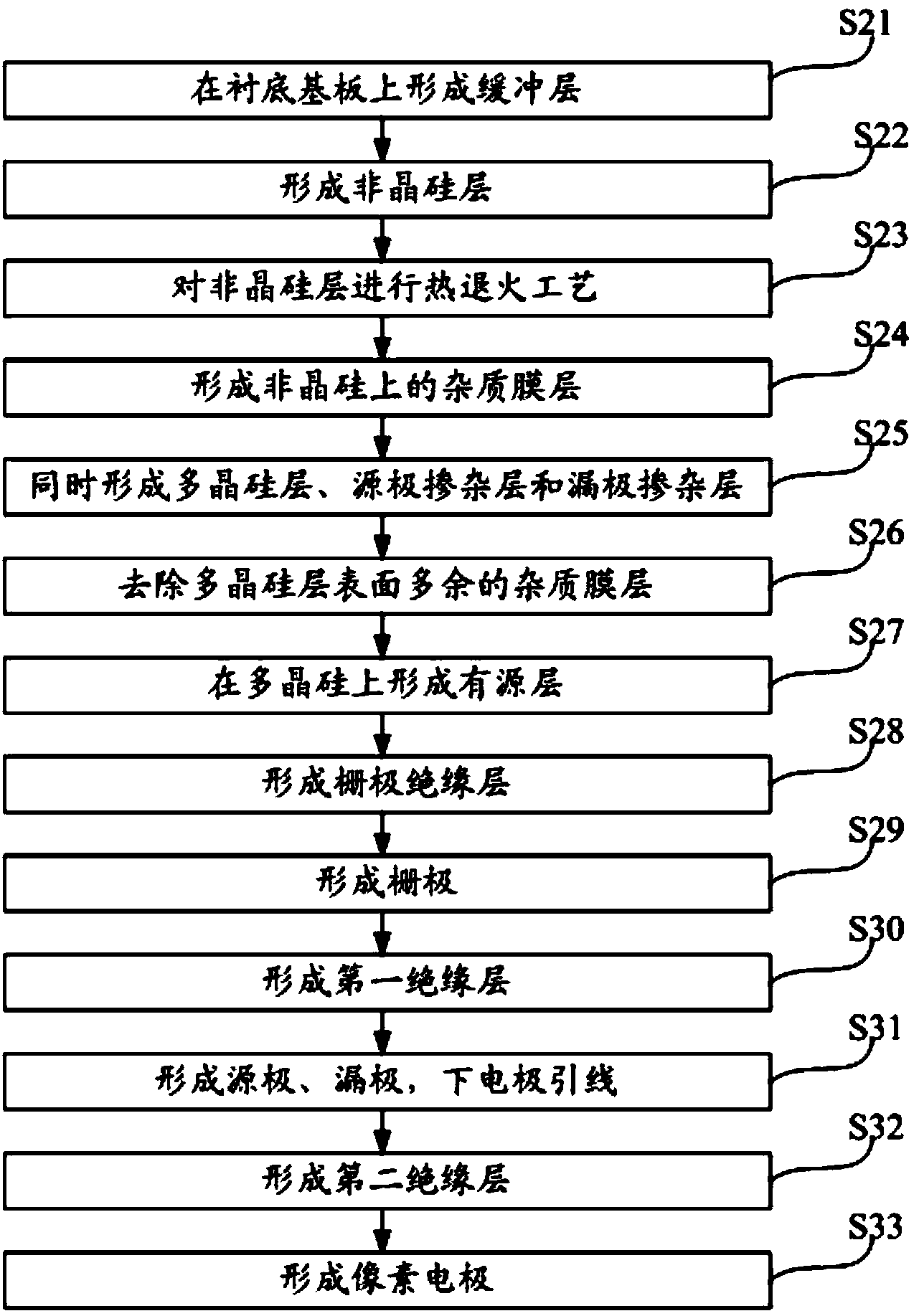

Low-temperature polycrystalline silicon thin film transistor, array substrate and manufacturing method of array substrate

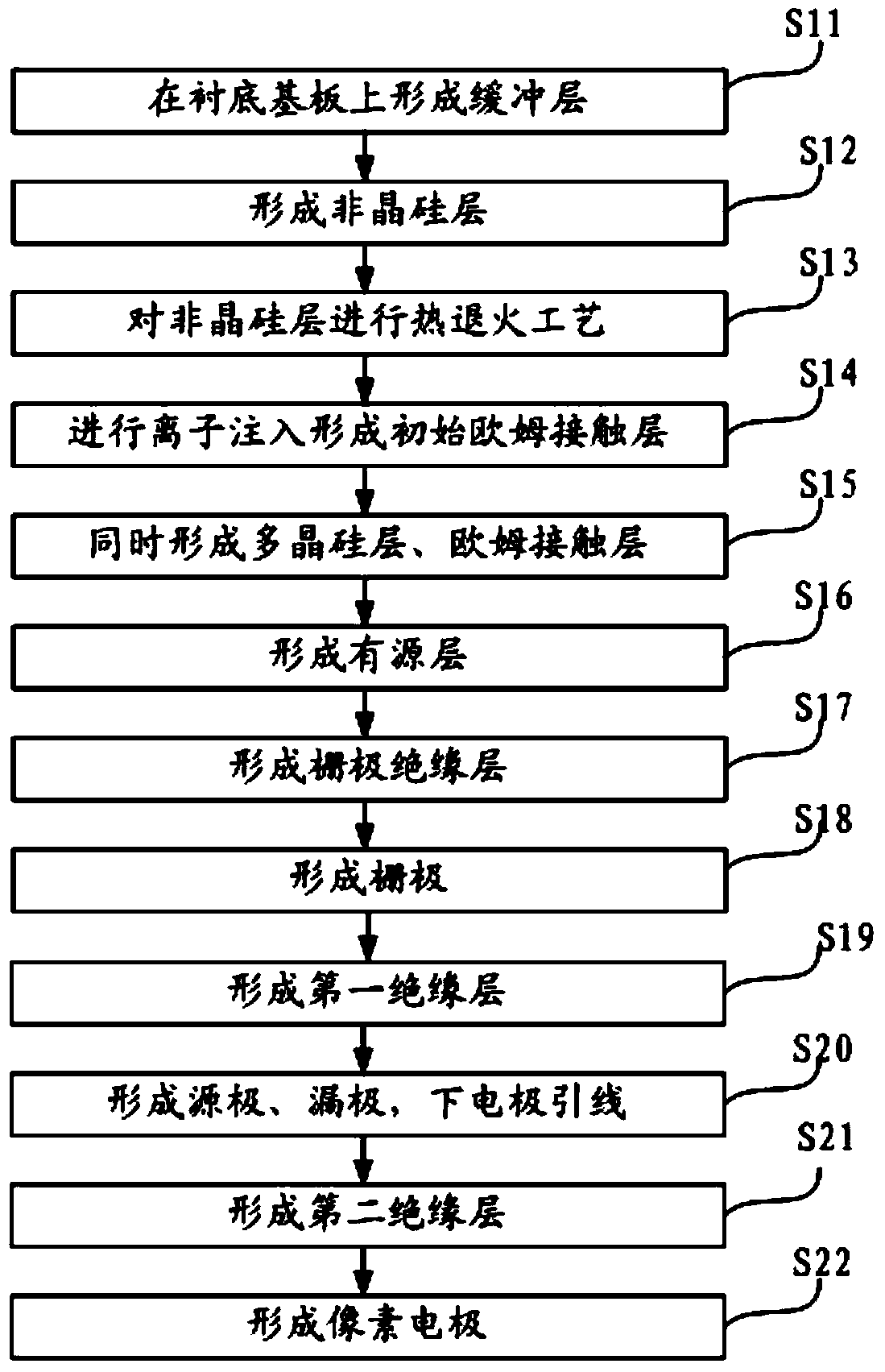

InactiveCN103839825AAvoid defectsAvoid bad phenomenaTransistorSolid-state devicesOhmic contactComposition process

The invention discloses a low-temperature polycrystalline silicon thin film transistor, an array substrate and a manufacturing method of the array substrate, so that manufacturing process procedures of the thin film transistor are simplified. The method includes the process that an active layer and an ohmic contact layer are formed on a substrate. The process that the active layer and the ohmic contact layer are formed on the substrate specifically includes the steps of forming an amorphous silicon layer on the substrate through; injecting impurity ions into at least the area of an ohmic contact layer to be formed of the amorphous silicon layer by means of an ion implantation method, wherein the area of the ohmic contact layer to be formed forms an initial ohmic contact layer; carrying out the excimer laser annealing process on the amorphous silicon layer after the impurity ion implantation technology; crystallizing the amorphous silicon layer after the excimer laser annealing process to form a polycrystalline silicon layer, and forming a final ohmic contact layer through the initial ohmic contact layer; carrying out the composition process on the polycrystalline silicon layer after the excimer laser annealing process to form the active layer.

