Laser annealing appts. and its tech

A technology of laser annealing and laser processing, which is applied in the direction of laser welding equipment, manufacturing tools, metal processing equipment, etc., can solve the problems of not being able to provide real-time, not being able to effectively improve the process qualification rate and film quality, and not being able to integrate the laser annealing process. Achieve the best film quality and the best process qualification rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

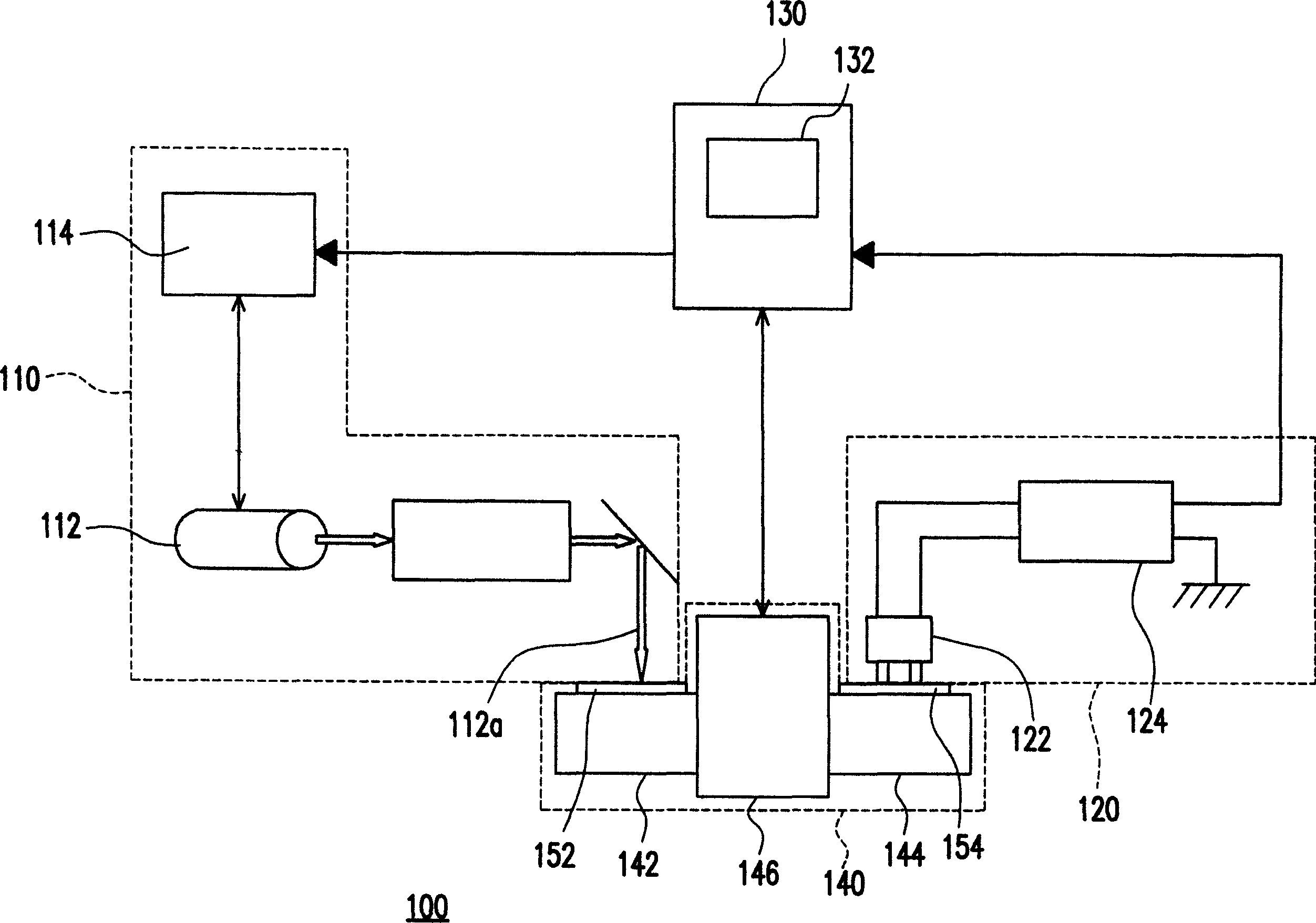

[0046] Please refer to figure 1, is a schematic diagram of a laser annealing device in a preferred embodiment of the present invention. The laser annealing device 100 is suitable for laser annealing process, and the laser annealing device 100 includes a laser processing module 110 , a resistance measurement module 120 , a host circuit module 130 and a carrying module 140 , for example. Wherein, a first carrier 142 of the carrier module 140 carries, for example, a first base material 152 that has not been subjected to laser annealing and whose surface is amorphous silicon, and a second carrier 144 of the carrier module 140, for example, carries a Laser annealing is completed, and the surface is a second substrate 154 of polysilicon type. In addition, for example, a transfer mechanism 146 is disposed between the first stage 142 and the second stage 144 , which is suitable for transferring the substrate on the first stage 142 to the second stage 144 .

[0047] please refer agai...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com