Laser crystallization system and method for controlling quasi-molecular laser annealing energy density

An excimer laser and energy density technology, which is applied in laser welding equipment, manufacturing tools, semiconductor/solid-state device manufacturing, etc., can solve the problems of not meeting the requirements of the production line, high price, and poor crystallization state of polysilicon

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

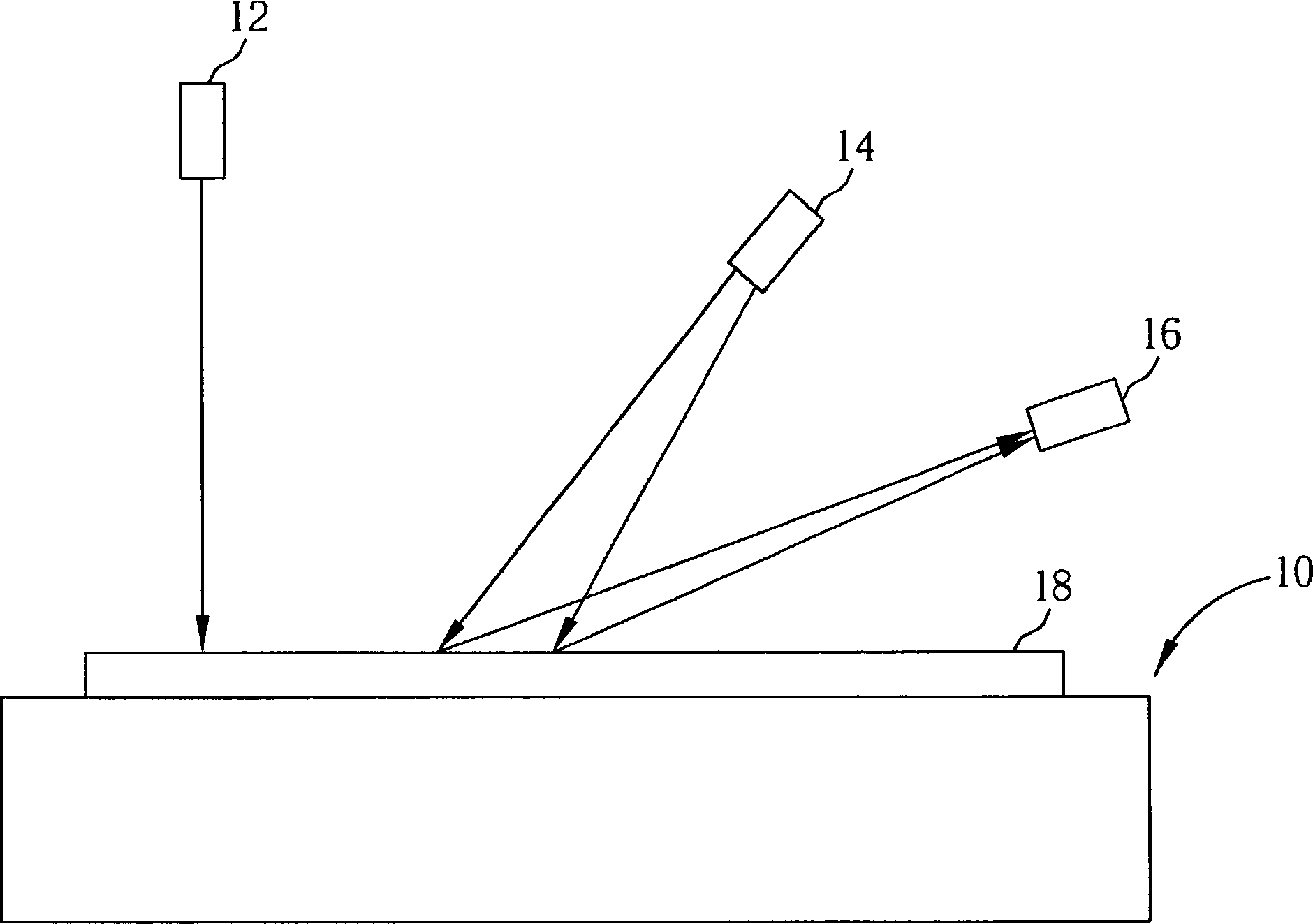

[0021] Please refer to figure 1 , figure 1 It is a schematic diagram of a laser crystallization system 10 with optical detection and laser energy density correction functions of the present invention. Such as figure 1 As shown, the laser crystallization system 10 includes an excimer laser annealing device 12 and an optical detection device composed of a light source generator 14 and an image receiver 16 . The excimer laser annealing device 10 can generate an excimer laser and irradiate a substrate 18 in a linear scanning manner, thereby recrystallizing a silicon thin film on the surface of the substrate 18 from an amorphous silicon structure to a polysilicon structure. The optical detection device is used to judge whether the silicon film on the surface of the substrate 18 irradiated by the excimer laser has formed a good polysilicon structure, wherein the light source generator 14 can generate a visible light (such as white light) to irradiate the substrate 18, and it is in...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com