Owner:BOE TECH GRP CO LTD

Thin film transistor and fabrication method thereof

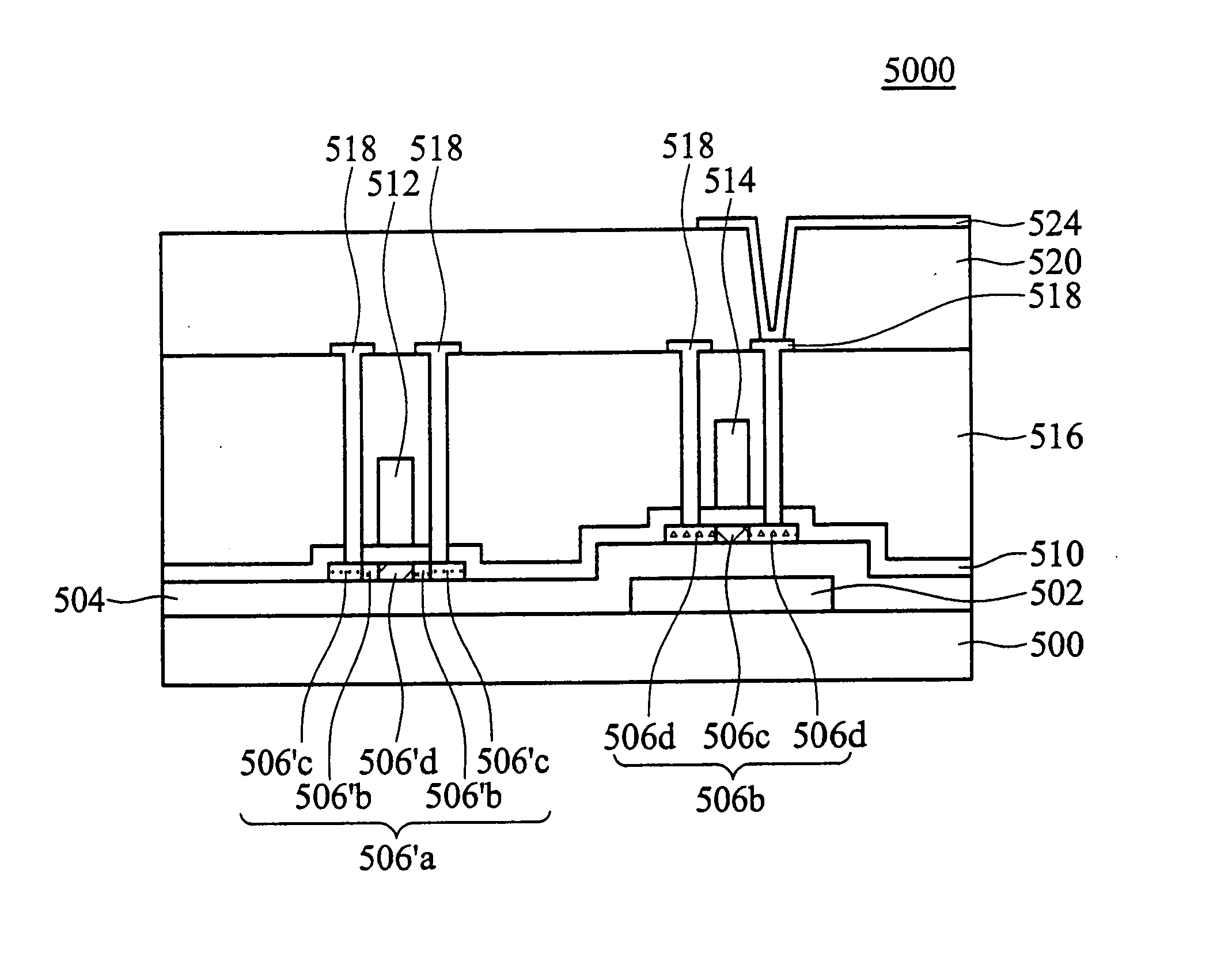

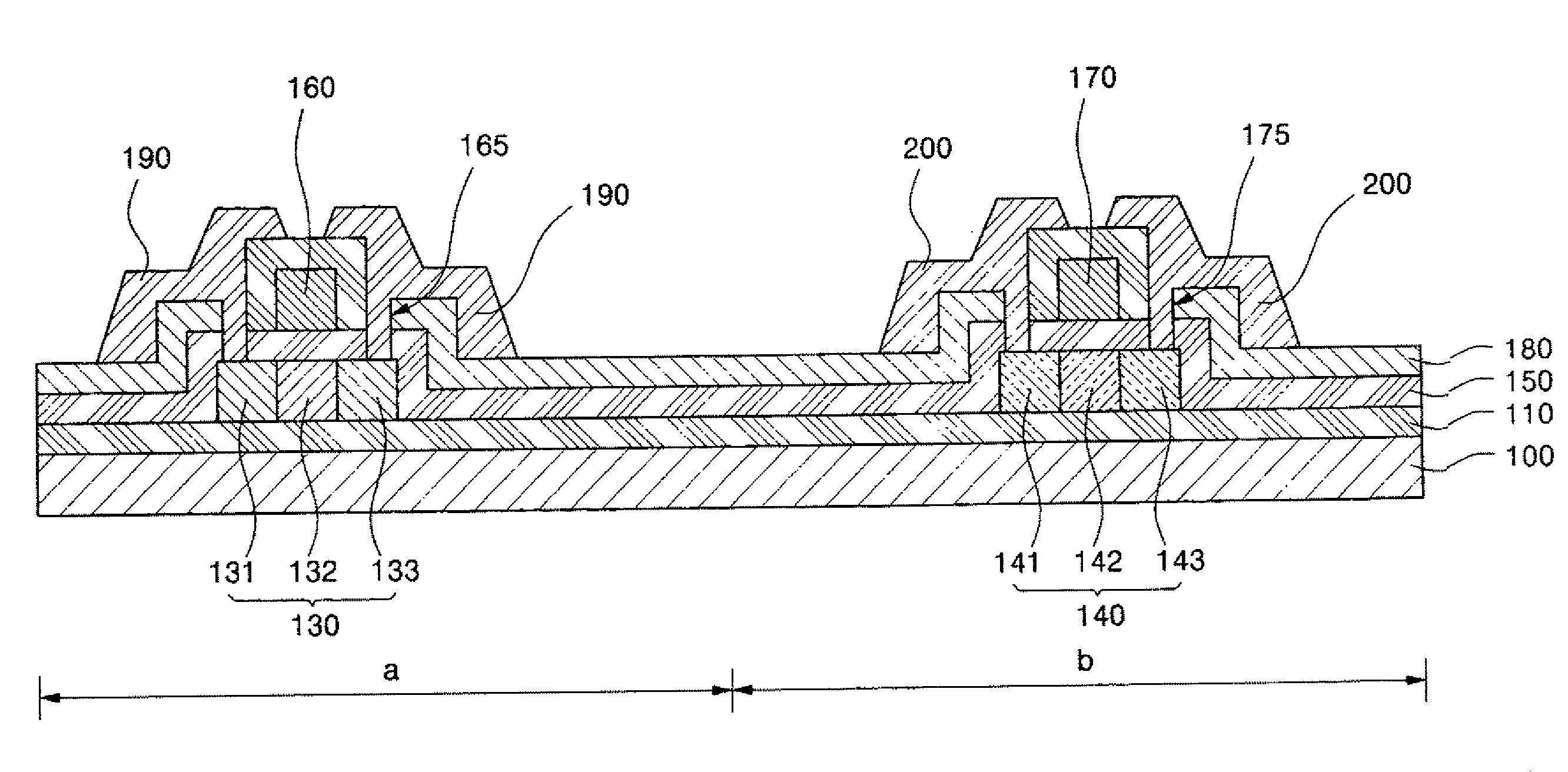

ActiveUS20080142808A1Solid-state devicesSemiconductor/solid-state device manufacturingElectrical conductorSurface roughness

A thin film transistor and a fabrication method thereof, in which one excimer laser annealing (ELA) makes a pixel portion and a driver portion different from each other in surface roughness and grain size. The thin film transistor includes: a substrate including a pixel portion and a driver portion; a first semiconductor layer disposed in the pixel portion and having a first surface roughness; a second semiconductor layer disposed in the driver portion and having a second surface roughness smaller than the first surface roughness; a gate insulating layer formed on the substrate including the first and second semiconductor layers; a first gate electrode placed to correspond to the first semiconductor layer on the gate insulating layer; a second gate electrode placed to correspond to the second semiconductor layer on the gate insulating layer; an interlayer insulating layer formed on the substrate including the first and second gate electrodes; first source and drain electrodes formed on the interlayer insulating layer and electrically connected with the first semiconductor layer; and second source and drain electrodes formed on the interlayer insulating layer and electrically connected with the second semiconductor layer.

Owner:SAMSUNG DISPLAY CO LTD

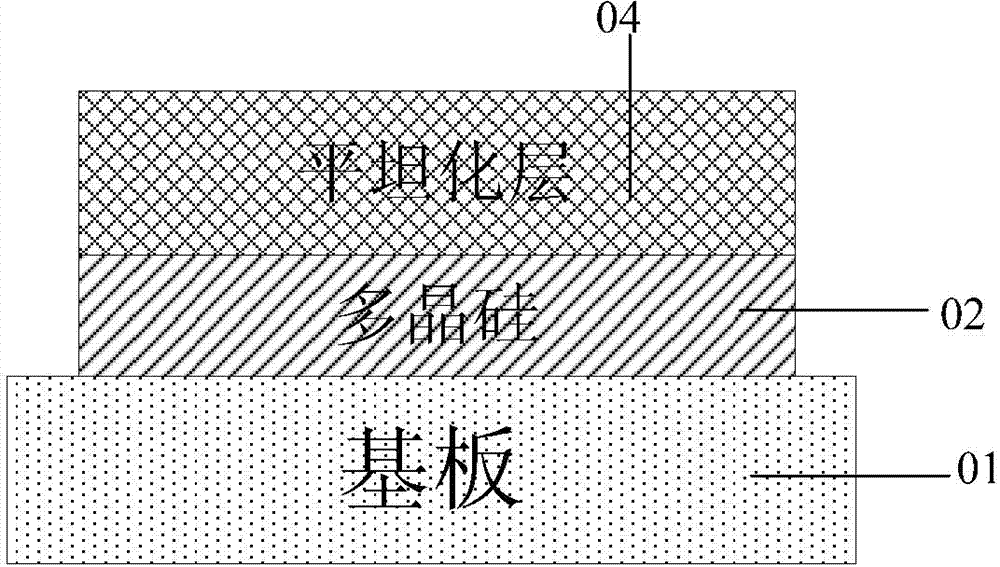

Thin film transistor manufacturing method

InactiveCN104752203ALower bump heightImprove uniformityTransistorSolid-state devicesActive matrixChemical vapor deposition

The invention discloses a thin film transistor manufacturing method, which comprises the following steps: (1) a chemical vapor deposition method is firstly used for depositing a layer of amorphous silicon on the substrate of the thin film transistor; (2) excimer laser annealer (ELA) technology is used for crystallizing the amorphous silicon to form poly-silicon, and during the crystallizing process, a large number of ridges caused by laser annealing crystallizing are generated on the surface of the poly-silicon; (3) a coating mode is used for manufacturing a flattening layer on the poly-silicon with the ridges to enable the flattening layer to fully cover the ridges of the poly-silicon; and (4) etching is carried out on the flattening layer, when the ridges are etched, the flattening layer and the ridges are etched altogether, and a remaining flattening layer and a remaining small number of ridges are left on the poly-silicon. By adopting the thin film transistor manufacturing method of the invention, the ridge height of the poly-silicon after ELA crystallizing can be greatly reduced, uniformity of AMOLED (Active Matrix Organic Light Emitting Diode) backplane can be improved, and display effects are better.

