Quasi molecule laser annealing apparatus and preparation method of low-temperature polysilicon thin film

An excimer laser and annealing device technology, which is applied in semiconductor/solid-state device manufacturing, electrical components, circuits, etc., can solve the problems of lower annealing temperature of amorphous silicon thin film 23, difficulty in forming low-molecular polysilicon, and greater influence of annealing time , to achieve the effect of reducing temperature difference, prolonging annealing time and high mobility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

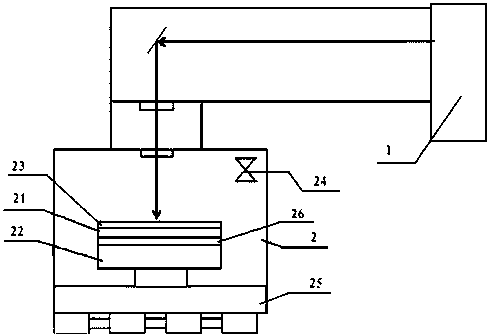

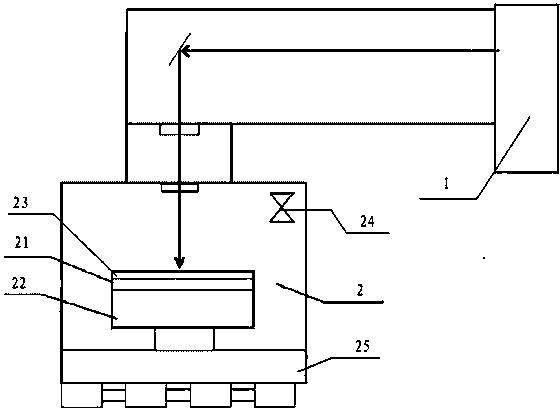

[0027] Such as figure 2 As shown, the present embodiment provides an excimer laser annealing device, comprising: a laser generating unit 1 and a process chamber 2, a workbench 22 is provided in the process chamber 2, and a workbench 22 is provided on the workbench 22 Heating unit 26.

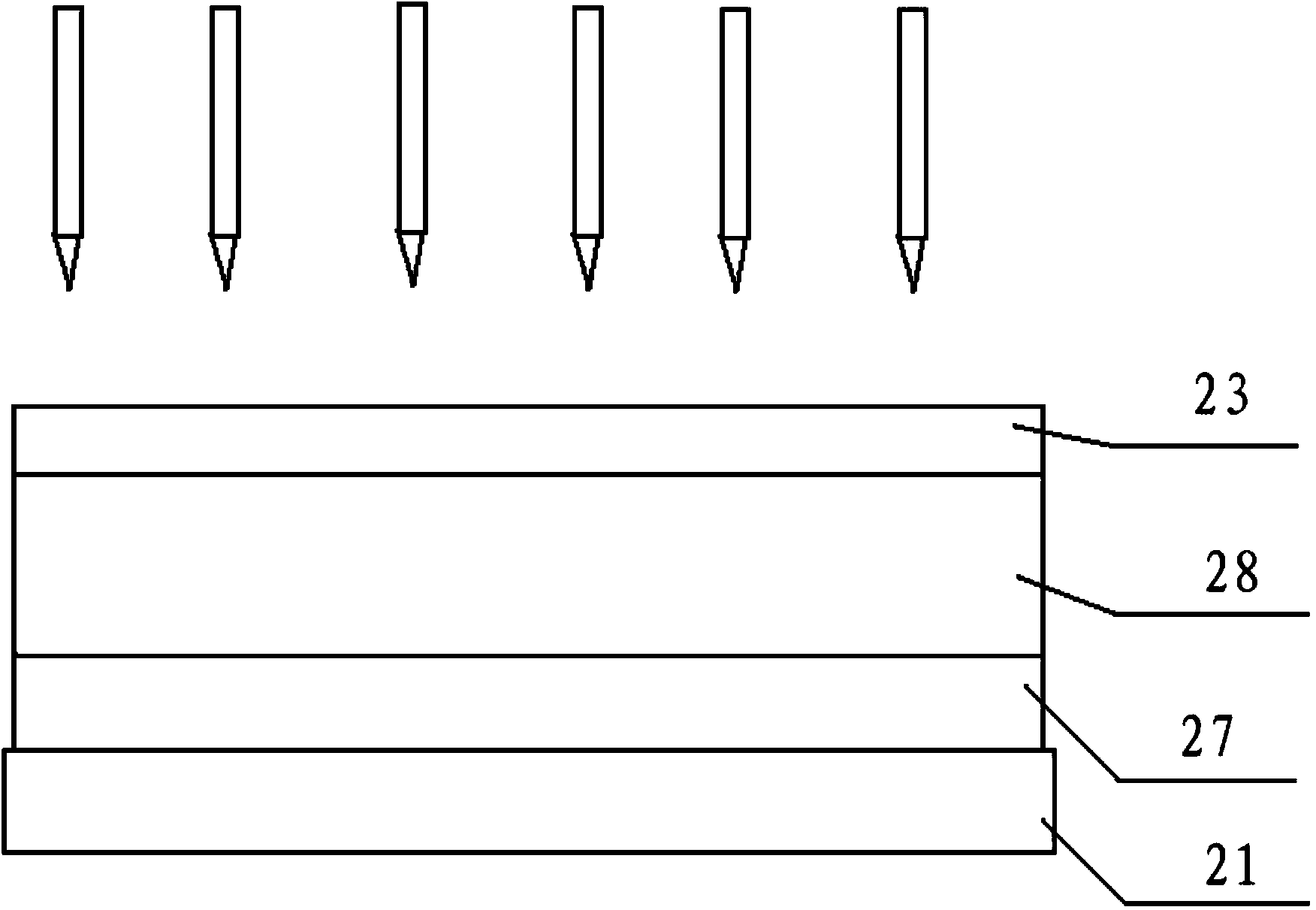

[0028] Such as image 3 As shown, the substrate 21 to be processed includes an amorphous silicon thin film 23 disposed on a buffer layer; the buffer layer includes a silicon nitride layer 27 and a silicon dioxide layer 28 sequentially disposed from the surface of the substrate 21 to be processed.

[0029] When the substrate 21 to be processed is placed on the workbench 22 for annealing, since the workbench 22 is provided with a heating unit 26, the heating unit 26 heats the substrate 21 to be processed during the annealing process of the substrate 21 to be processed, reducing the The temperature difference between the substrate 21 to be processed and the amorphous silicon film 23, laser irrad...

Embodiment 2

[0039] Such as image 3 with figure 2 As shown, this embodiment provides a method for preparing a low-temperature polysilicon thin film, comprising the following steps:

[0040] A thin film of amorphous silicon is formed on the substrate by a deposition method;

[0041] heating the amorphous silicon film;

[0042] Using a heating unit equipped with excimer laser annealing to heat the substrate to a predetermined temperature and keep it warm;

[0043] The amorphous silicon thin film is annealed by an excimer laser annealing device.

[0044] Since the substrate is heated and then the amorphous silicon film is annealed, the heat of the melted amorphous silicon will not be quickly conducted to the substrate, resulting in a rapid drop in the temperature of the melted amorphous silicon, resulting in insufficient annealing time, which cannot A polysilicon film with large grains is formed.

[0045] The above method is easy to operate in the production process, the process is sim...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com