Owner:KUNSHAN NEW FLAT PANEL DISPLAY TECH CENT +1

Low-temperature polycrystalline silicon film pre-cleaning method, low-temperature polycrystalline silicon film preparation method and low-temperature polycrystalline silicon film manufacturing system

InactiveCN103681244AImprove uniformityImprove the state of uneven thicknessSemiconductor/solid-state device manufacturingFrom chemically reactive gasesLiquid-crystal displayRoom temperature

The invention relates to the technical field of liquid crystal display, in particular to a low-temperature polycrystalline silicon film preparation method. The preparation method includes the steps: firstly, sequentially growing a buffer layer and an amorphous silicon layer on a substrate from bottom to top; secondly, heating the amorphous silicon layer to reach the temperature higher than the room temperature and pre-cleaning the amorphous silicon layer; thirdly, irradiating the amorphous silicon layer pre-cleaned in the second step by the aid of an excimer laser beam and converting amorphous silicon into polycrystalline silicon. The invention further provides a polycrystalline silicon film manufacturing system. By improving the low-temperature polycrystalline silicon film manufacturing system and the low-temperature polycrystalline silicon film pre-cleaning method, the non-uniform thickness of the amorphous silicon layer is improved, and accordingly, uniformity of converting the amorphous silicon layer into a polycrystalline silicon film by ELA (excimer laser annealing) in subsequent steps is improved.

Owner:TCL CHINA STAR OPTOELECTRONICS TECH CO LTD

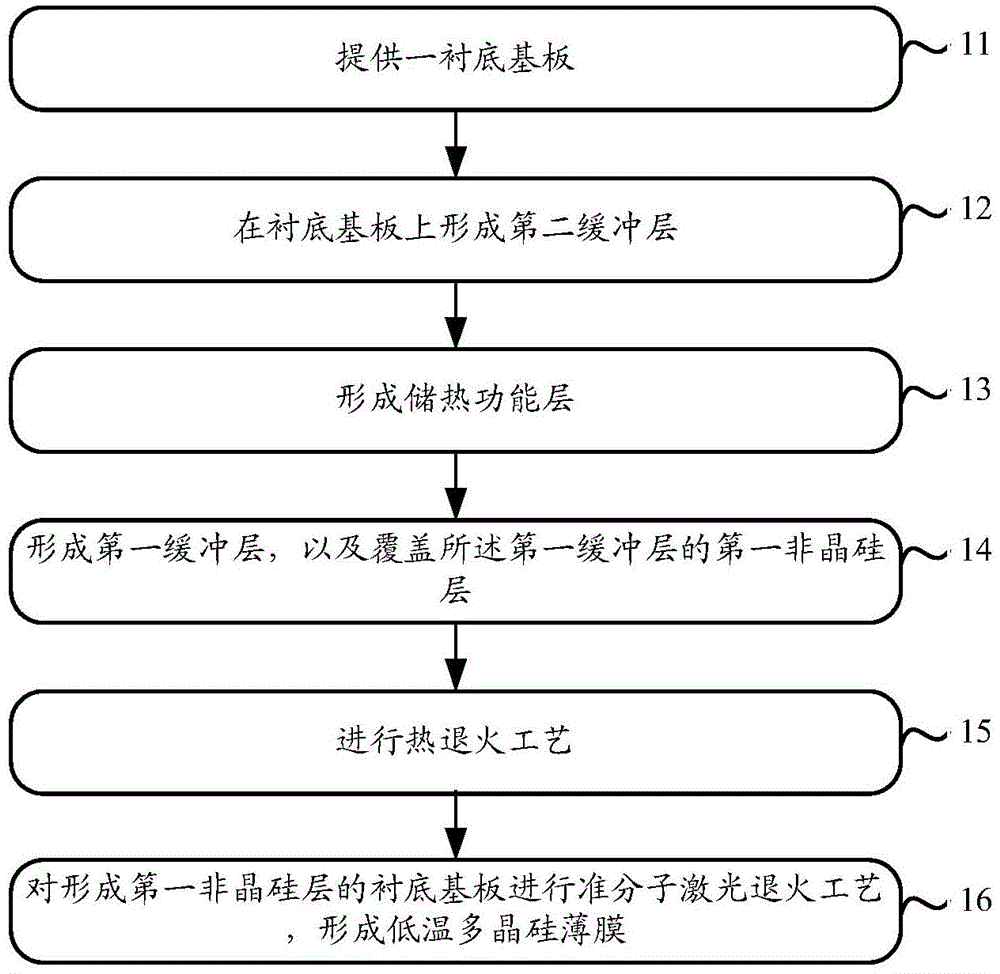

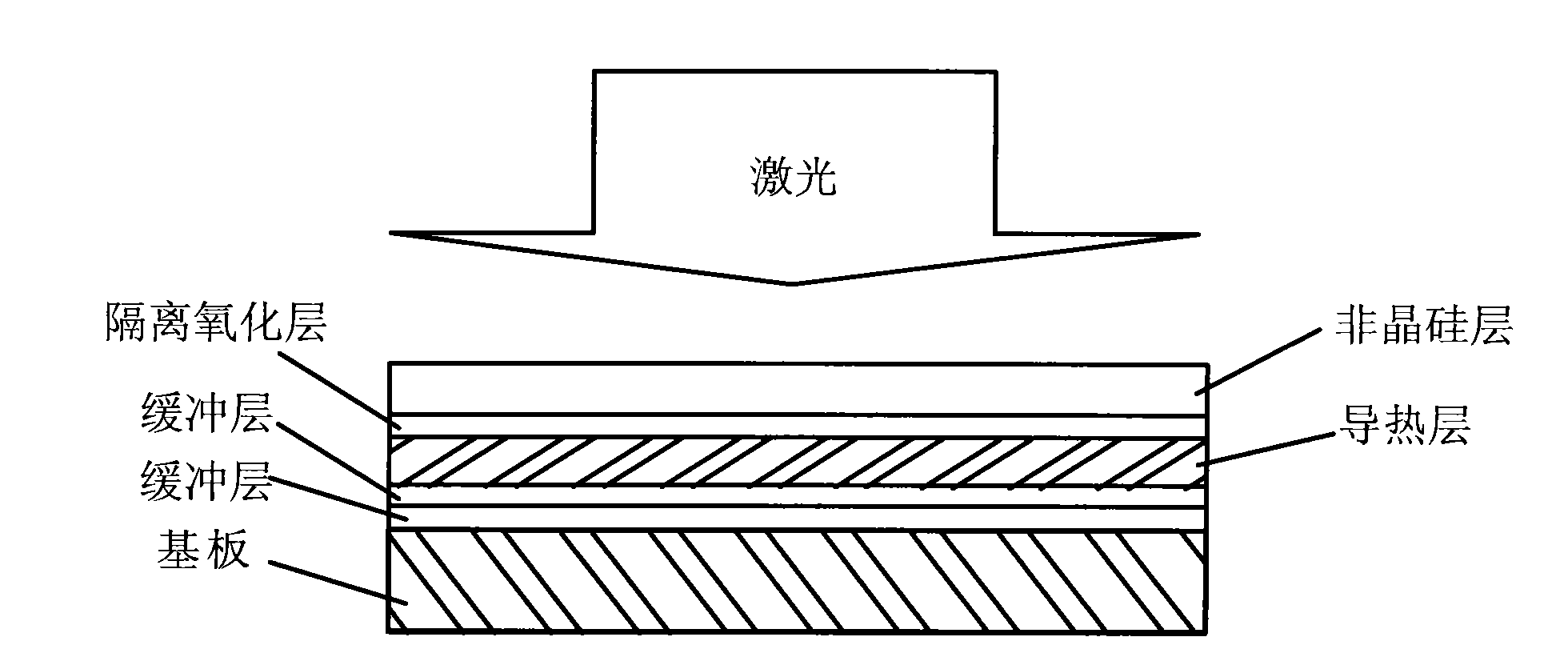

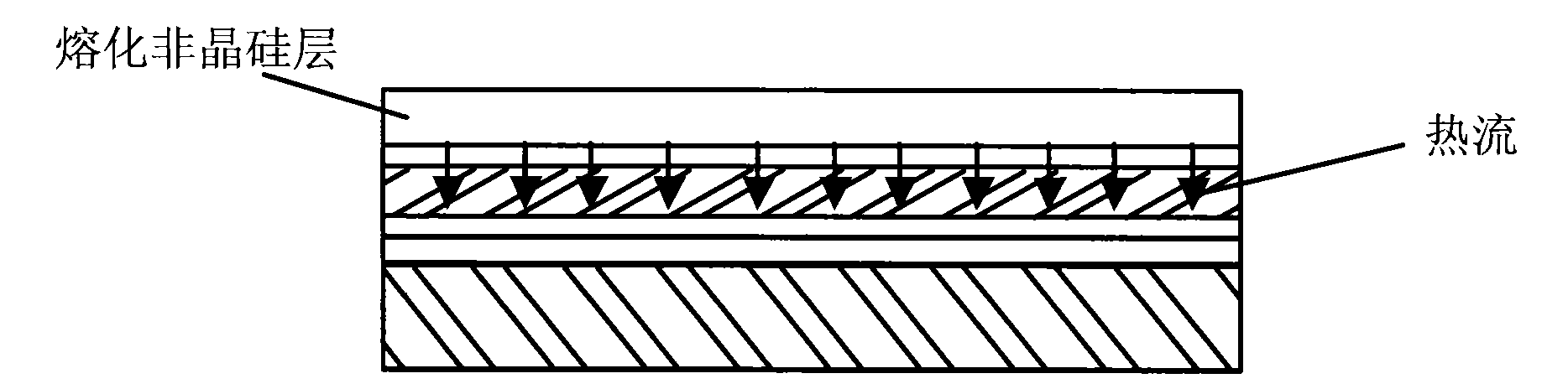

Low-temperature polycrystalline silicon thin film, manufacturing method thereof and related device

ActiveCN104934372AExtended growth timeRefine the grain sizeTransistorPolycrystalline material growthOptoelectronicsExcimer laser annealing

The invention discloses a low-temperature polycrystalline silicon thin film, a manufacturing method thereof and a related device. The method mainly comprises the steps of providing an underlayment substrate, forming a heat storage function layer on the underlayment substrate, forming a first buffer layer on the heat storage function layer, forming a first amorphous silicon layer to cover the first buffer layer, and conducting the excimer laser annealing treatment on the underlayment substrate provided with the first amorphous silicon layer to form a low-temperature polycrystalline silicon film. The heat storage function layer and the first amorphous silicon layer can be in the heat absorption state at the same time, and can also be in the heat radiation state at the same time. Therefore, during the excimer laser annealing treatment, the cooling duration is prolonged by the first amorphous silicon layer on the surface of the polycrystalline silicon thin film, based on the utilization of the heat storage function layer at the bottom of the polycrystalline silicon thin film. In this way, the growth duration of low-temperature polysilicon is prolonged, and the grain size of low-temperature polysilicon is increased.

Owner:BOE TECH GRP CO LTD

Film control method and device thereof

InactiveUS20060240647A1Avoid problemsSolid-state devicesSemiconductor/solid-state device manufacturingHydrofluoric acidOptoelectronics

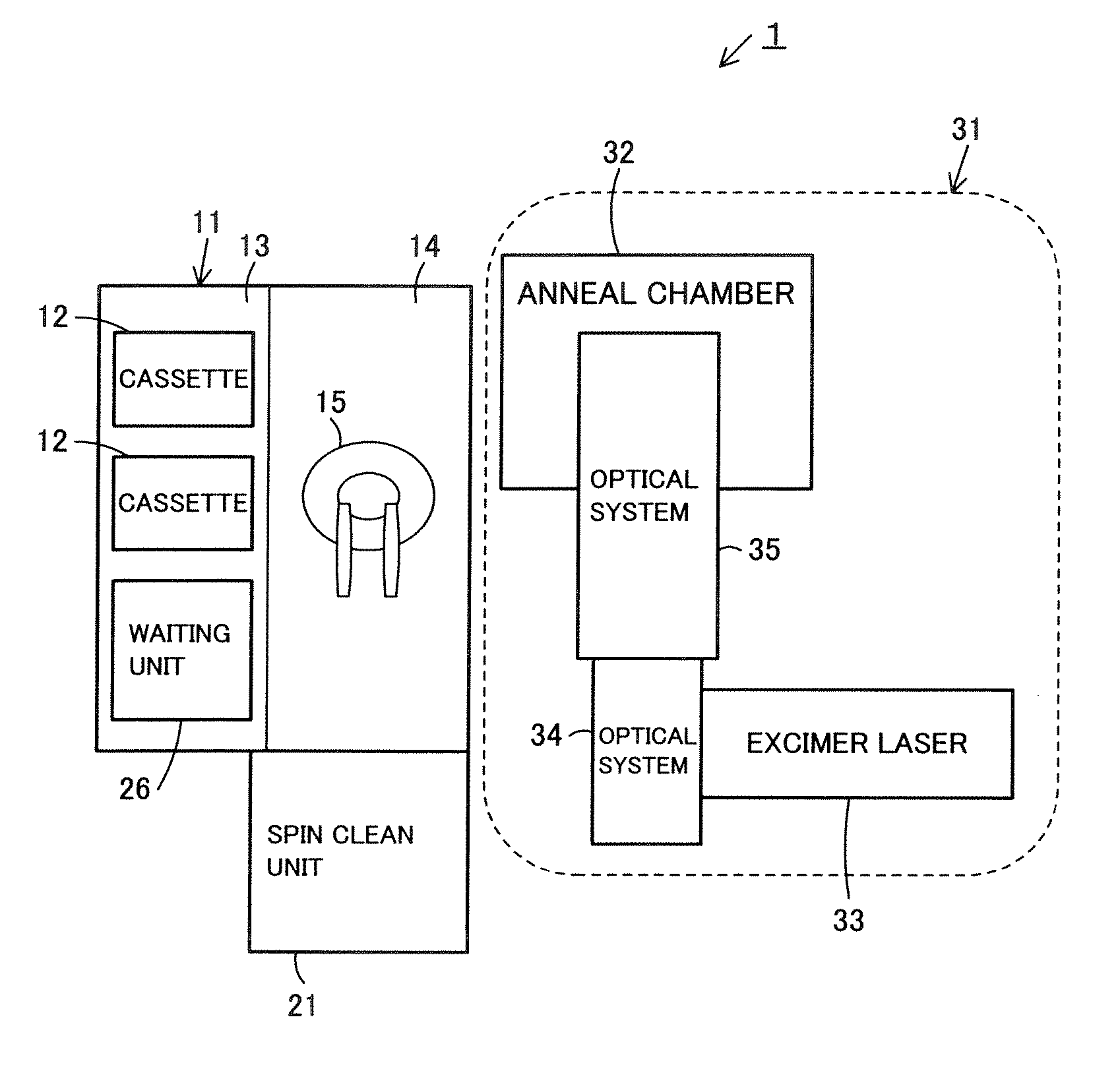

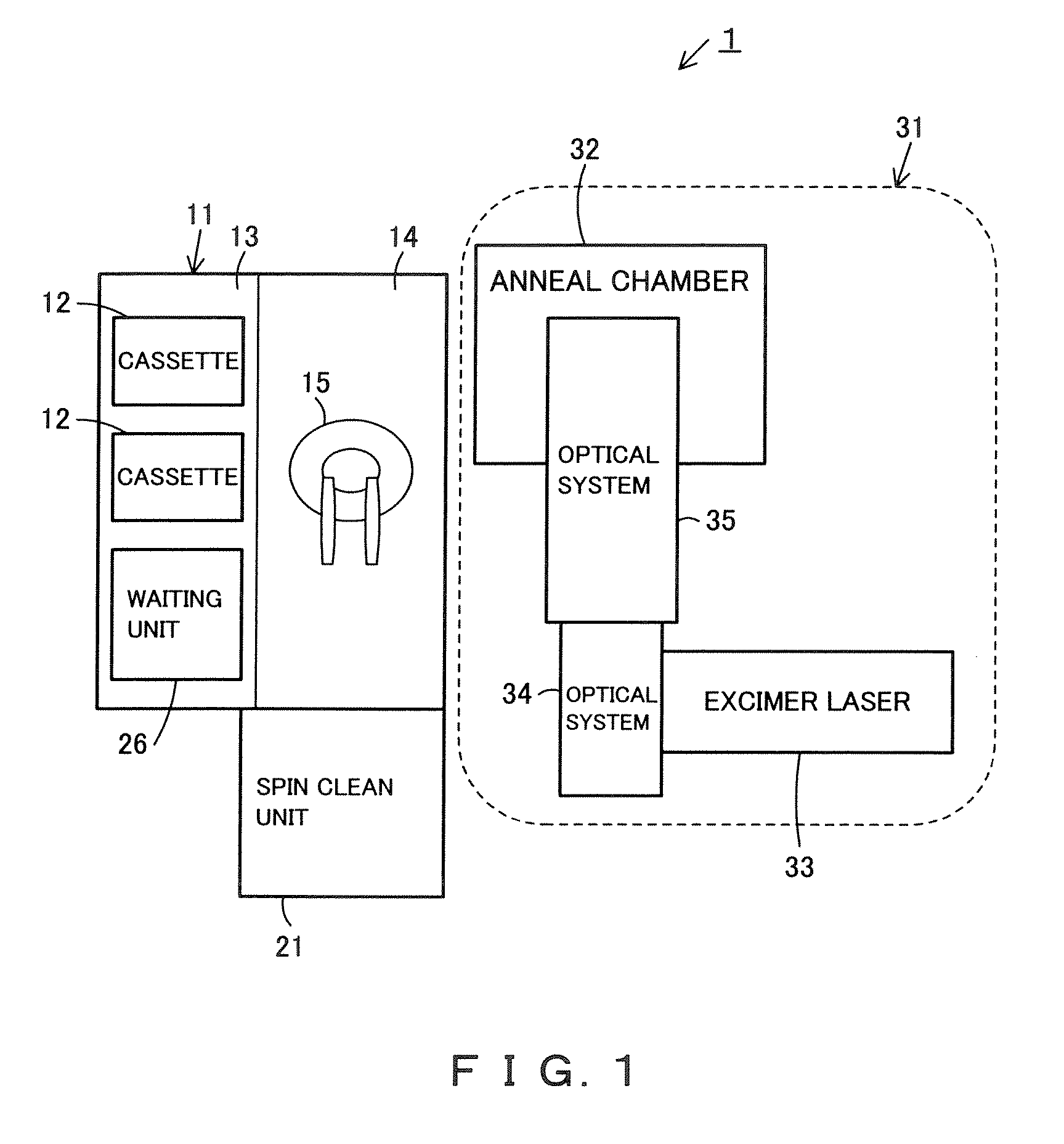

The surface of an amorphous silicon film formed on a glass substrate is cleaned by hydrofluoric acid in a spin clean unit. The glass substrate is conveyed to a waiting unit where the glass substrate is made to wait for about 15 minutes. Active fluoride adhered on the amorphous silicon film is sublimated. The glass substrate in which the active fluoride is sublimated is conveyed into a laser annealing device where the amorphous silicon film is excimer laser annealed to reform the amorphous silicon film into a polysilicon film. The residuals of the charges in the polysilicon film generated by excimer laser annealing the surface of the amorphous silicon film with the active fluoride adhered to the surface of the amorphous silicon film can be prevented. A thin film transistor having desired TFT characteristics can be manufactured.

Owner:TOSHIBA MATSUSHITA DISPLAY TECH

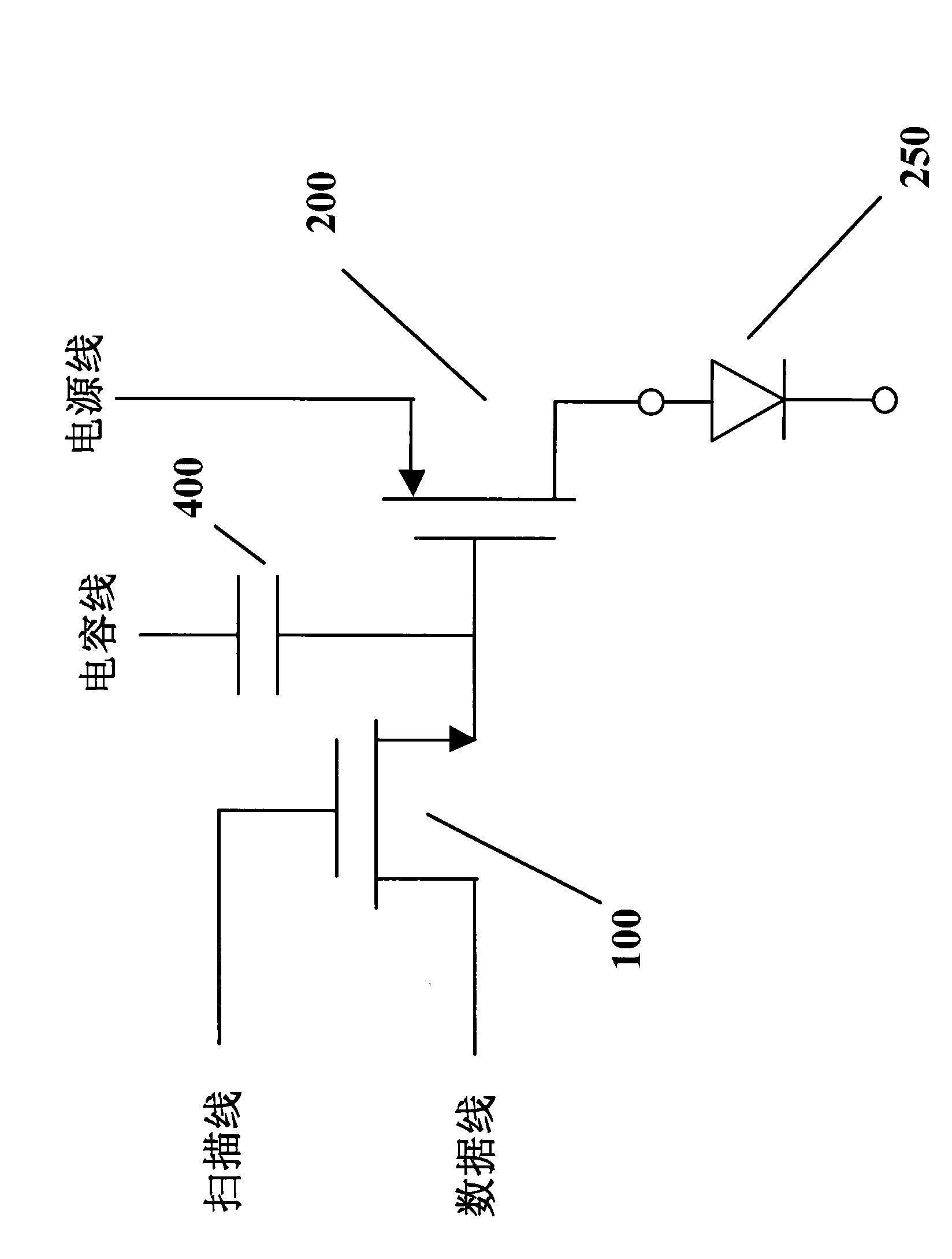

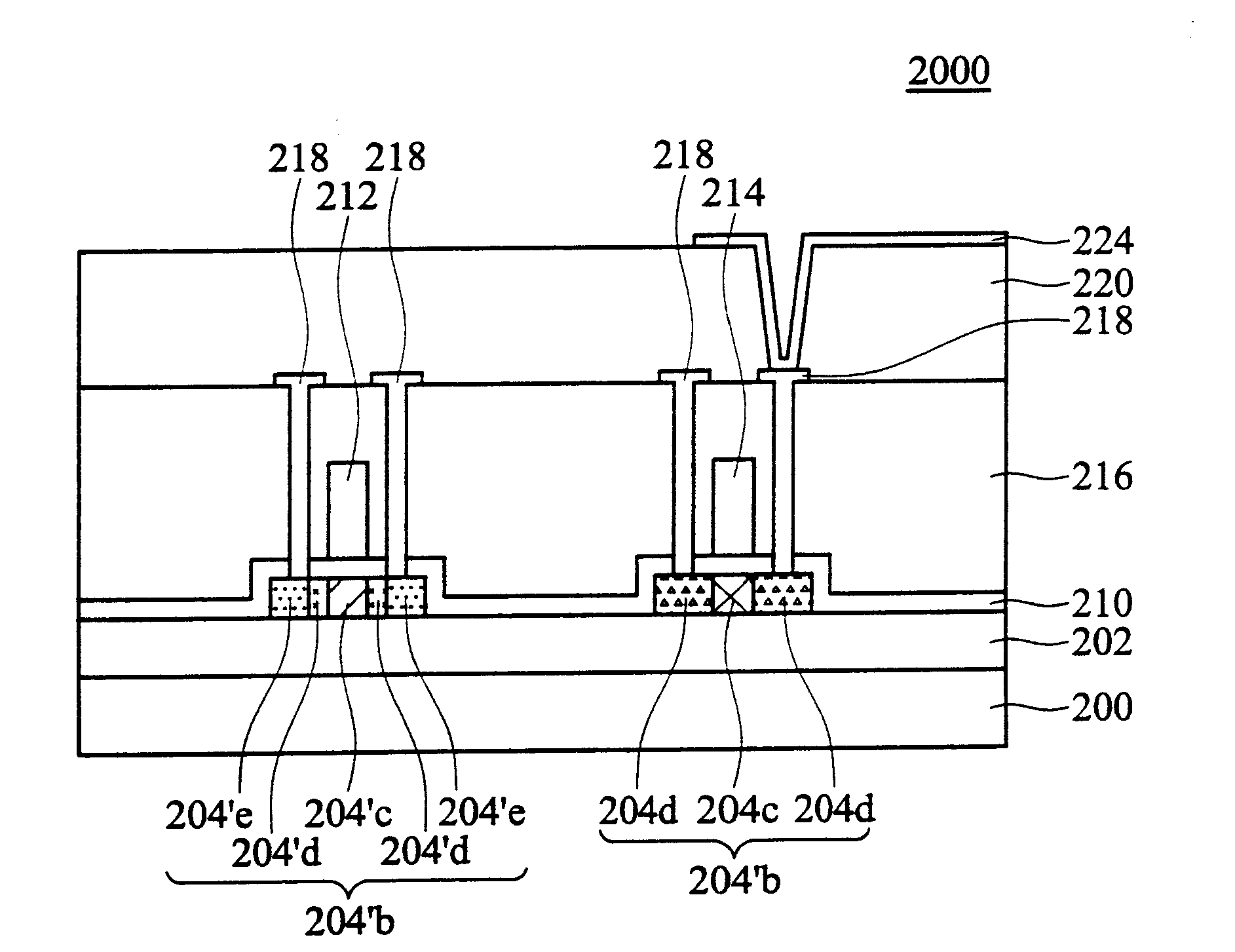

Image display system and manufacture method thereof

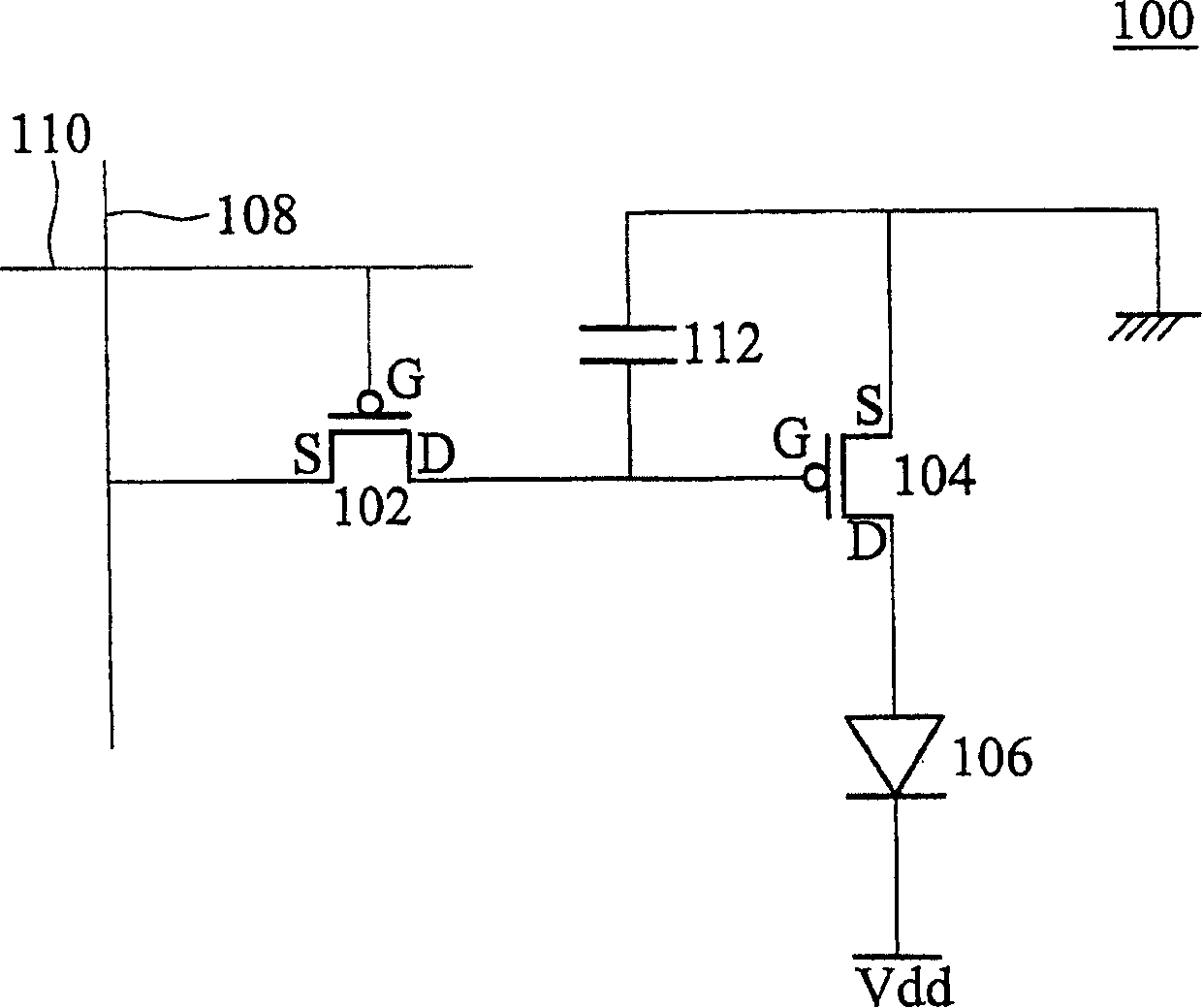

InactiveCN101593730AImprove photosensitivityIncrease opening ratioSolid-state devicesSemiconductor/solid-state device manufacturingCapacitanceLight sensing

The invention relates to an image display system and a manufacture method thereof. The image display system comprises a basal plate, a switch film transistor, a driving film transistor, a light-sensing component and a capacitor, wherein a baffle layer is formed on the basal plate; no conductive layer is formed in a first section predicted to form the switch film transistor so as to form a shielding layer; and a conductive layer is formed in a second section predicted to form the driving film transistor, the light-sensing component and the capacitor so as to form the shielding layer. Weather the conductive layer exists or not in the single crystallized processing procedure and the thermal conductive phenomenon of a quasimolecule laser annealing method are utilized to form polycrystalline silicon layers with different grain sizes in the first section and the second section so that the image display system has favorable uniformity of luminance.

Owner:INNOLUX CORP

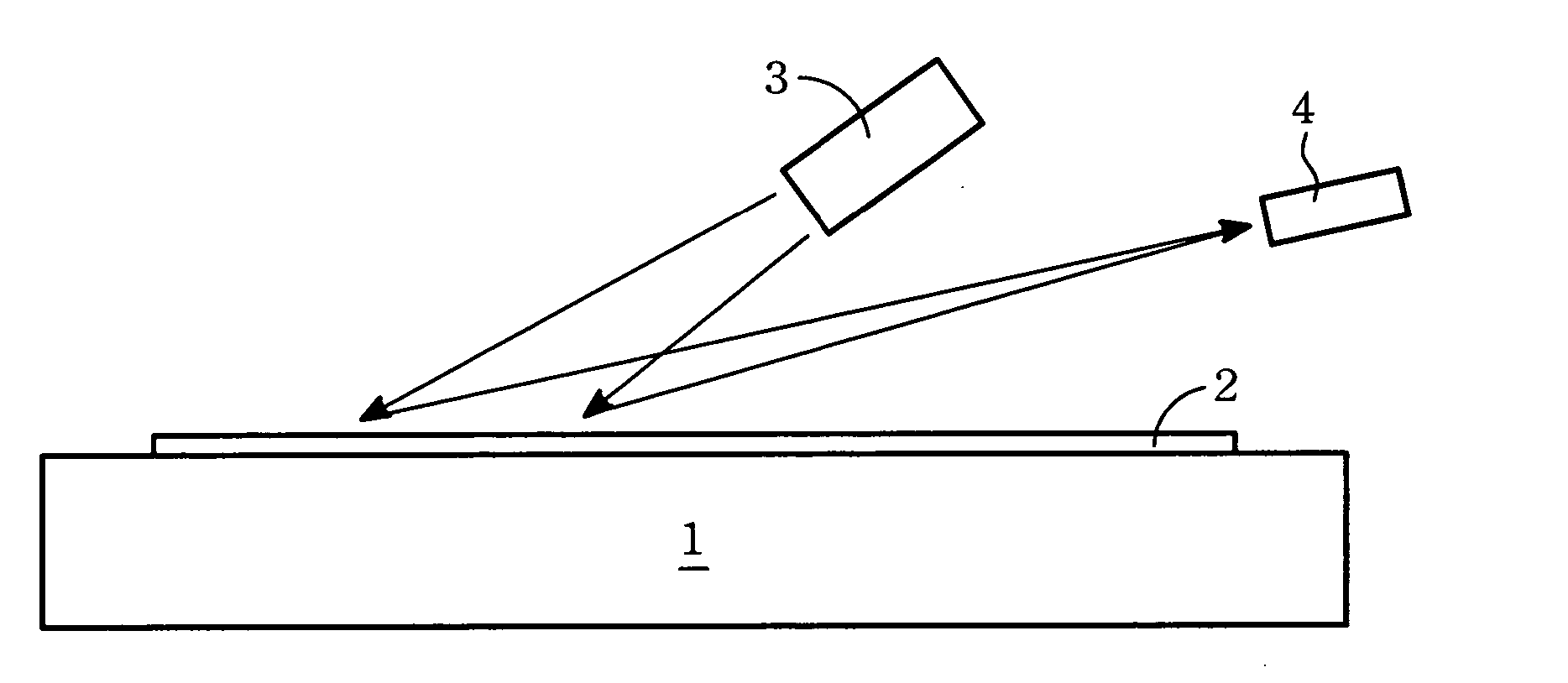

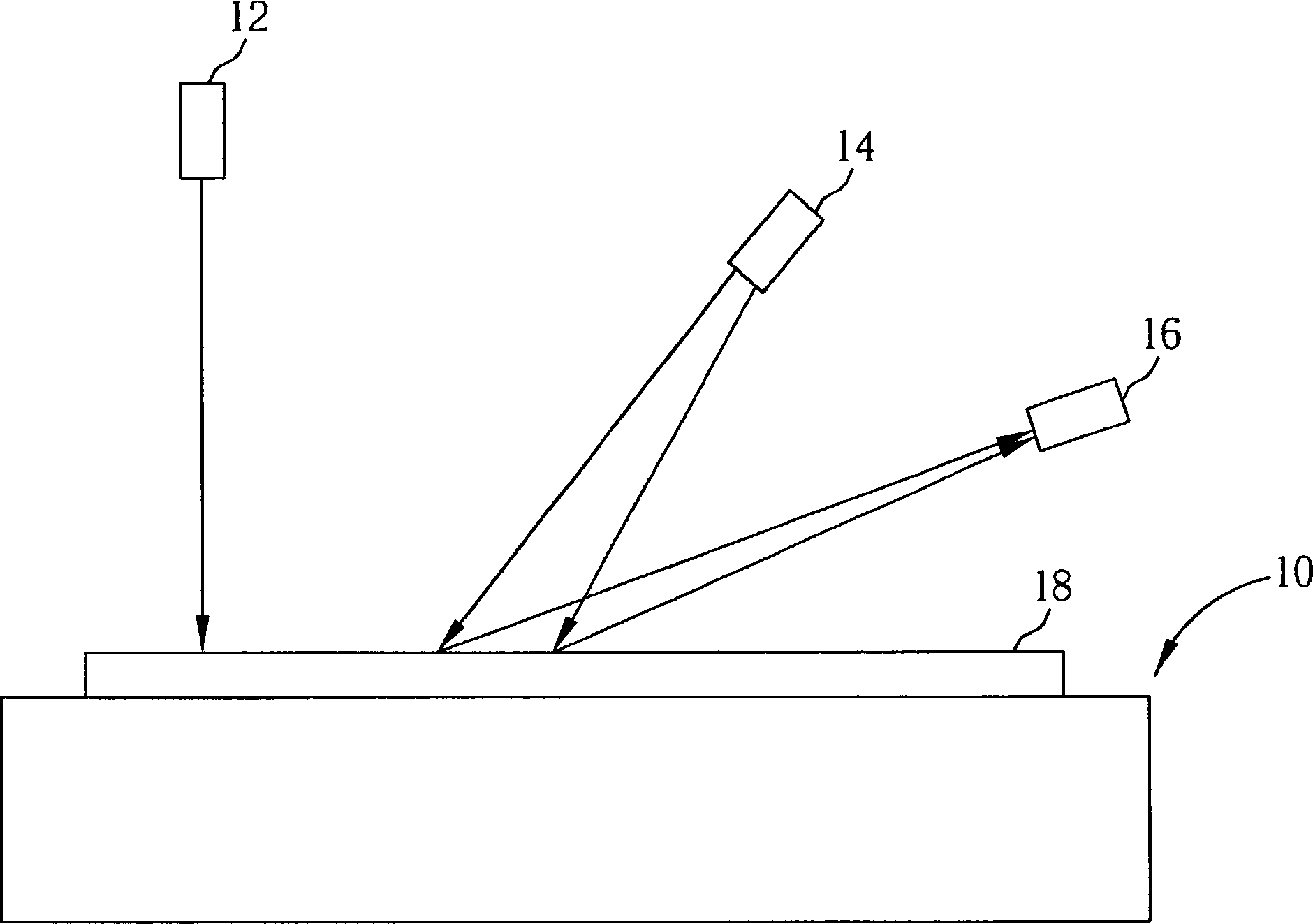

Inspection method and apparatus of laser crystallized silicons

ActiveUS7184132B2The method is simple and fastSemiconductor/solid-state device testing/measurementSemiconductor/solid-state device manufacturingExcimer laser annealingLaser

An inspection method and apparatus of laser crystallized silicons in the low-temperature poly Si (LTPS) process. The crystalline quality is inspected by using a visible light source to irradiate the surface of the poly Si and examining the variations of the reflected light caused by the protrusion arrangement at the surface of the poly Si. This method can be adopted on the poly Si samples prepared by the line scanning of the excimer laser annealing (ELA) technology.

Owner:AU OPTRONICS CORP

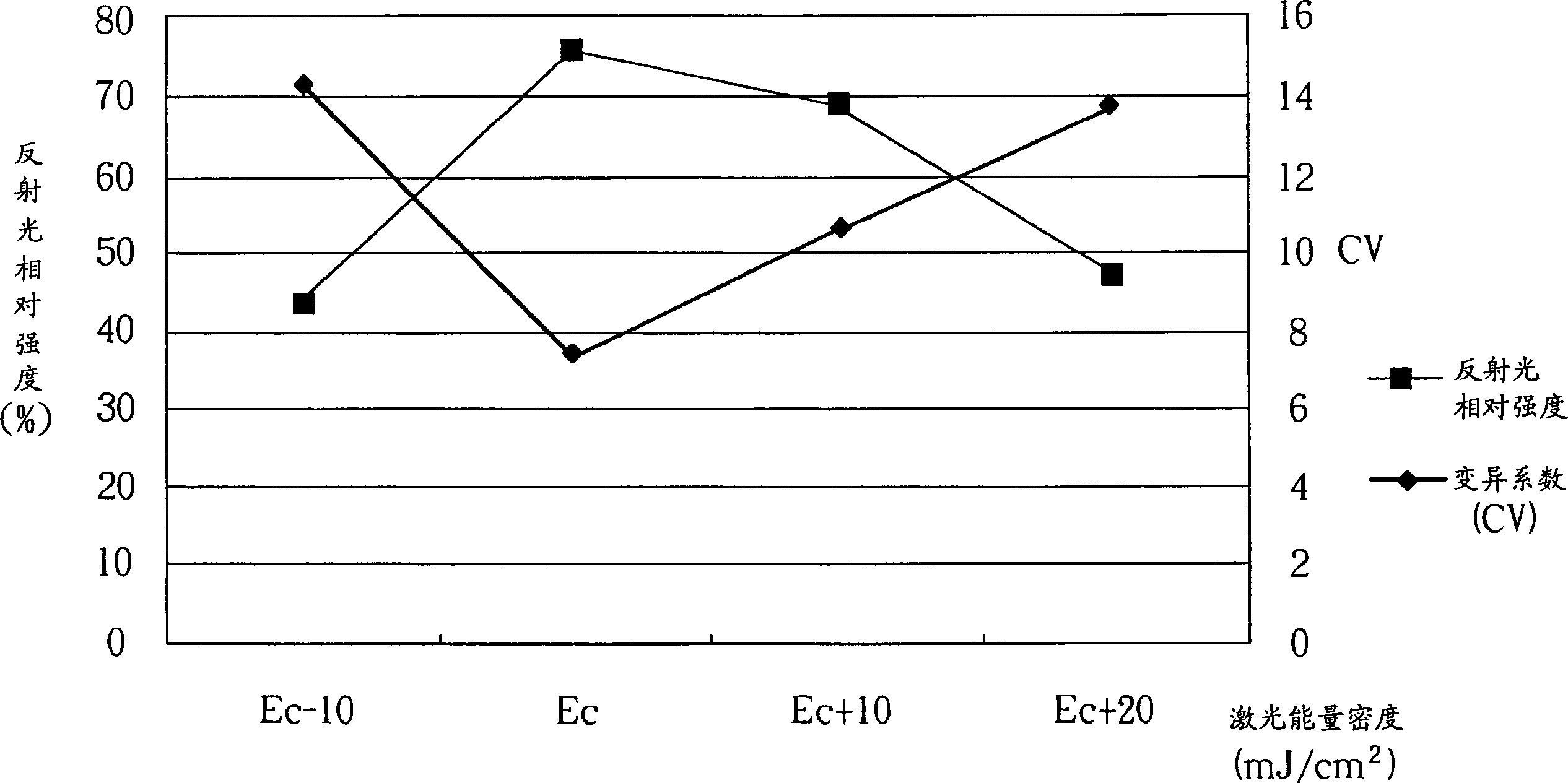

Laser crystallization system and method for controlling quasi-molecular laser annealing energy density

ActiveCN1553477AReal-time adjustment of energy densityEnsure crystallizationSemiconductor/solid-state device testing/measurementSemiconductor/solid-state device manufacturingLaser crystallizationExcimer laser annealing

Laser crystallizing system includes a quasi molecule laser annealing device and an optical detection device. Energy density method for controlling annealing procedure of quasi molecule laser in real time includes a procedure of determining optimal energy density and an annealing procedure of quasi molecule laser. The former procedure decides optimal energy density, and the latter carries out an annealing procedure of quasi molecule laser by using optimal energy density decided.

Owner:AU OPTRONICS CORP

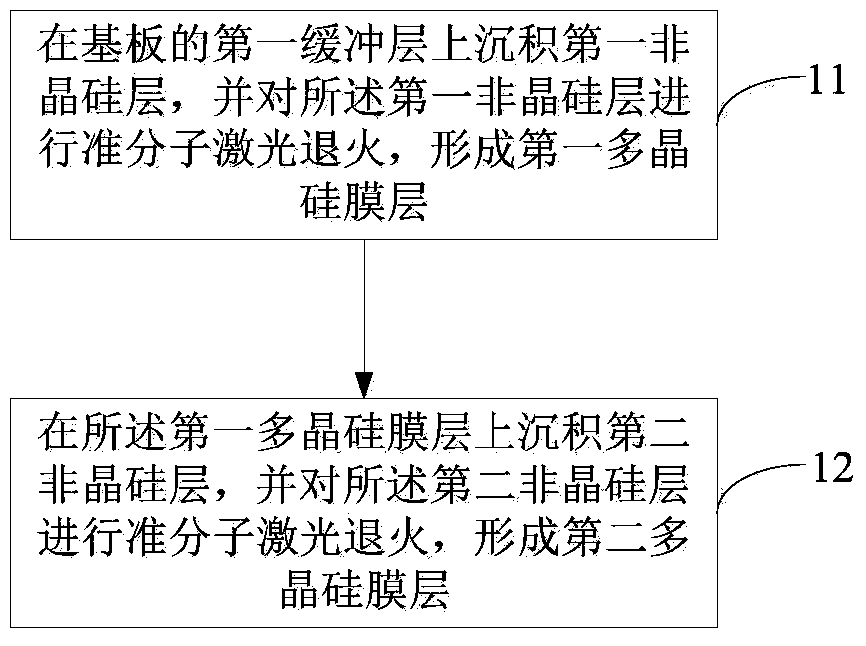

Low-temperature polycrystalline silicon thin film and preparation method thereof and low-temperature polycrystalline silicon thin film transistor

ActiveCN104362084AImprove fullyLower the altitudeTransistorSemiconductor/solid-state device manufacturingOptoelectronicsExcimer laser annealing

Disclosed are a low-temperature polycrystalline silicon thin film and a preparation method thereof and a low-temperature polycrystalline silicon thin film transistor. The preparation method includes precipitating a first amorphous silicon layer on a first buffer layer of a substrate, and subjecting the first amorphous silicon layer to excimer laser annealing to form a first polycrystalline silicon film; precipitating a second amorphous silicon layer on the first polycrystalline silicon film, and subjecting the second amorphous silicon layer to the excimer laser annealing to form a second polycrystalline silicon film. According to the low-temperature polycrystalline silicon thin film and the preparation method thereof, surface protrusion height of the polycrystalline is reduced, polycrystalline grain distribution is more uniform, and other material is omitted during the preparation.

Owner:CHENGDU VISTAR OPTEOLECTRONICS CO LTD

Monitoring method and apparatus for excimer laser annealing process

ActiveCN104641460AInvestigating semiconductor impuritiesPolycrystalline material growthIrradiationMonitoring methods

A method is disclosed evaluating a silicon layer crystallized by irradiation with pulses form an excimer-laser. The crystallization produces periodic features on the crystalized layer dependent on the number of and energy density in the pulses to which the layer has been exposed. An area of the layer is illuminated with light. A detector is arranged to detect light diffracted from the illuminated area and to determine from the detected diffracted light the energy density in the pulses to which the layer has been exposed.

Owner:COHERENT LASERSYST

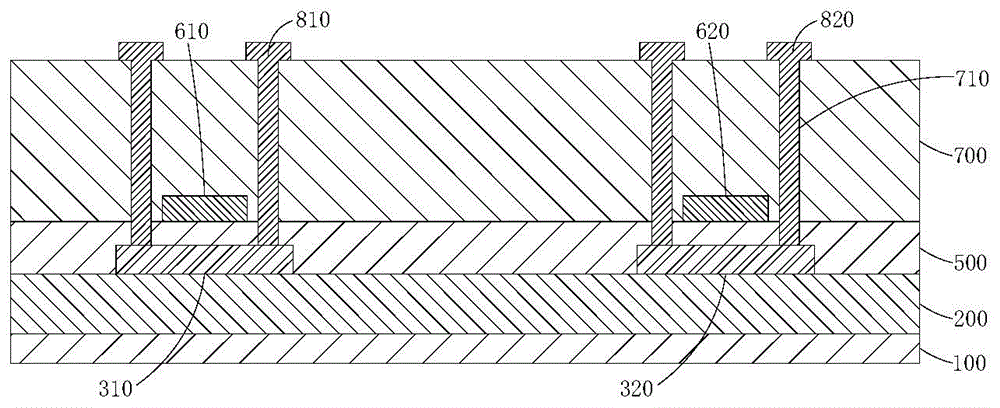

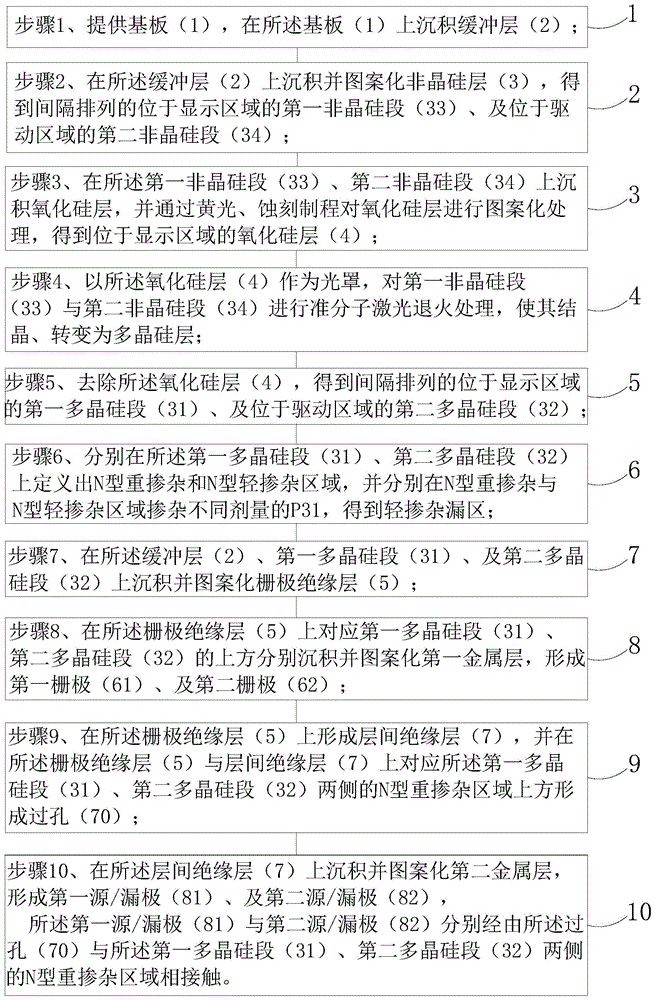

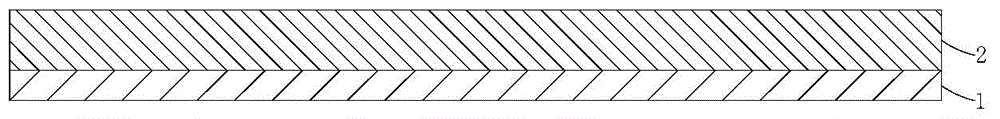

Manufacturing method and structure of low-temperature polycrystalline silicon TFT substrate

ActiveCN104600028AImprove qualityExcellent electrical propertiesSolid-state devicesSemiconductor/solid-state device manufacturingInsulation layerSilicon oxide

The invention provides a manufacturing method and a structure of a low-temperature polycrystalline silicon TFT substrate. The method comprises the step 1 of providing a substrate (1) and depositing a buffer layer (2), the step 2 of depositing and patterning an amorphous silicon layer (3), the step 3 of depositing and patterning a silicon oxide layer (4), the step 4 of performing excimer laser annealing treatment on the amorphous silicon layer (3) with the silicon oxide layer (4) as a photomask so that the amorphous silicon layer (3) can be crystalized and converted into a polycrystalline silicon layer, the step 5 of obtaining a first polycrystalline silicon section (31) and a second polycrystalline silicon section (32), the step 6 of defining an N type heavy-doped region and an N type light-doped region on the first polycrystalline silicon section (31) and the second polycrystalline silicon section (32), respectively, and obtaining a light-doped drain region, the step 7 of depositing and patterning a gate insulation layer (5), the step 8 of forming a first gate (61) and a second gate (62), the step 9 of forming a via hole (70), and the step 10 of forming a first source / drain (81) and a second source / drain (82).

Owner:SHENZHEN CHINA STAR OPTOELECTRONICS TECH CO LTD

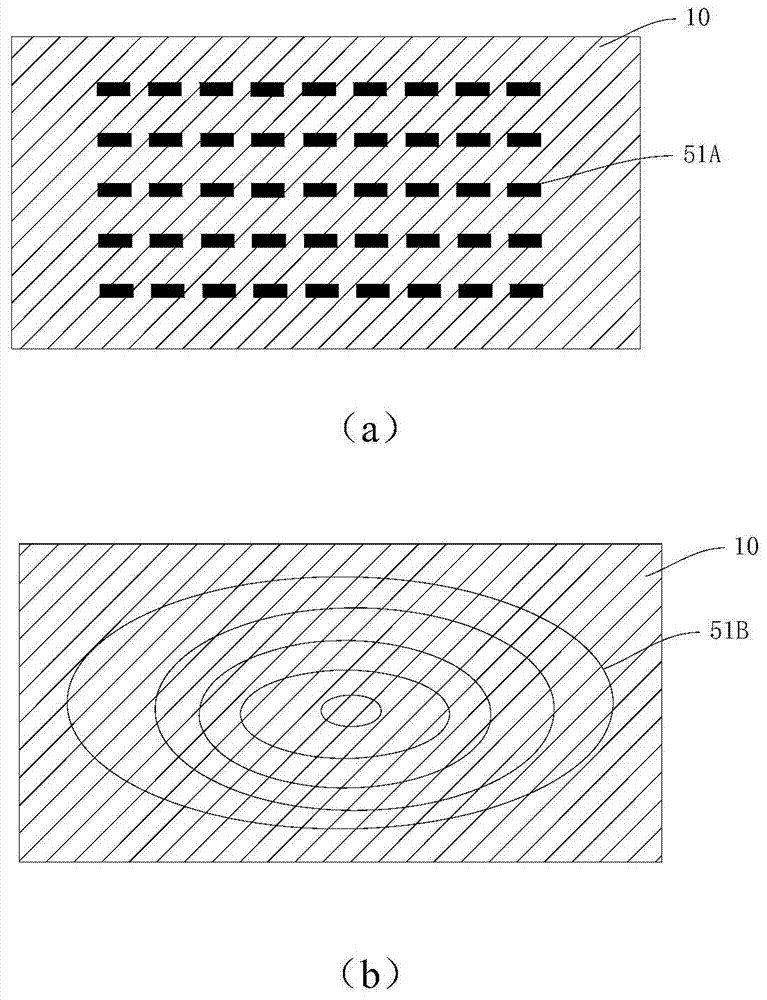

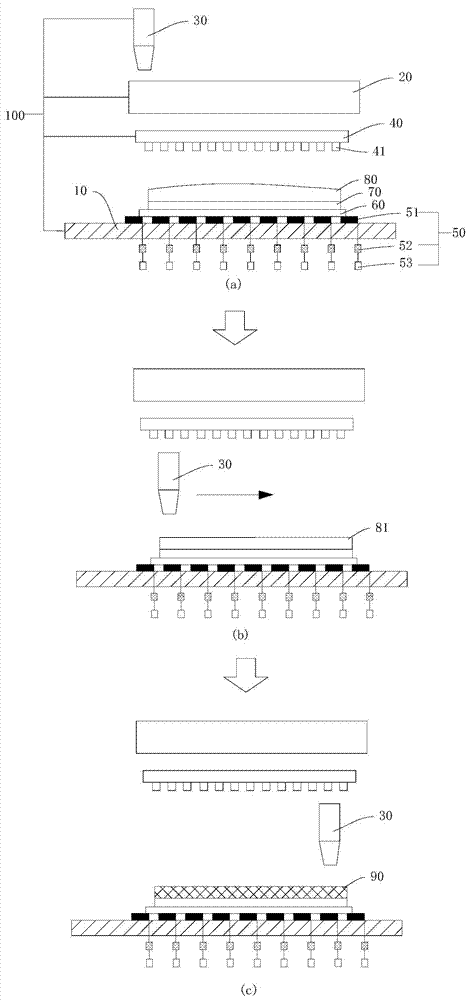

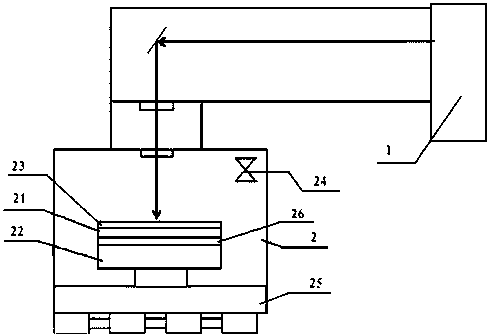

Quasi molecule laser annealing apparatus and preparation method of low-temperature polysilicon thin film

ActiveCN104392913AReduce temperature differenceReduce the rate at which the temperature decreasesSemiconductor/solid-state device manufacturingState of artOptoelectronics

The invention provides a quasi molecule laser annealing apparatus and a preparation method of a low-temperature polysilicon thin film, for solving the problems of short effective annealing time and quite small crystal grains during annealing of a conventional low-temperature polysilicon thin film in the prior art. In the quasi molecule laser annealing apparatus, a heating unit is arranged at one side, which is far away from an amorphous silicon thin film, at a substrate to be processed, for heating the substrate to the processed. The heating unit heats the substrate during the annealing process of the substrate to be processed, such that the temperature difference between the substrate to the processed and the amorphous silicon thin film is reduced, heat generated when laser is irradiated on the amorphous silicon thin film is not rapidly conducted to the substrate, the temperature reduction speed of the amorphous silicon thin film is slowed down, the annealing time is prolonged, and fused amorphous silicon can be conveniently annealed to form the large-crystal-grain polysilicon thin film. Since the preparation method of the low-temperature polysilicon thin film employs the quasi molecule laser annealing apparatus, the large-crystal-grain polysilicon thin film can be obtained, and a polysilicon thin film transistor with higher mobility can be obtained.

Owner:BOE TECH GRP CO LTD

Method of fabricating an organic electroluminescent device and system of displaying images

InactiveUS20110134045A1Decrease difference of electric propertyAperture can be increasedInput/output for user-computer interactionSolid-state devicesTectorial membraneOptoelectronics

A method for fabricating organic electroluminescent devices is disclosed. The method comprises providing a substrate divided into first and second regions, forming an amorphous silicon layer on the substrate, forming a protection film on the amorphous silicon layer within the second region, performing an excimer laser annealing process on the amorphous silicon layer for converting it to a polysilicon layer, removing the protection film, patterning the polysilicon layer, thus a first patterned polysilicon layer in the first region and a second patterned polysilicon layer in the second region are formed. A resultant organic electroluminescent device is obtained. Specifically, the grain size of the first patterned polysilicon layer is large than that of the second patterned polysilicon layer.

Owner:TPO DISPLAY

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com